Unisig

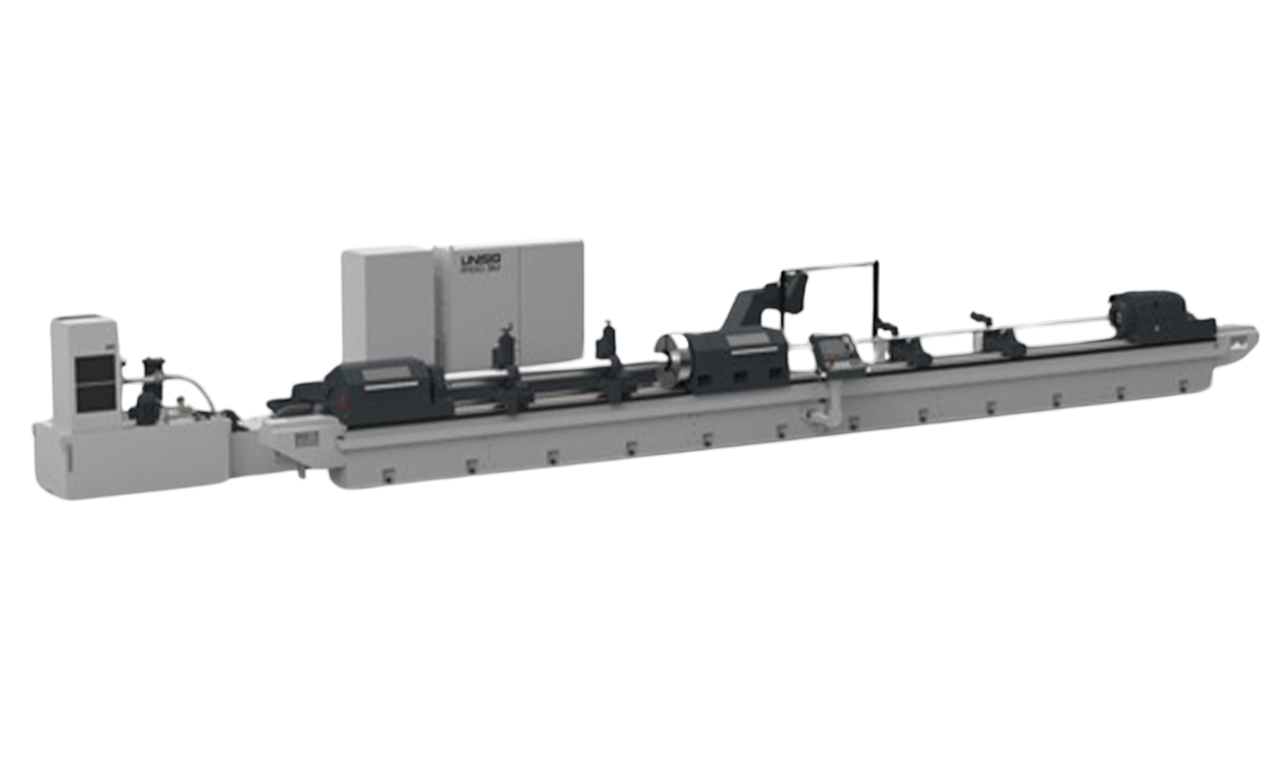

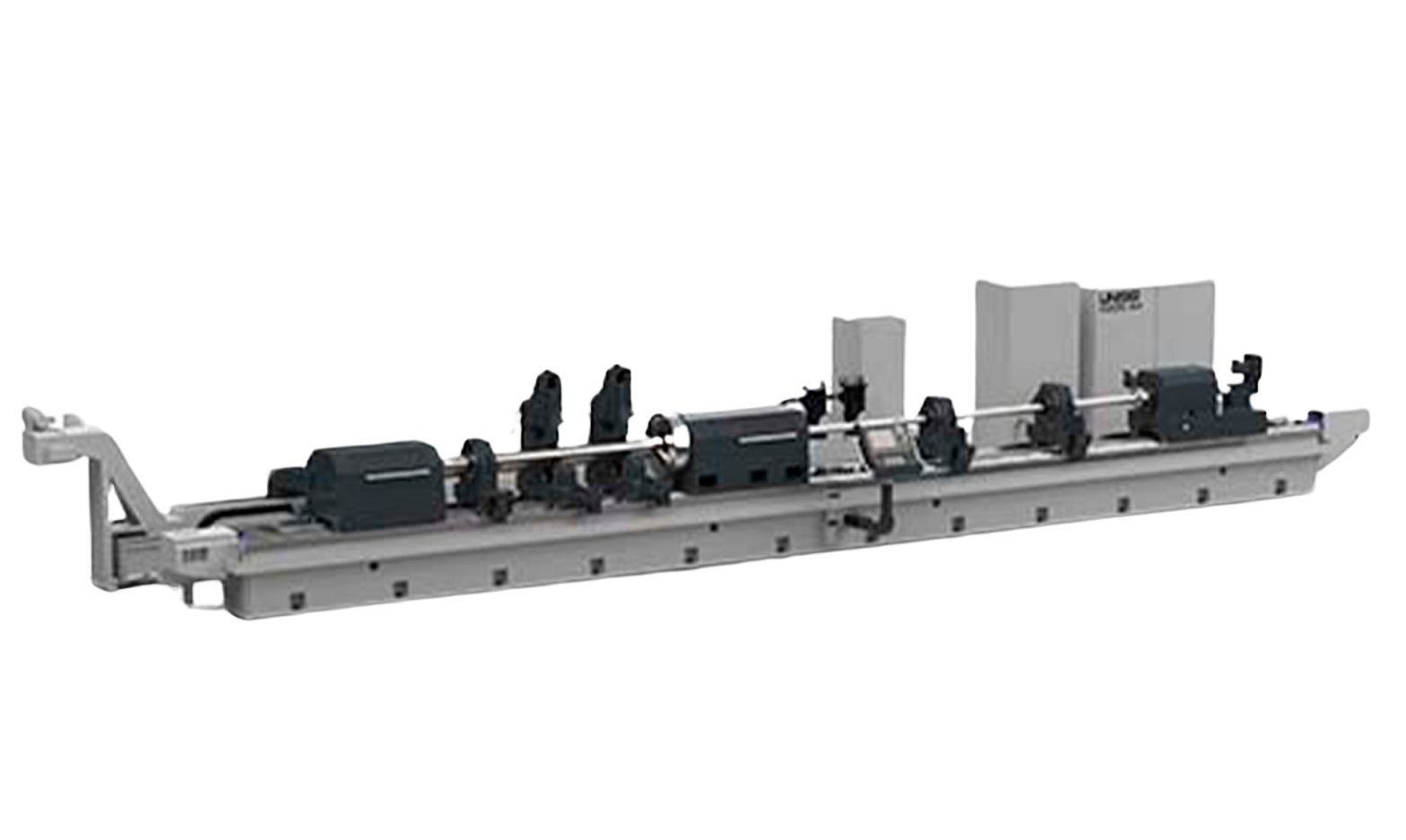

UNR12-2

Unisig

UNR12-2

Product description

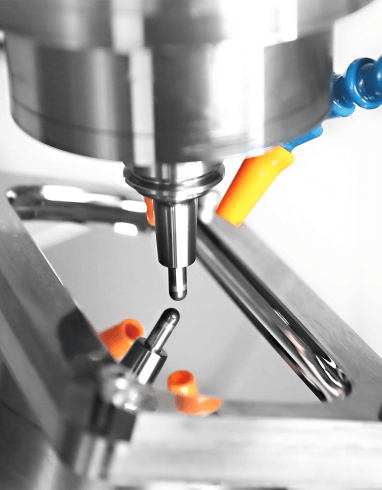

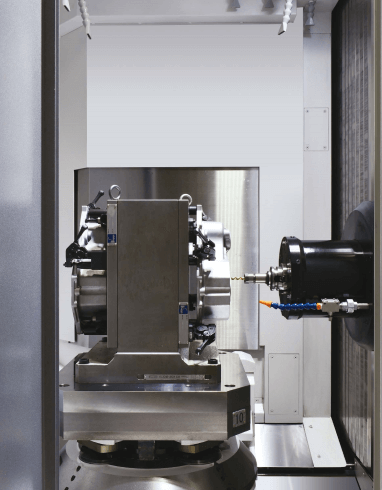

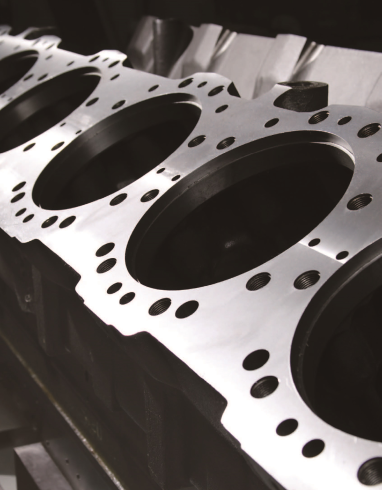

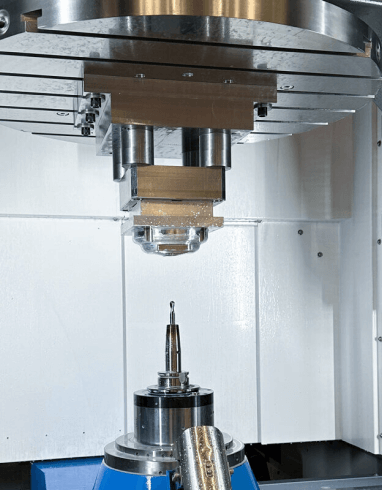

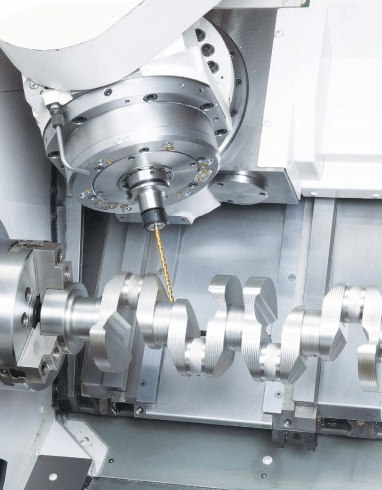

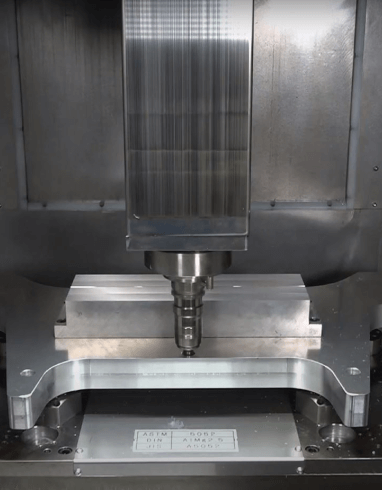

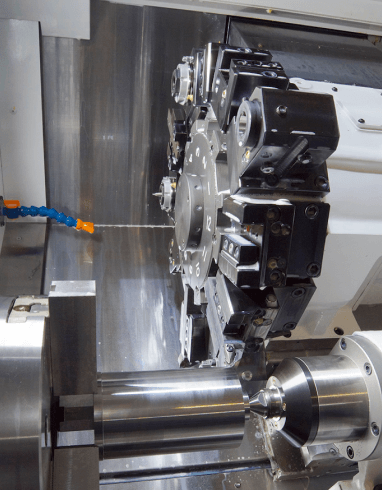

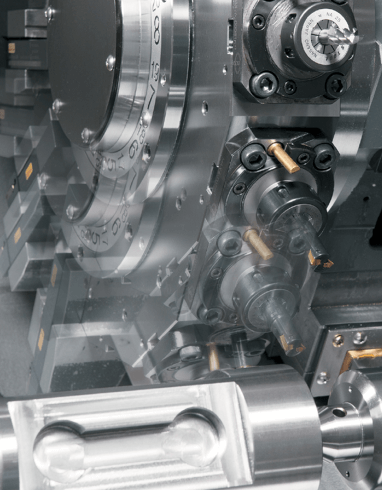

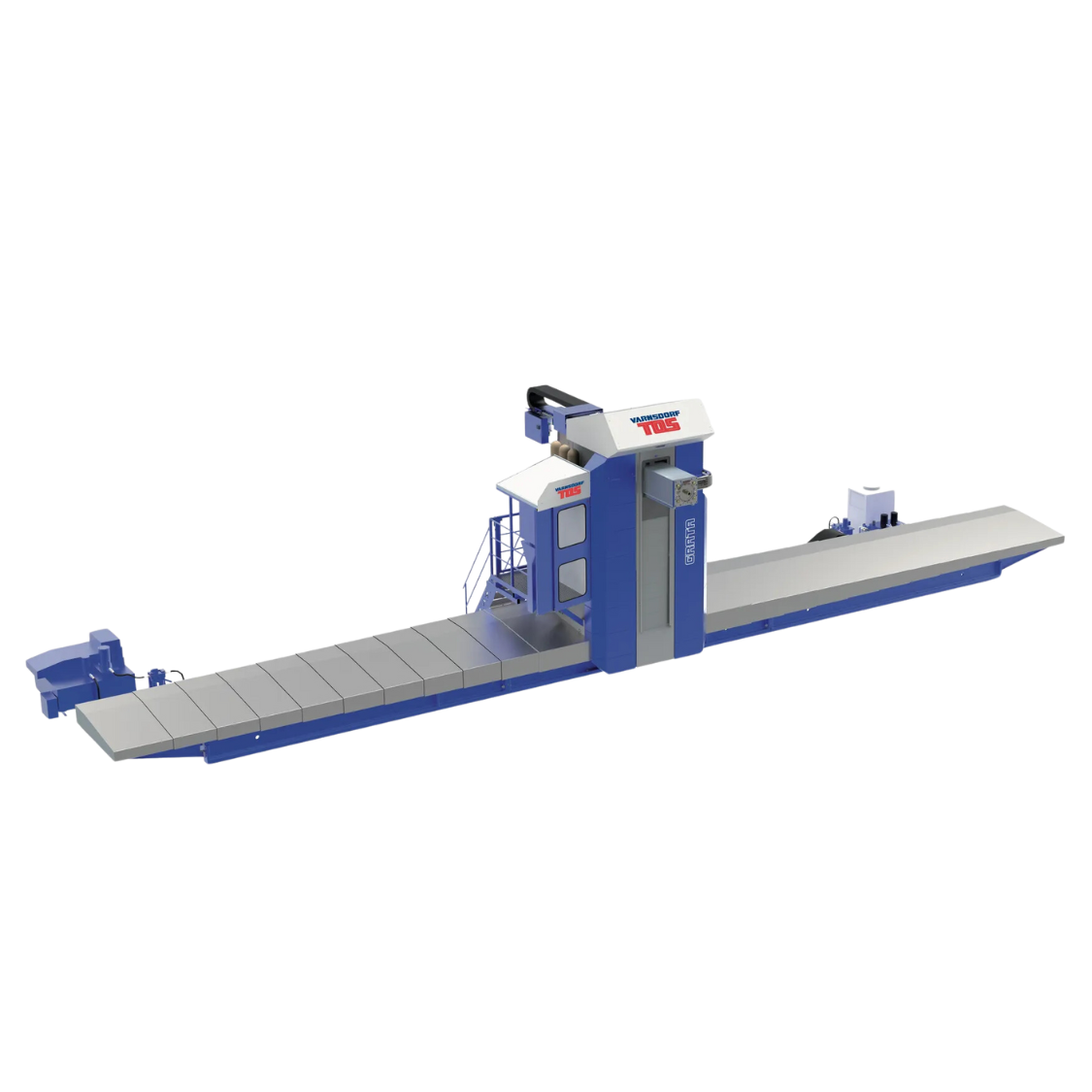

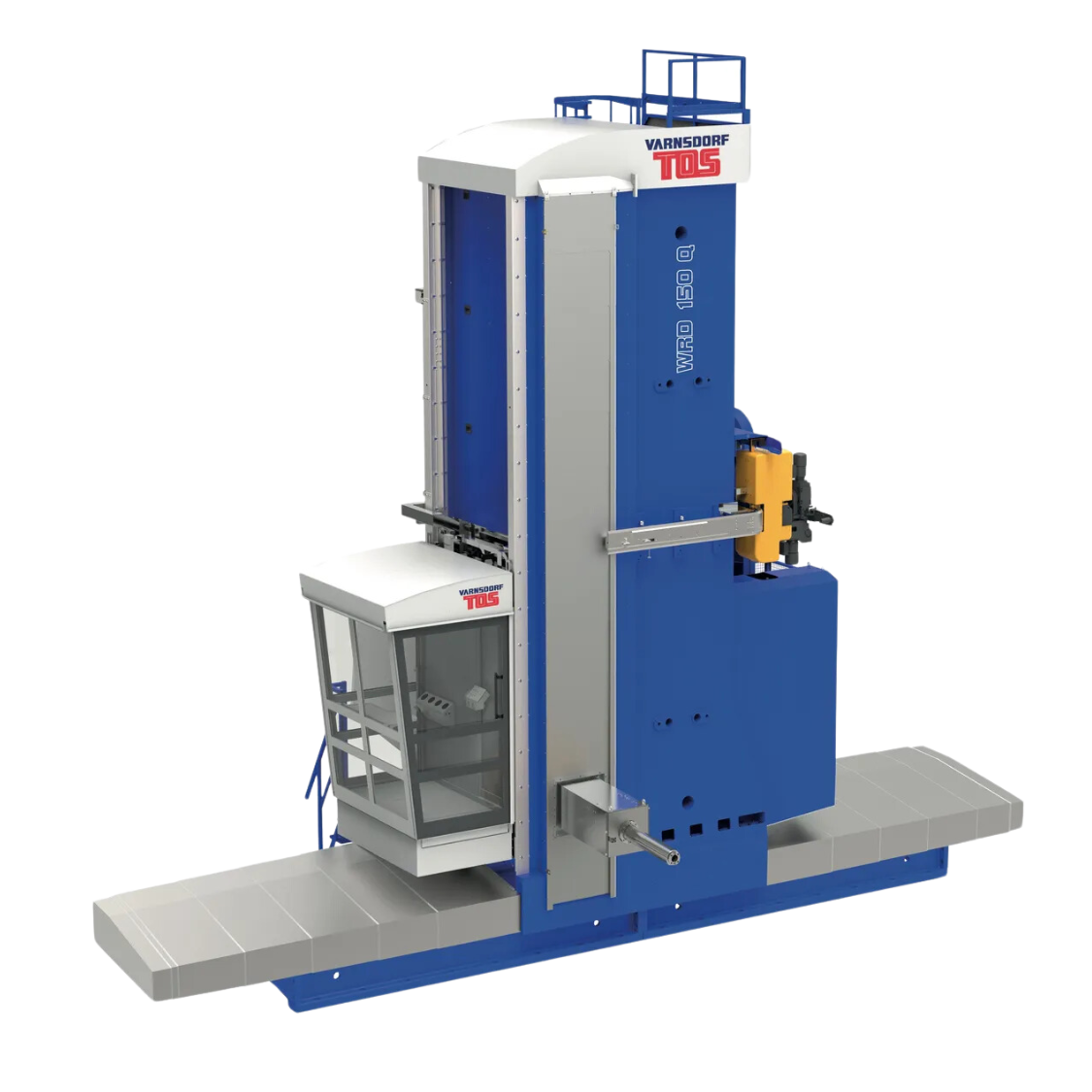

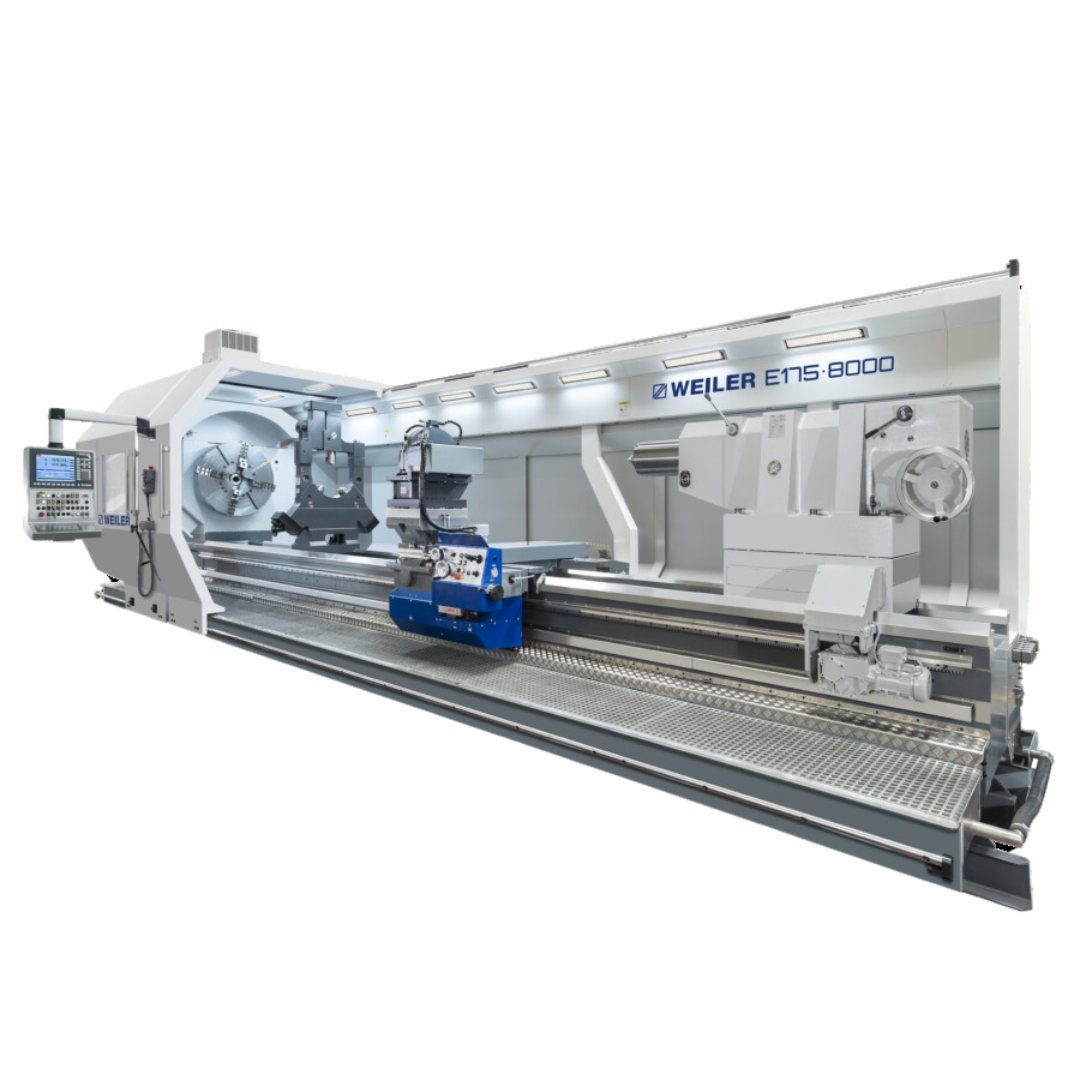

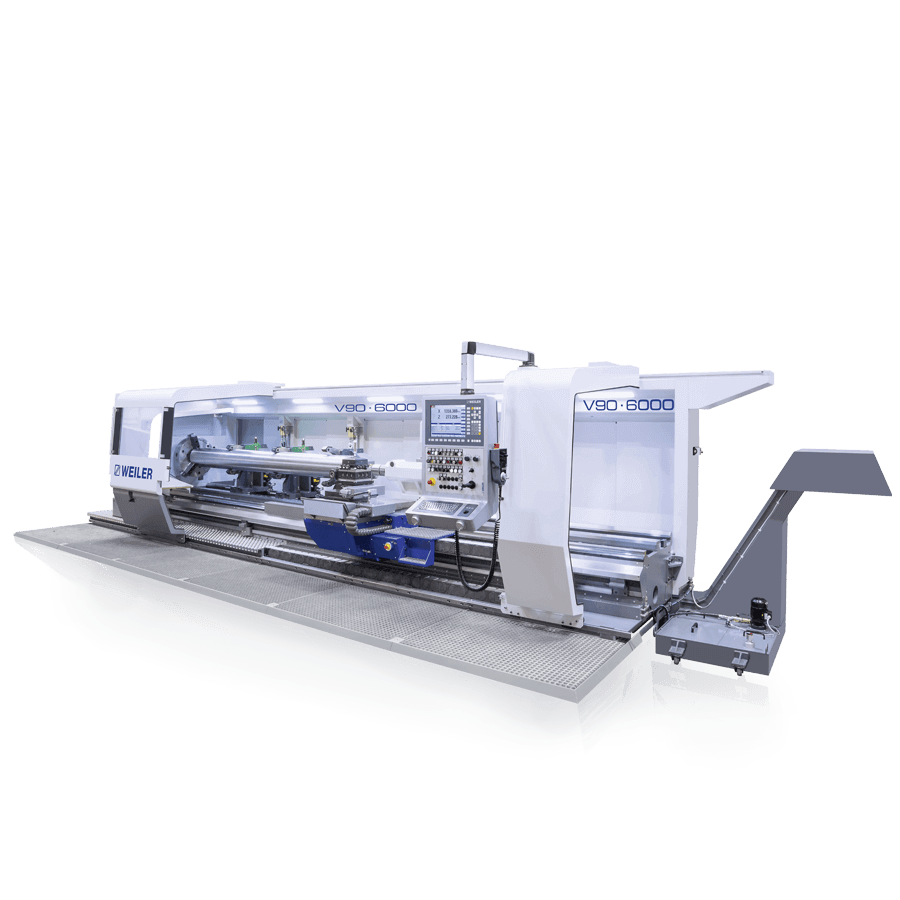

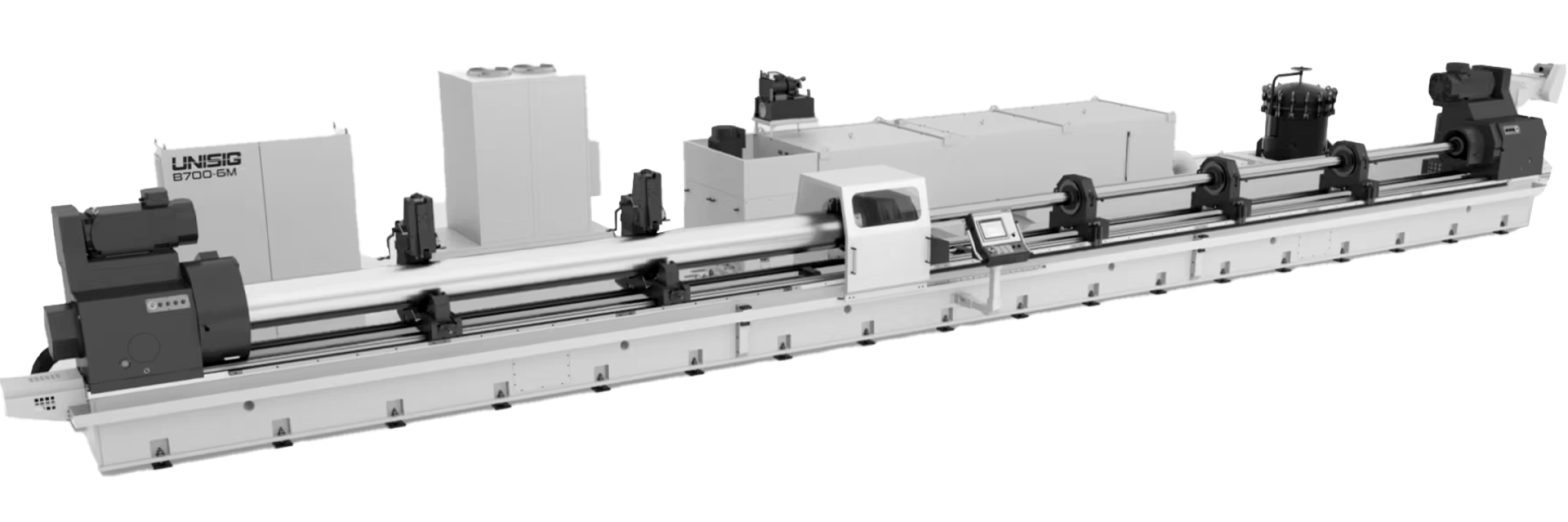

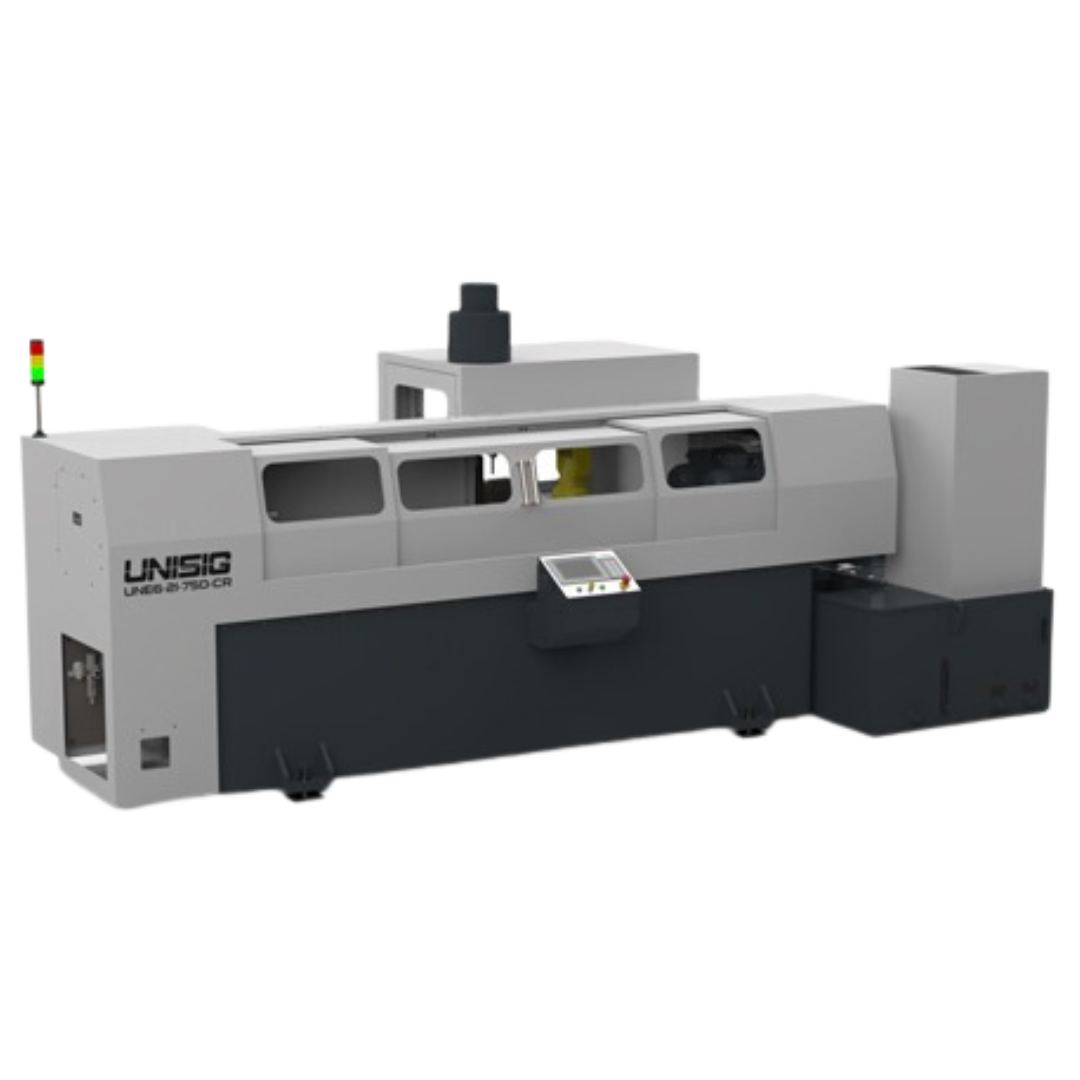

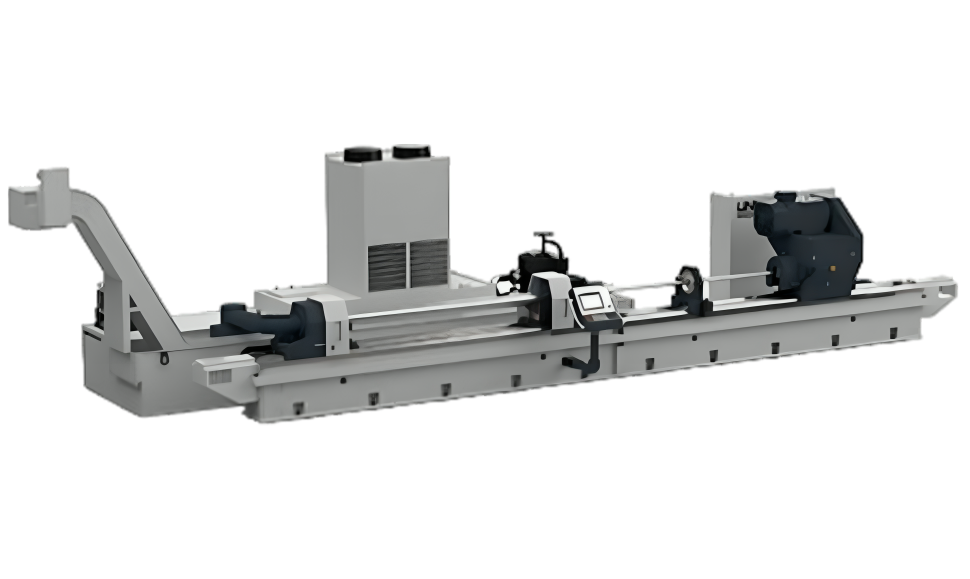

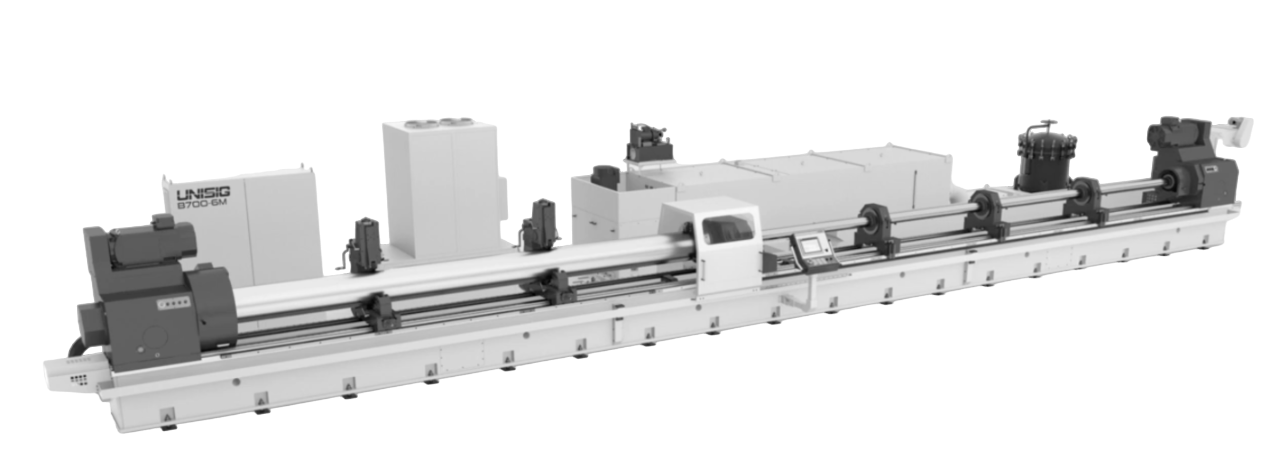

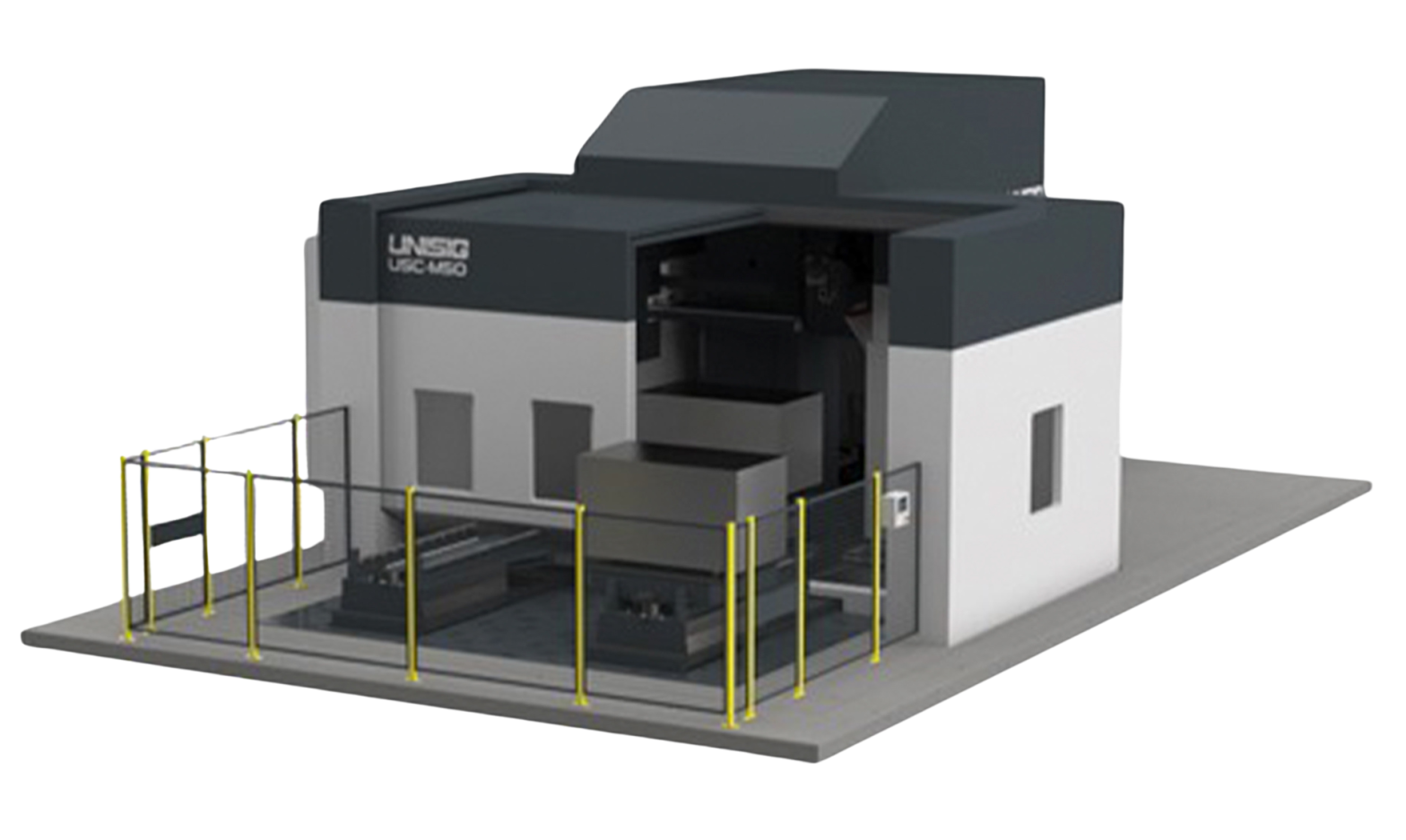

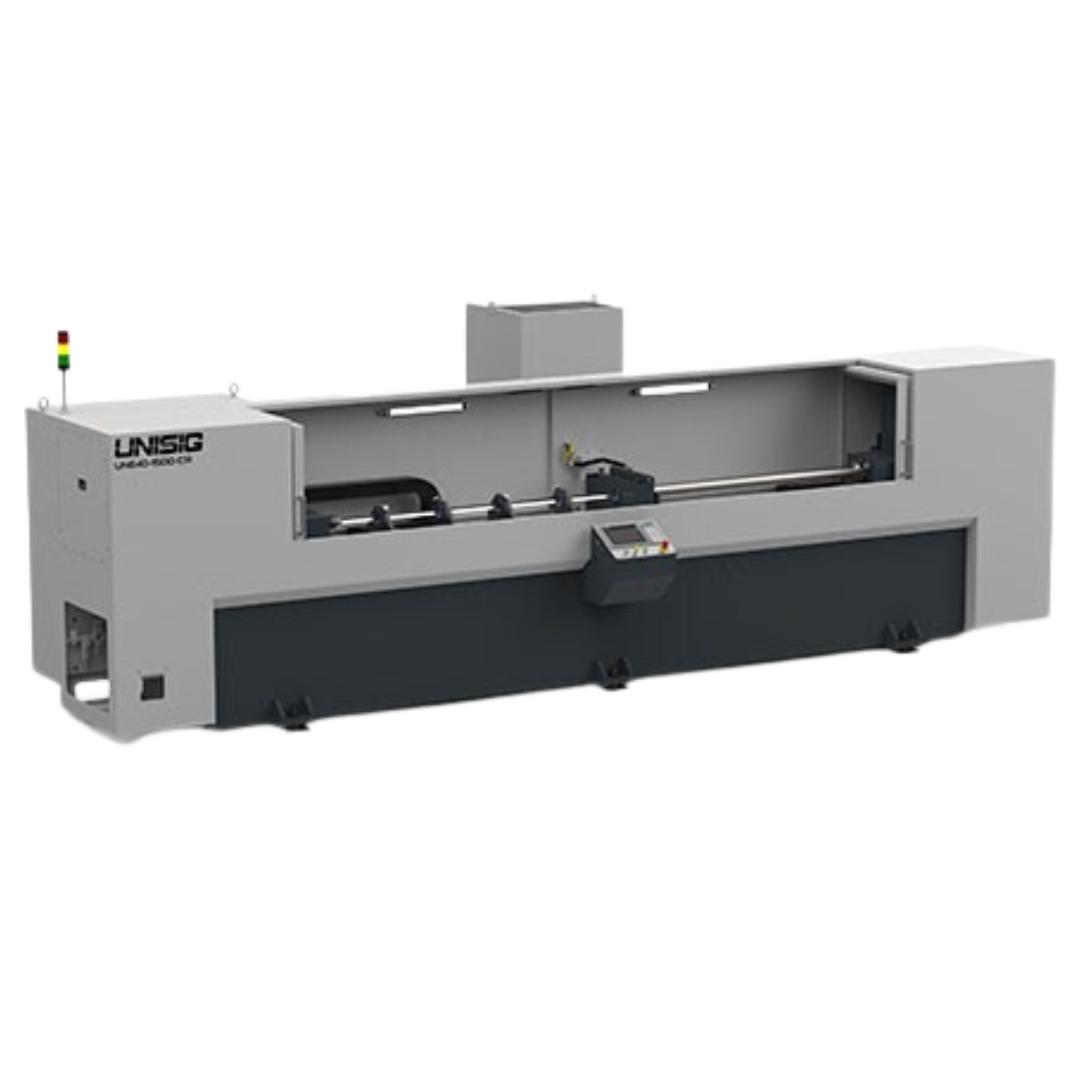

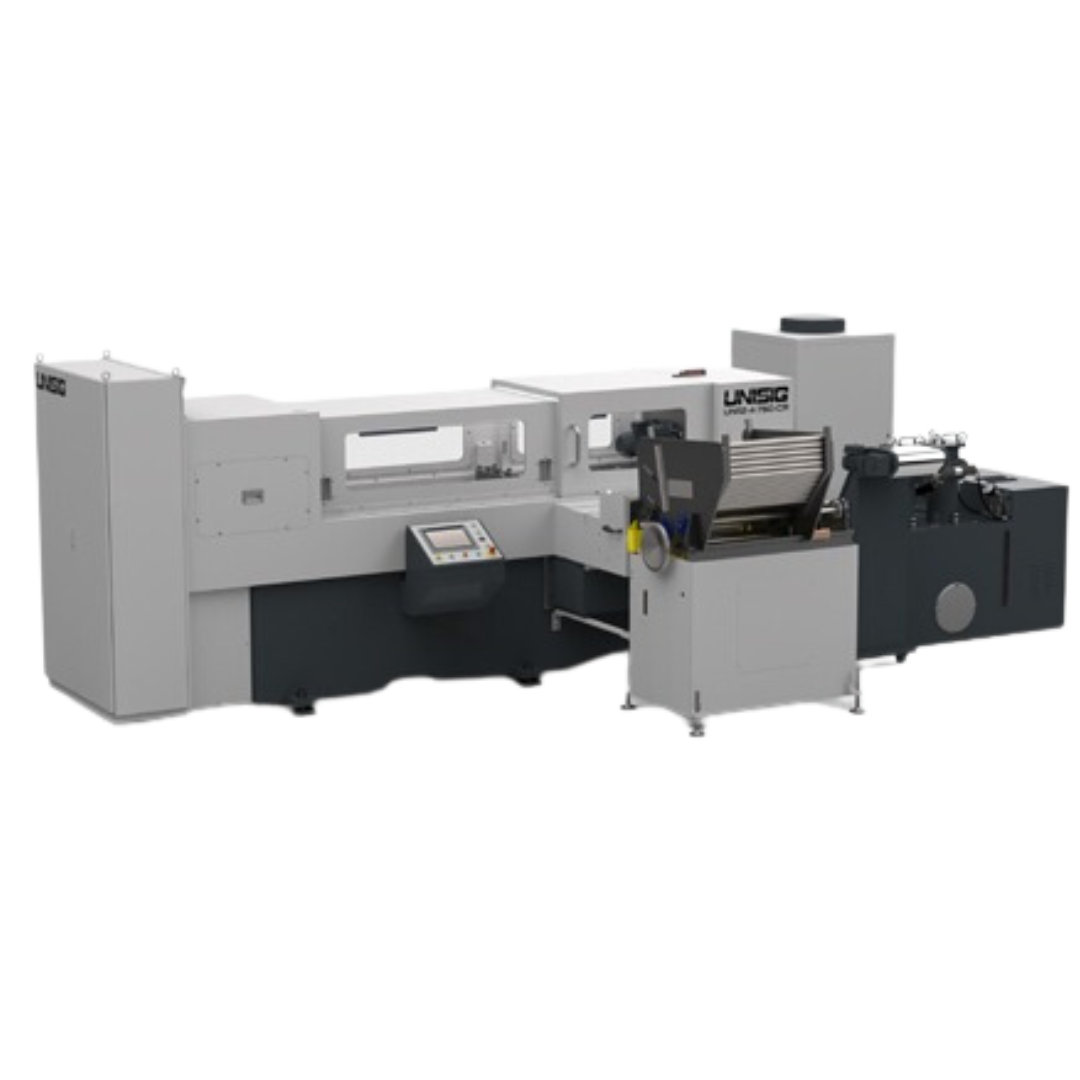

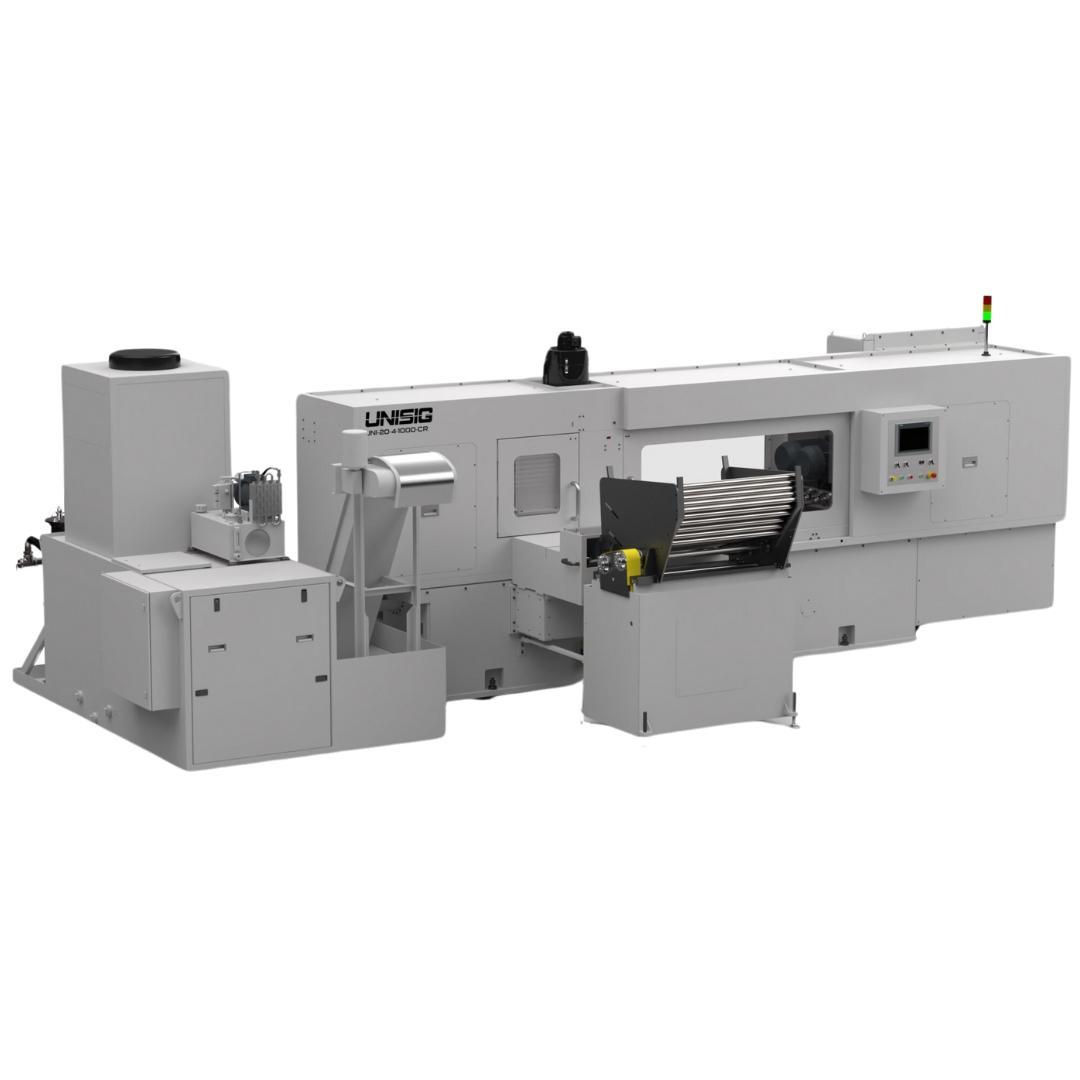

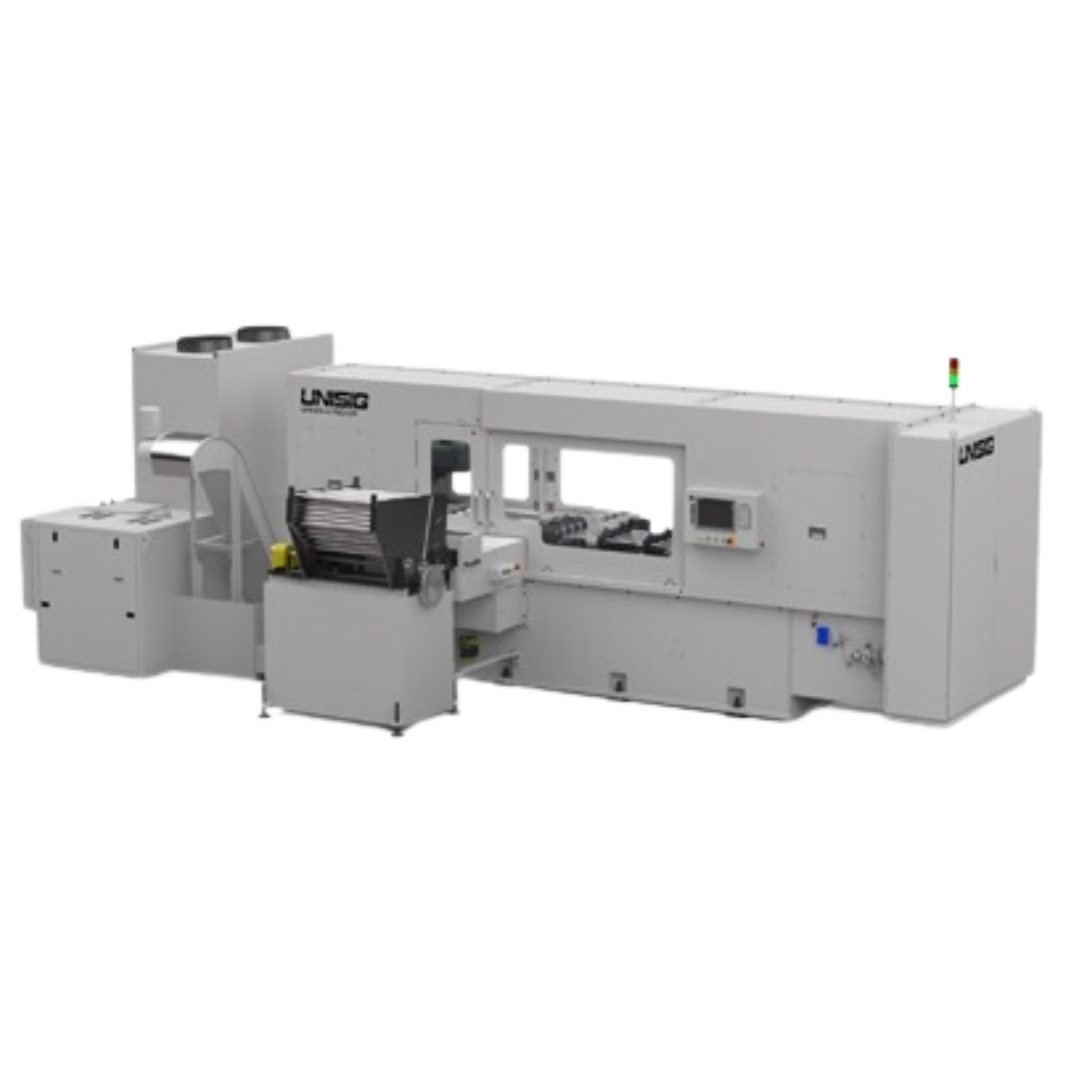

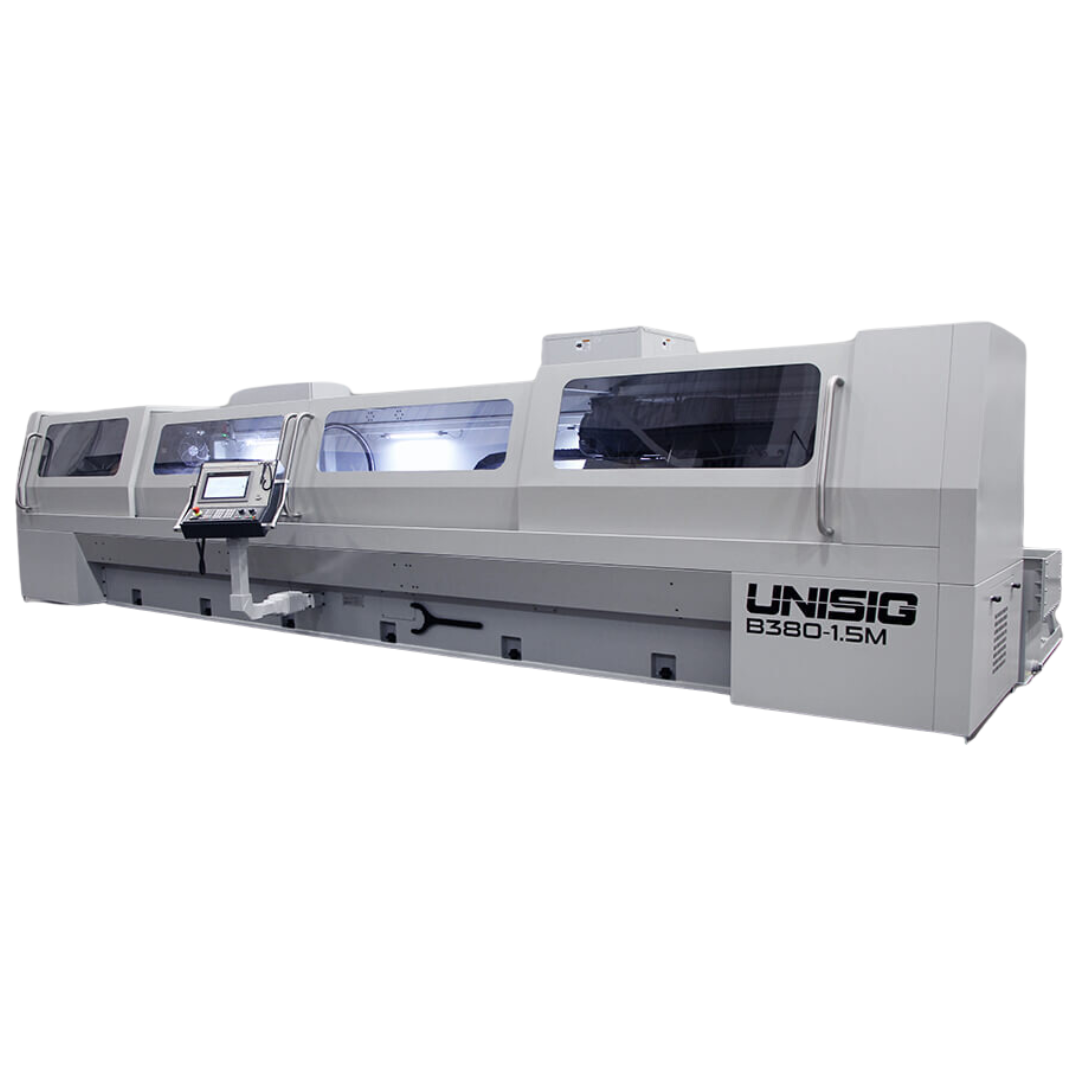

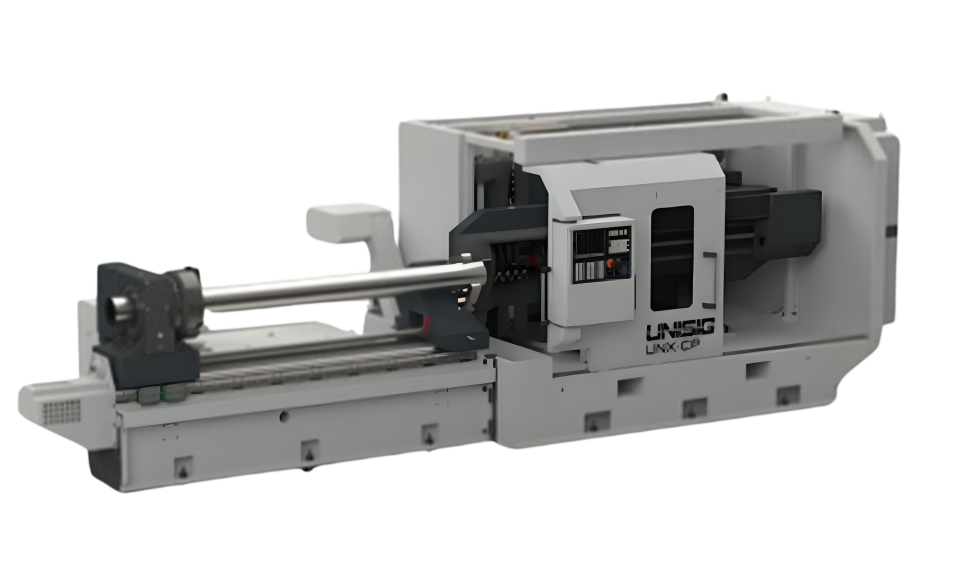

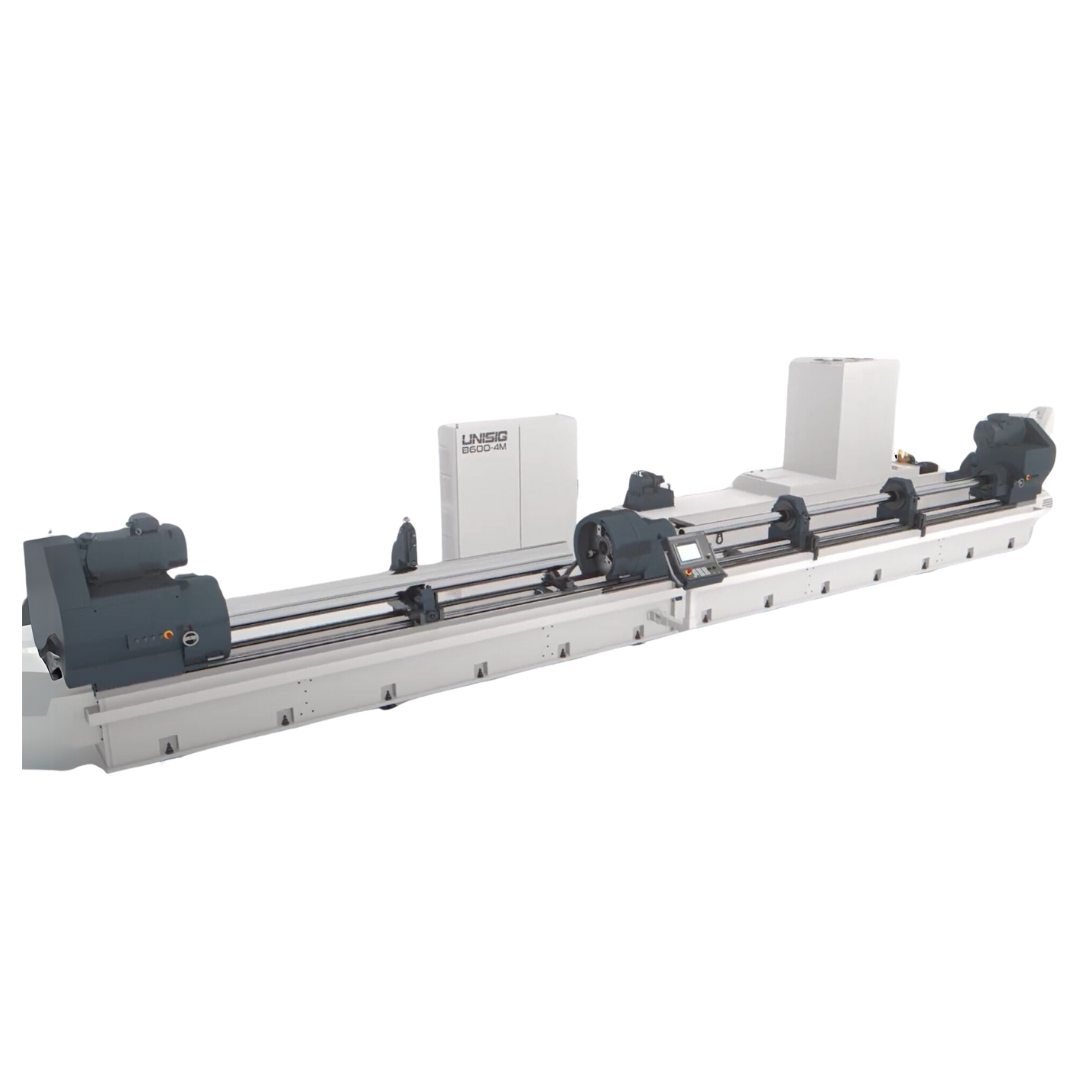

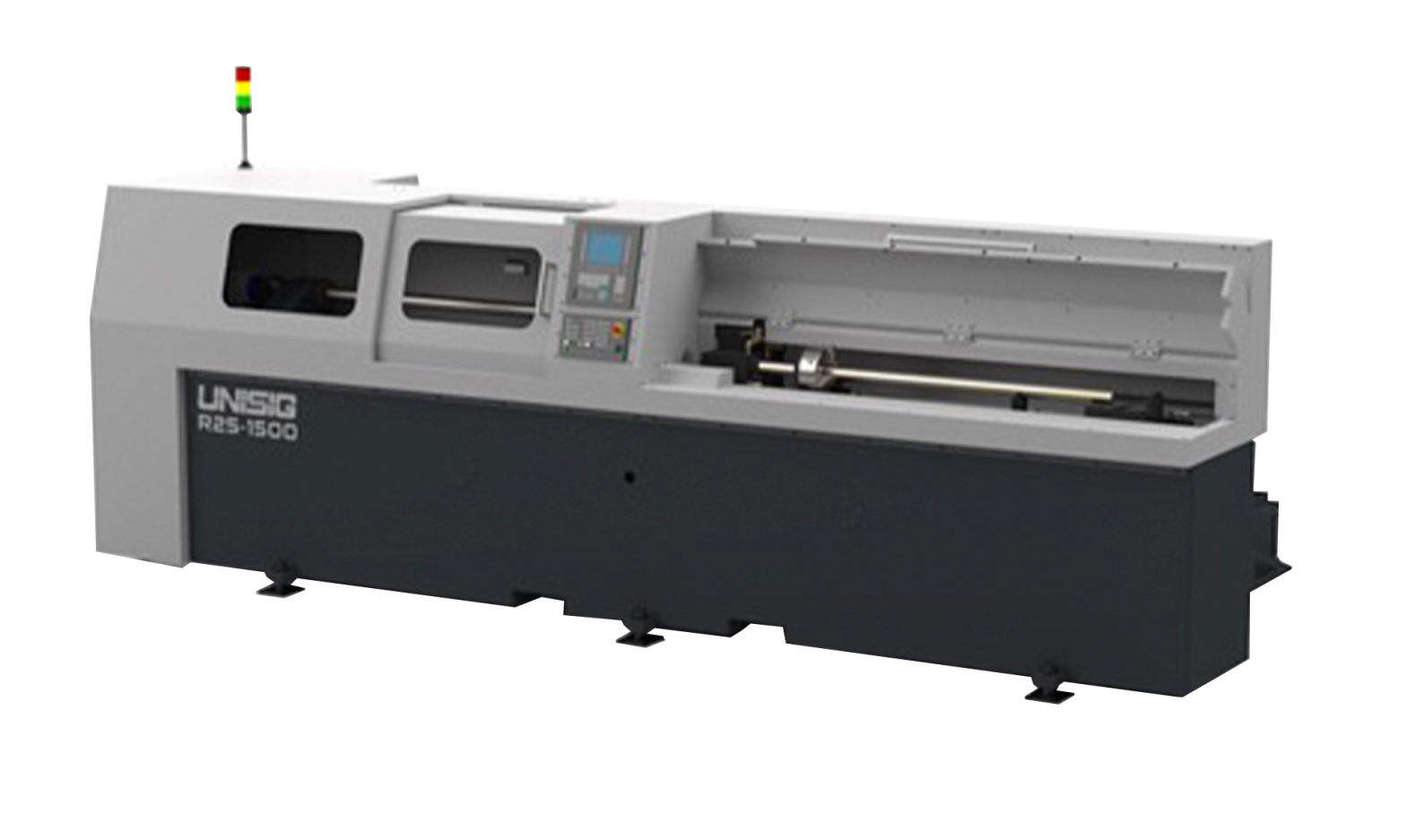

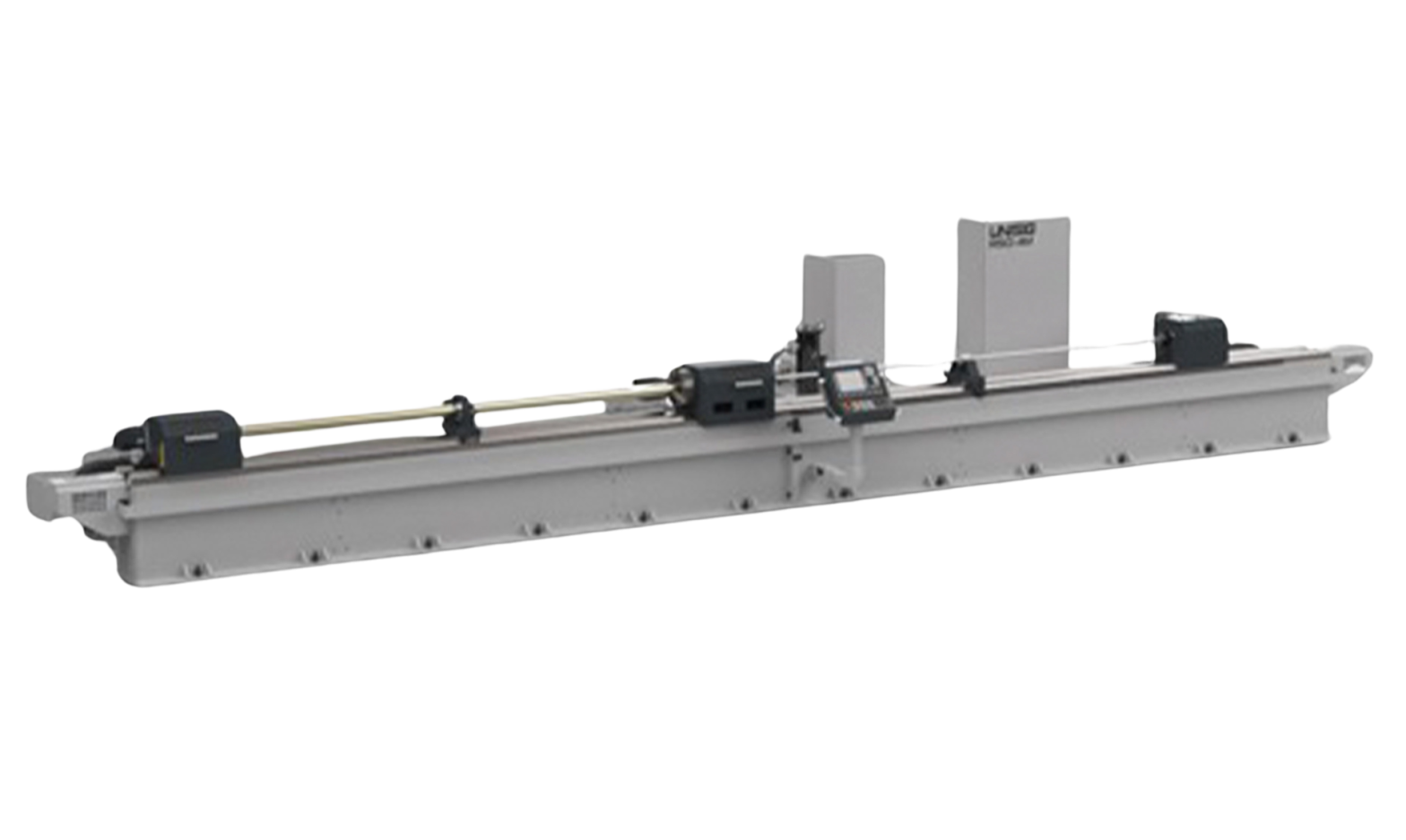

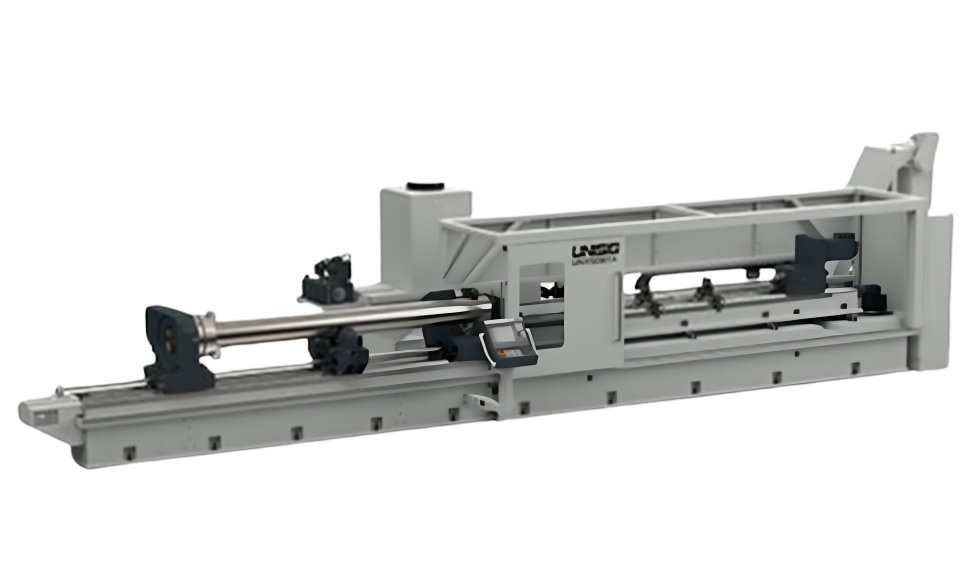

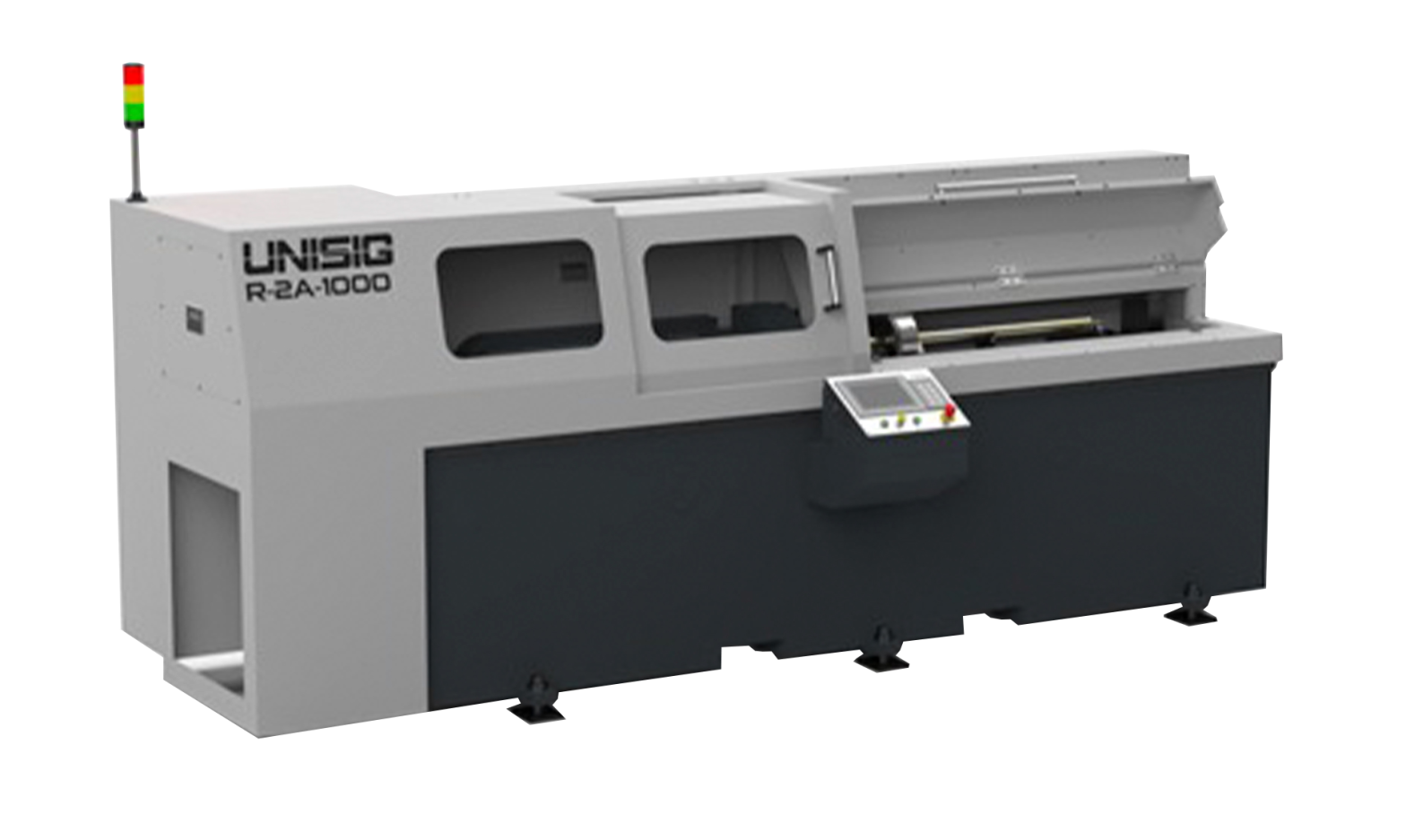

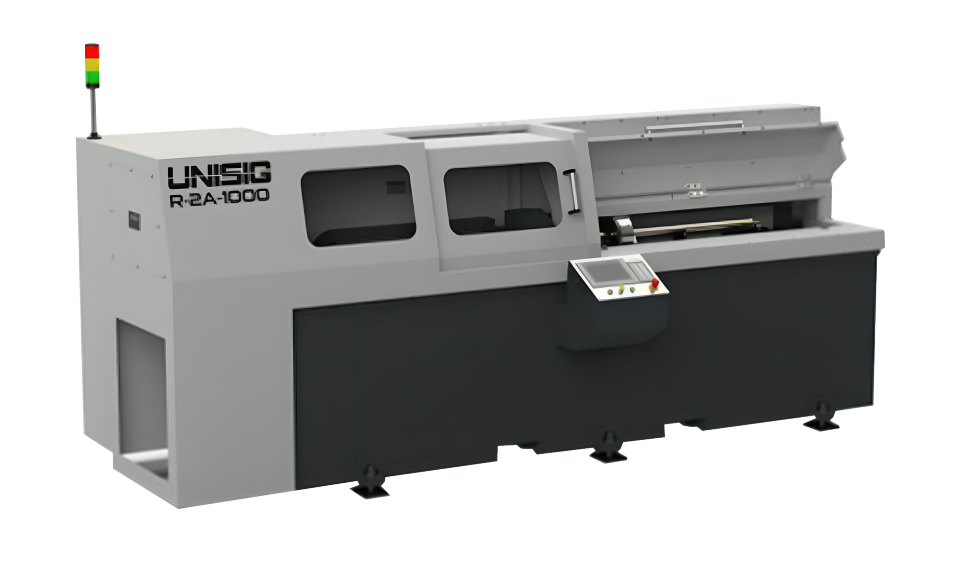

The reaming process is a vital step in barrel manufacturing. UNR reaming machines are built with intuitive controls, ergonomic operation, and improved accuracy in reaming. Machines can be configured for push- or pull-reaming operations, expanding manufacturing capabilities and allowing manufacturers to maximize tooling while pushing the limits of rifle barrels.

UNR reaming machines are capable of extremely high accuracy in roundness and diameter tolerances in any rifle gauge. Machines are available in one or two spindle options, and can be configured with combination gundrill-reaming capabilities to meet production requirements for industry-leading barrel manufacturers.

Industries

Aerospace

Automotive

Medical

Others

Product Highlights

Product Highlights

Number of Spindles

2

Hole Diameter Min (in) Hole Diameter Min (mm)

0.061.4

Drill Diameter Max (in) Drill Diameter Max (mm)

0.512

Hole Diameter Max (in) Hole Diameter Max (mm)

0.7519

Hole Depth Max (in) Hole Depth Max (mm)

59.061500

Workpiece dimensions (in) Workpiece dimensions (mm)

30, 40, 60750, 1000, 1500

Workpiece weight max (kg)

12

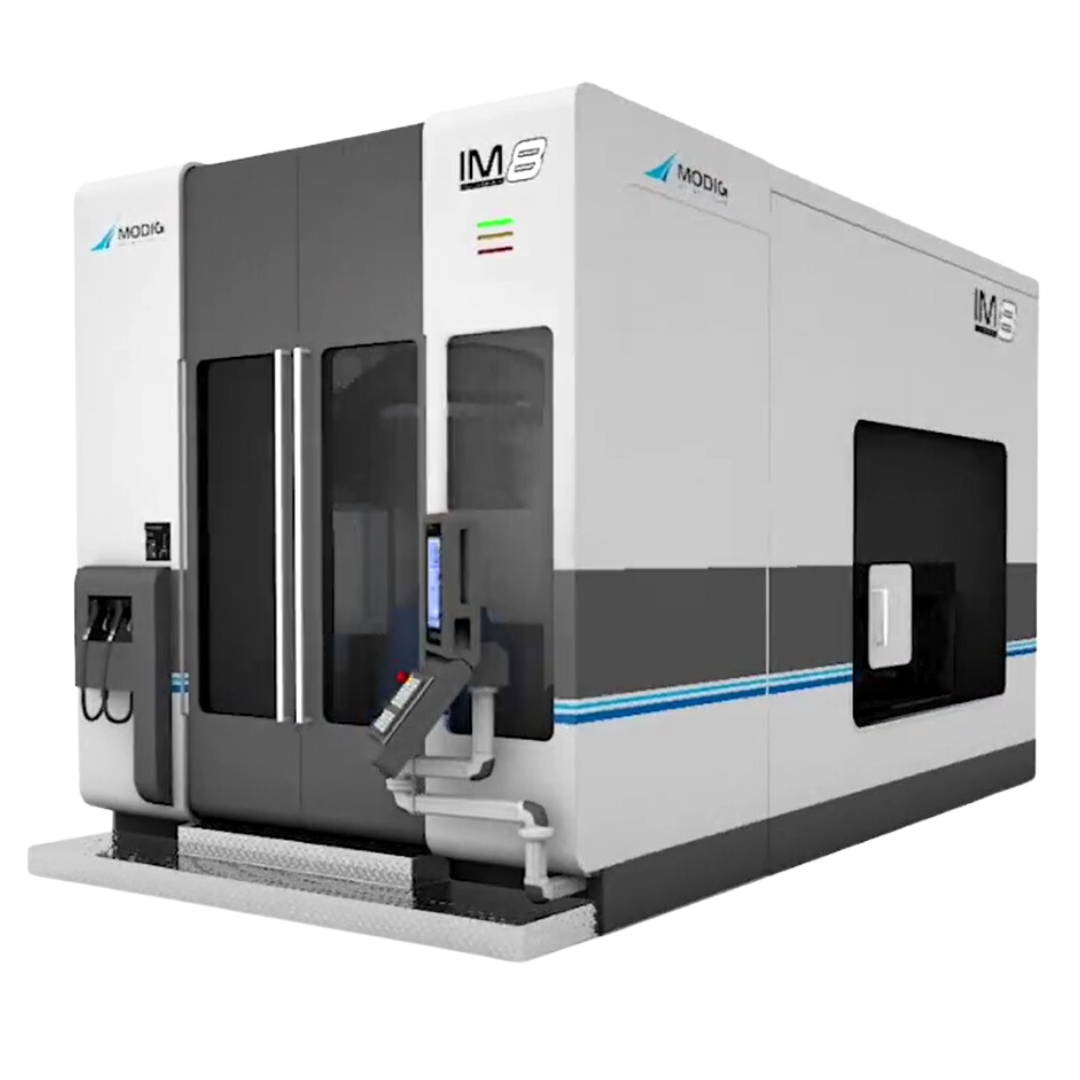

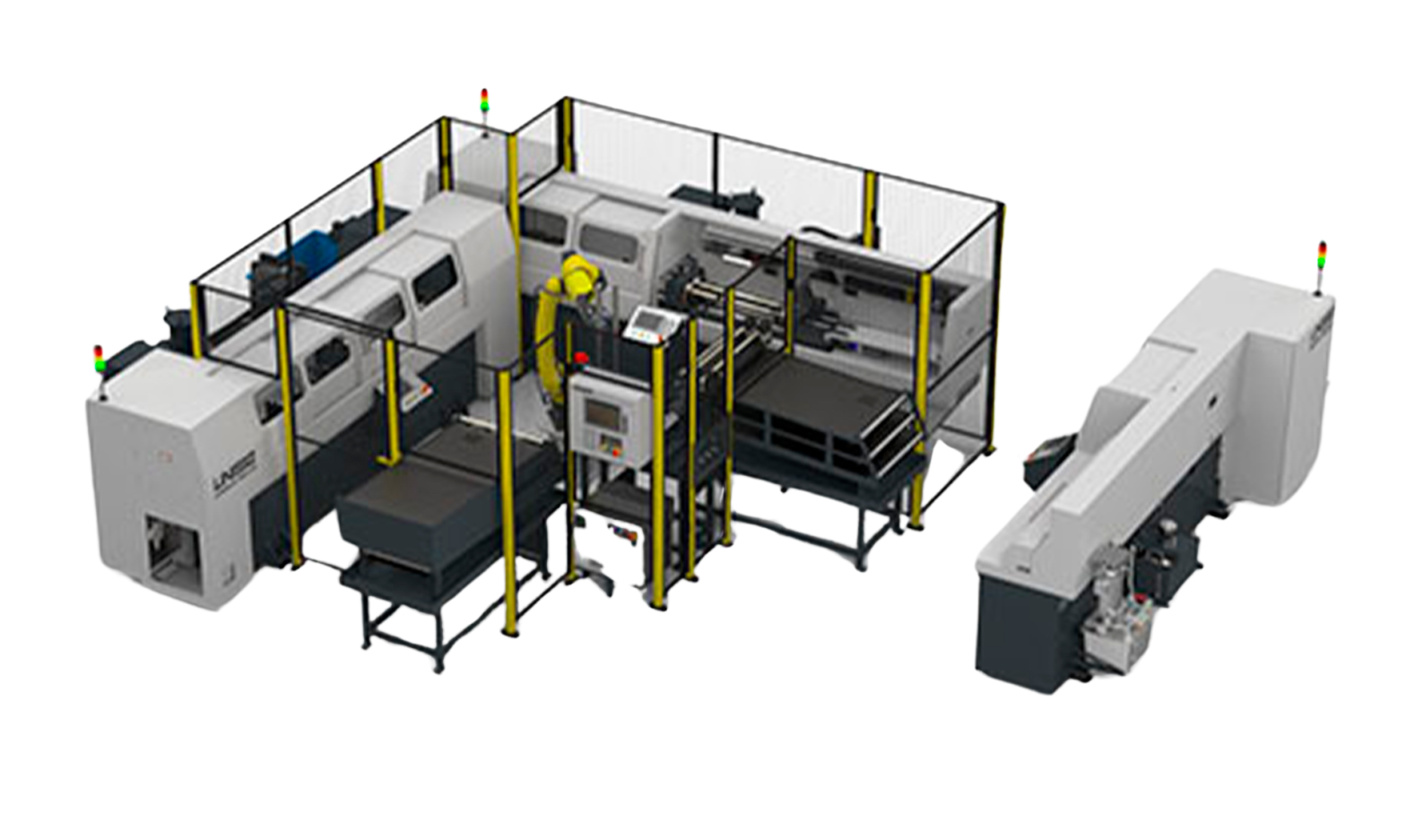

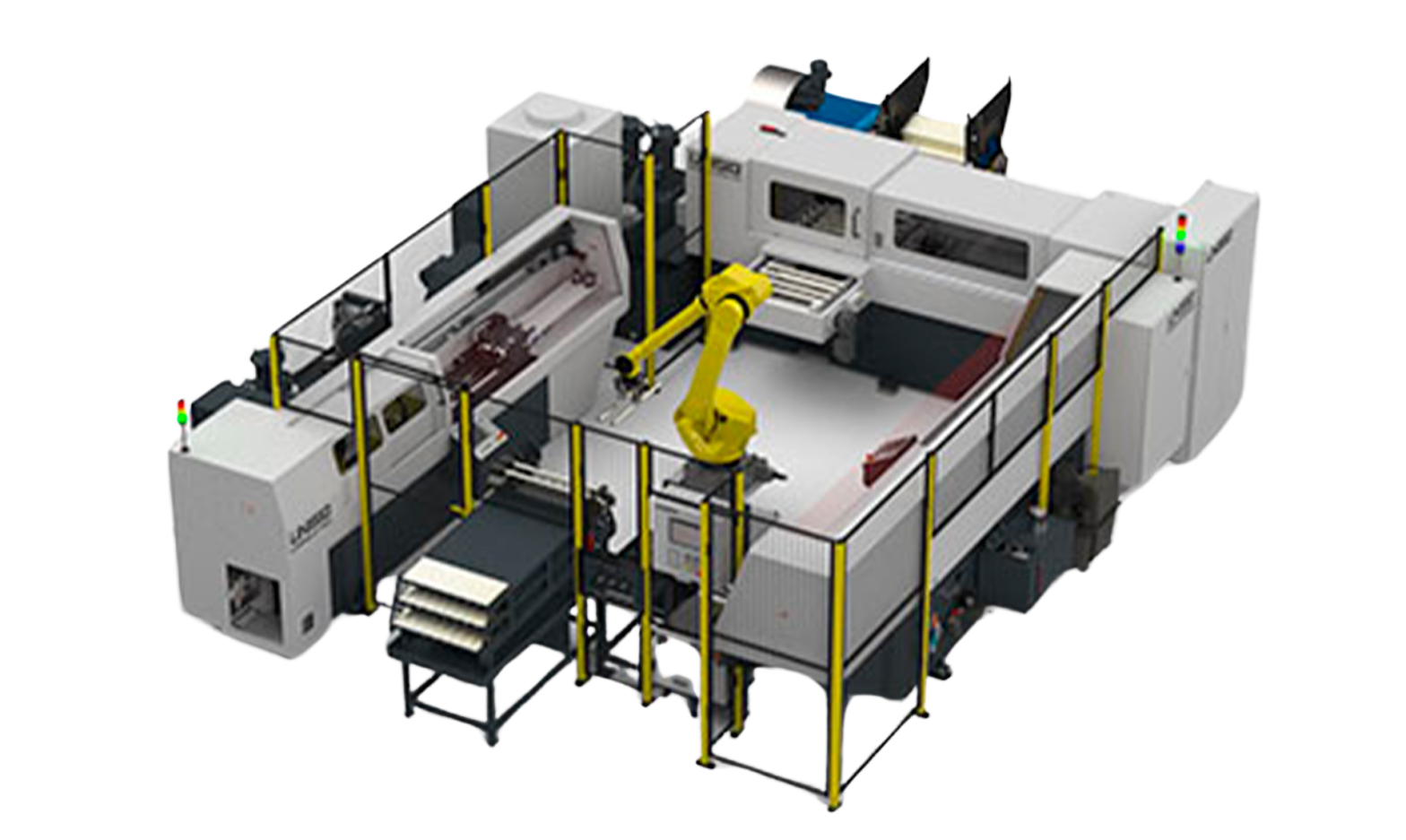

Recommended solutions to improve your processes

Equip and maximize the productivity of your CNC machines with comprehensive solutions.

Accessories and peripherals

Mist collector

Cooling system

Coolant filtration and magnetic separator equipment

Learn more about PERIFERIQ

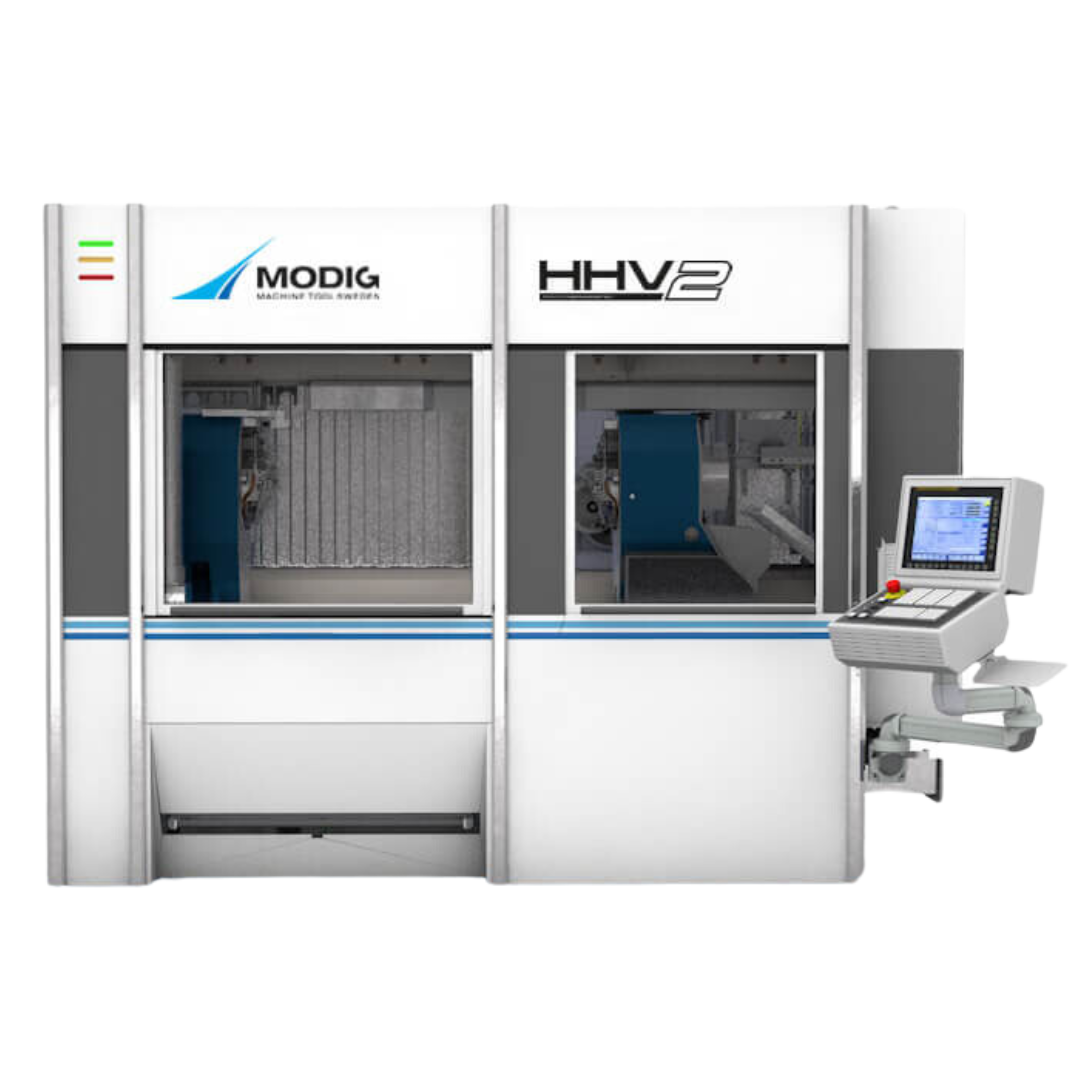

Creation and development of industrial automation customized to meet your needs.

Automatic doors

Automated loading and unloading system

Safety and cleaning systems

Interfaces to external clamping systems

Learn more about OTOMATIQA