Unisig

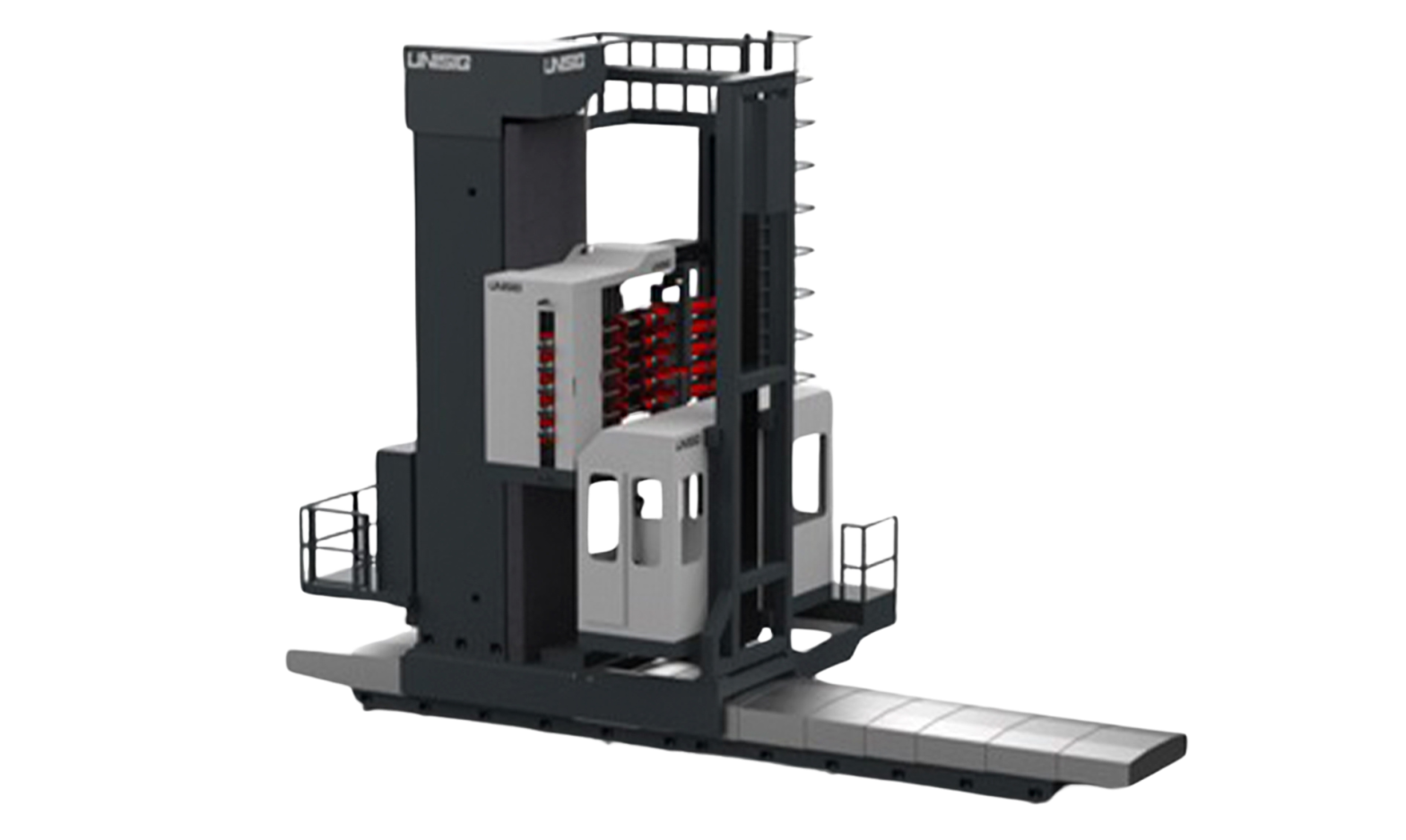

USC-2M-BTA

Unisig

USC-2M-BTA

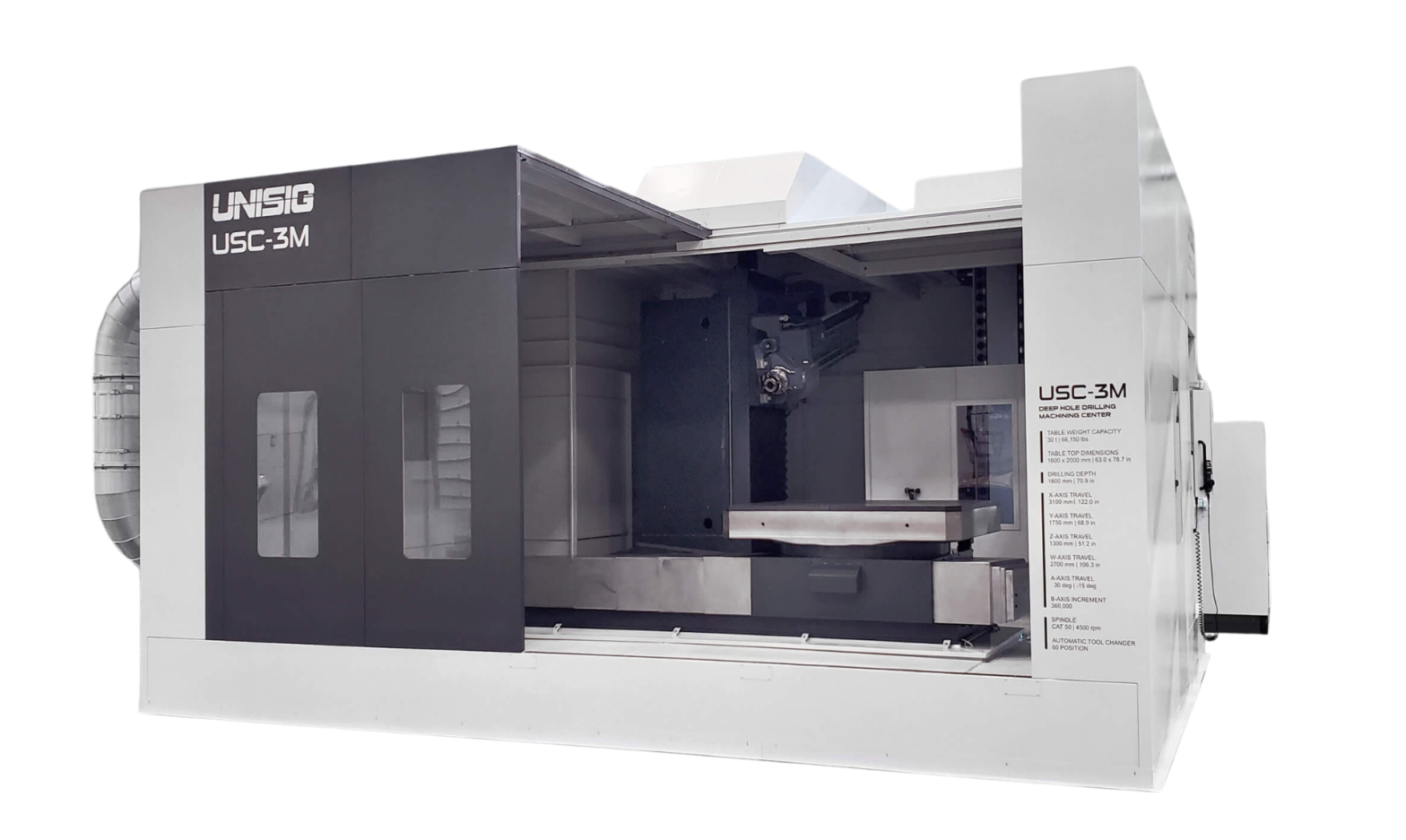

Product description

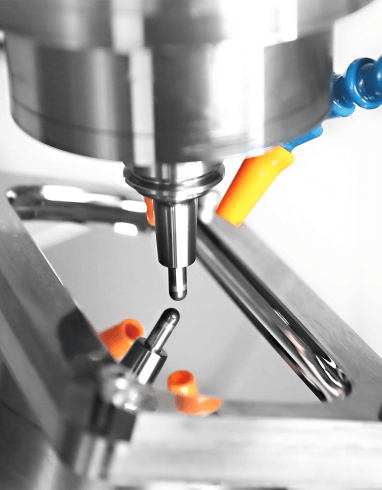

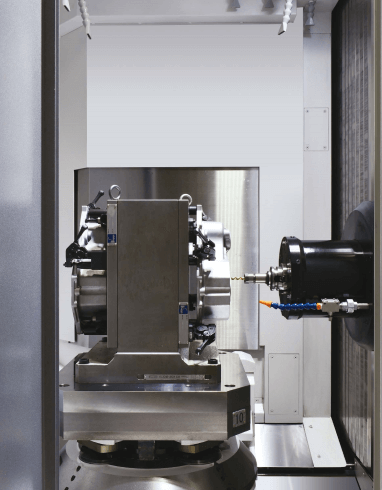

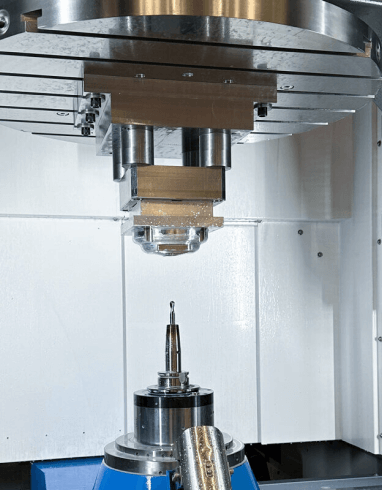

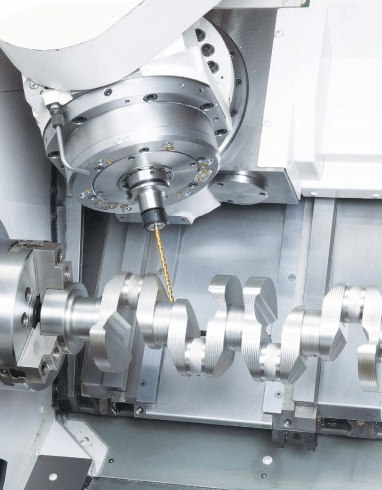

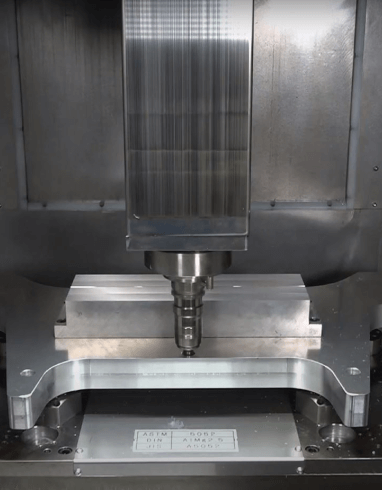

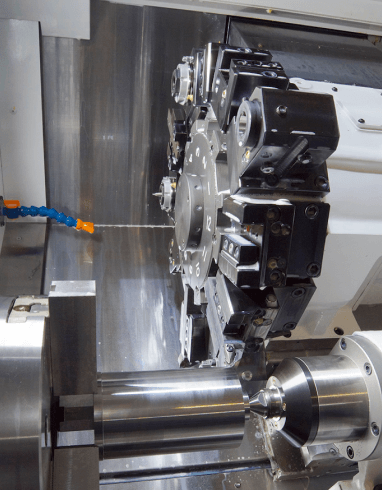

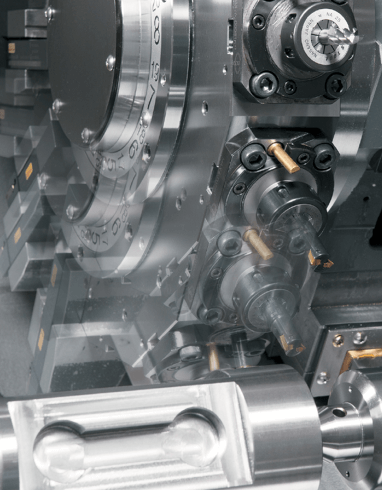

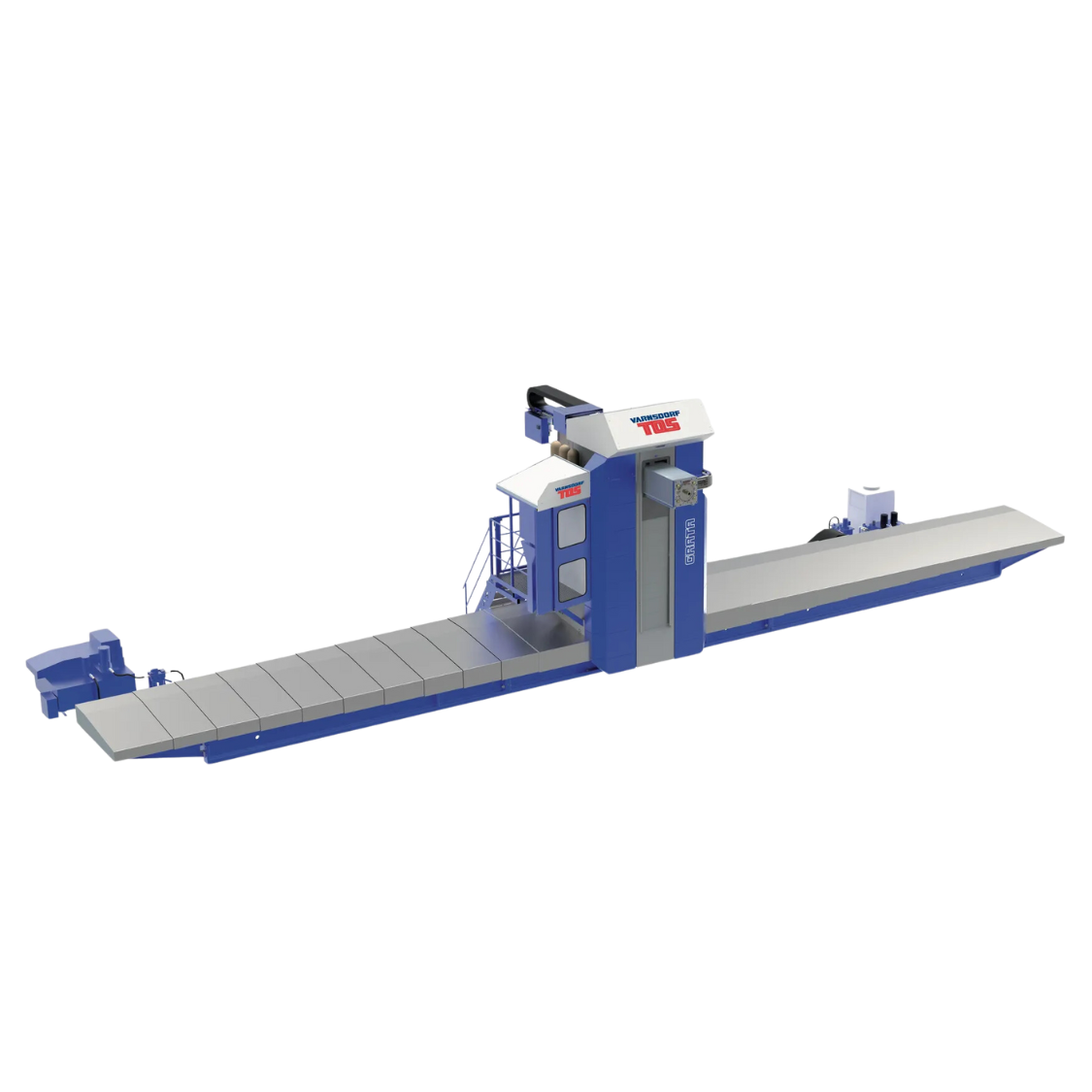

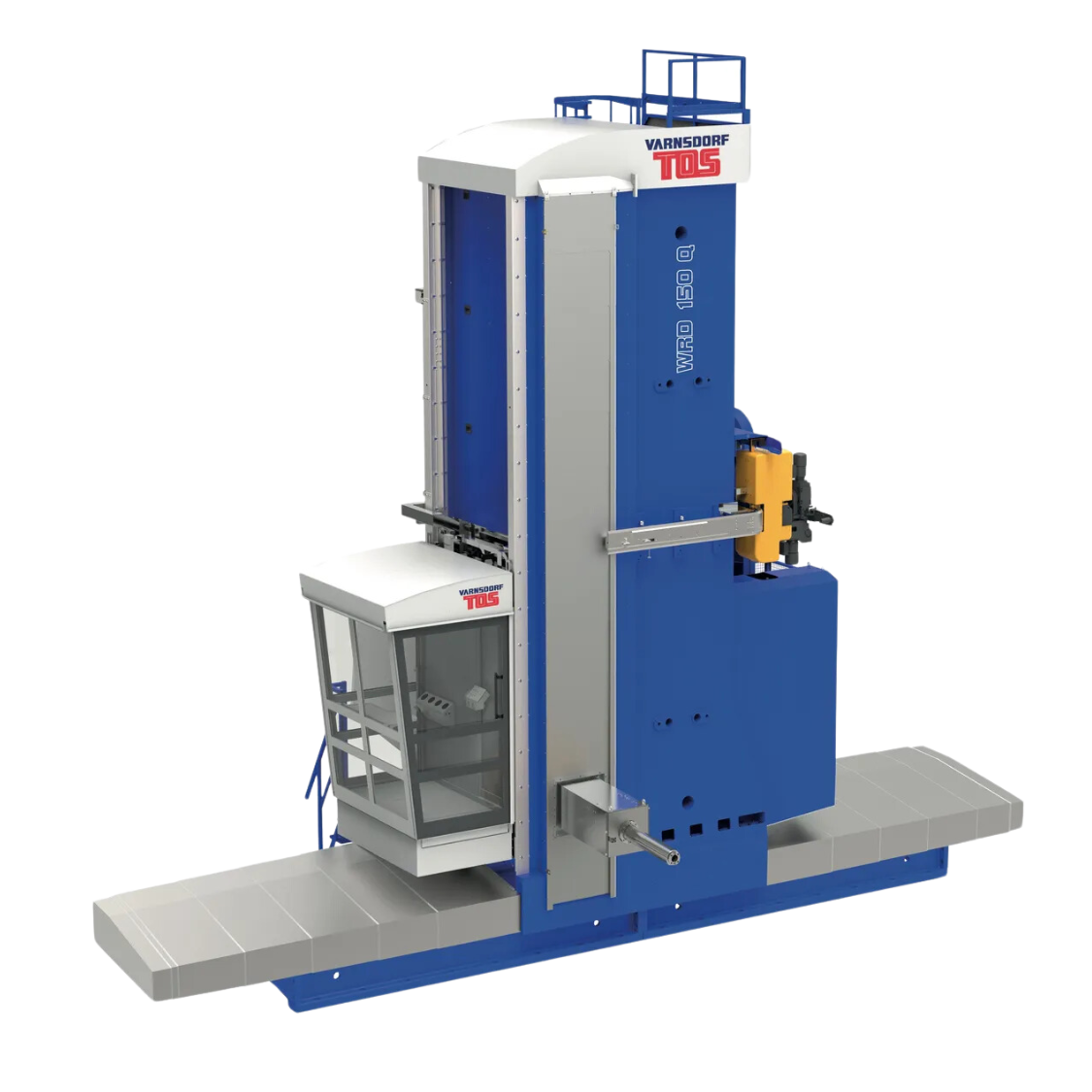

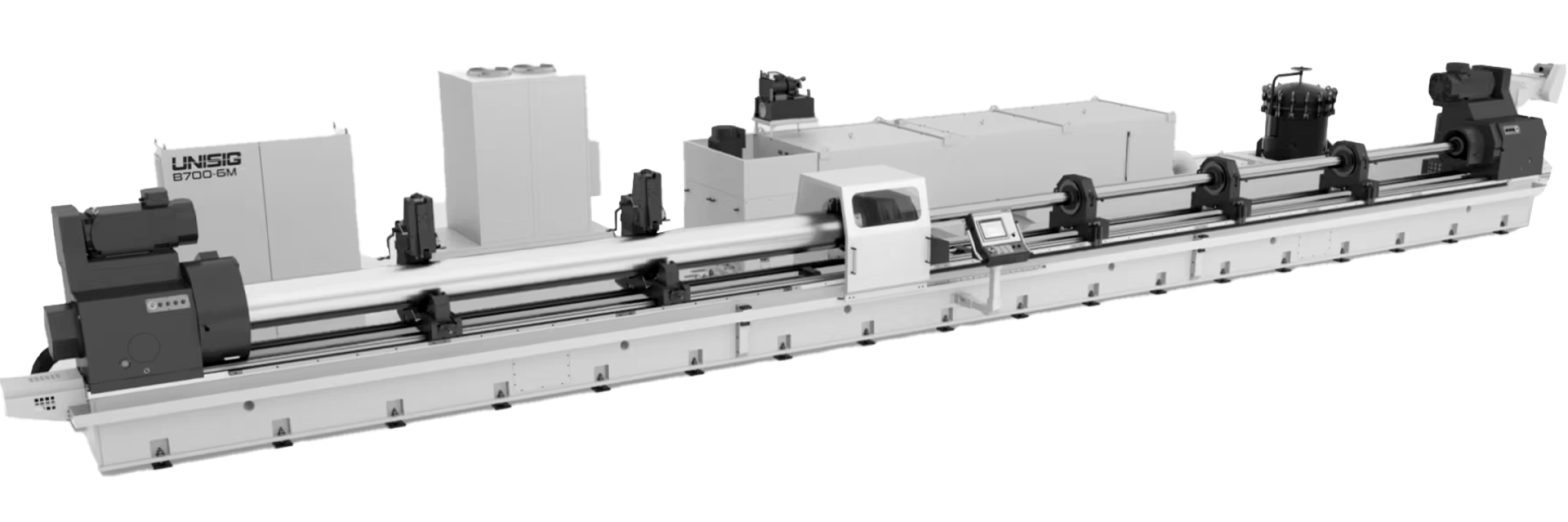

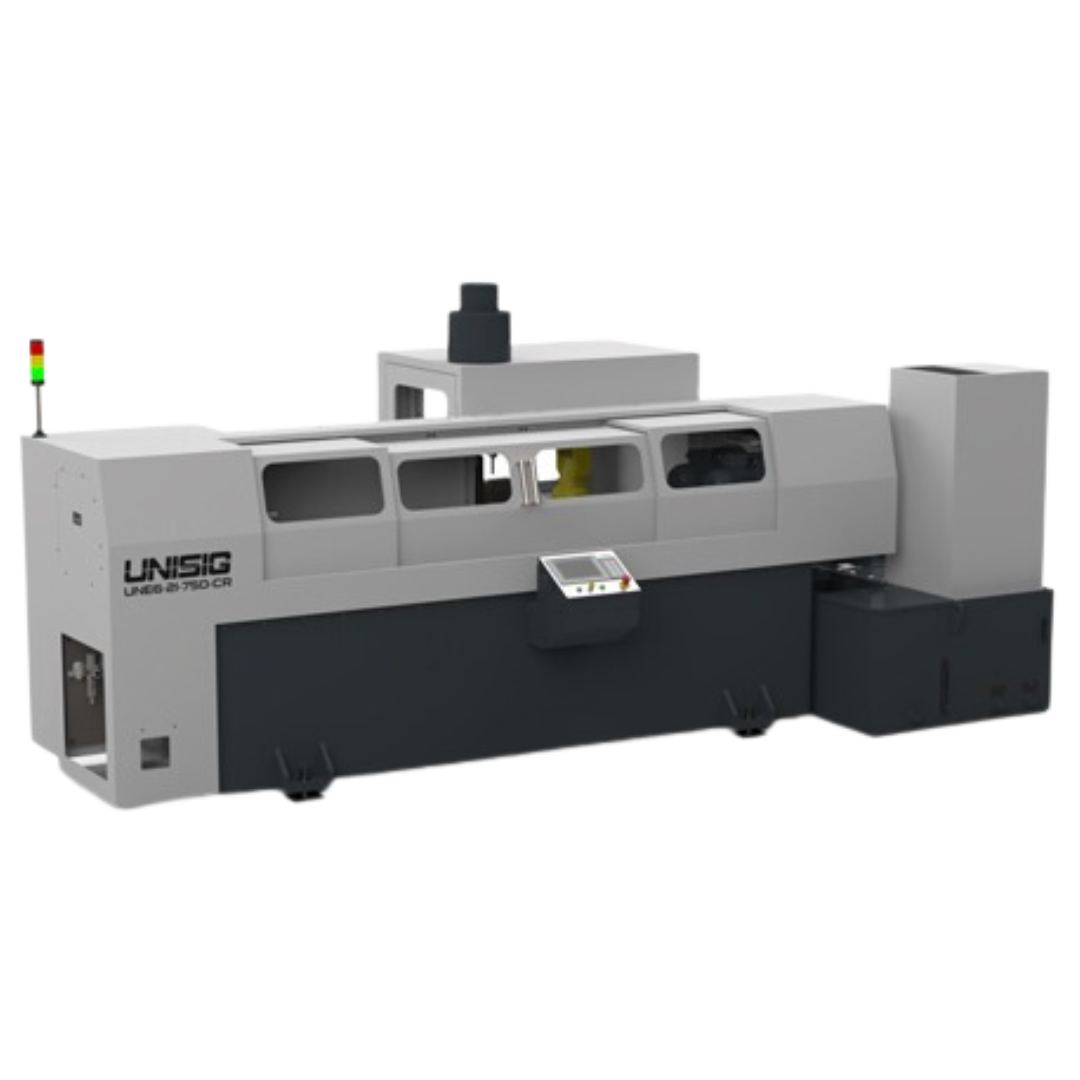

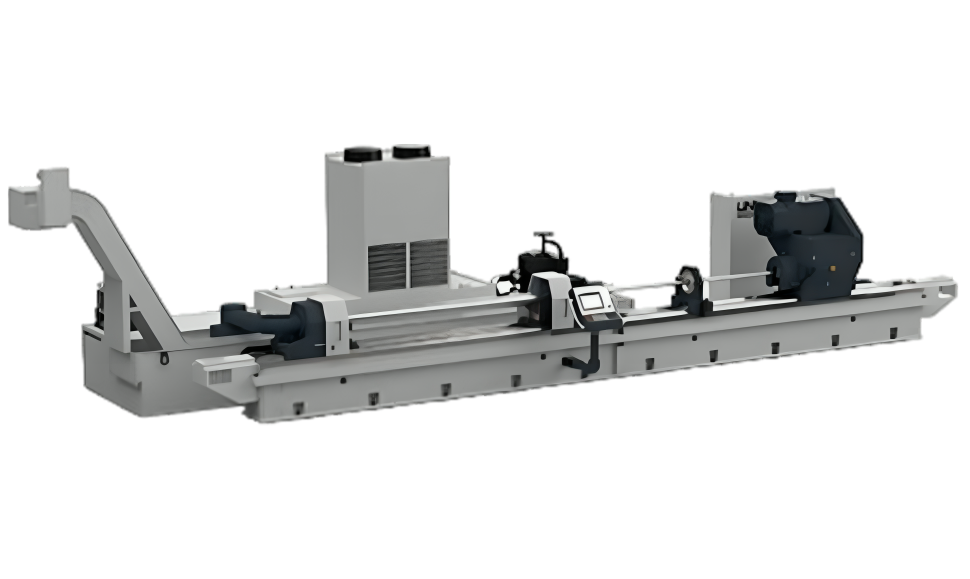

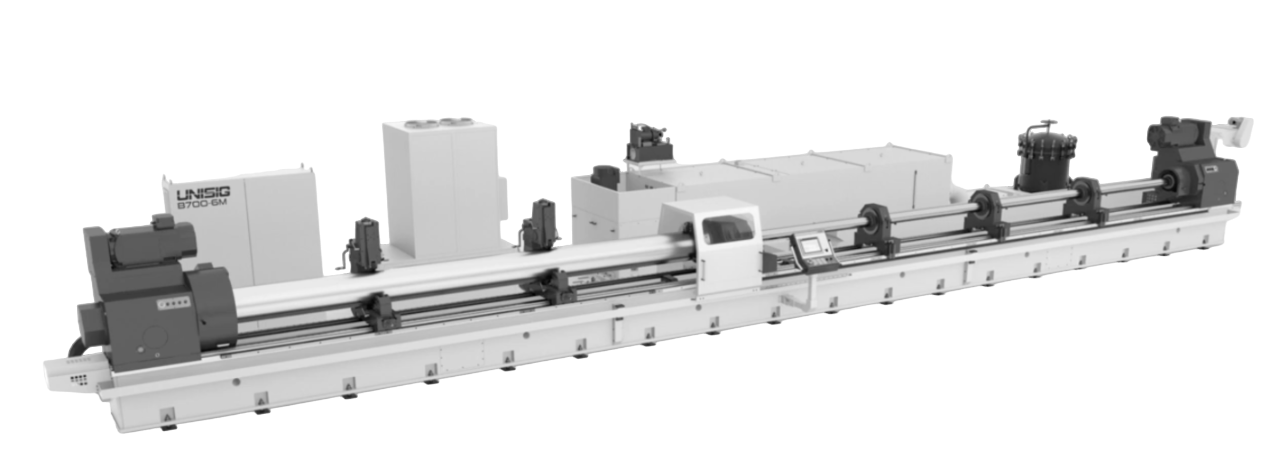

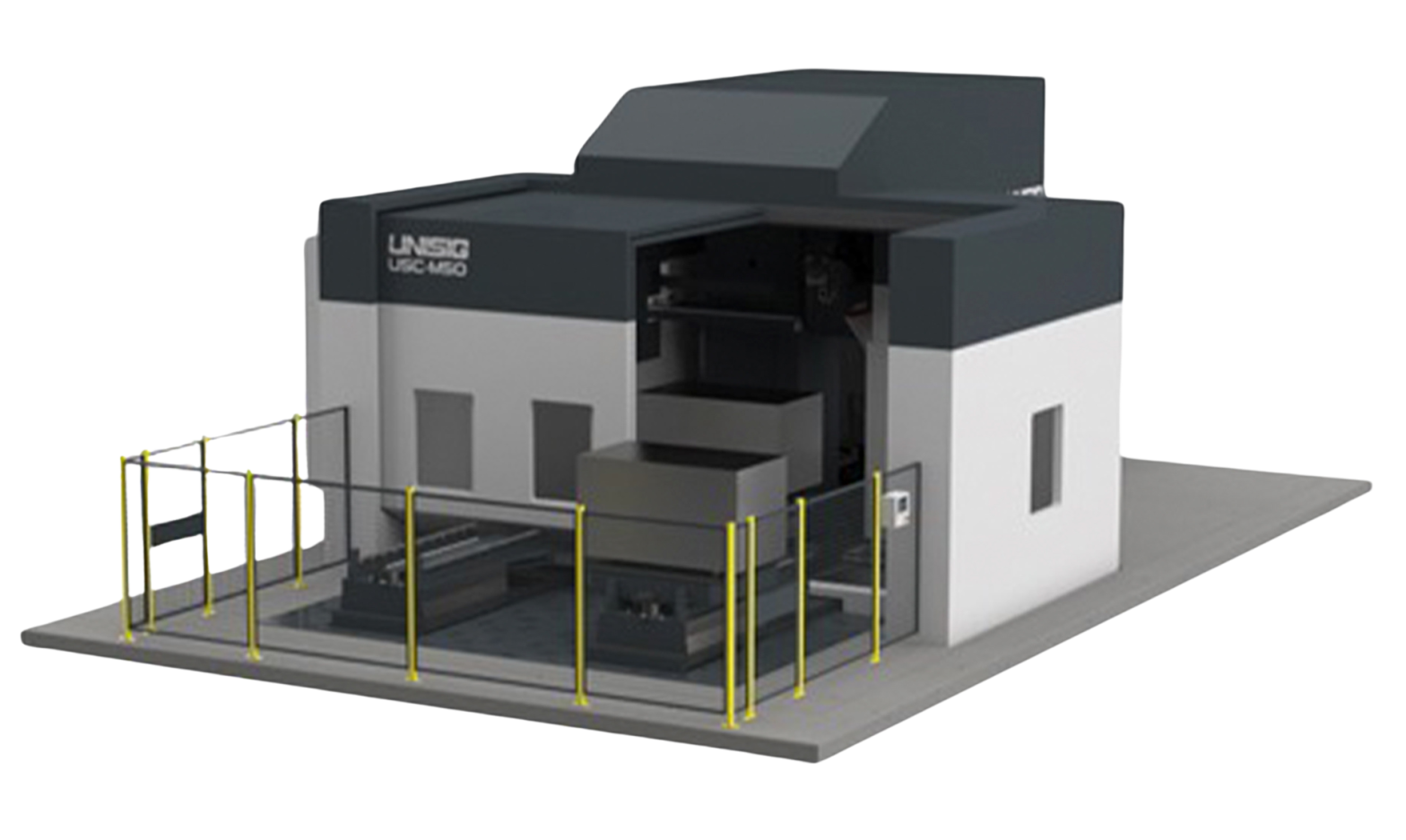

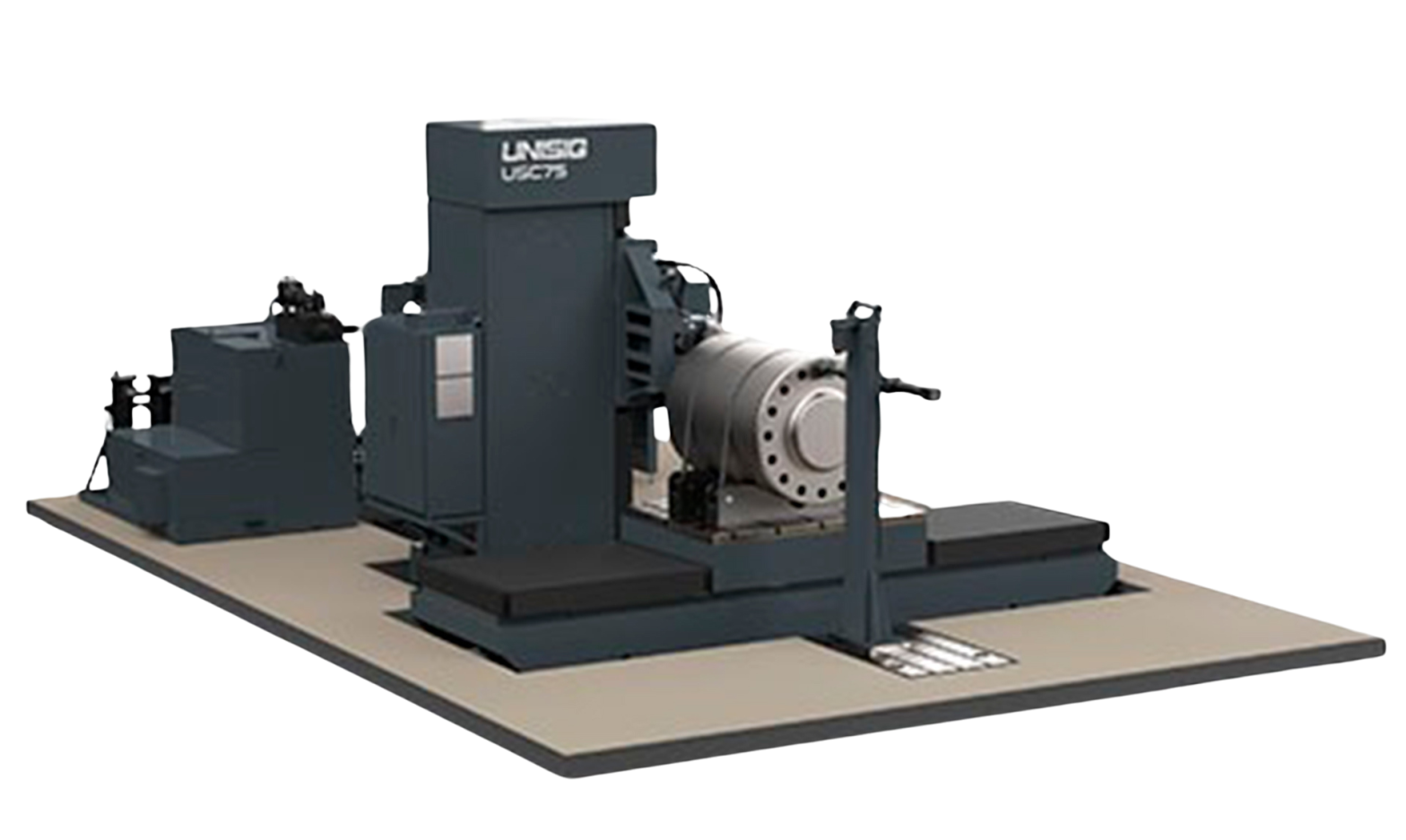

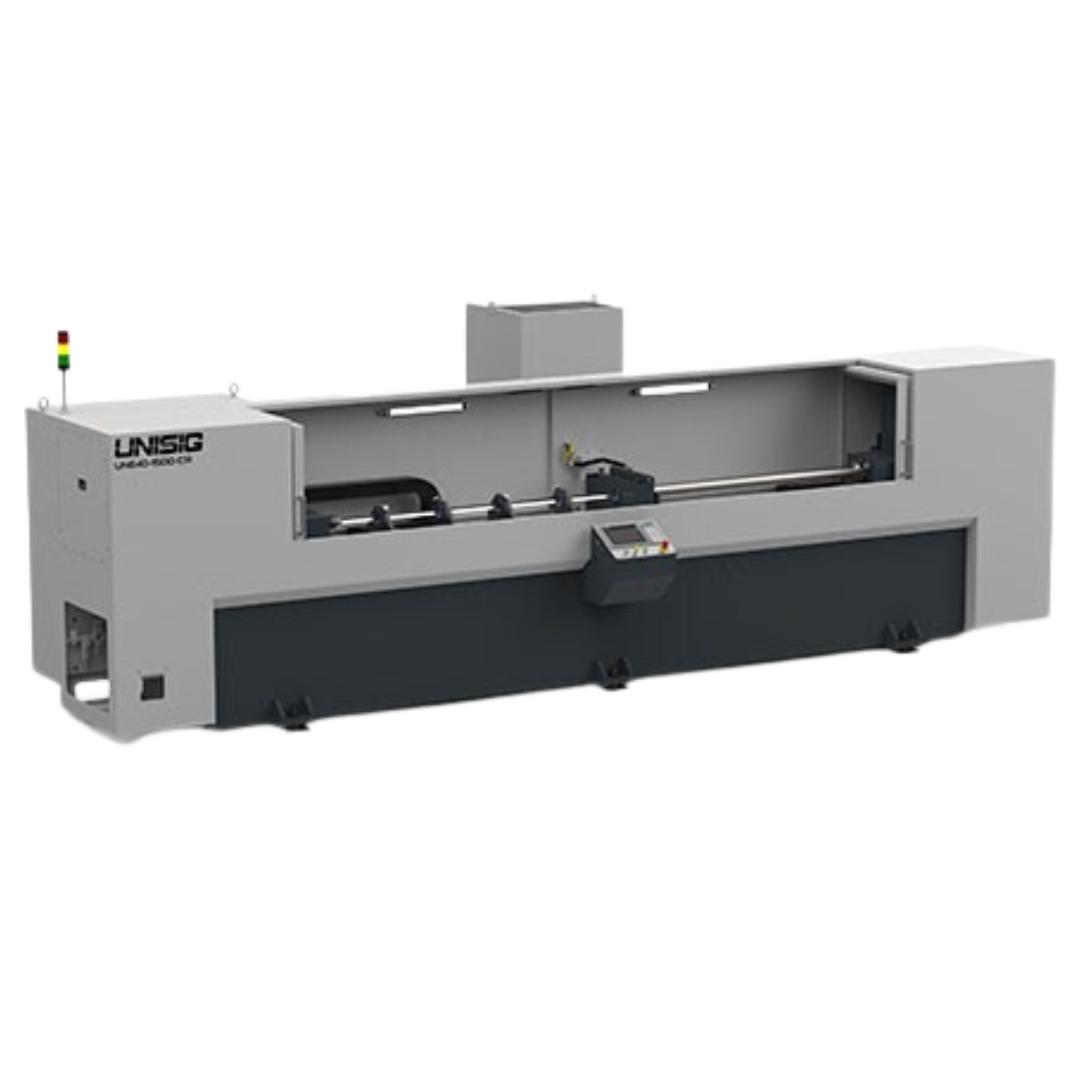

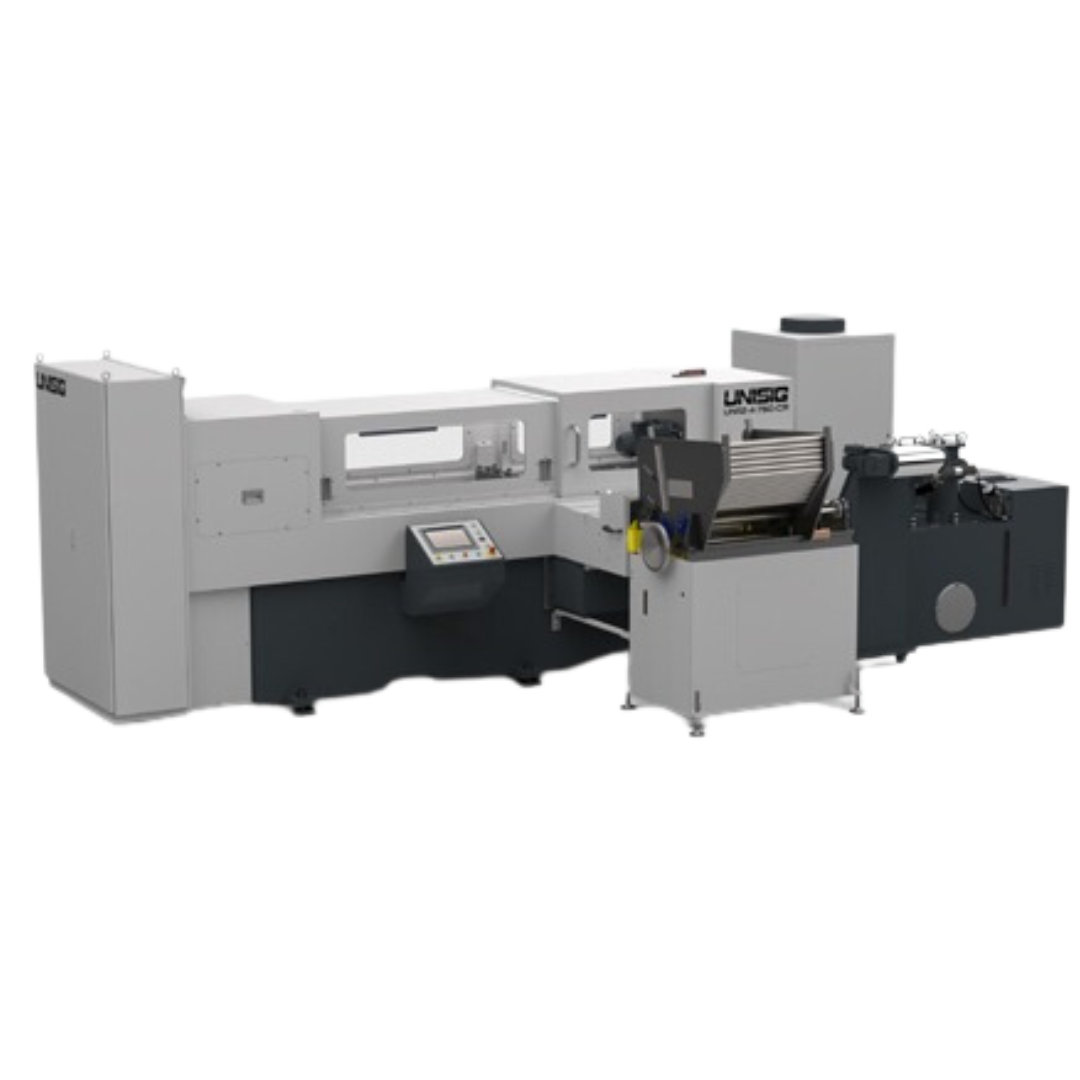

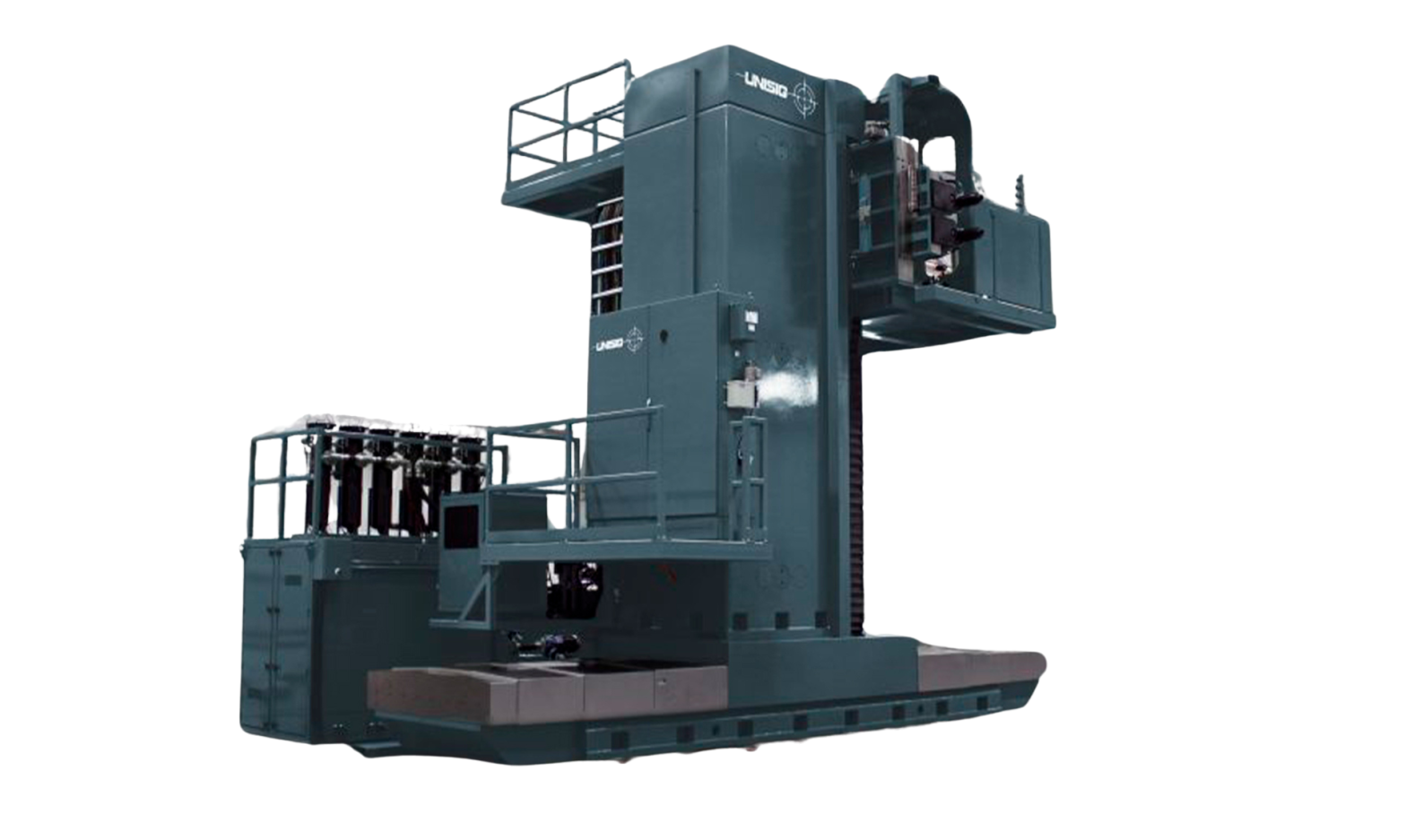

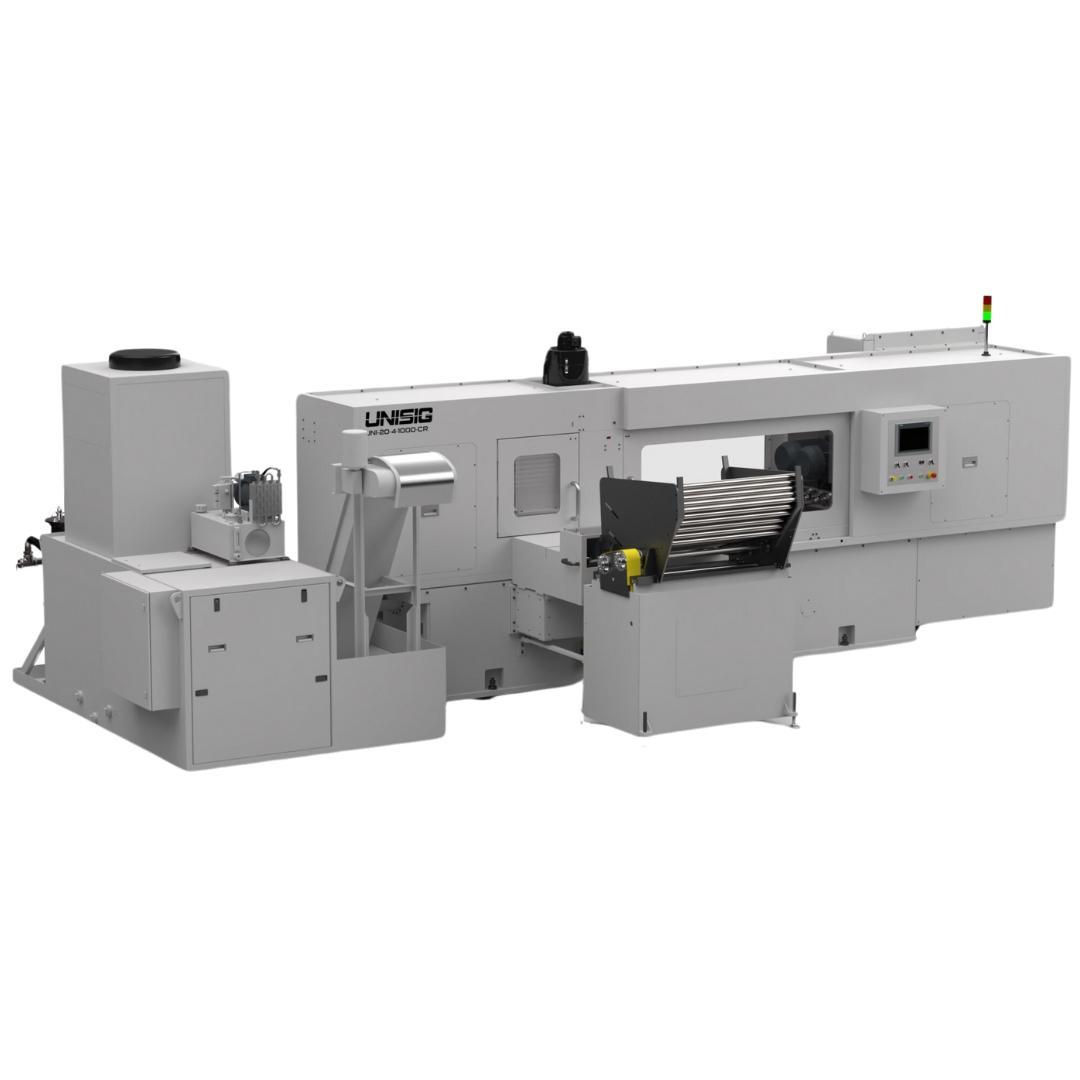

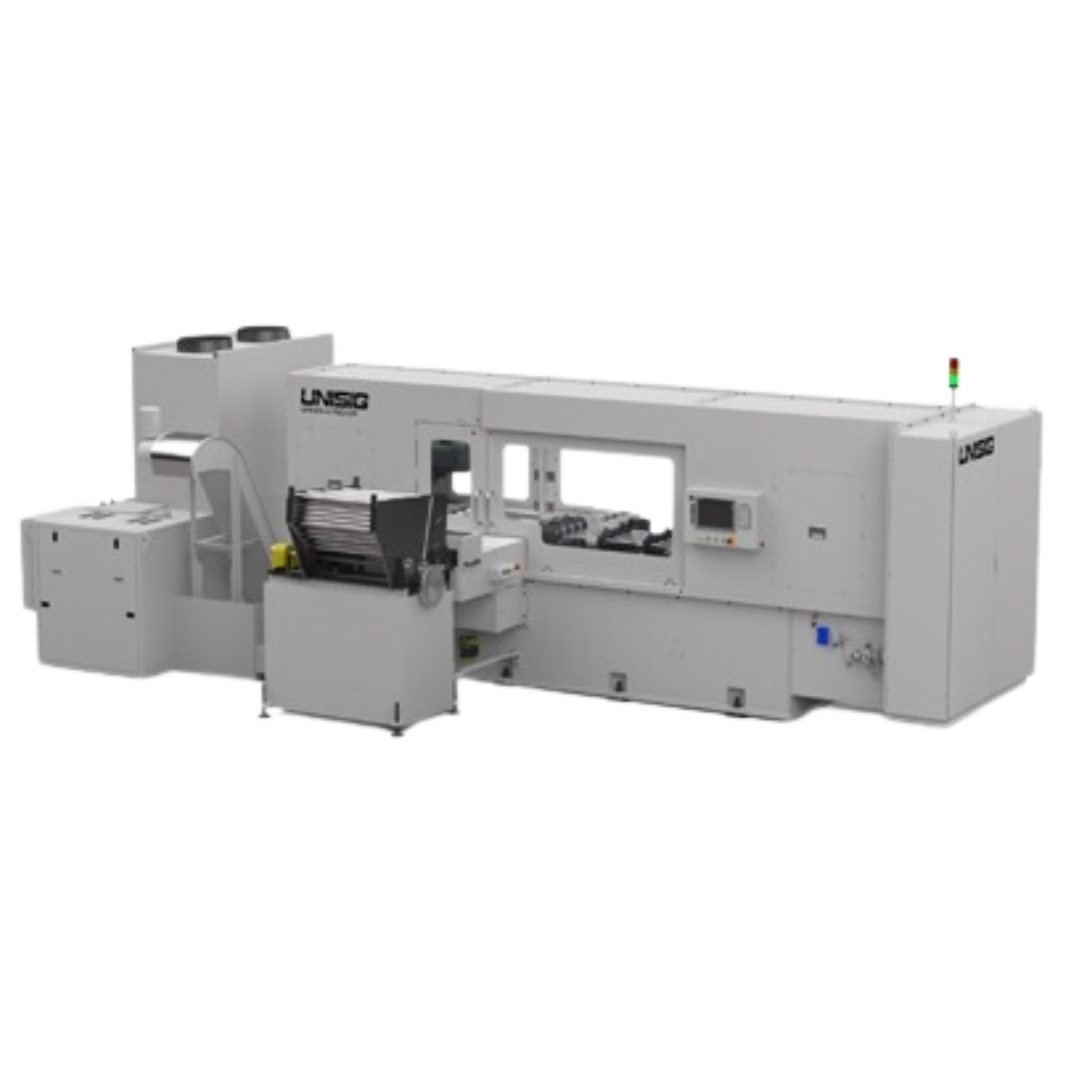

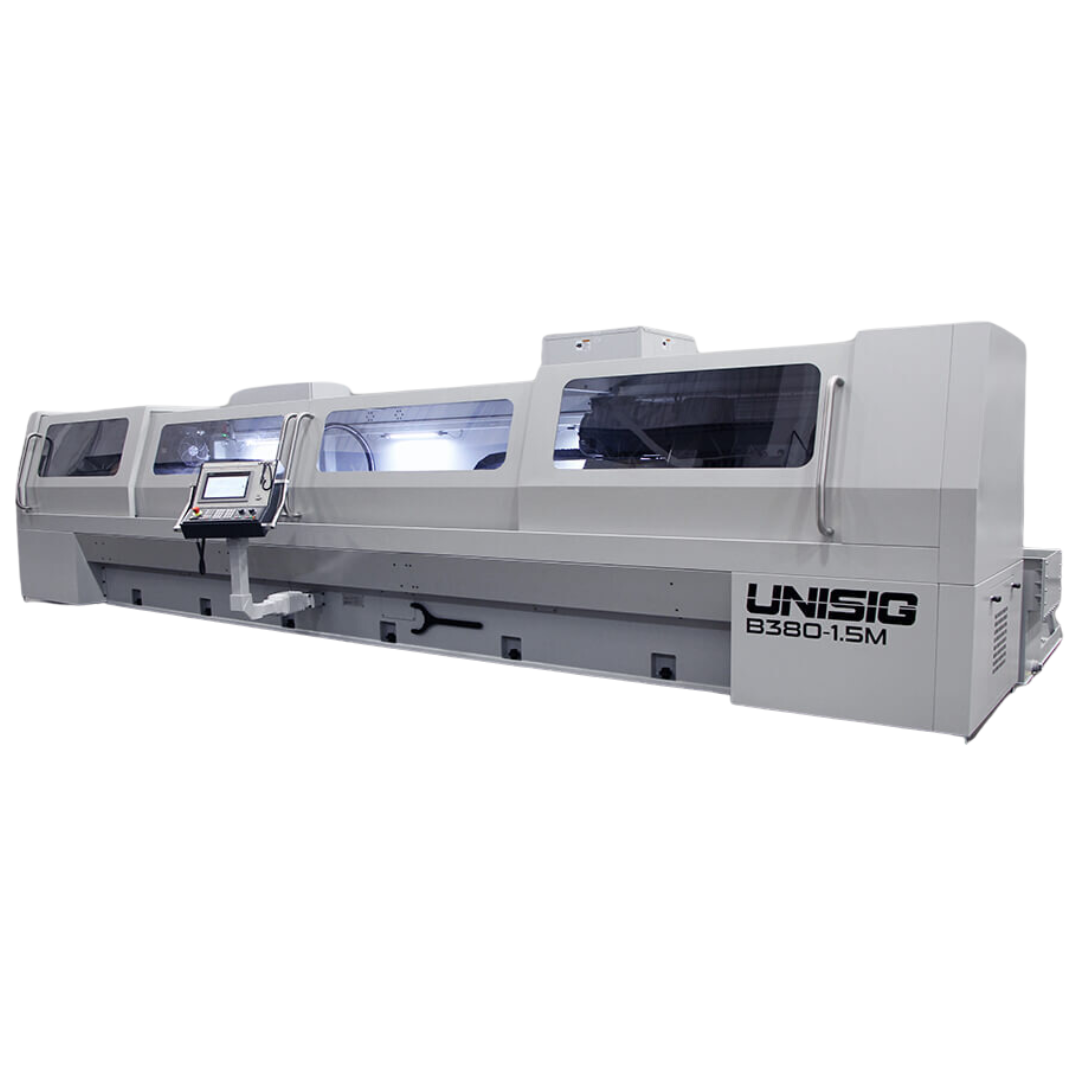

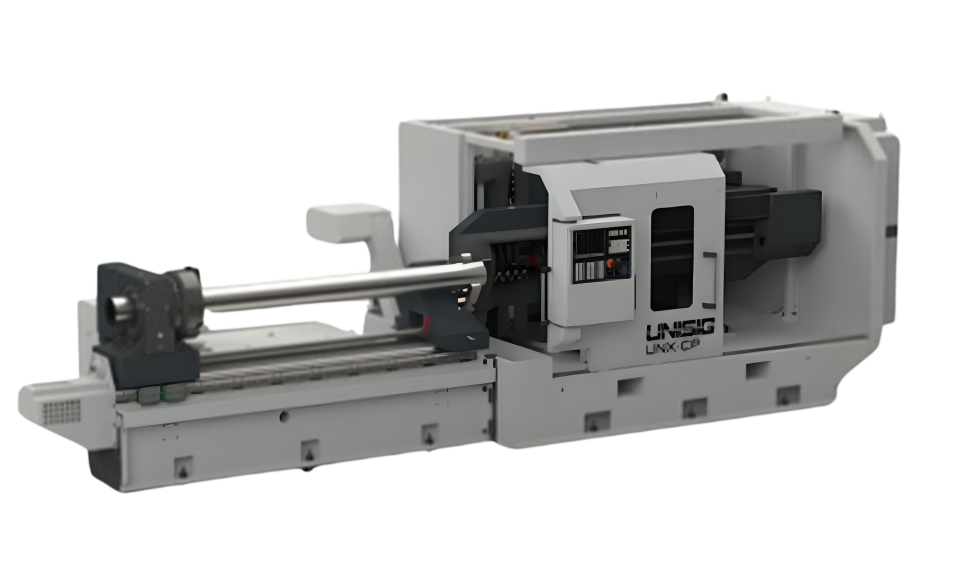

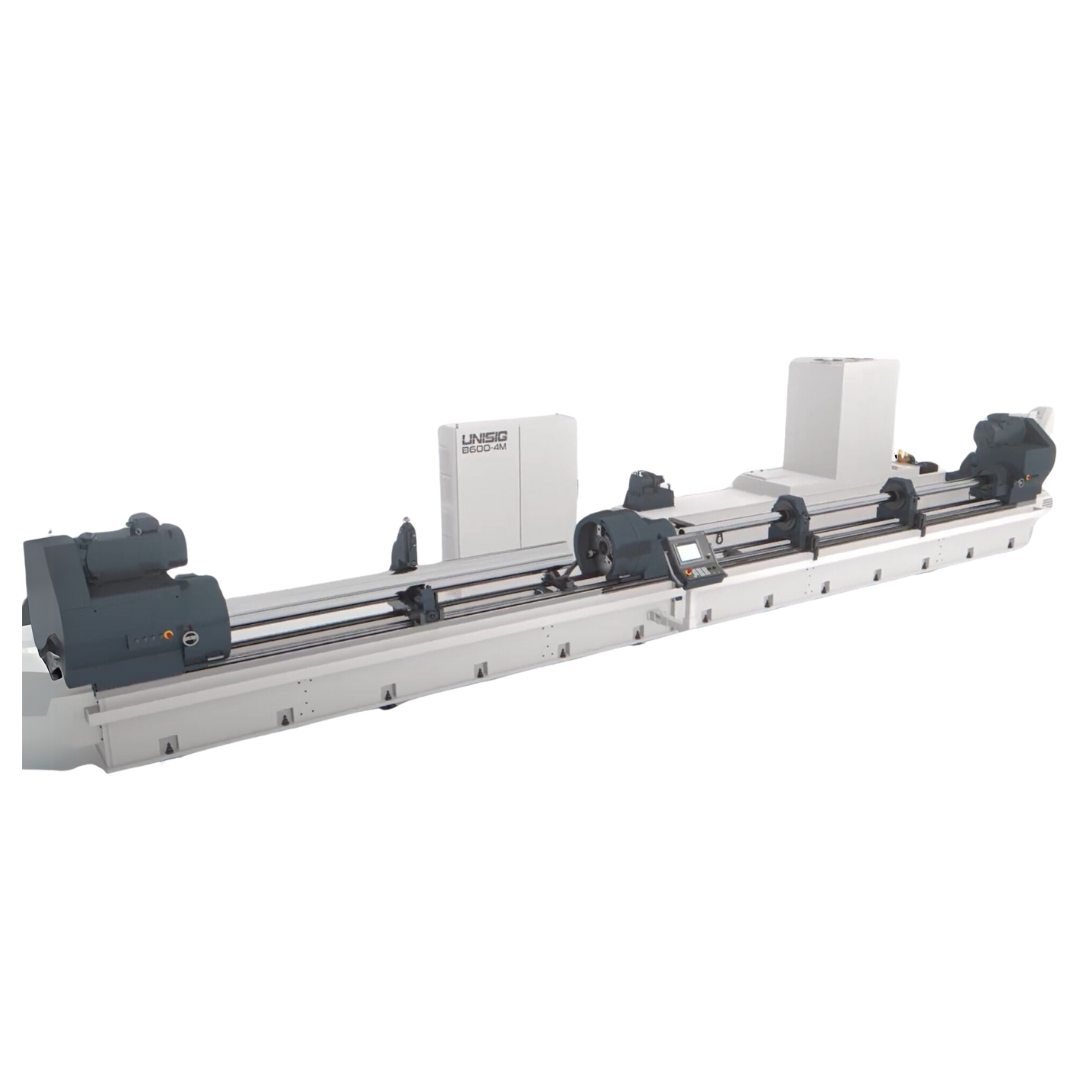

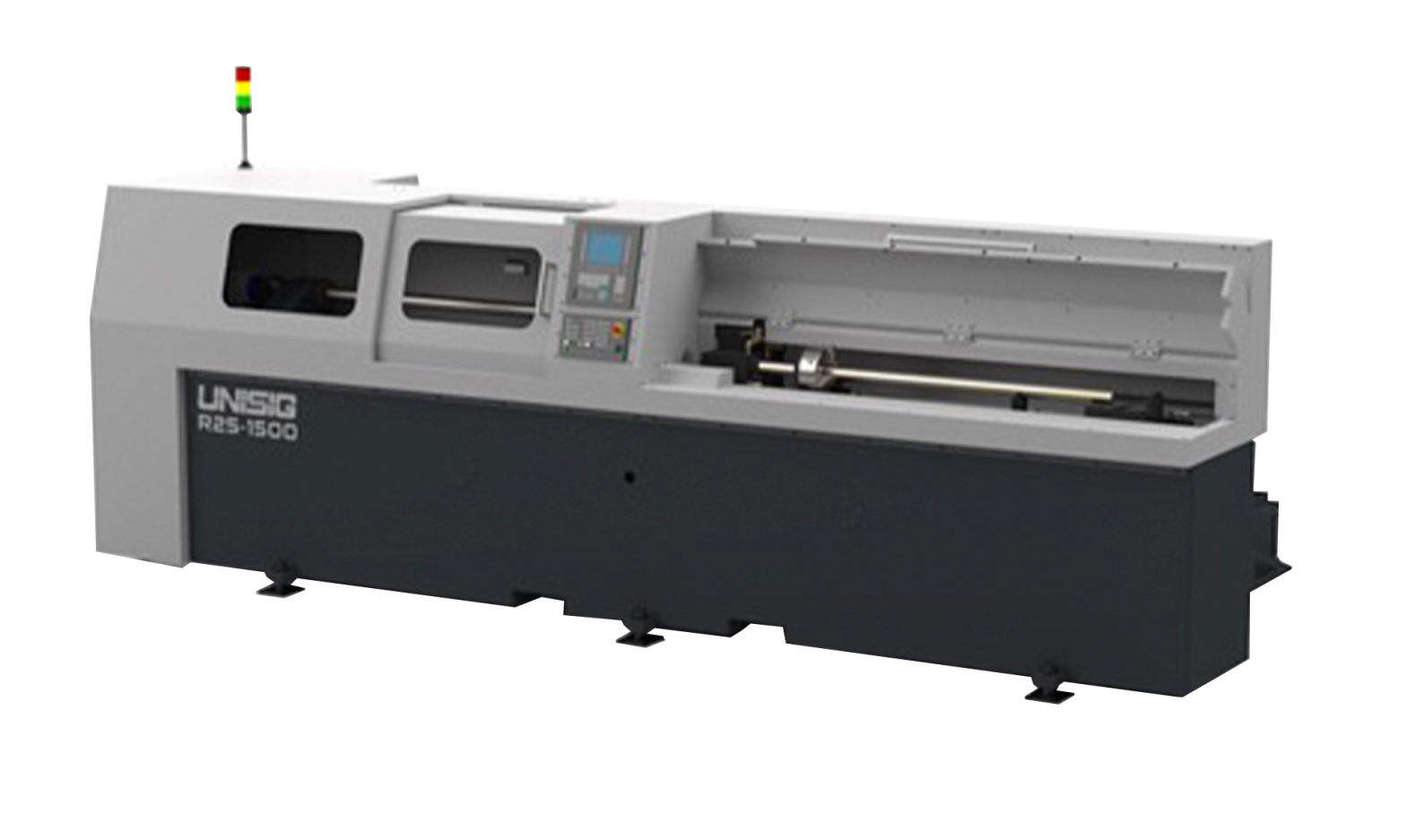

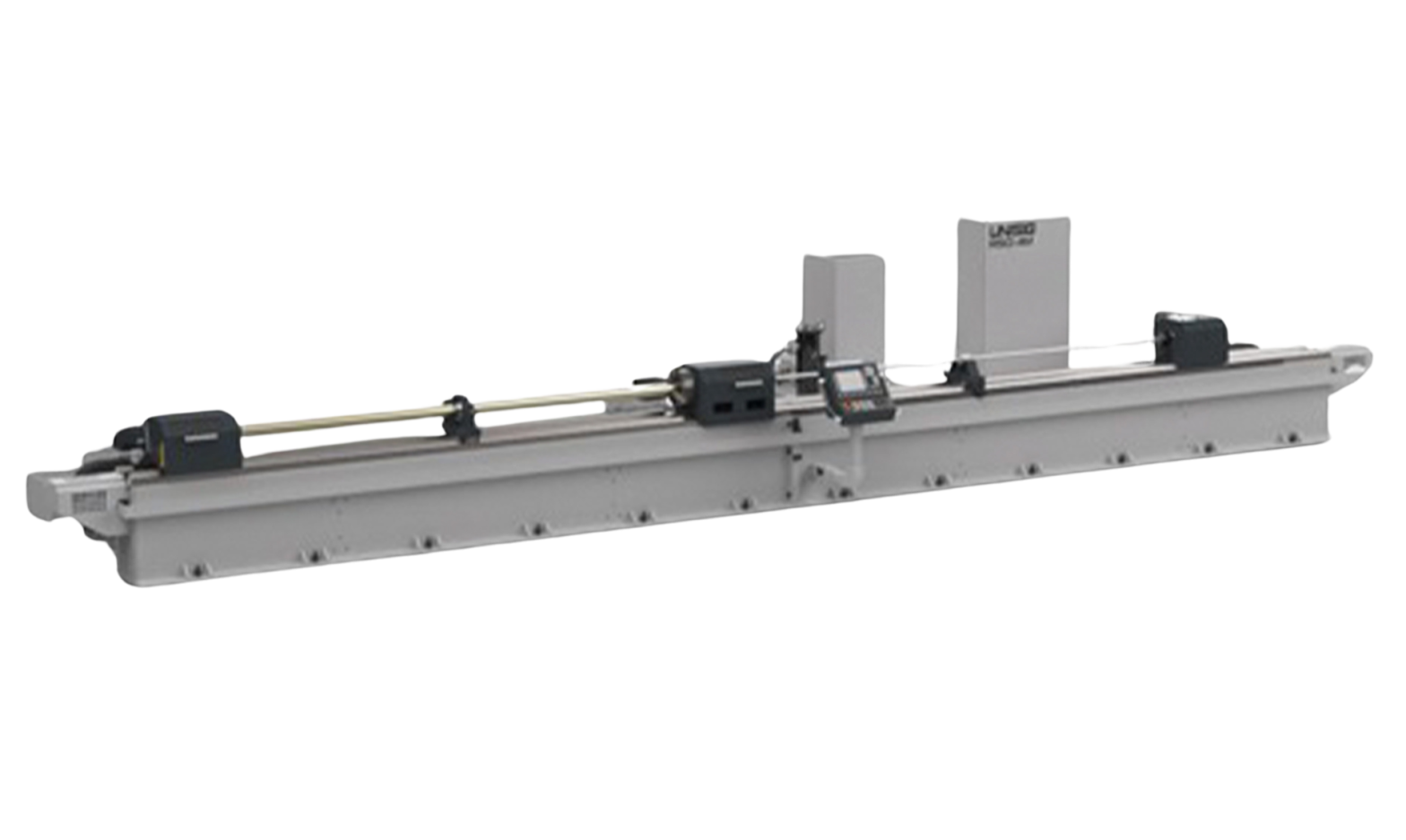

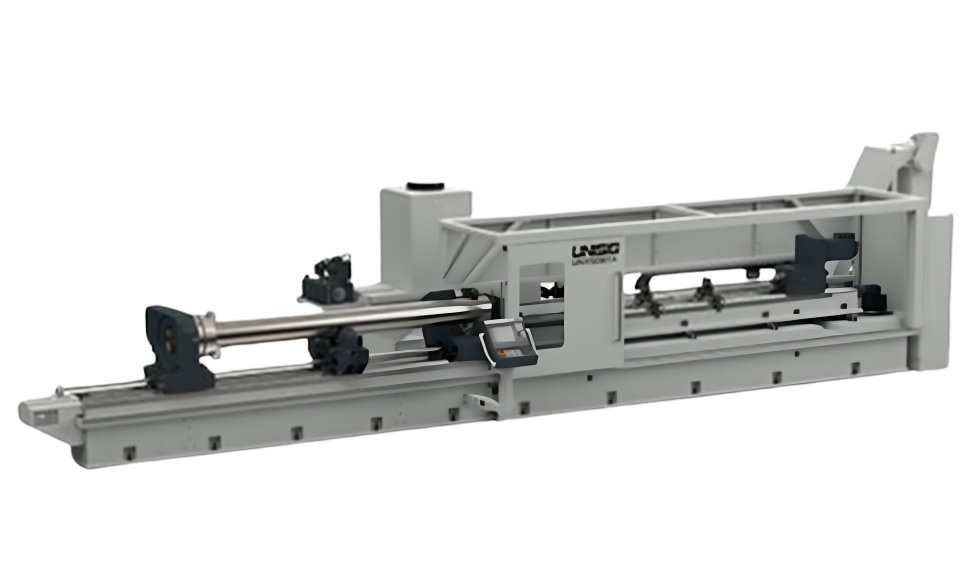

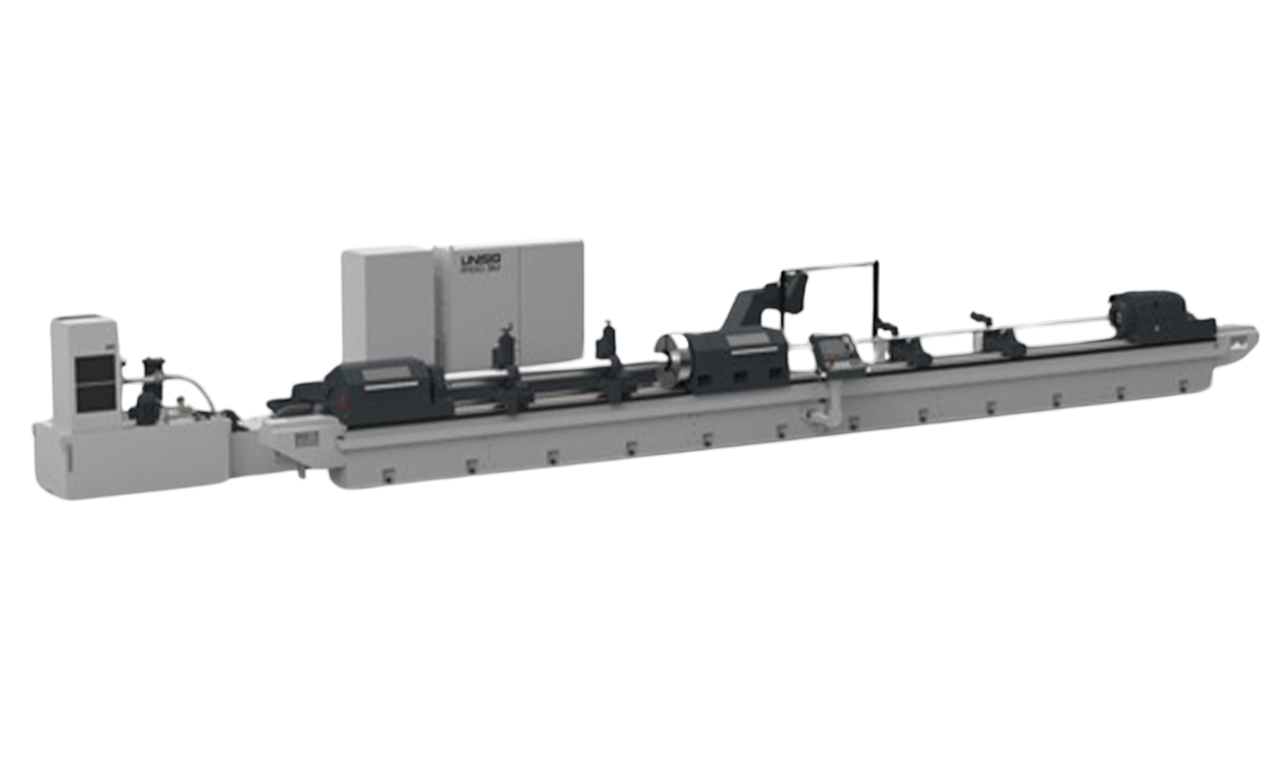

For manufacturers that have an opportunity to benefit from the combination of deep hole drilling and milling operations, UNISIG offers the USC-M series. Machines maximize production by allowing the fastest deep hole drilling with milling, with 5-axis positioning, to perform a range of complex machining in a single machine and setup.

USC-M series machines offer a full range of solutions for manufacturers, including heavy weight table capacities, a rotating A-axis, automatic tool changers, and intuitive controls on each machine. Models are available in a range of capacities and options, with engineered universal (gundrilling + machining) or dedicated (deep hole drilling, milling) spindles.

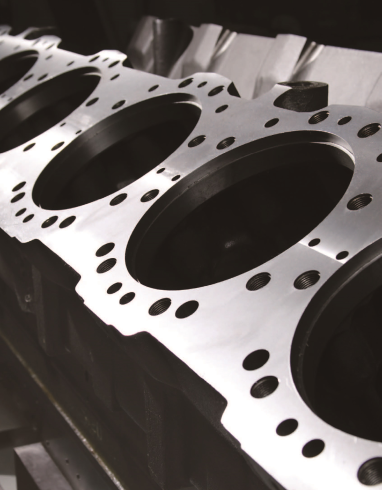

Industries

Energy

Molds & Dies

Others

Product Highlights

Product Highlights

Spindle Type

Dedicated

Nominal drilling depth (in)Nominal drilling depth (mm)

651,650

Gundrilling diameter (in)Gundrilling diameter (mm)

250

BTA Drilling Diameter (in)BTA Drilling Diameter (mm)

1.538

X-Axis (in)X-Axis (mm)

82.72,100

Y-Axis (in)Y-Axis (mm)

68.91,750

Z-Axis (in)Z-Axis (mm)

33.5850

A-Axis inclination

-30°, +15°

B-axis (rotary table)

360,000 positions

Drilling or Universal spindle (in)Drilling or Universal spindle (mm)

78.72,000

Machining spindle (in)Machining spindle (mm)

19.7500

Table Top surface (in)Table Top surface (mm)

49.2 x 63.01,250 x 1,600

Table Weight Capacity (lb)Table Weight Capacity (kg)

44,10020,000

Spindle nose

SK50/CAT 50

Maximum speed (rpm)

4,500

Power (480V S1 100% / S6 60%) (hp)Power (480V S1 100% / S6 60%) (kW)

27 / 3420 / 25

Automatic Tool Changer

40 positions

CNC Controls

Heidenhain CNC

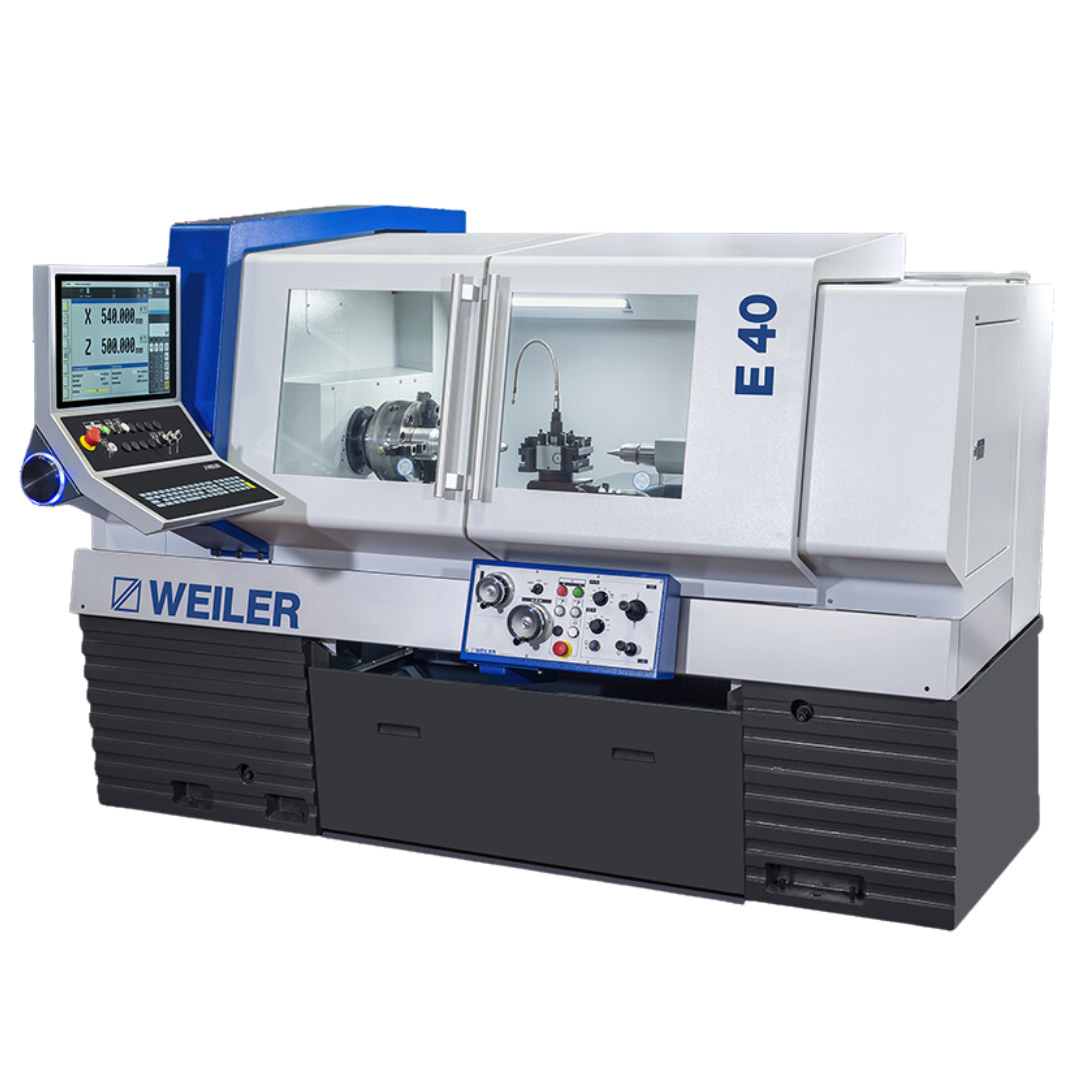

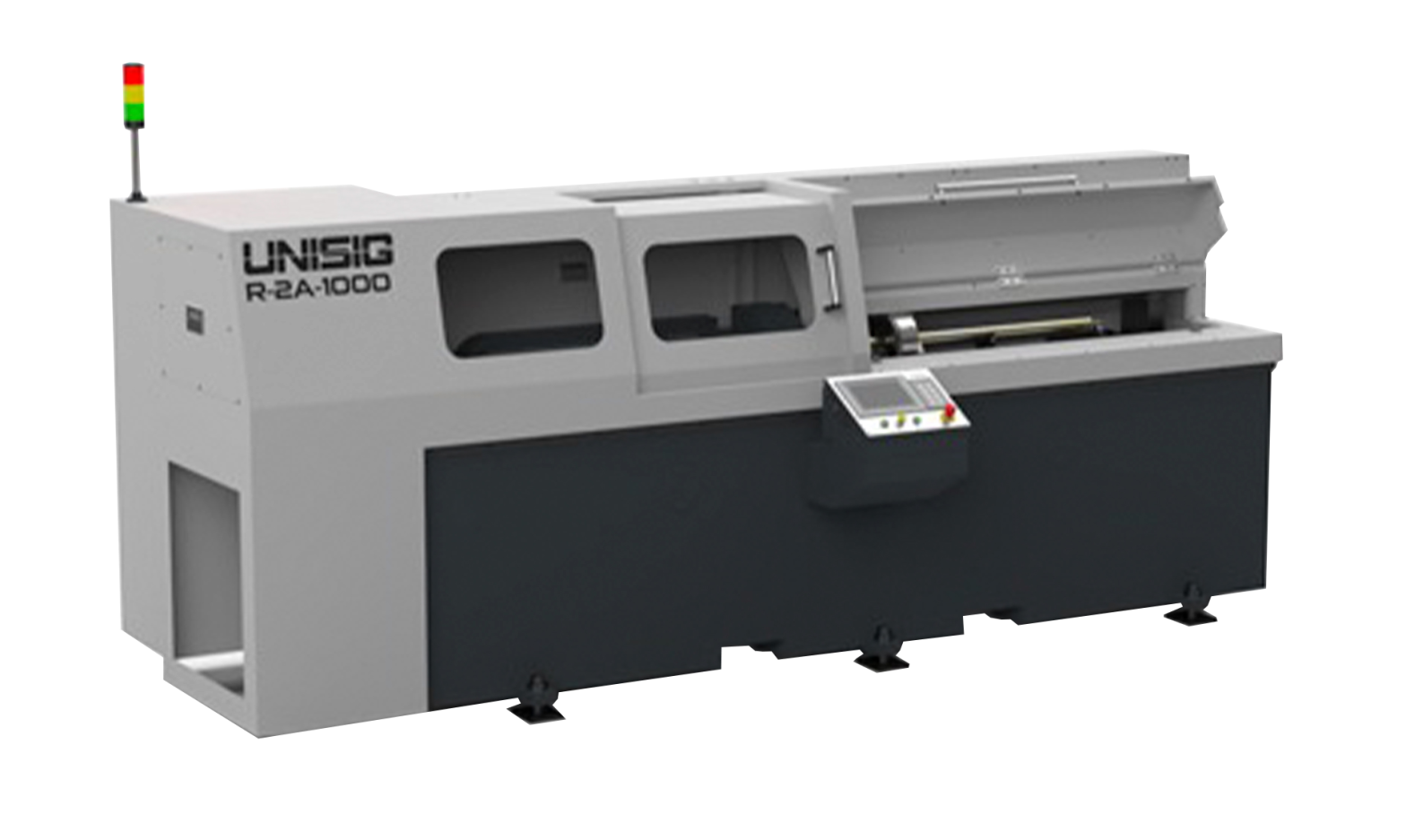

Recommended solutions to improve your processes

Equip and maximize the productivity of your CNC machines with comprehensive solutions.

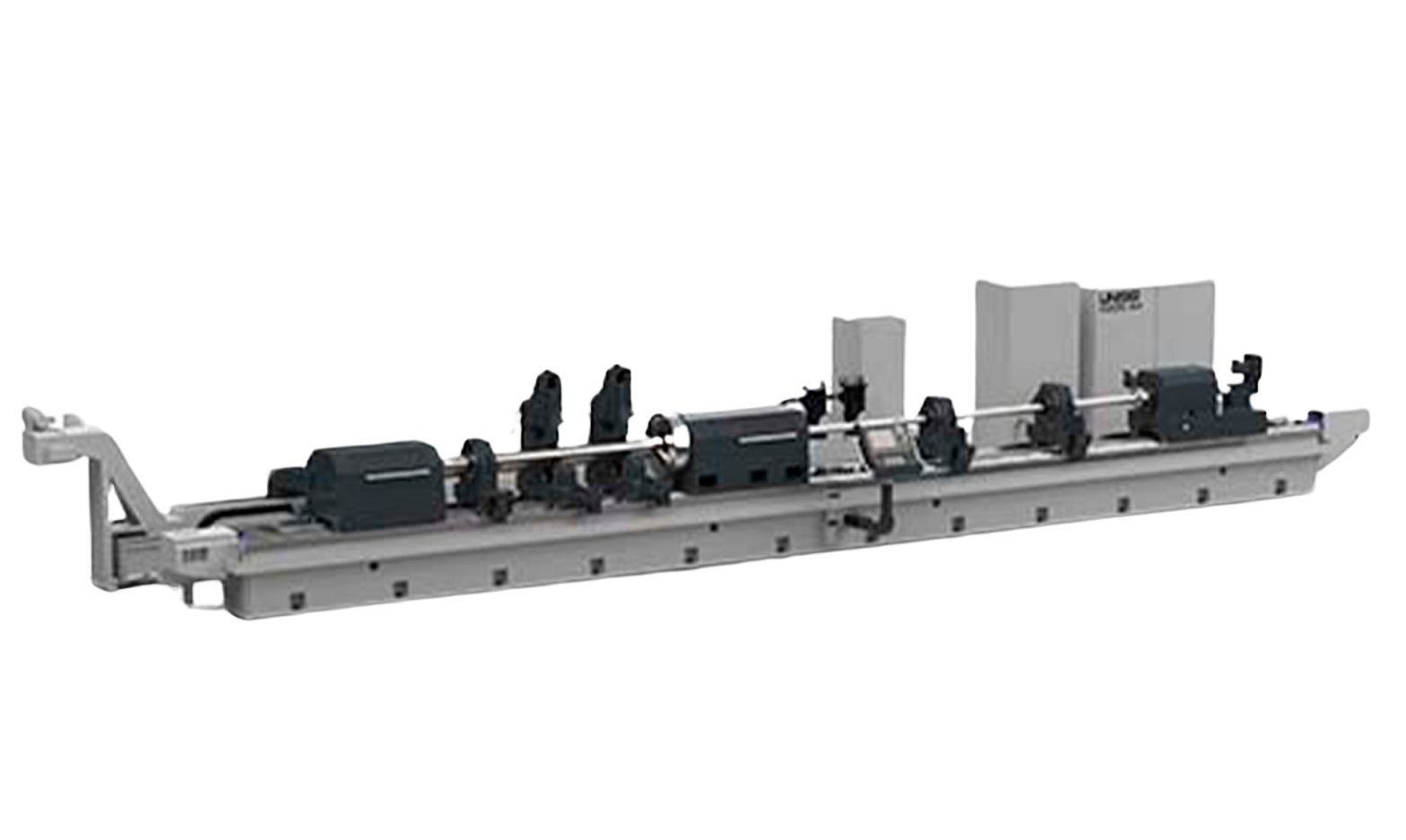

Accessories and peripherals

Mist collector

Cooling system

Coolant filtration and magnetic separator equipment

Learn more about PERIFERIQ

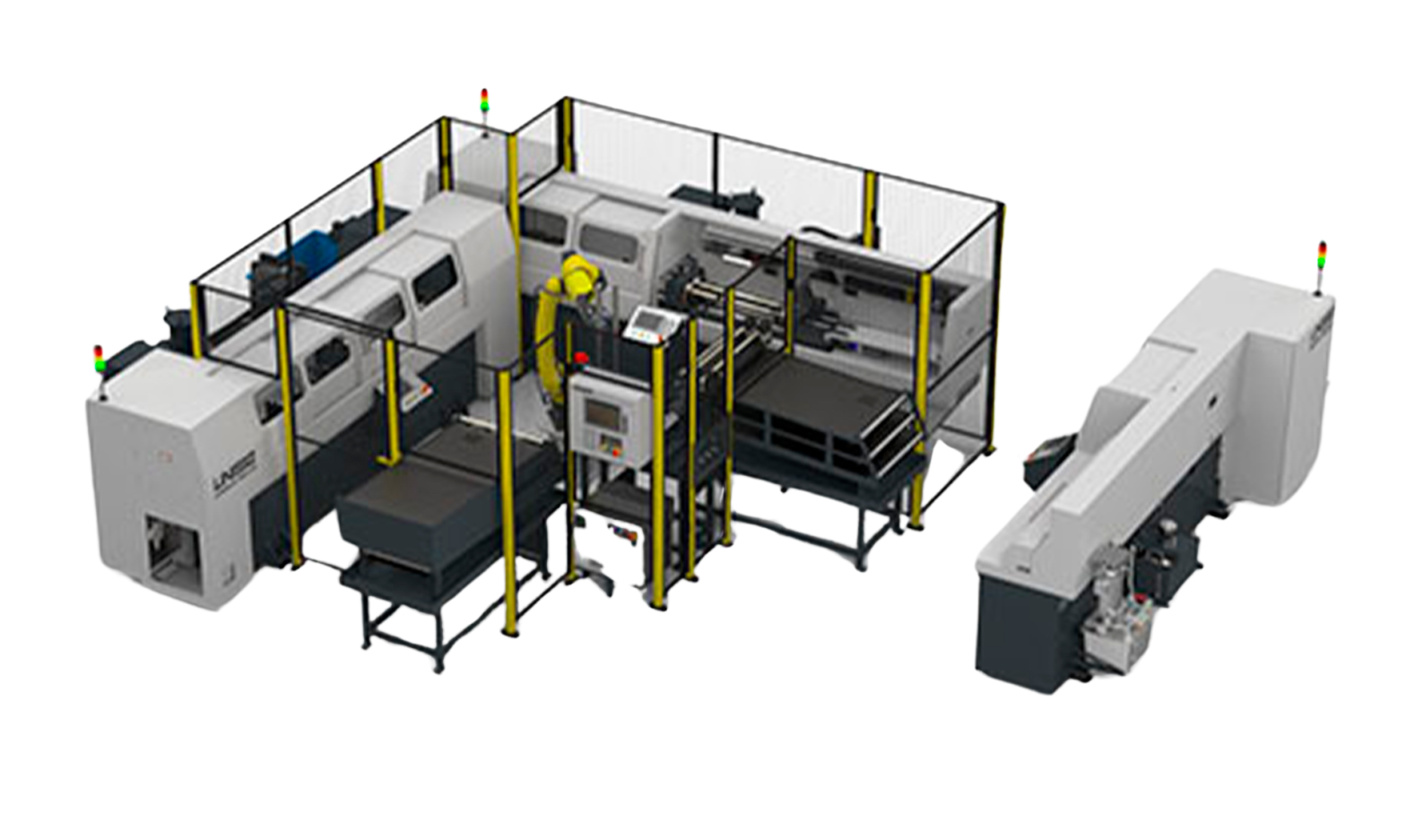

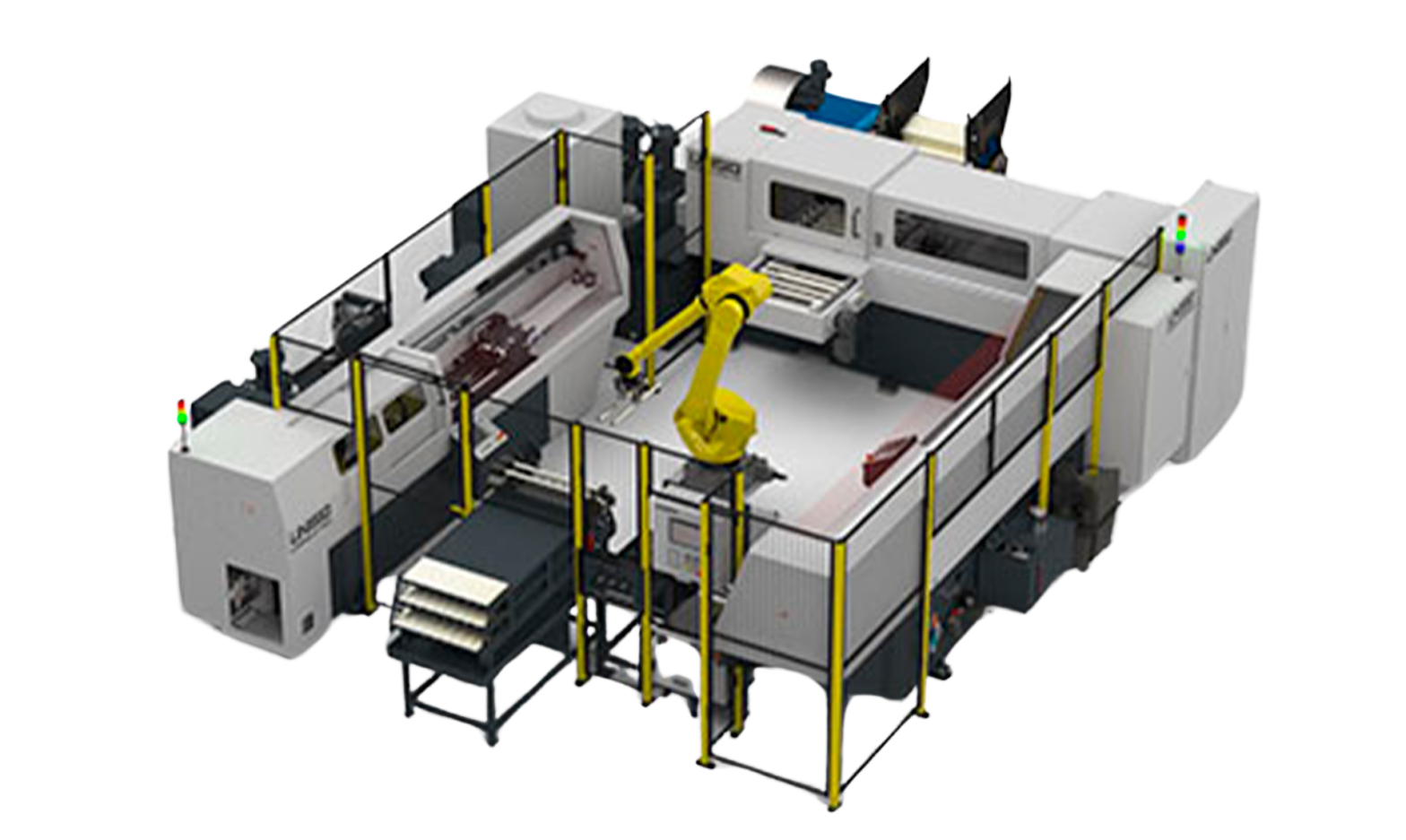

Creation and development of industrial automation customized to meet your needs.

Automatic doors

Automated loading and unloading system

Safety and cleaning systems

Interfaces to external clamping systems

Learn more about OTOMATIQA