Unisig

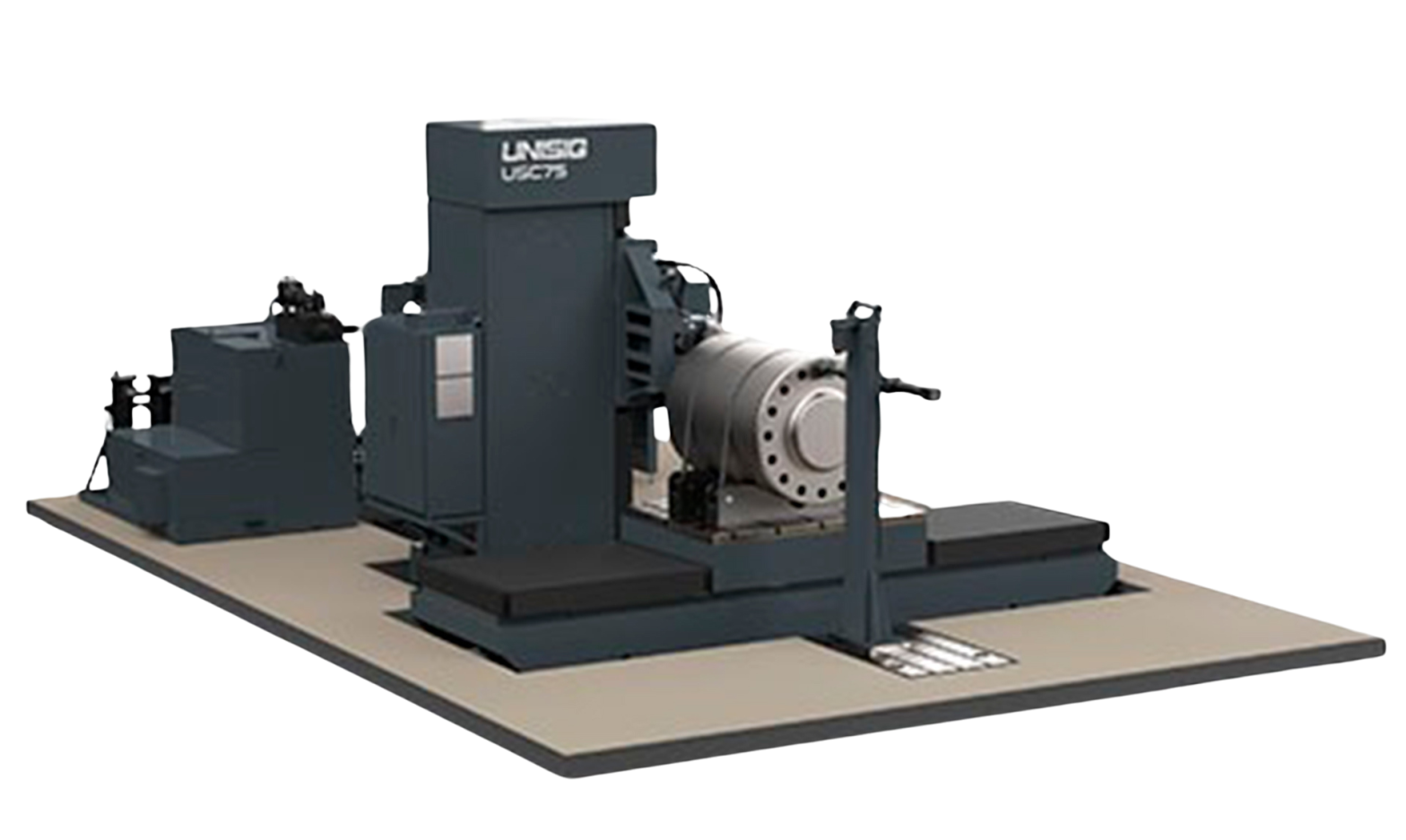

USC75

Unisig

USC75

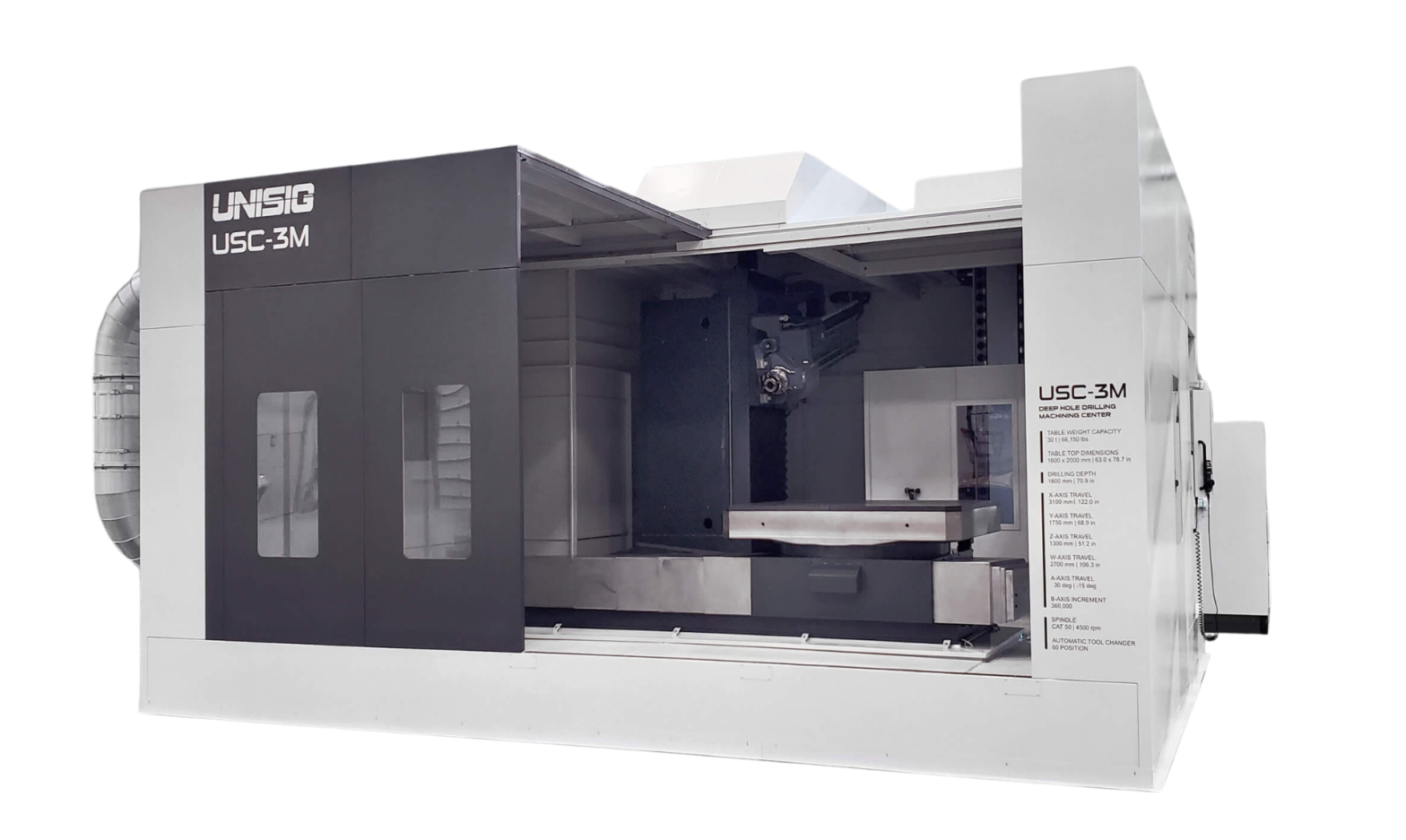

Product description

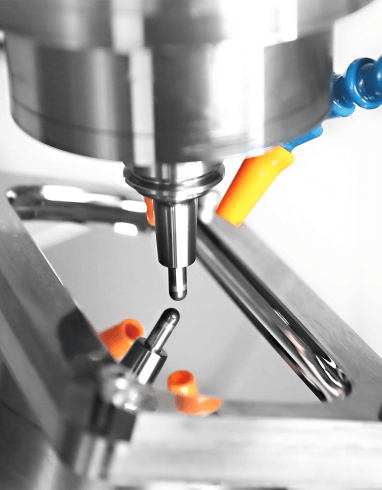

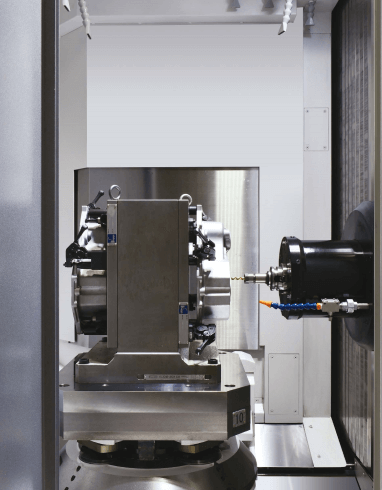

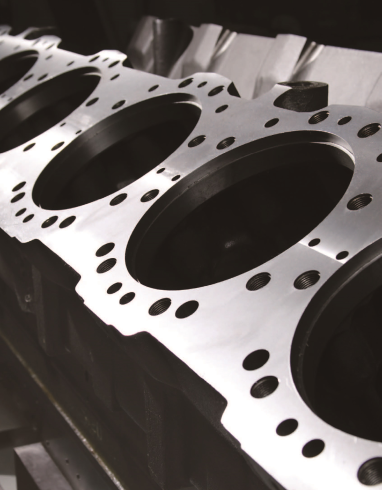

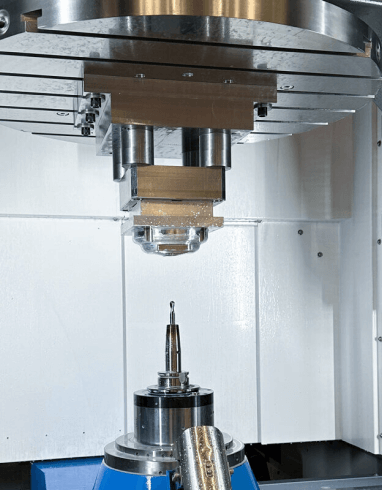

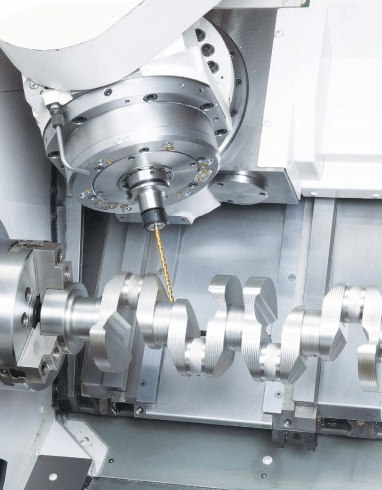

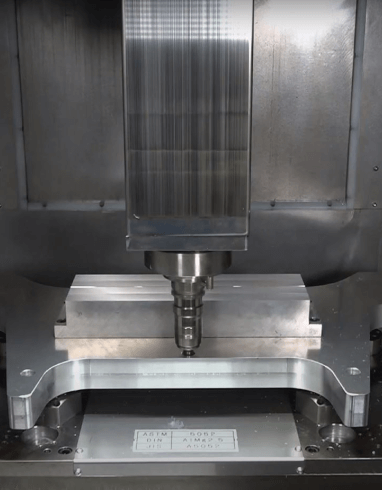

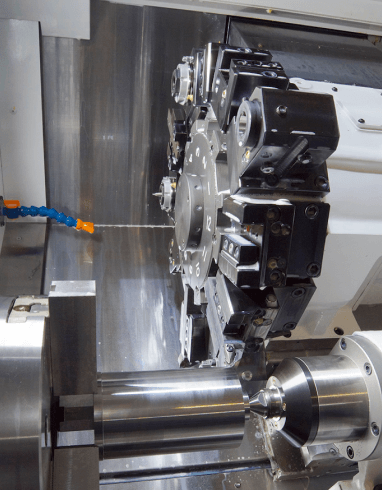

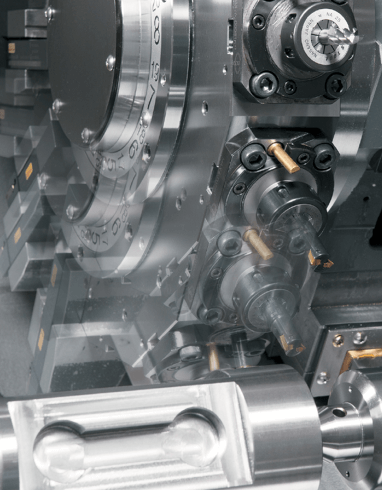

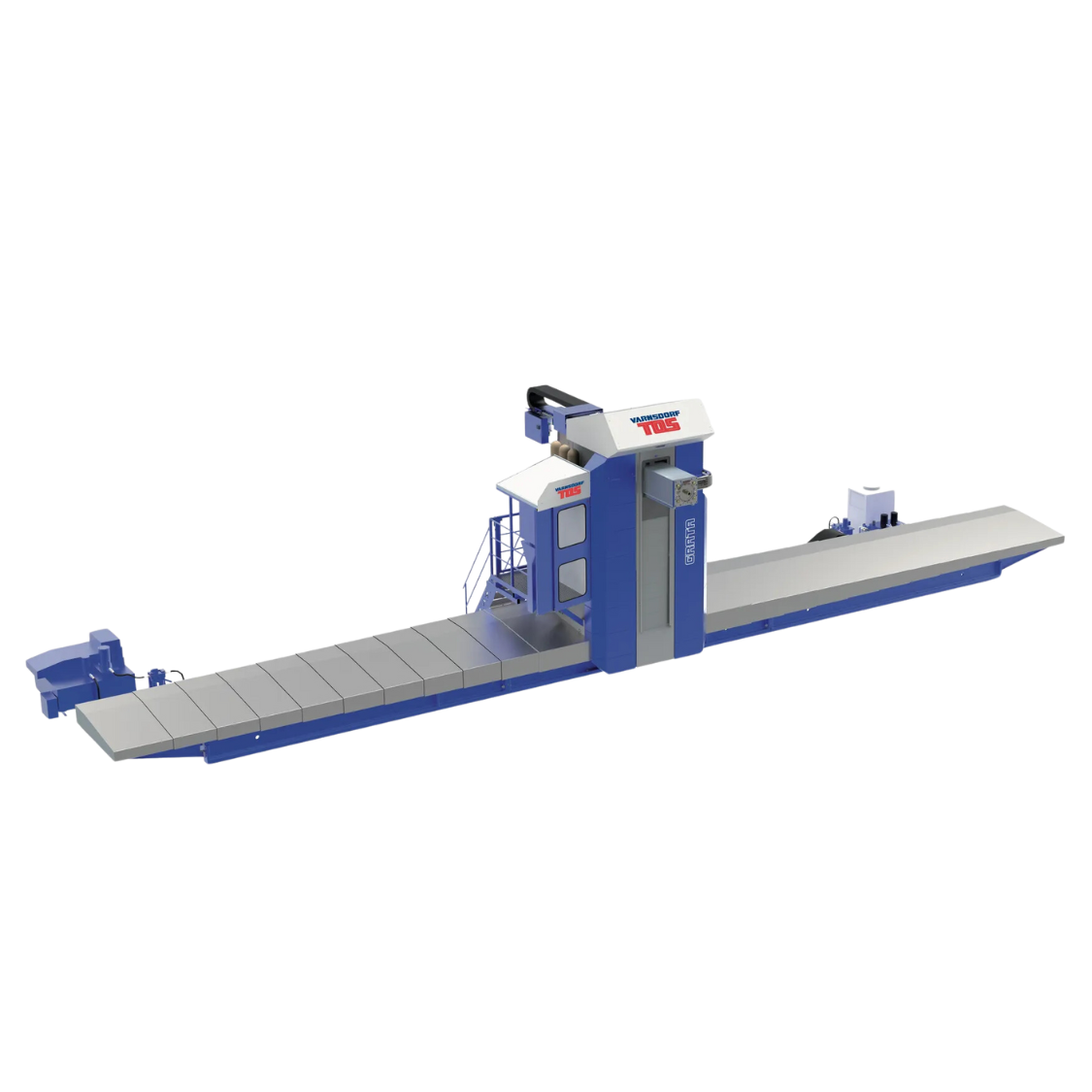

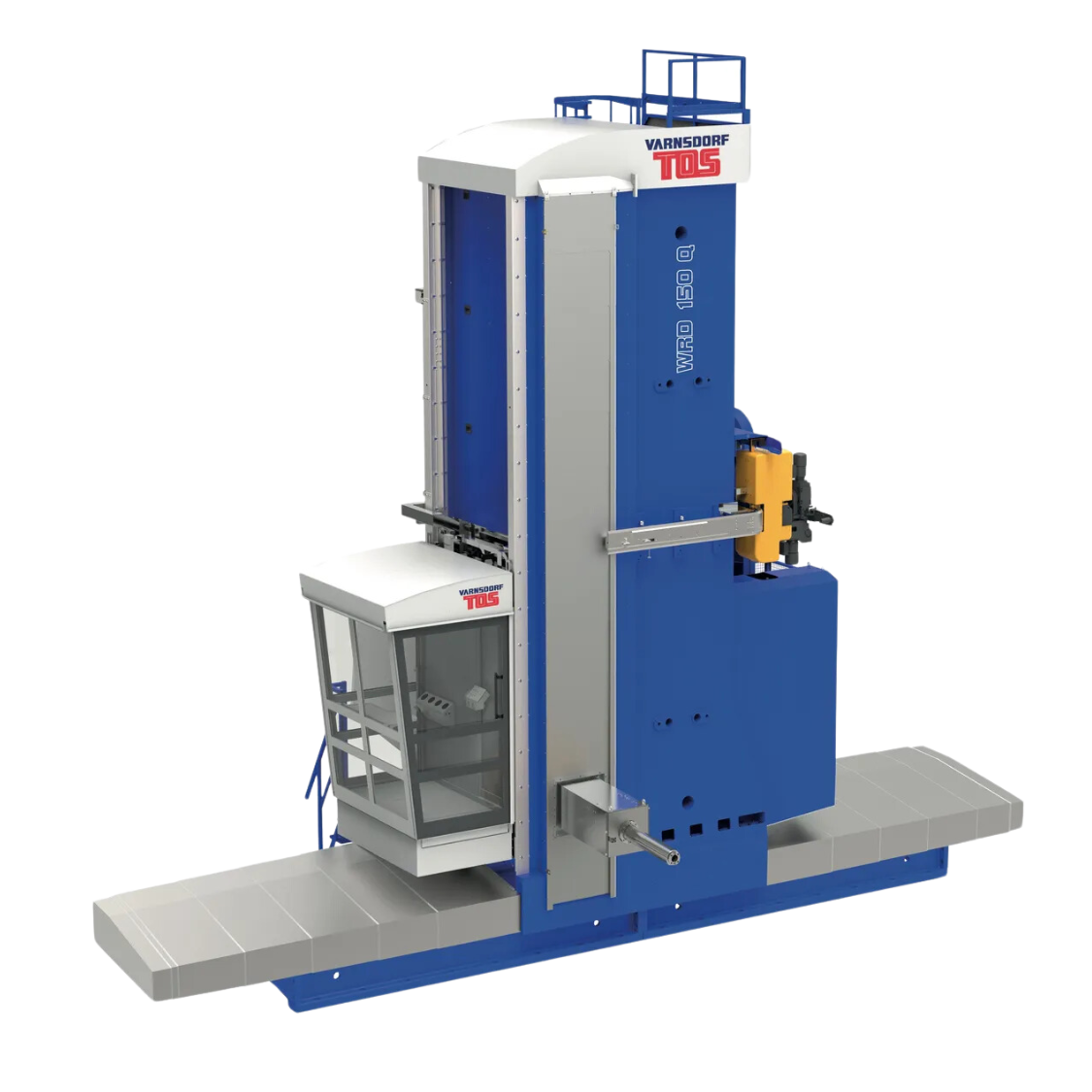

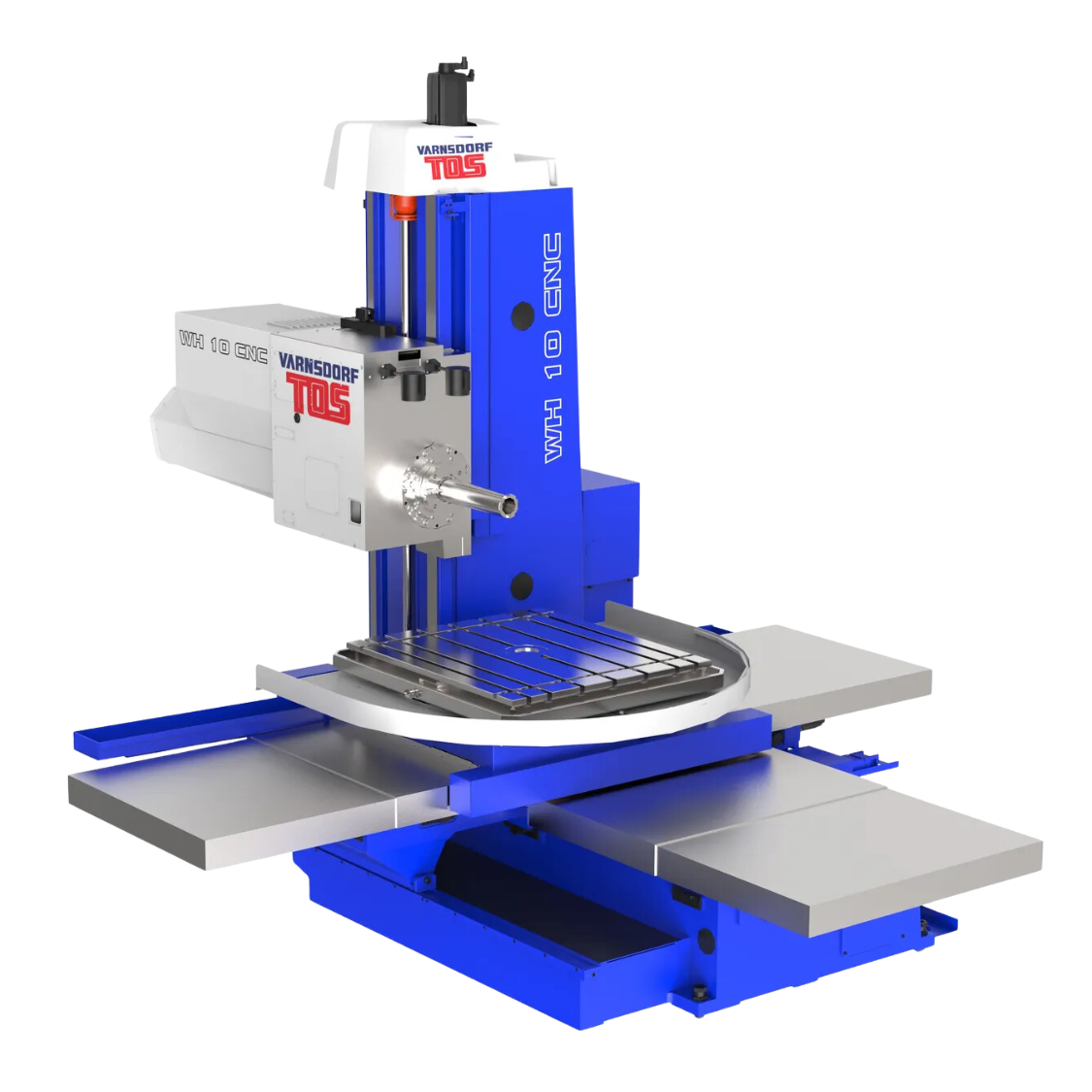

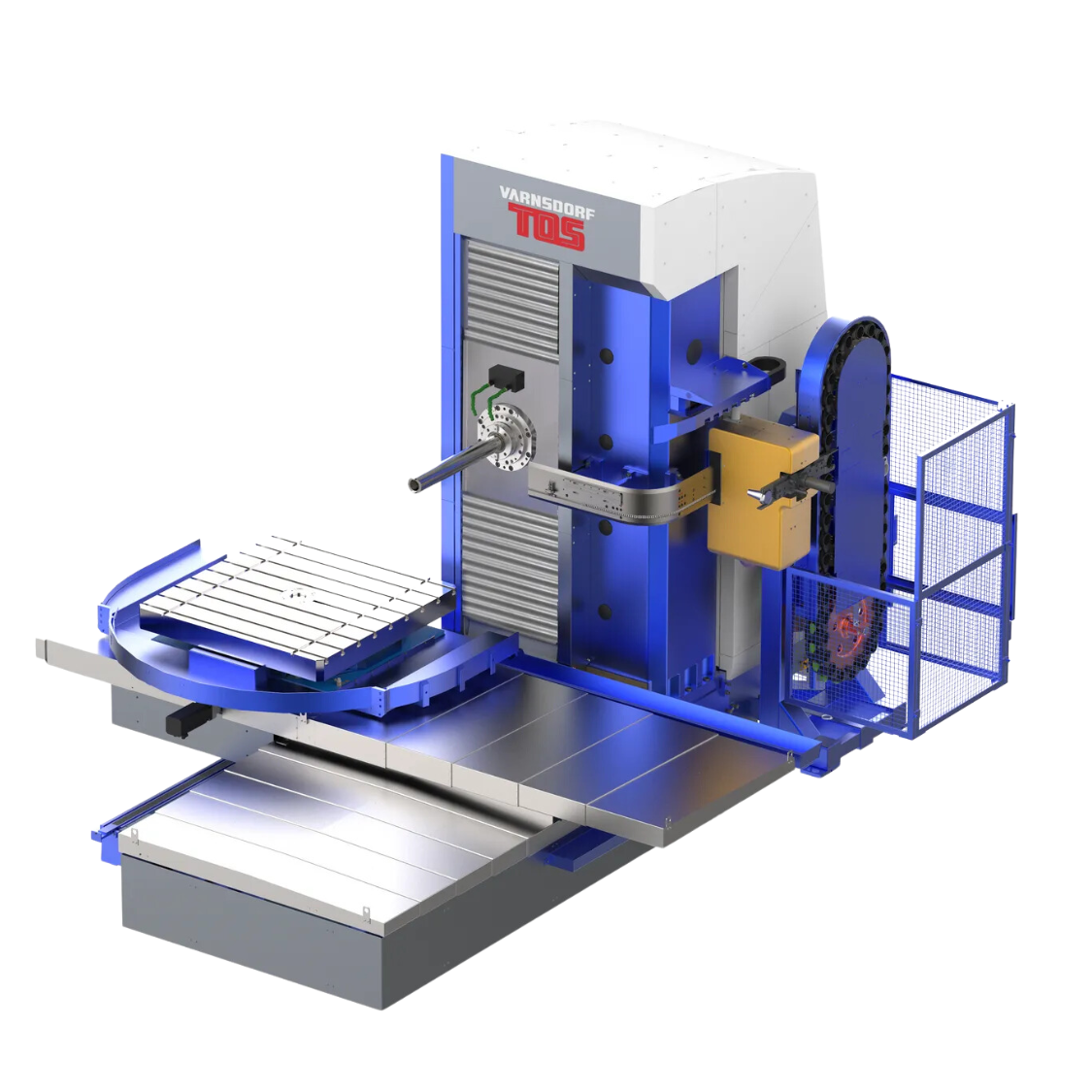

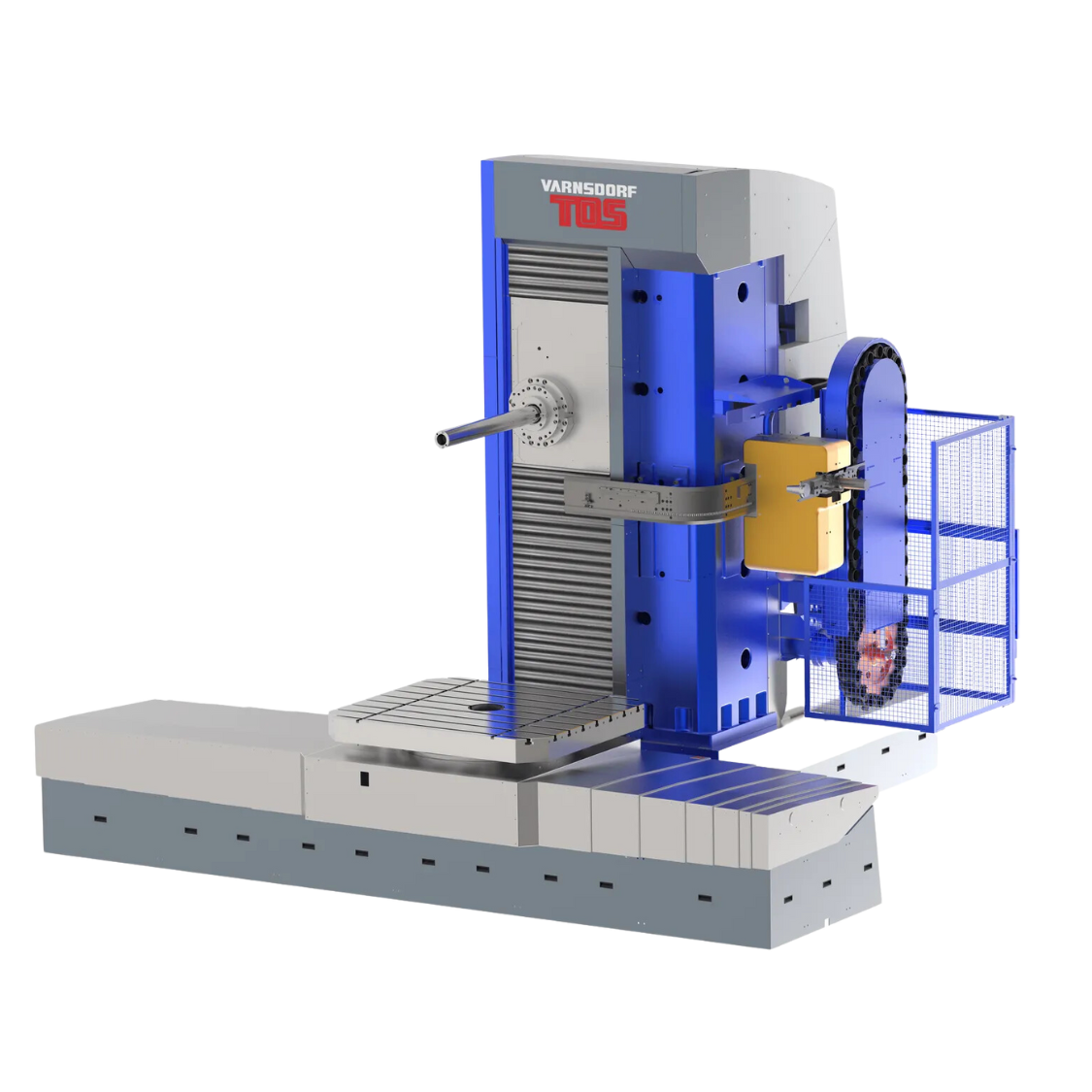

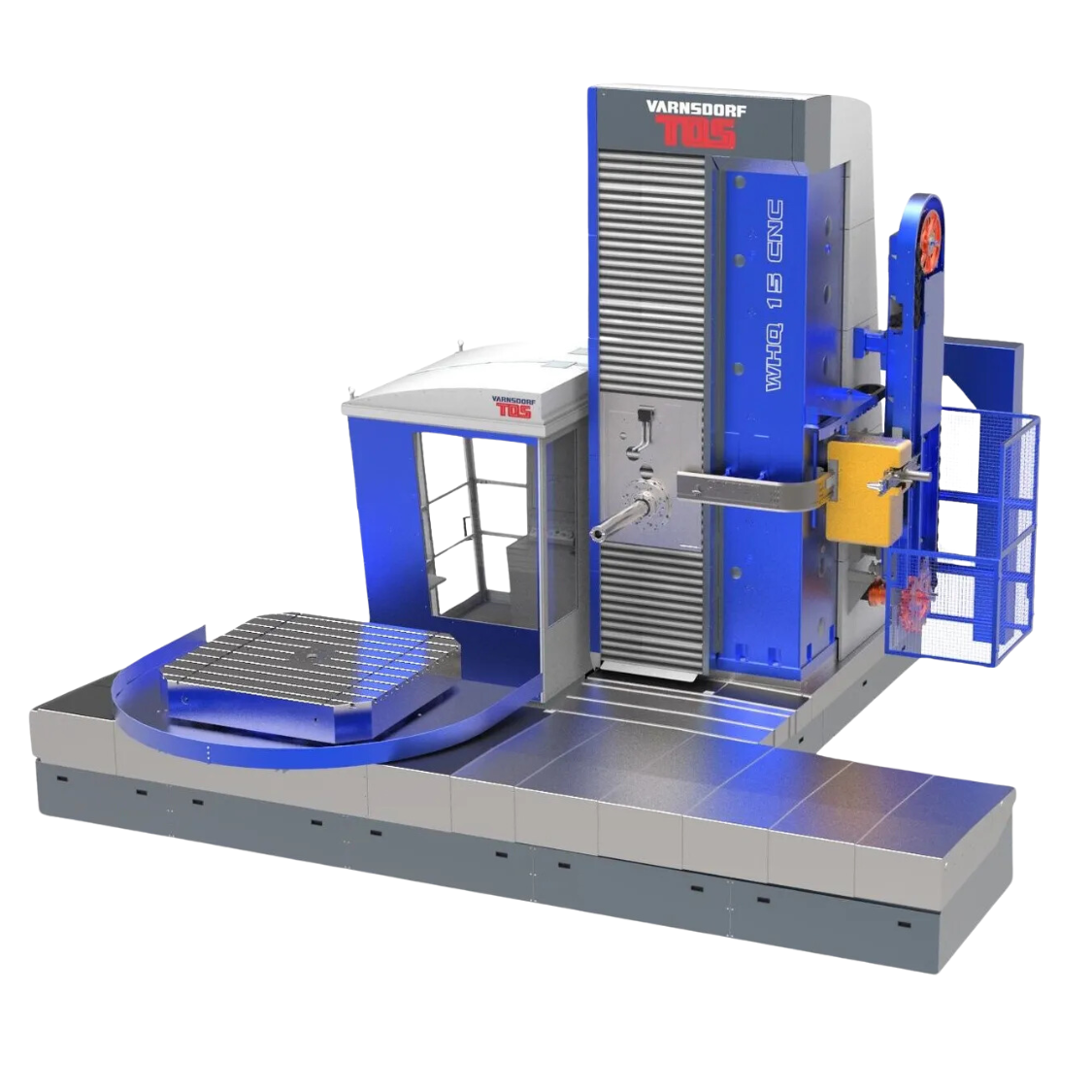

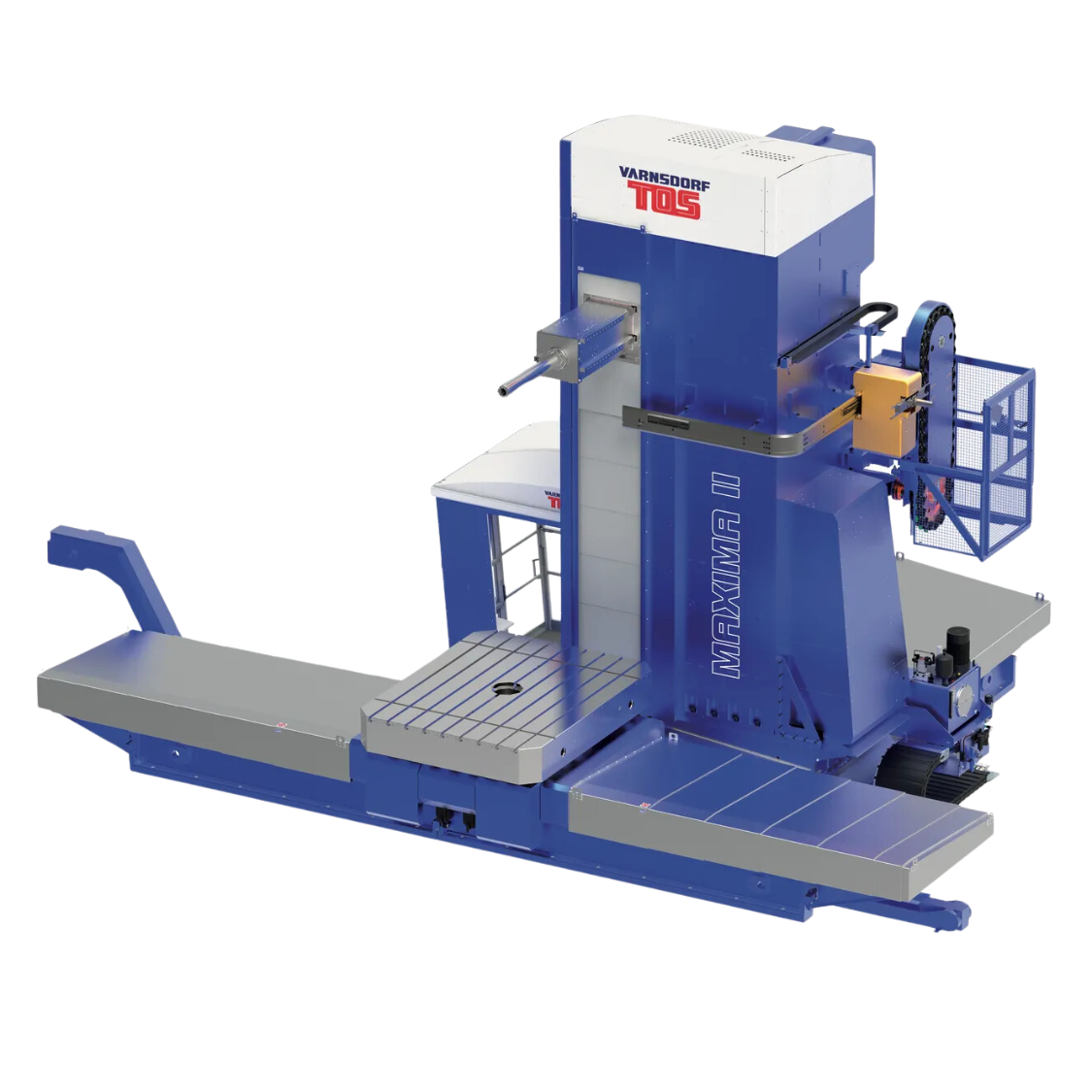

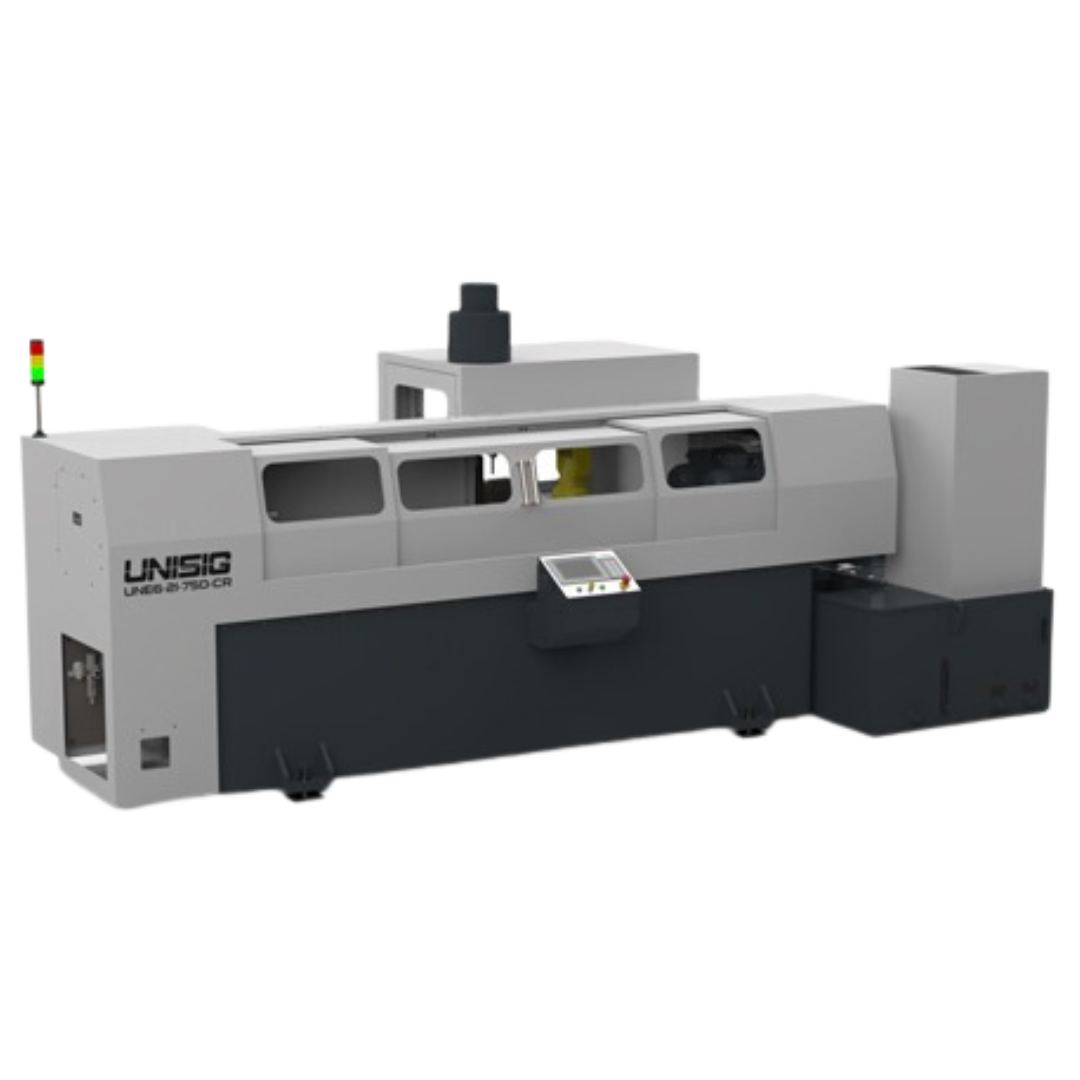

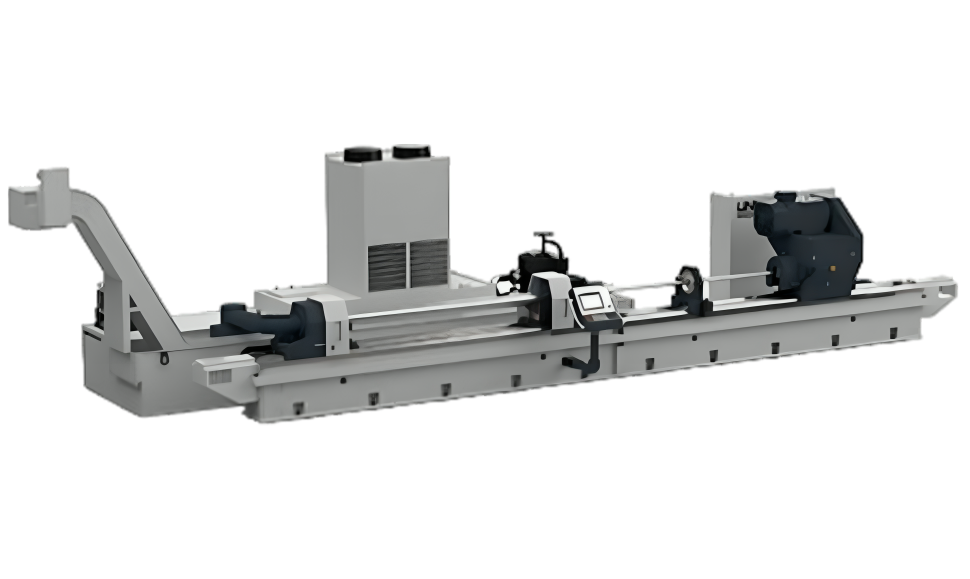

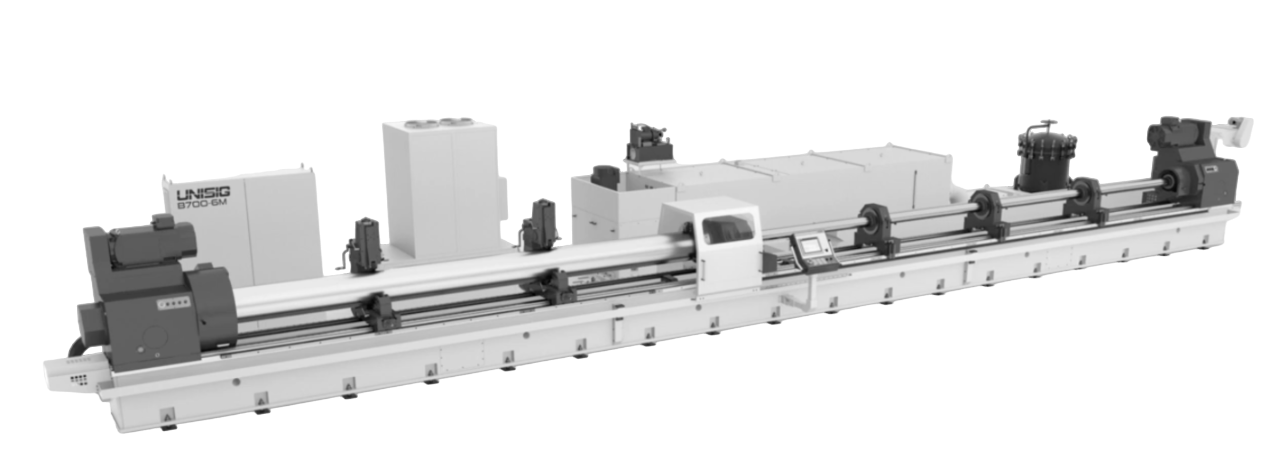

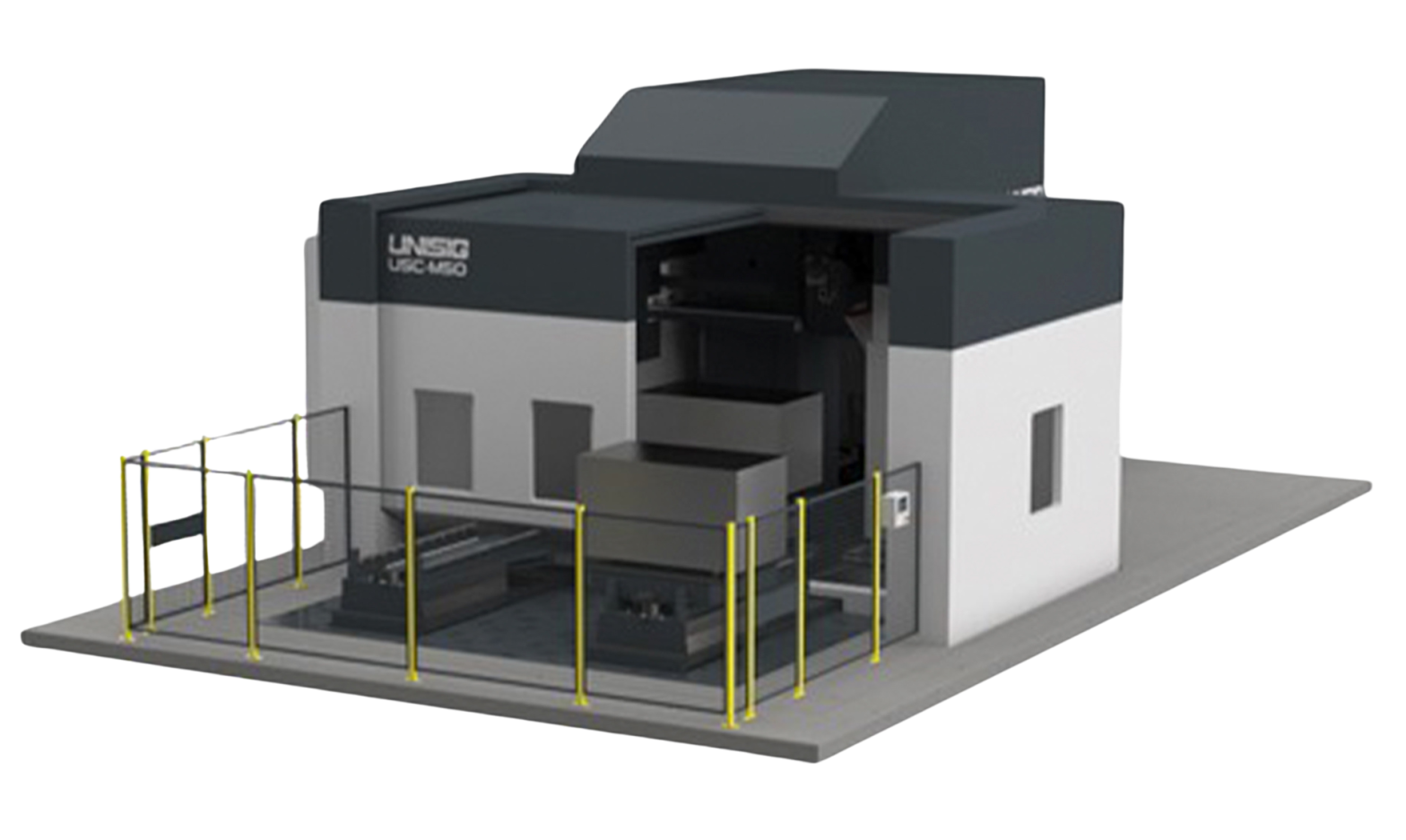

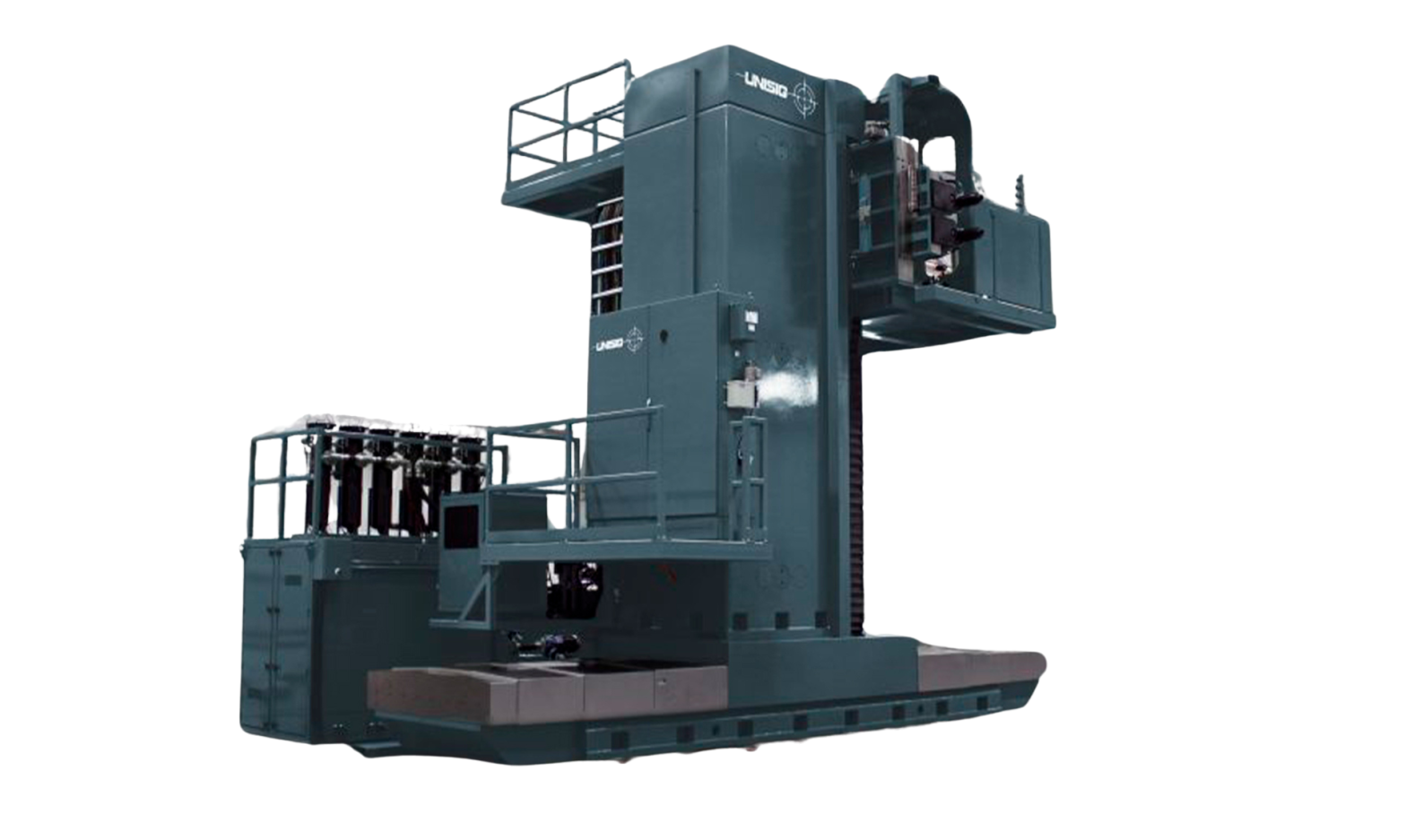

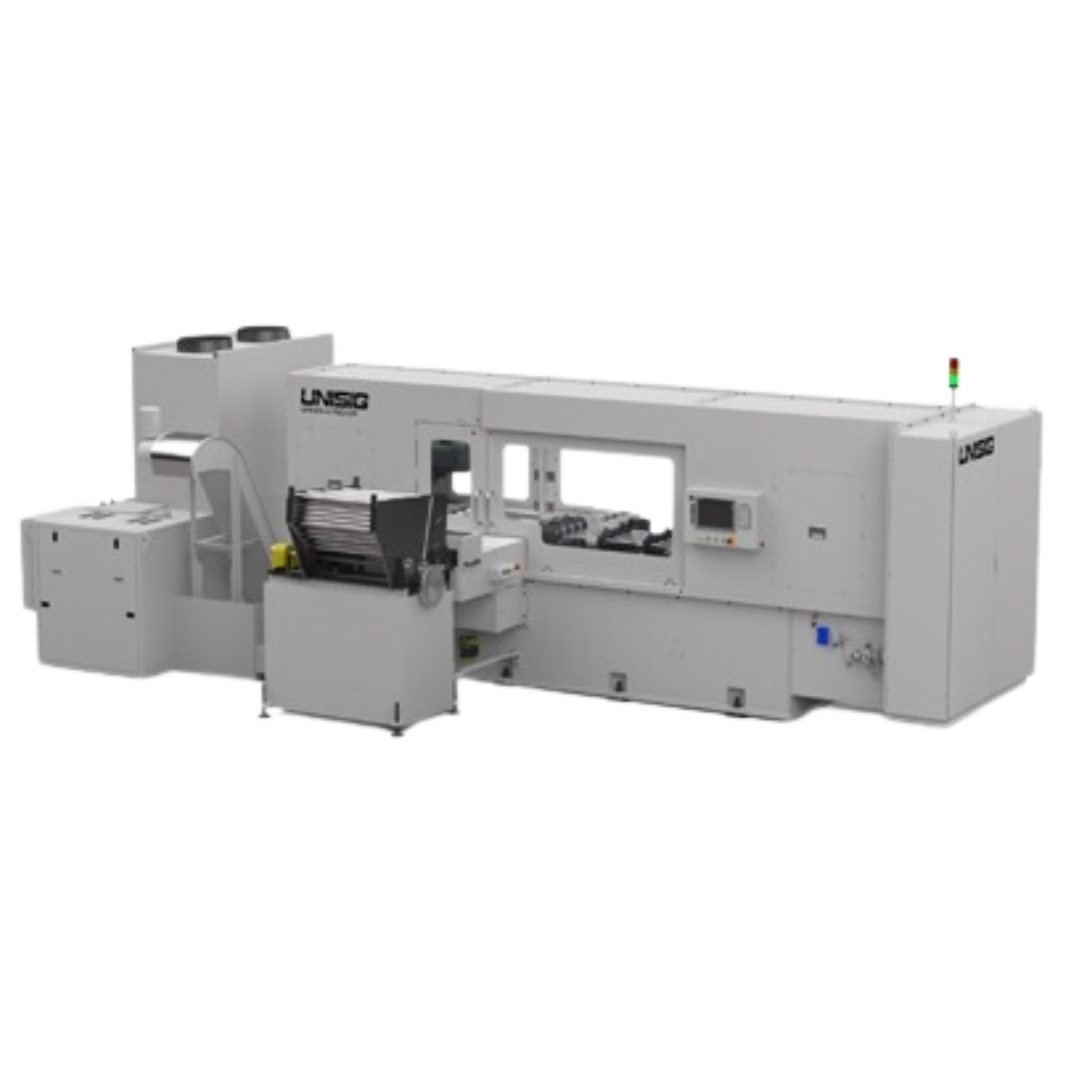

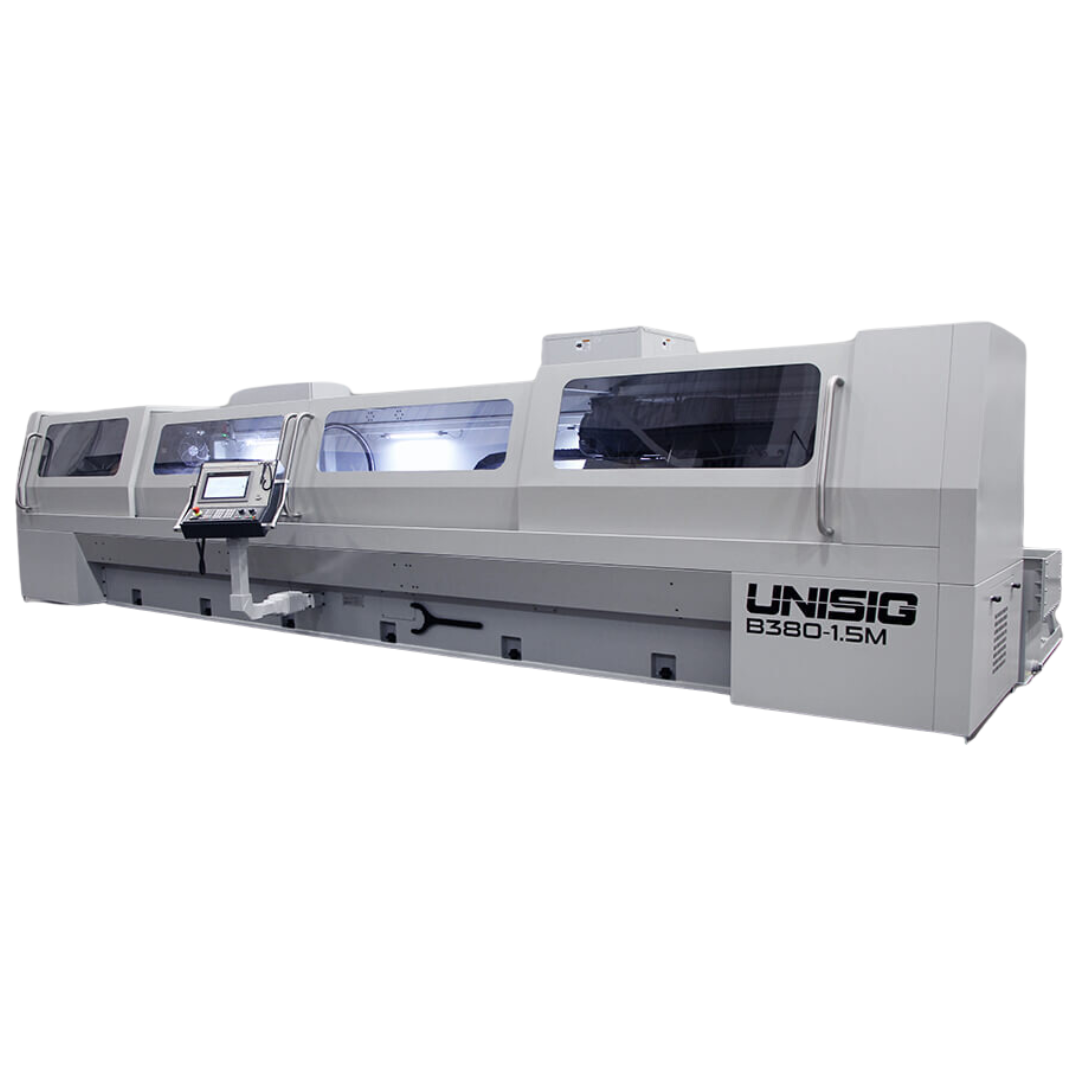

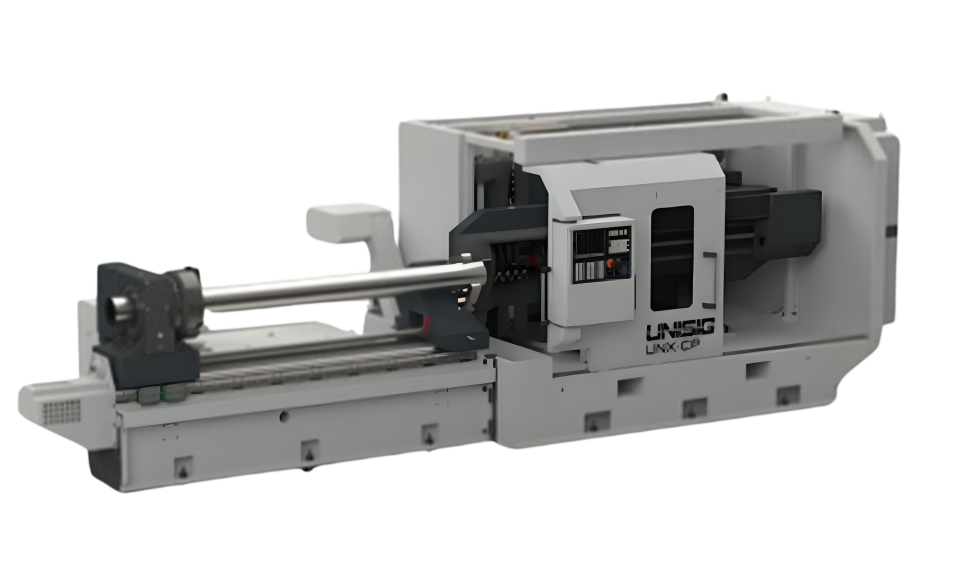

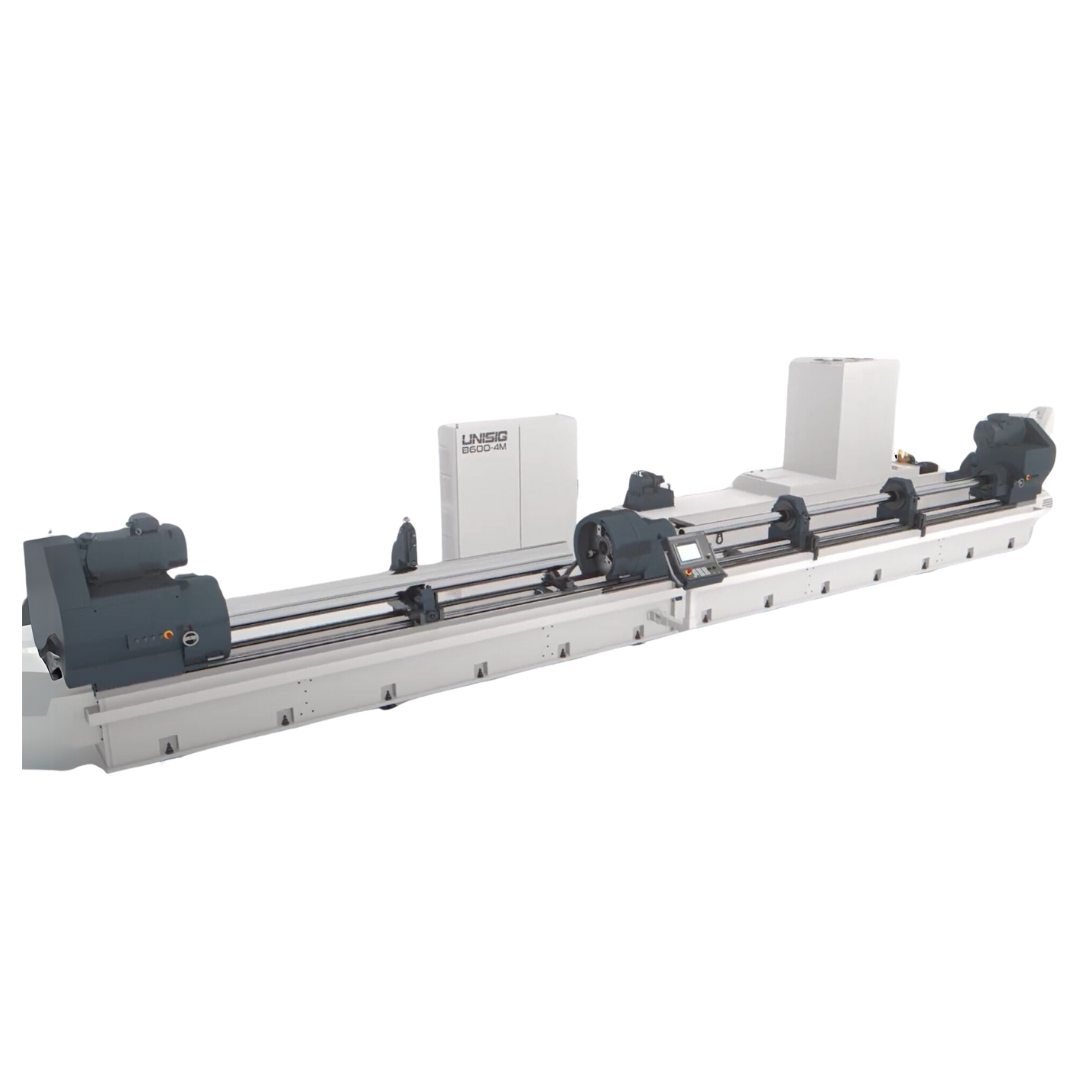

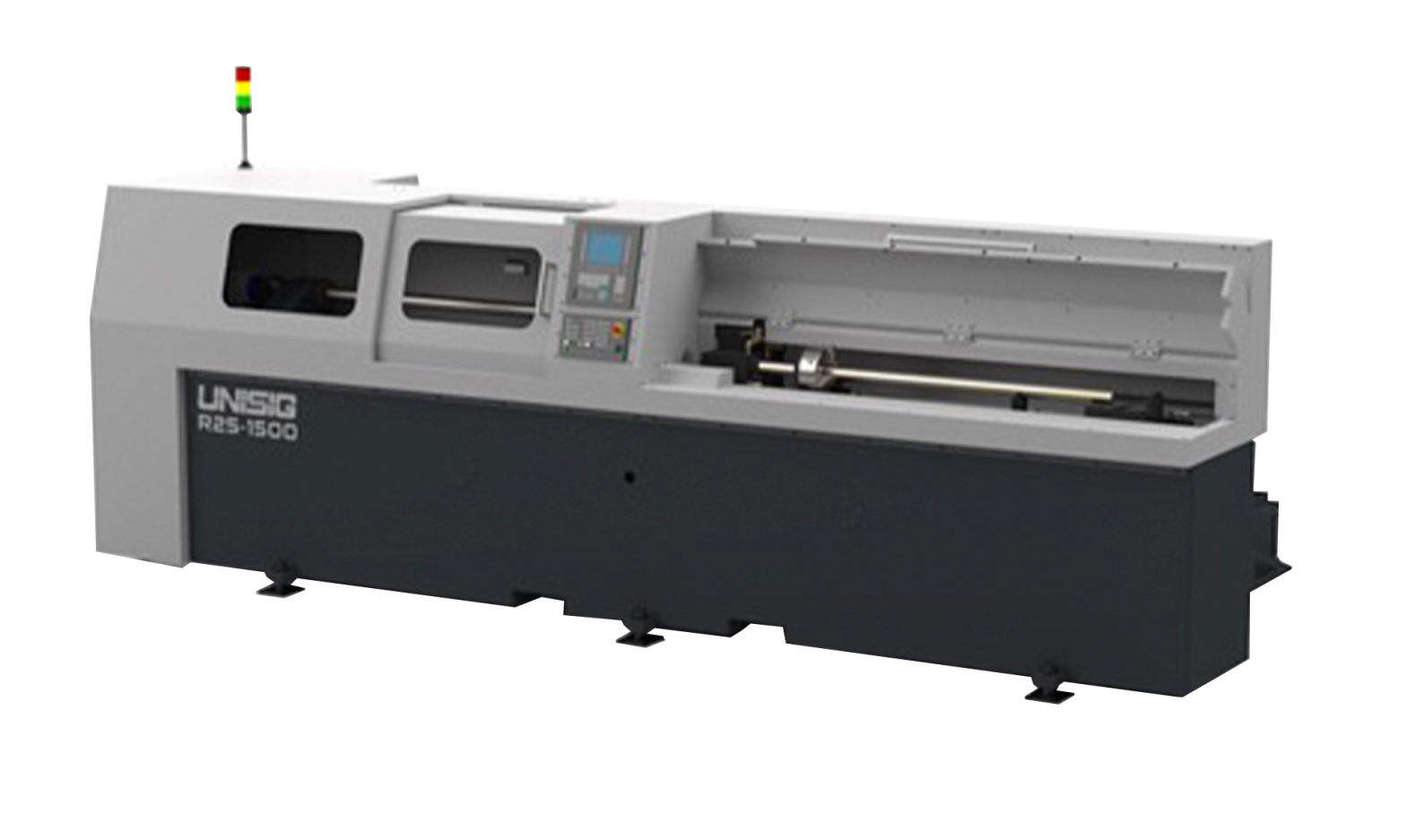

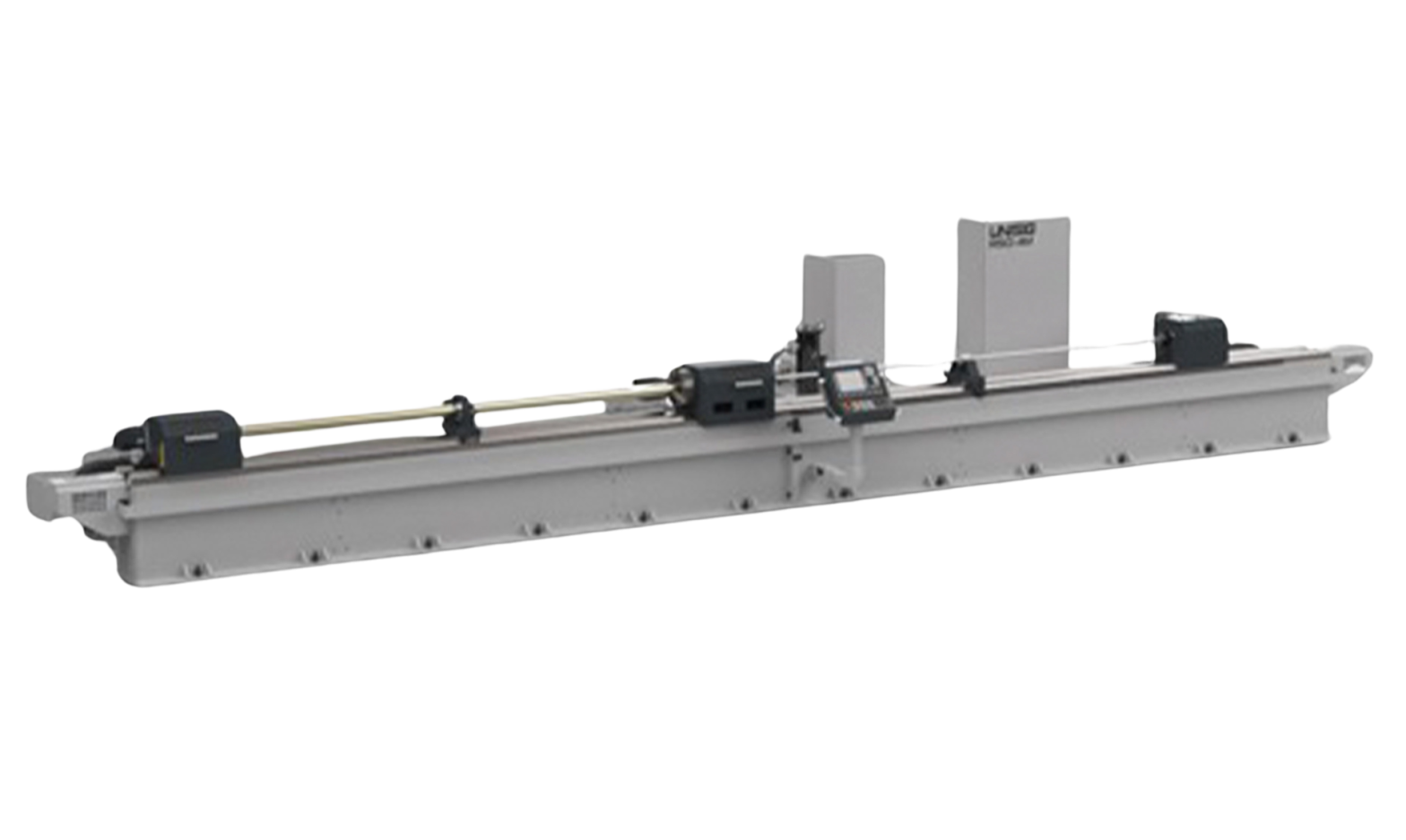

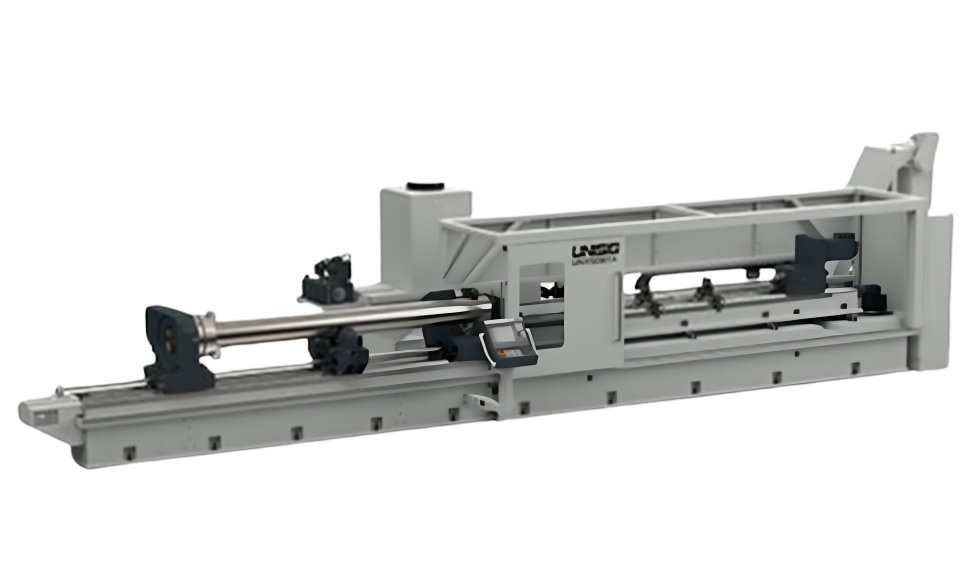

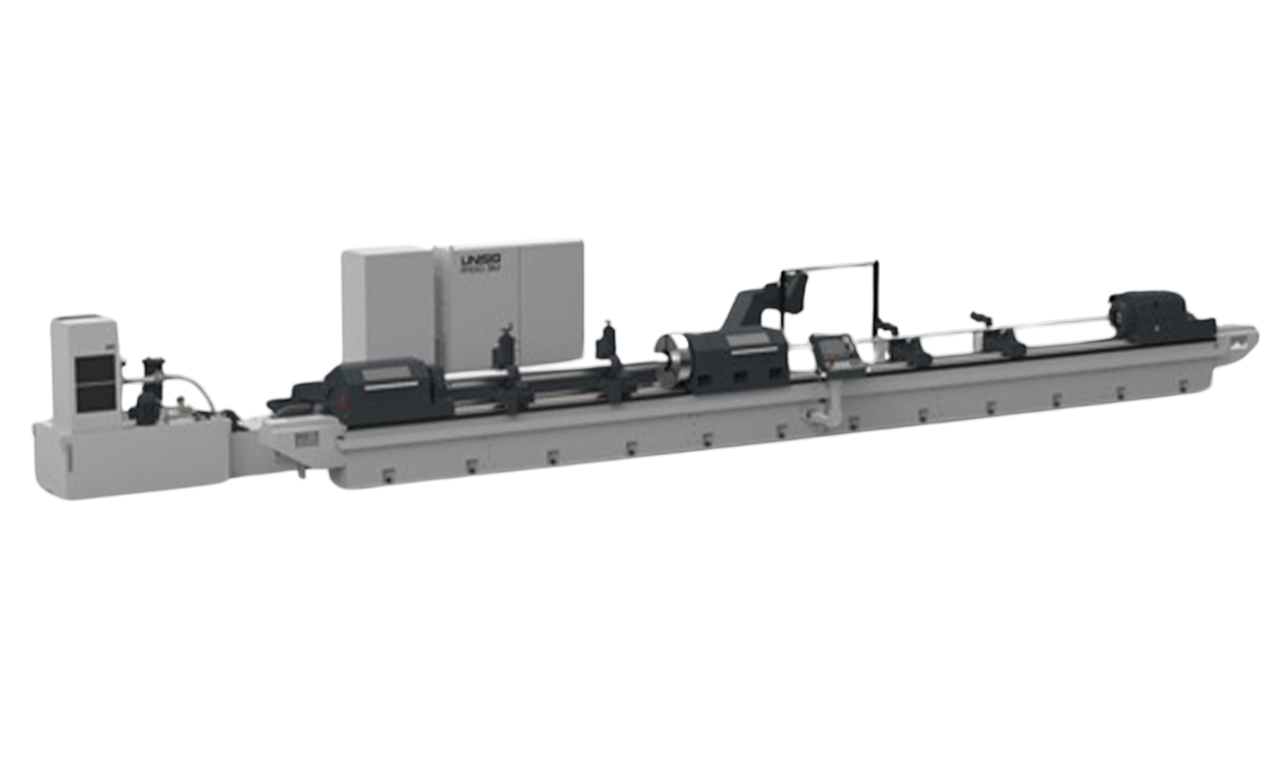

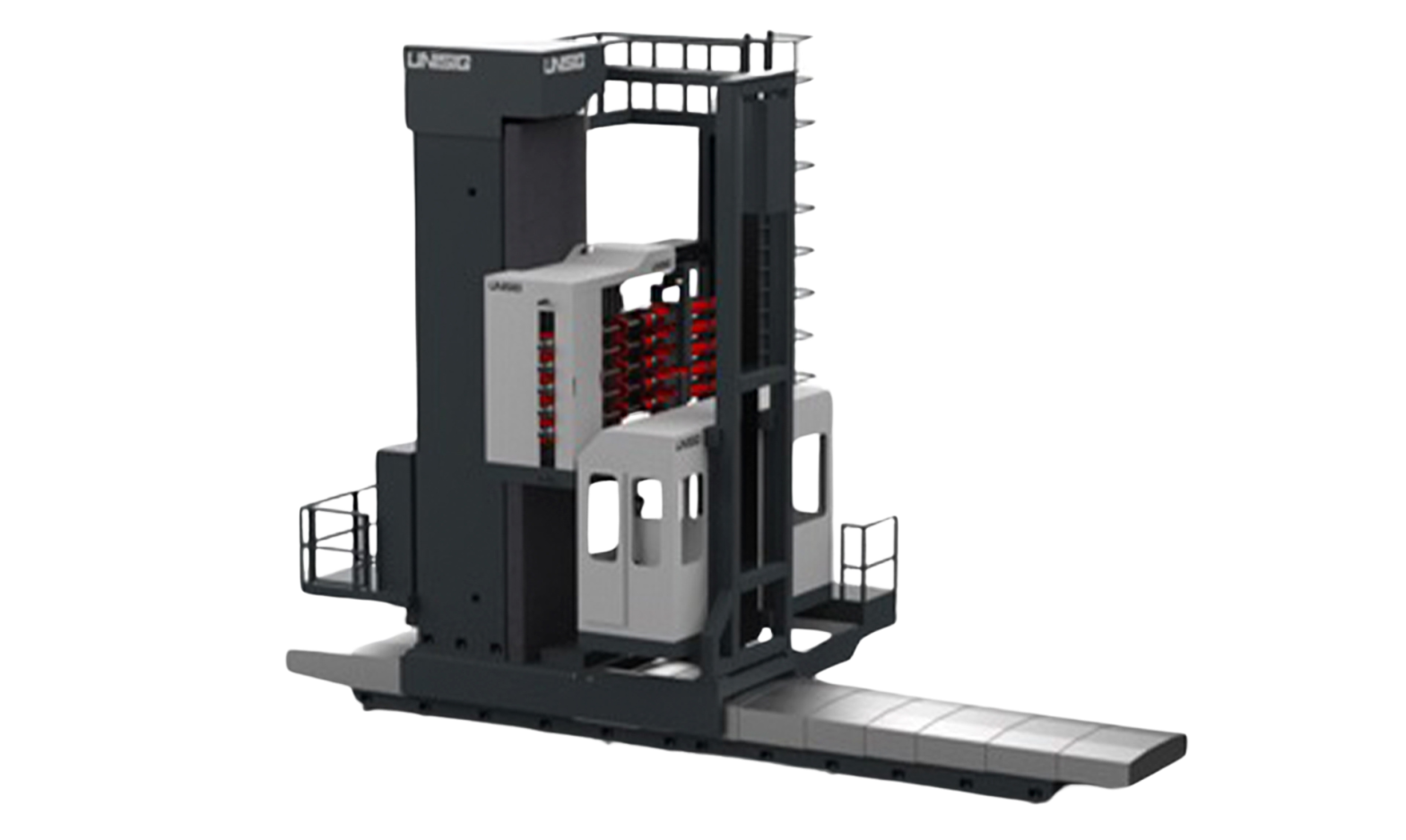

Larger, cubic workpieces with deep holes are handled with confidence on USC column-type machines, designed for the ultimate in rigidity and accuracy. Superior machine alignment, rigid construction, and choice components are combined in these machines to provide impressive capabilities at an approachable investment level, ideal for workpieces such as mold plates and frack pumps.

An available milling spindle adds additional machining capabilities to the standard BTA and gundrilling processes, for workpieces up to 27 tons [25,000 kg]. USC machines are designed to serve as a workhorse machine for manufacturers, providing significant capability with easy, flat-floor installation, providing a significant opportunity for return on investment.

Industries

Aerospace

Energy

Fluid Control

Molds & Dies

Product Highlights

Product Highlights

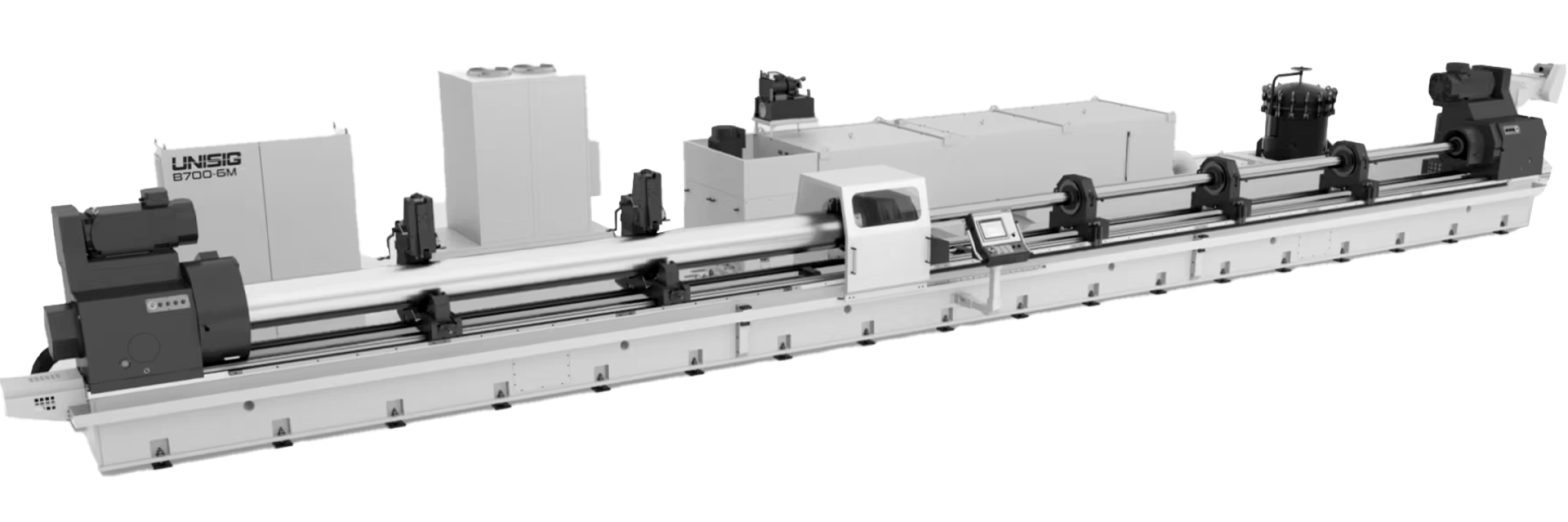

Number of Spindles

1

Hole Diameter Min (in) Hole Diameter Min (mm)

0.7920

Drill Diameter Max (in) Drill Diameter Max (mm)

4.02102

Hole Diameter Max (in) Hole Diameter Max (mm)

4.25108

Hole Depth Max (in) Hole Depth Max (mm)

78.742000

Workpiece dimensions (in) Workpiece dimensions (mm)

802000

Workpiece weight max (kg)

15000

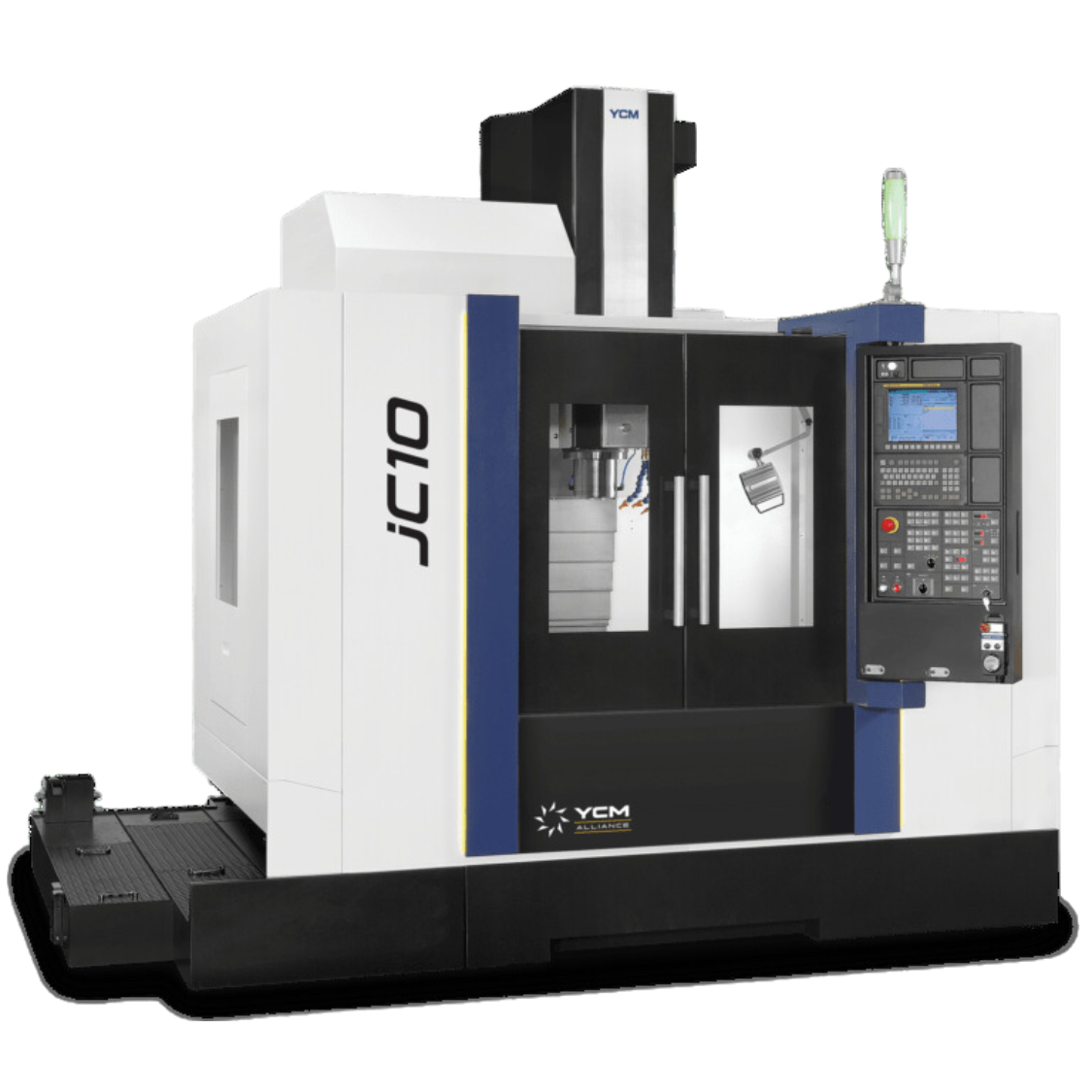

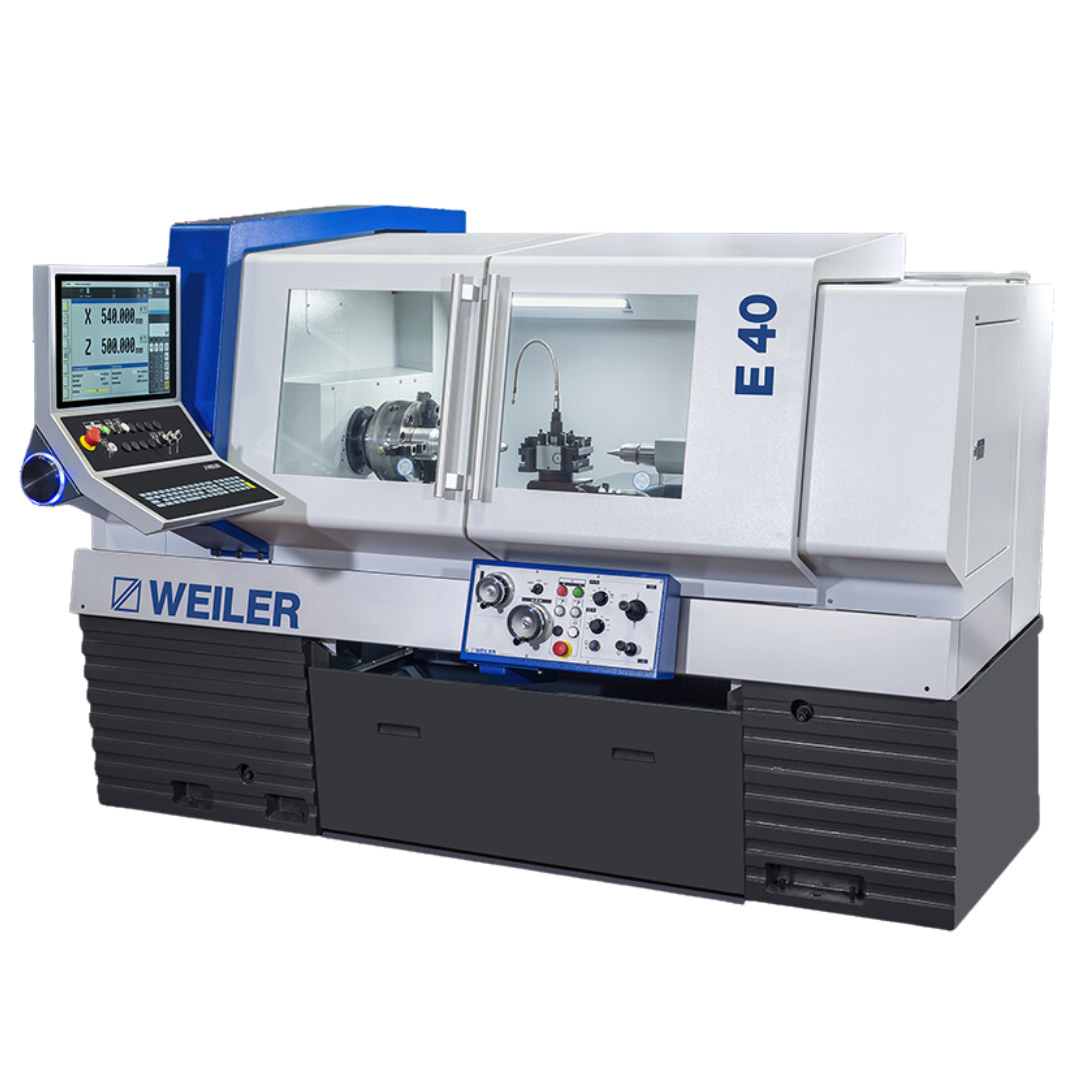

Recommended solutions to improve your processes

Equip and maximize the productivity of your CNC machines with comprehensive solutions.

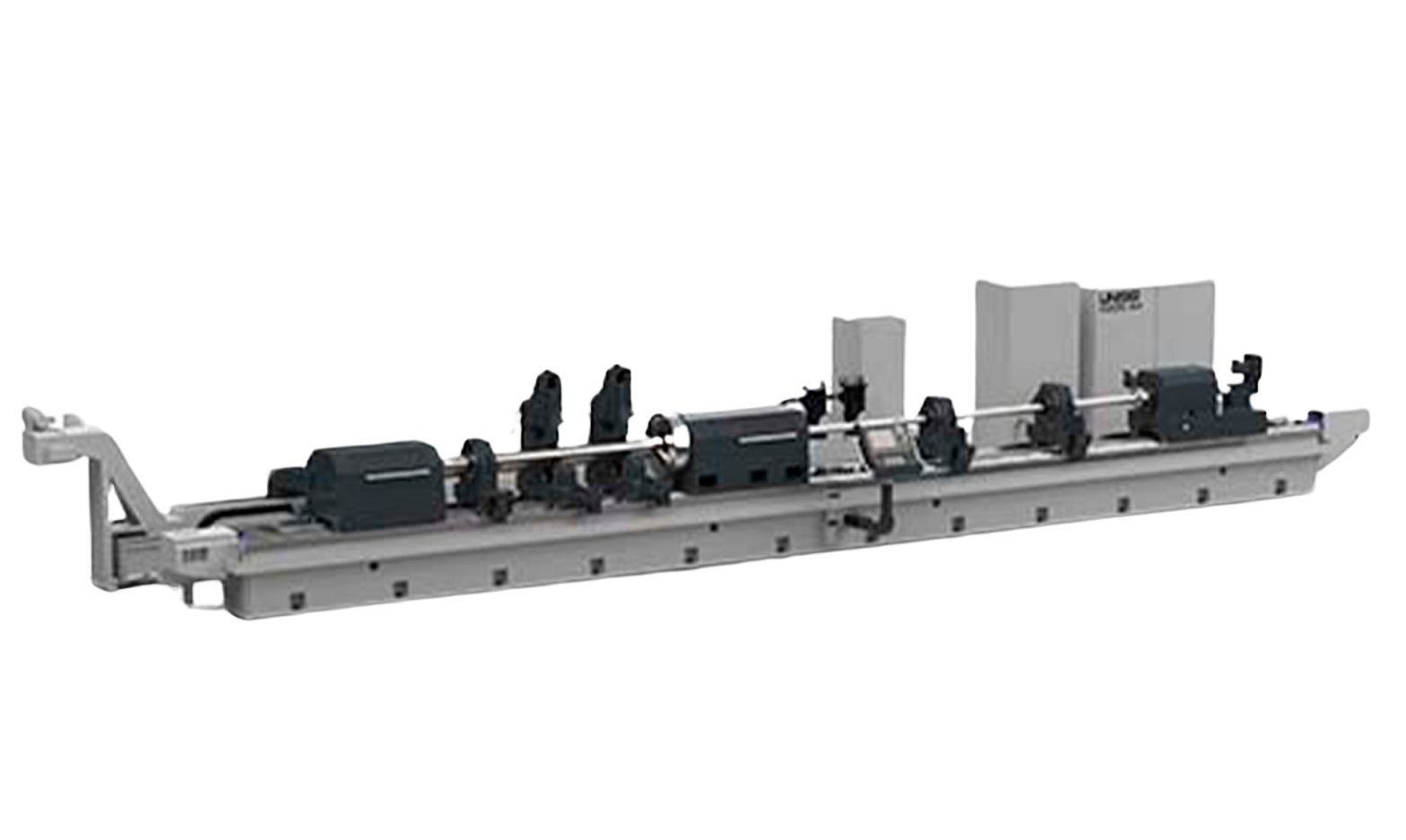

Accessories and peripherals

Mist collector

Cooling system

Coolant filtration and magnetic separator equipment

Learn more about PERIFERIQ

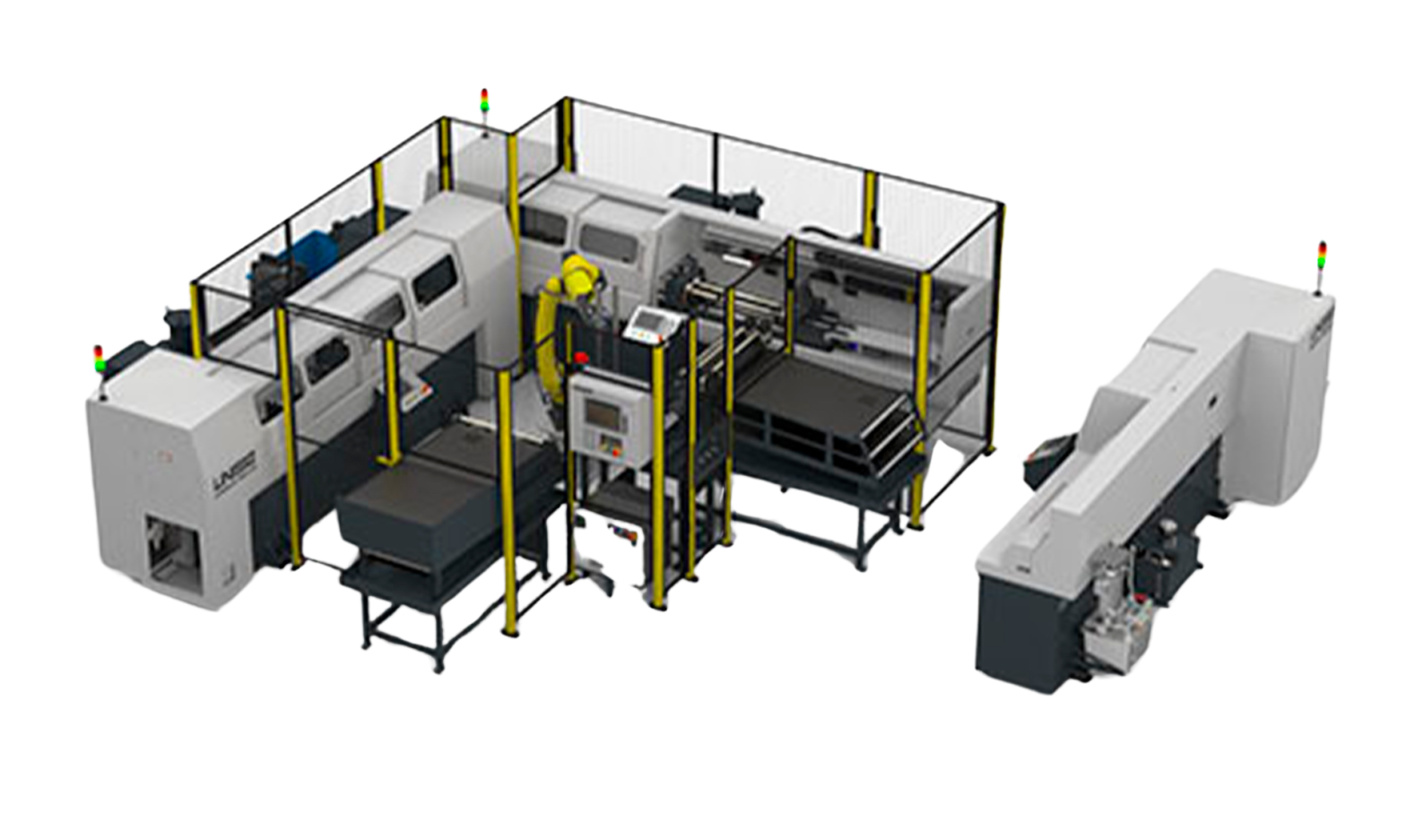

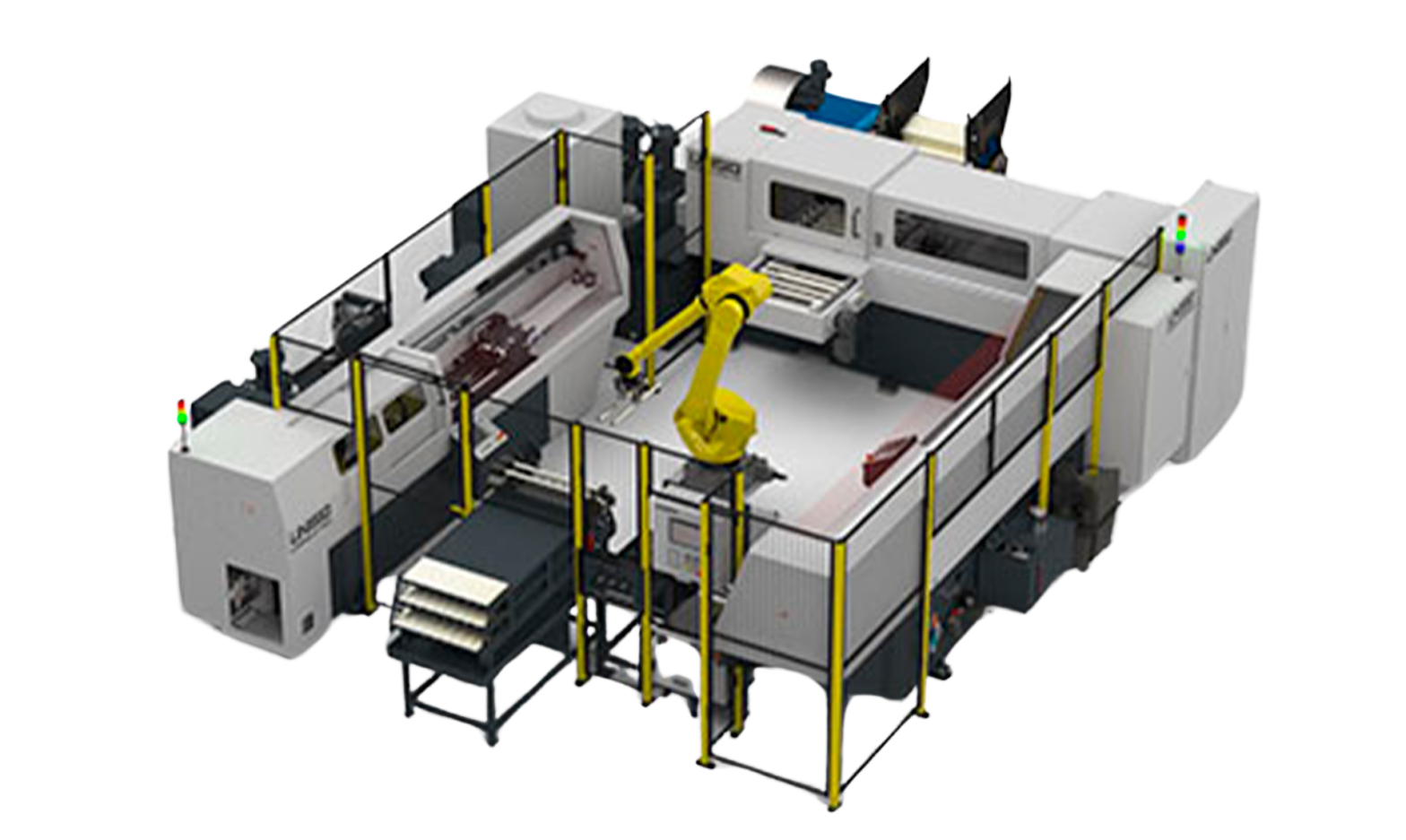

Creation and development of industrial automation customized to meet your needs.

Automatic doors

Automated loading and unloading system

Safety and cleaning systems

Interfaces to external clamping systems

Learn more about OTOMATIQA