Unisig

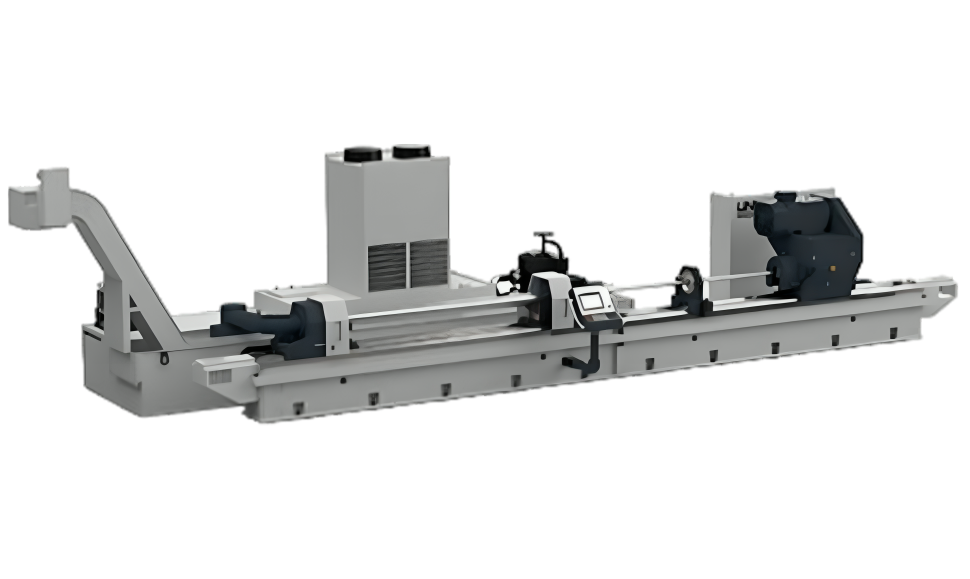

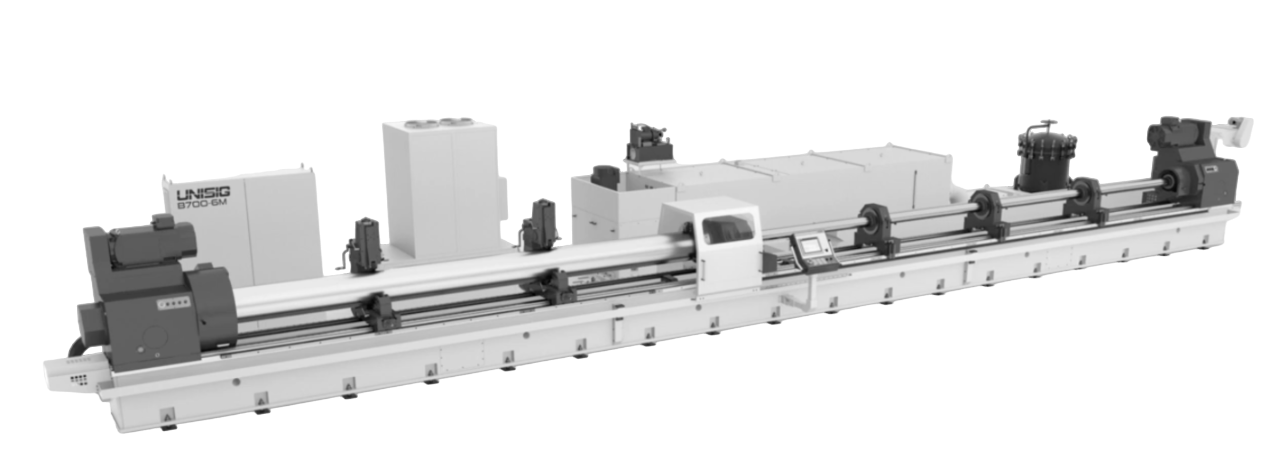

S500

Unisig

S500

Product description

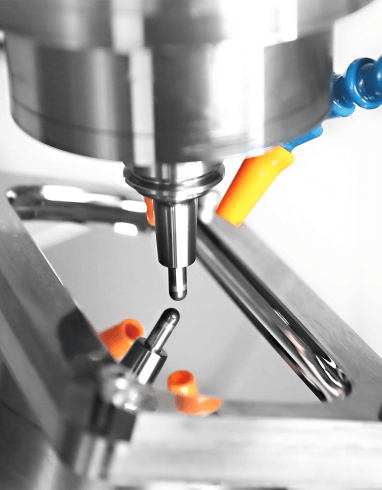

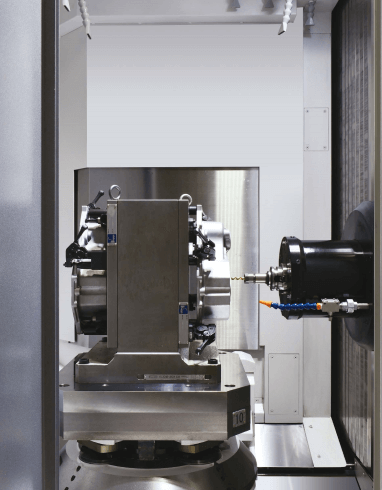

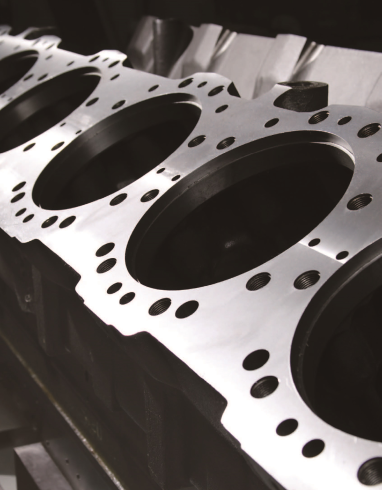

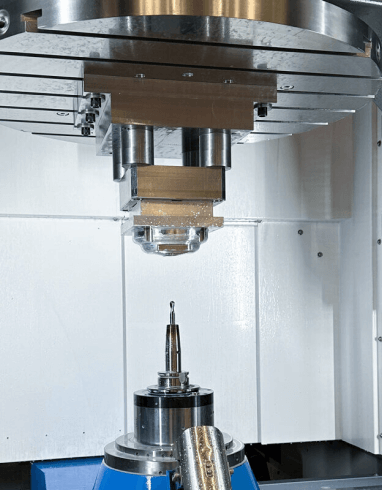

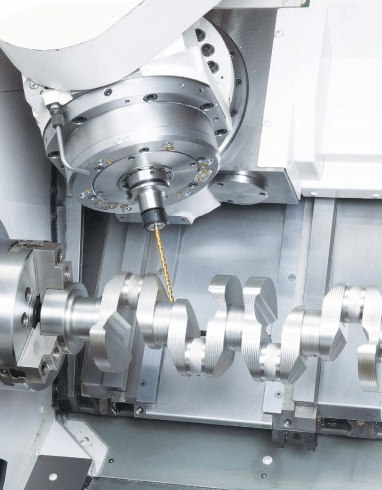

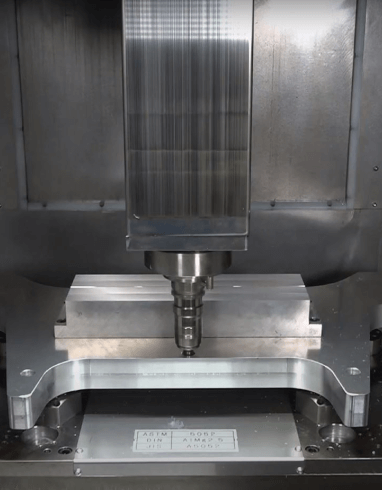

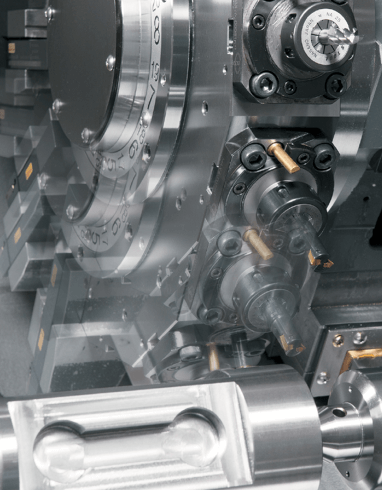

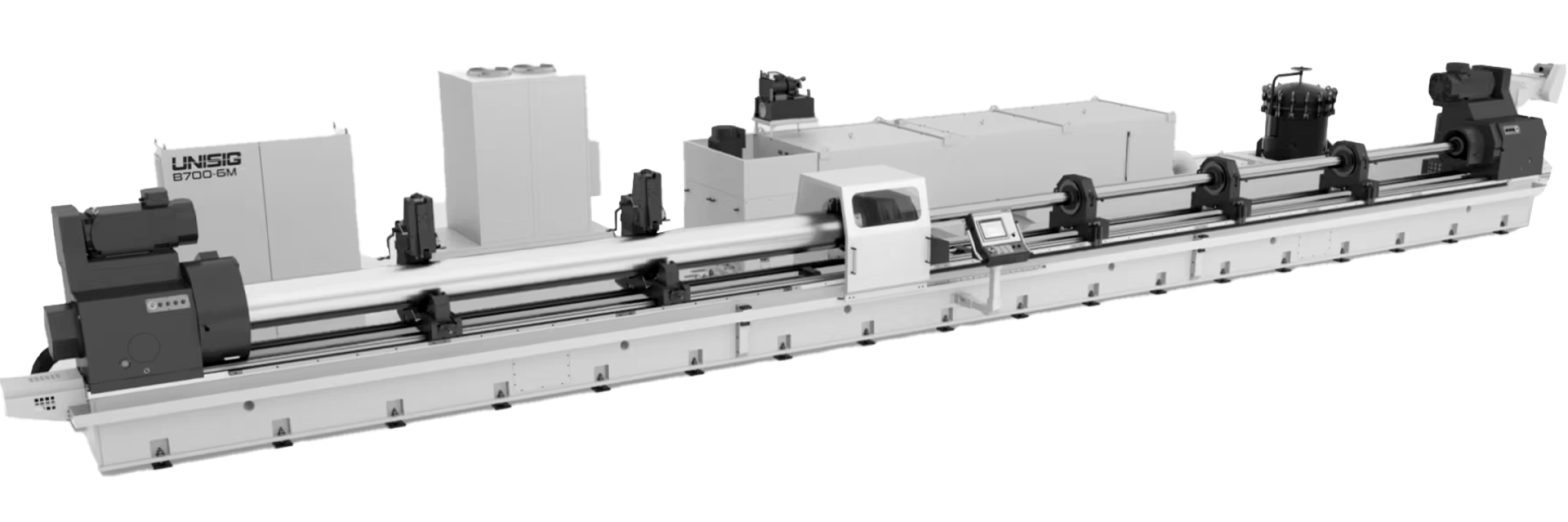

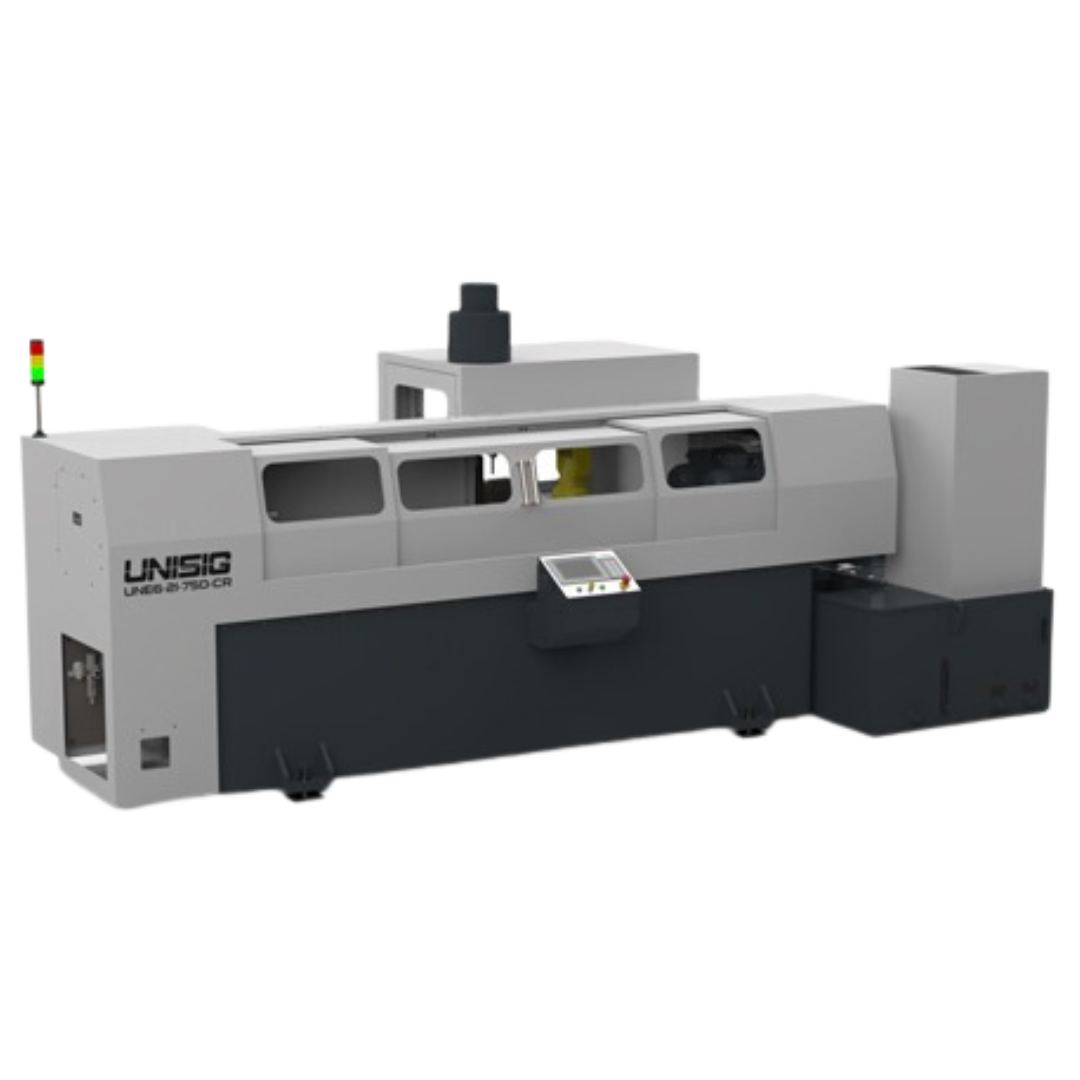

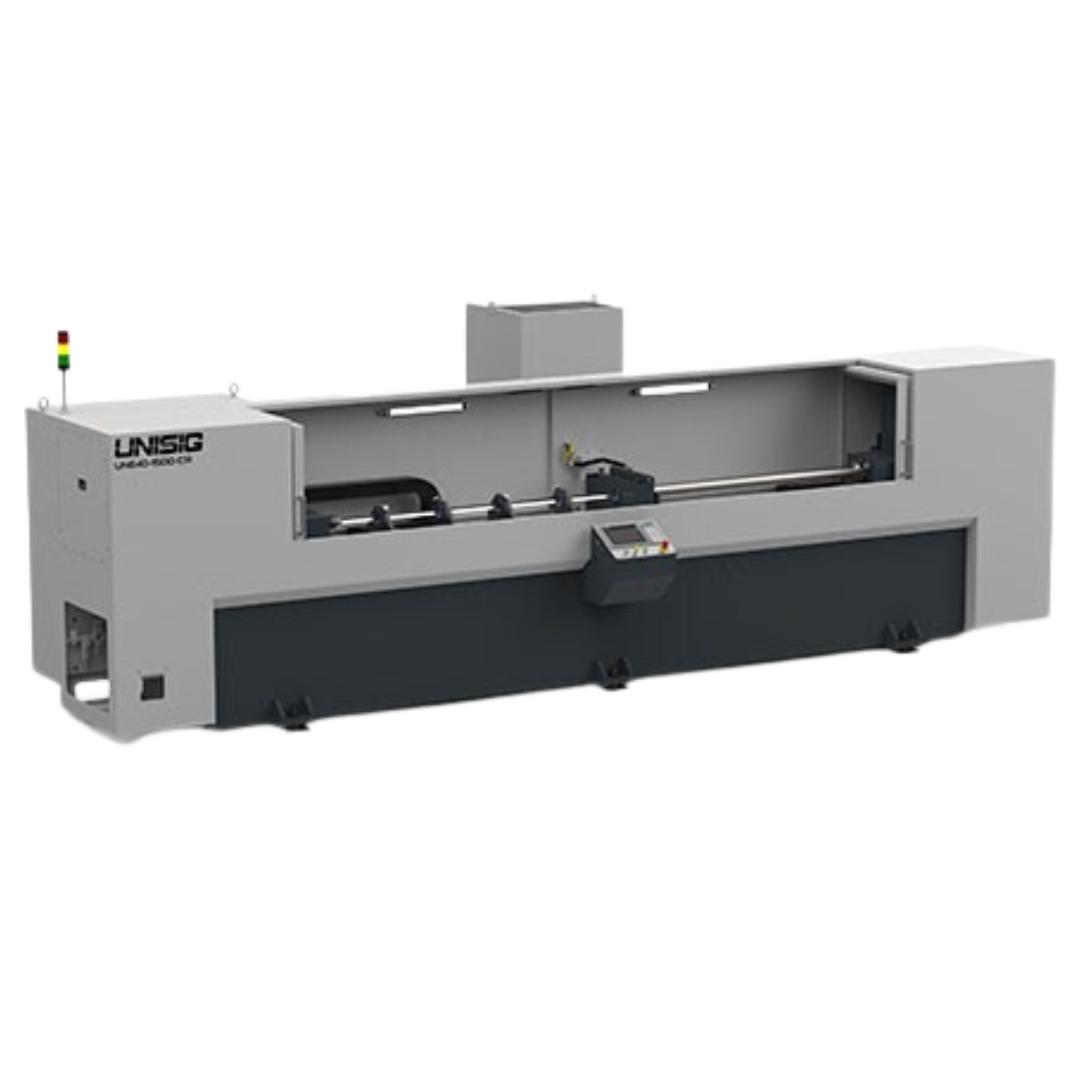

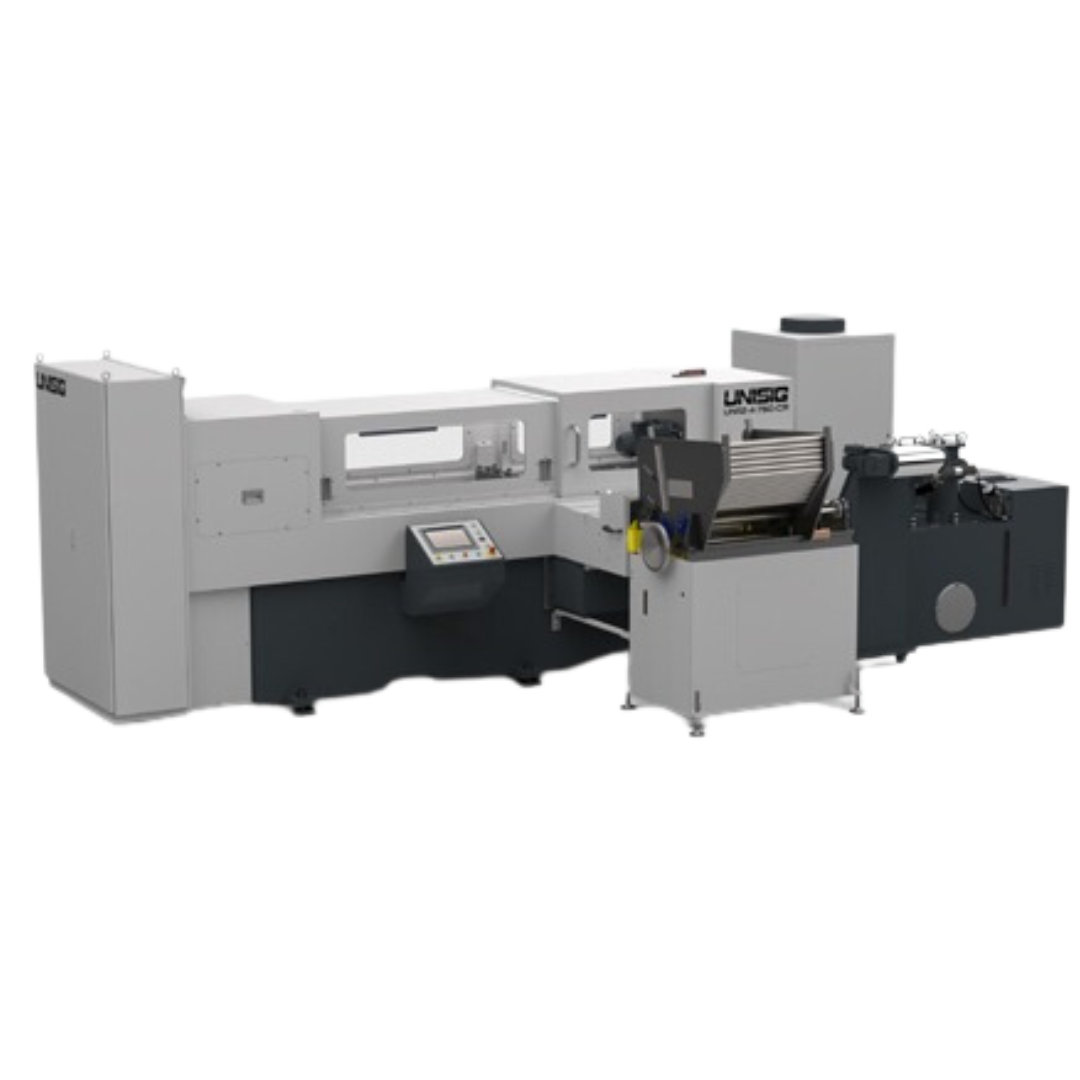

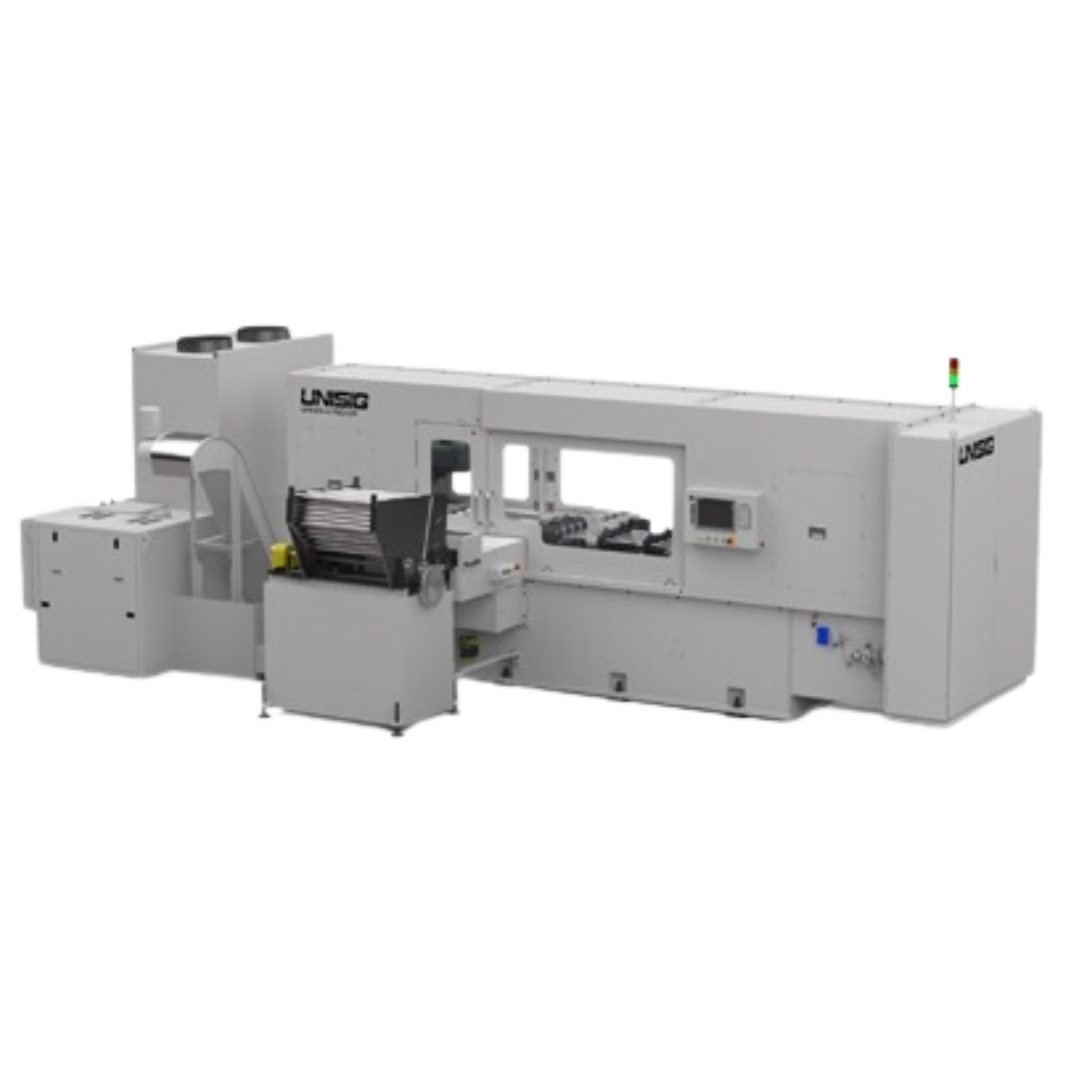

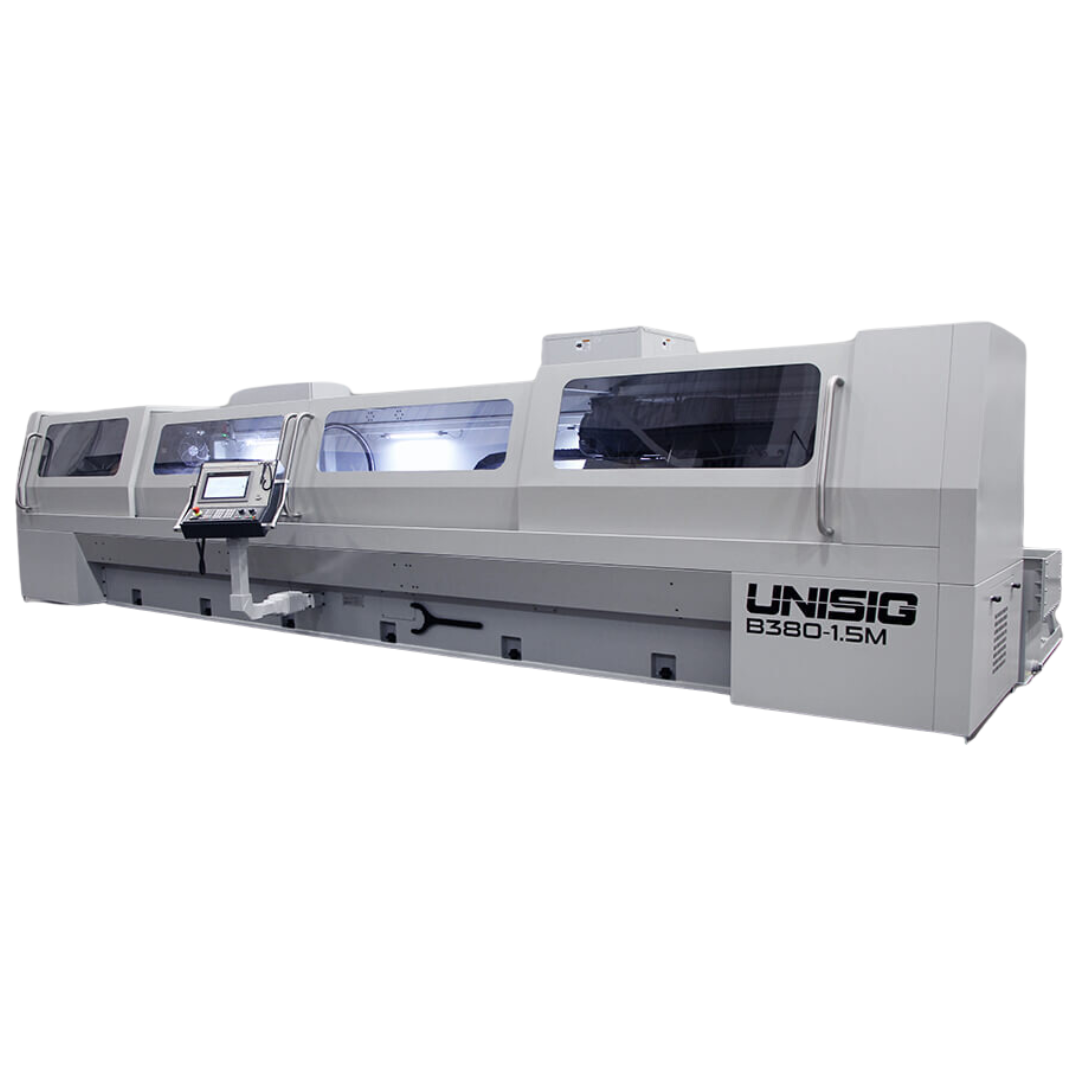

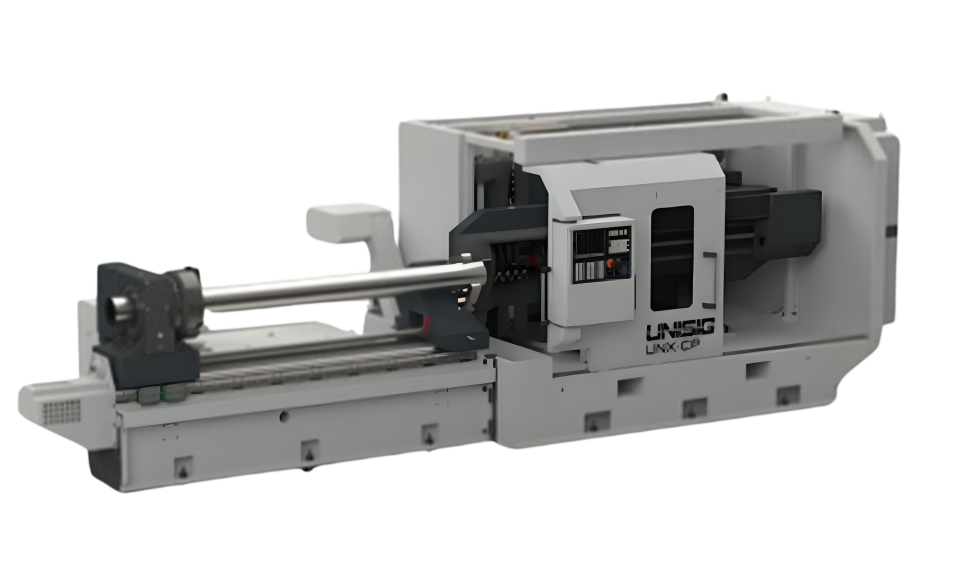

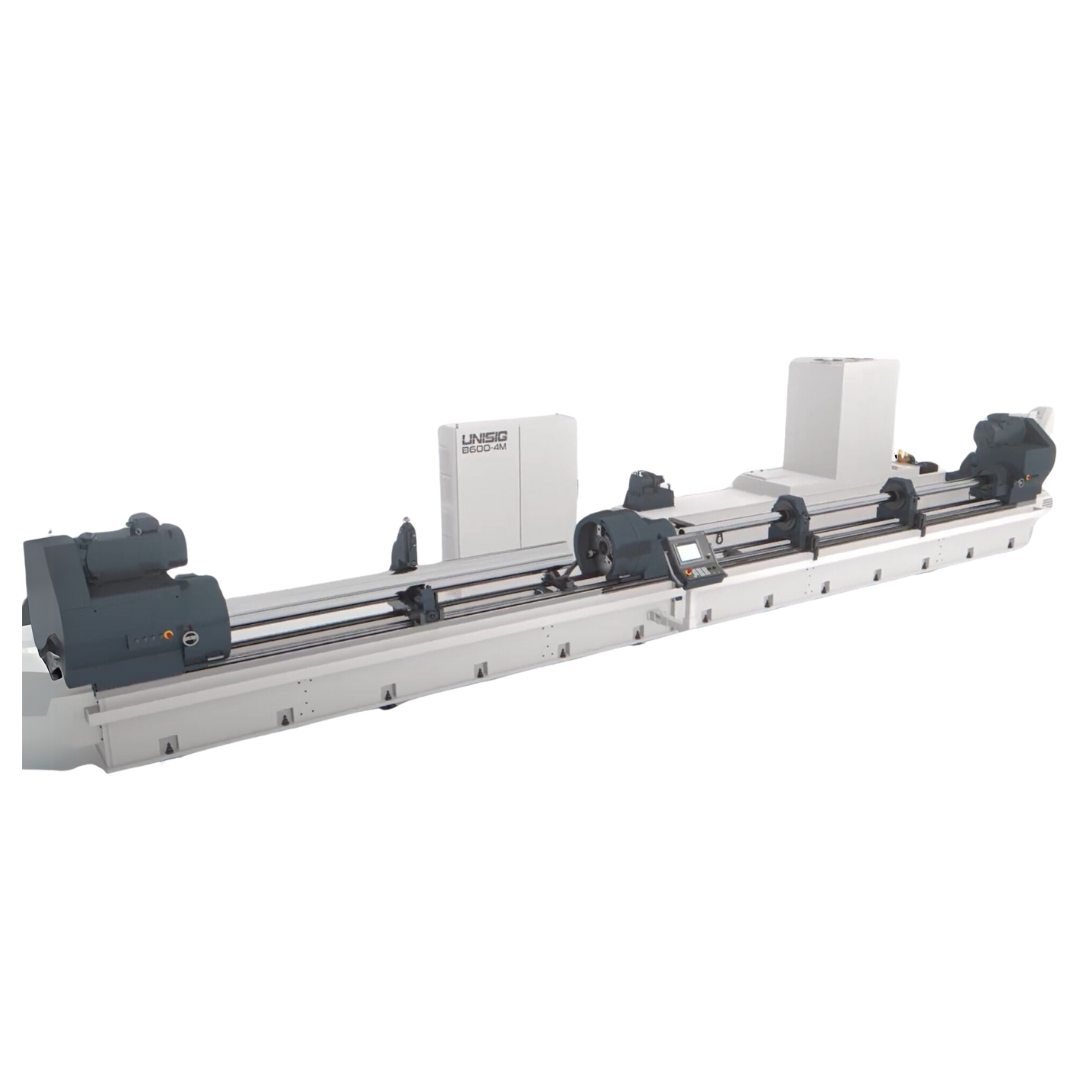

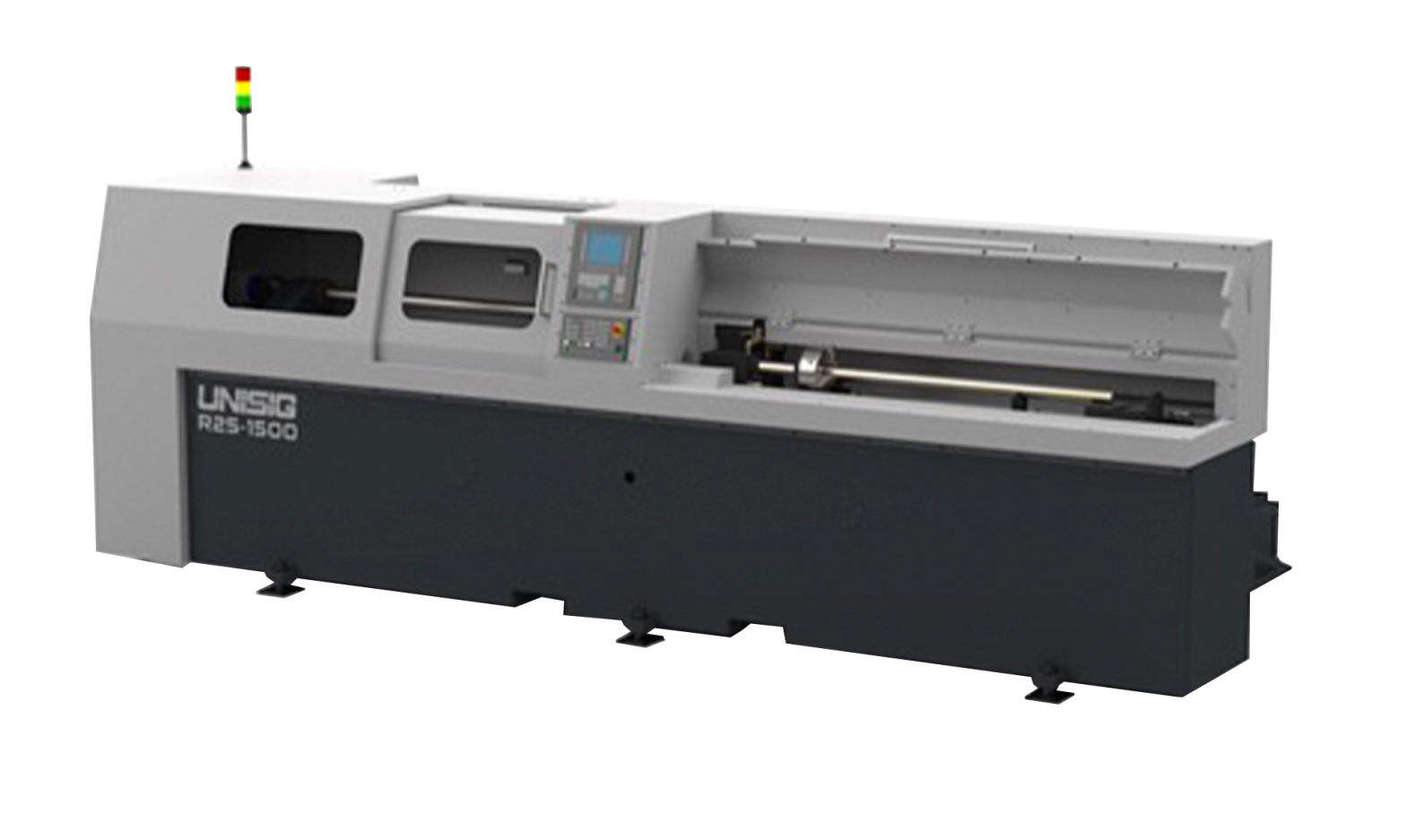

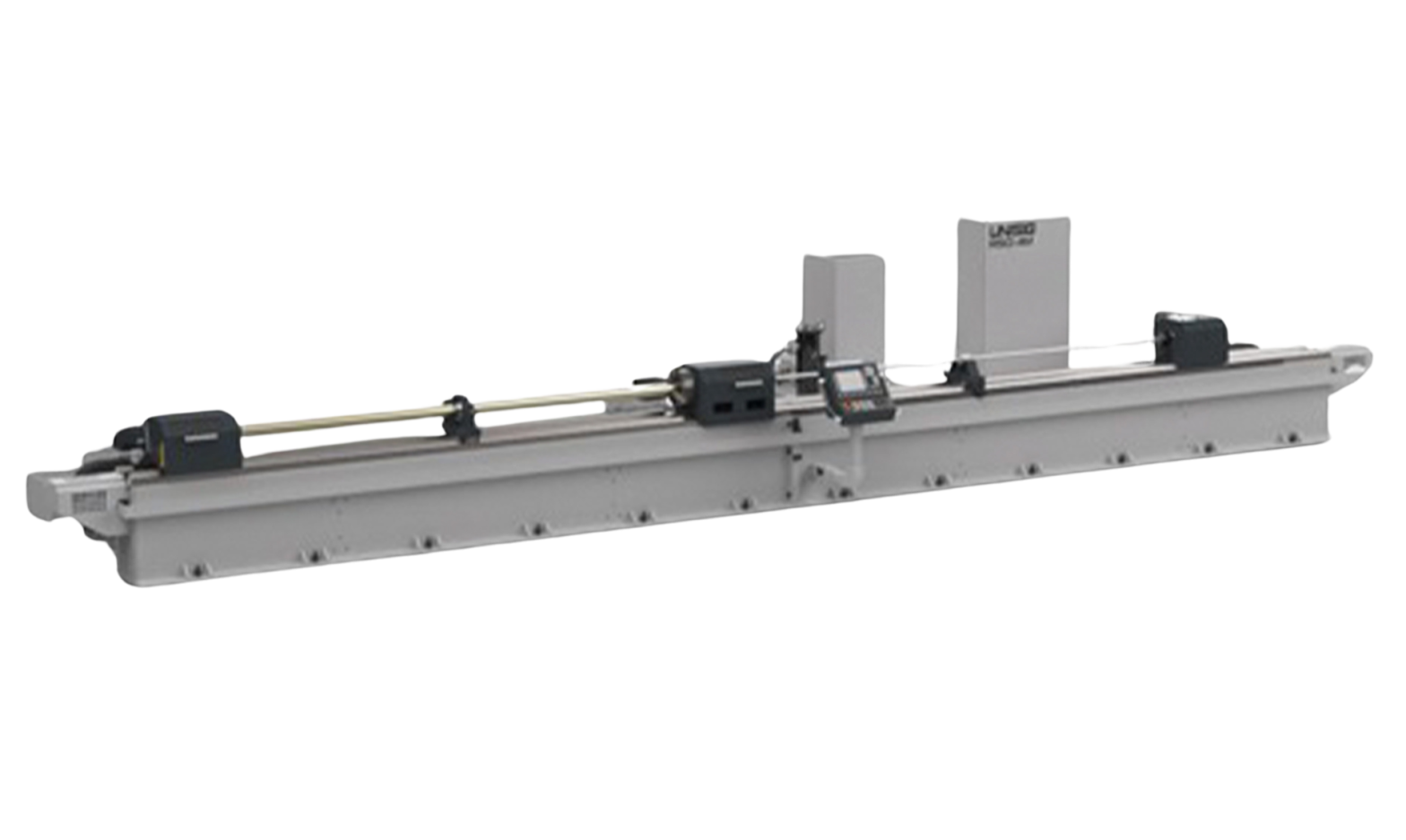

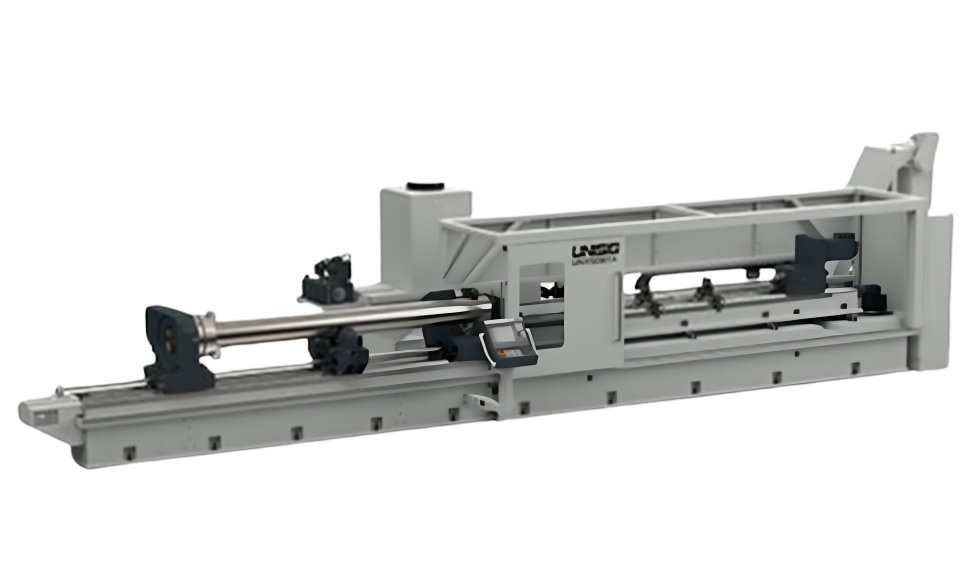

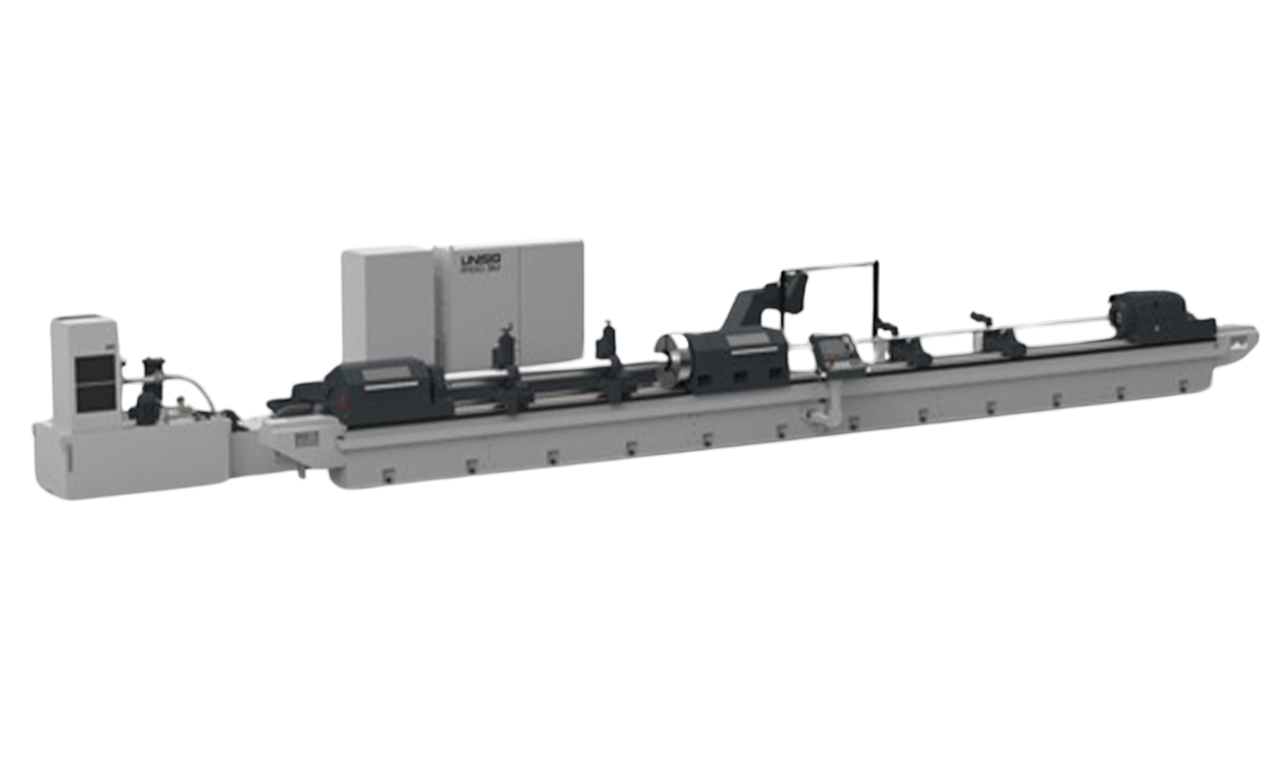

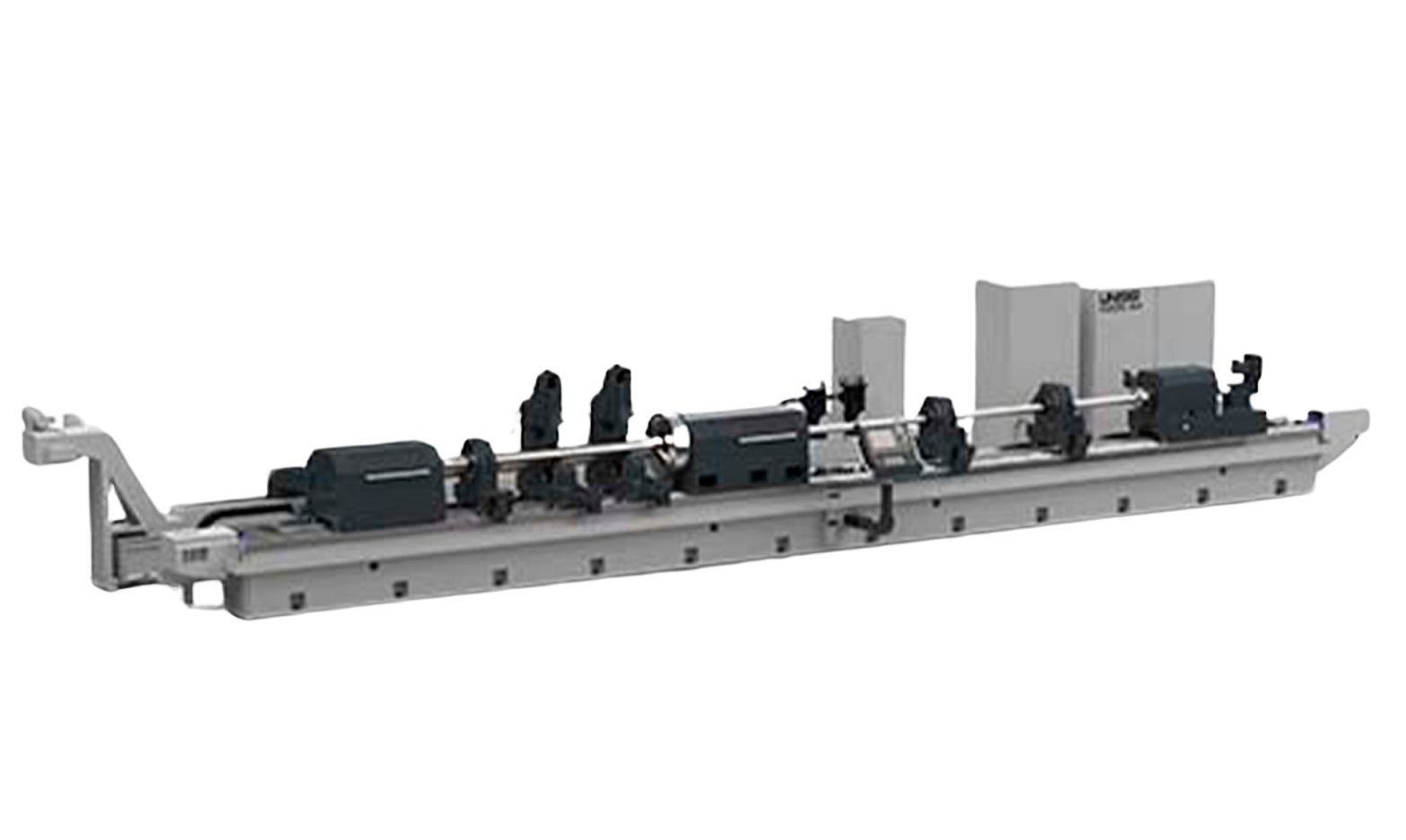

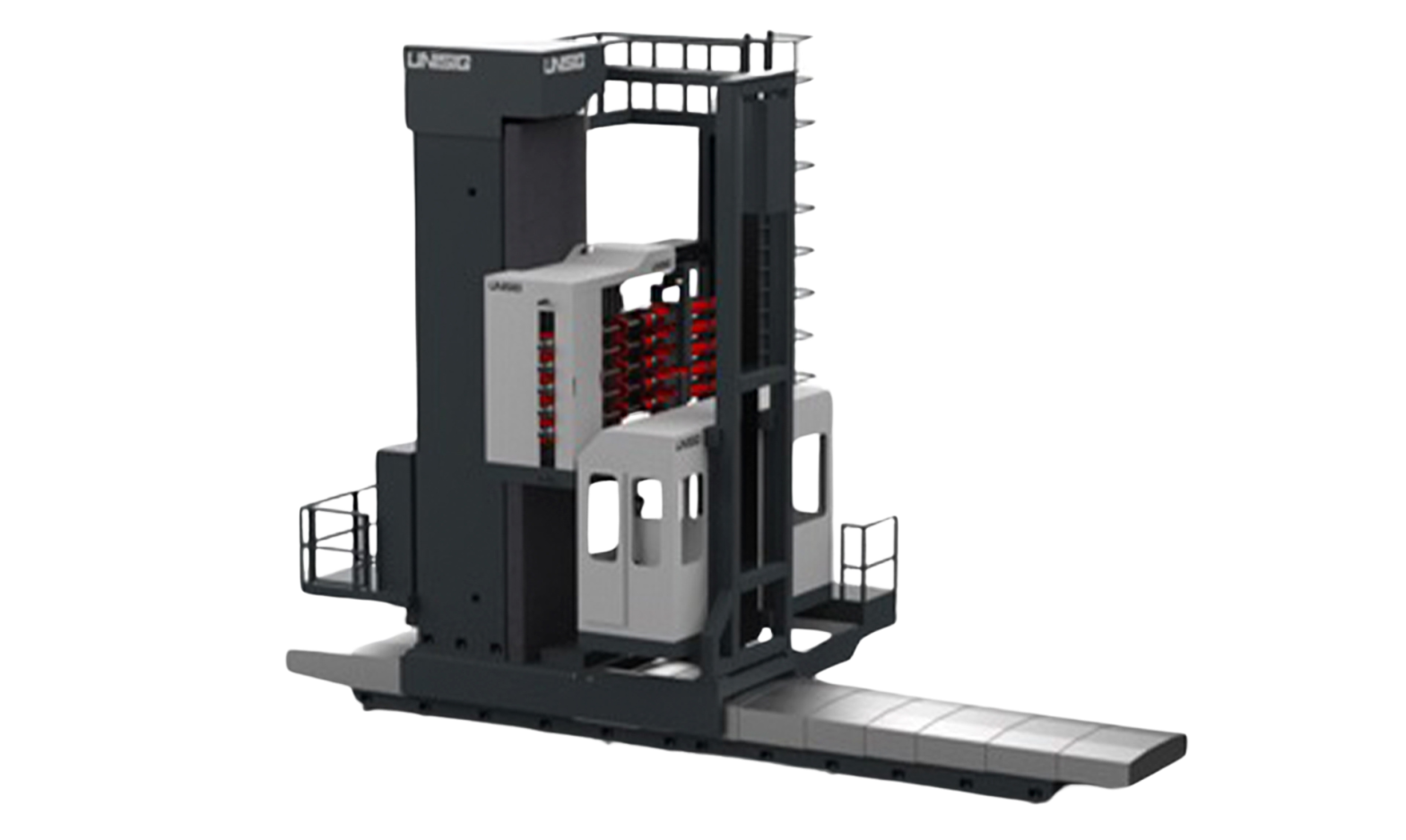

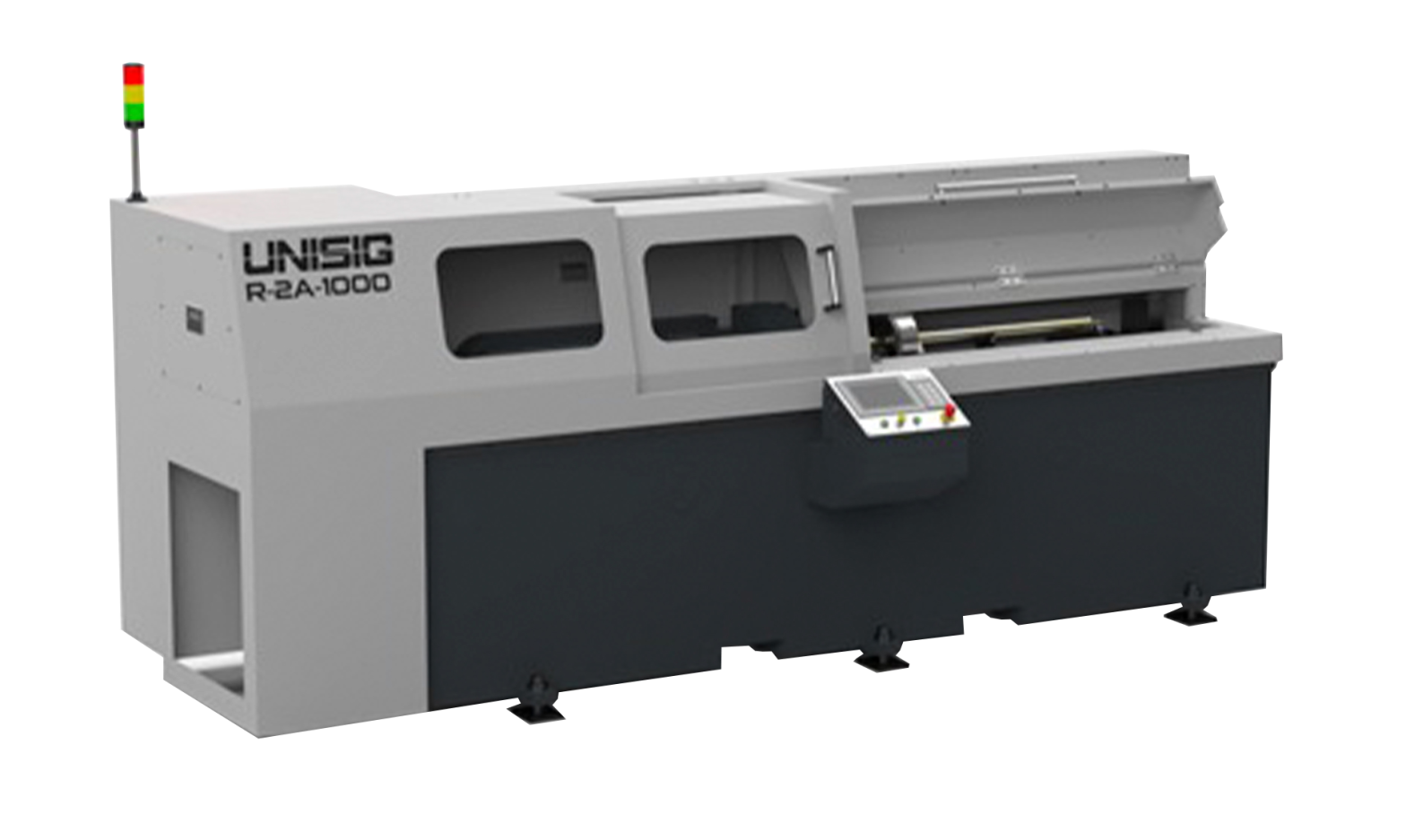

For hydraulic cylinder manufacturers, UNISIG S-Series machines enable skiving and roller burnishing, a productive and reliable process that reaches diameter and surface finish requirements with maximum efficiency. S-Series machines are based on proven machine technology, optimized for the specific demands of skiving and burnishing, and ease of operation.

S-Series skiving machines are designed for rapid tool and size changeover, easy part loading, and intuitive setup and operation for the skiving and roller burnishing process. These capable machines allow confident production of hydraulic cylinders, even in high production environments.

Industries

Fluid Control

Molds & Dies

Others

Product Highlights

Product Highlights

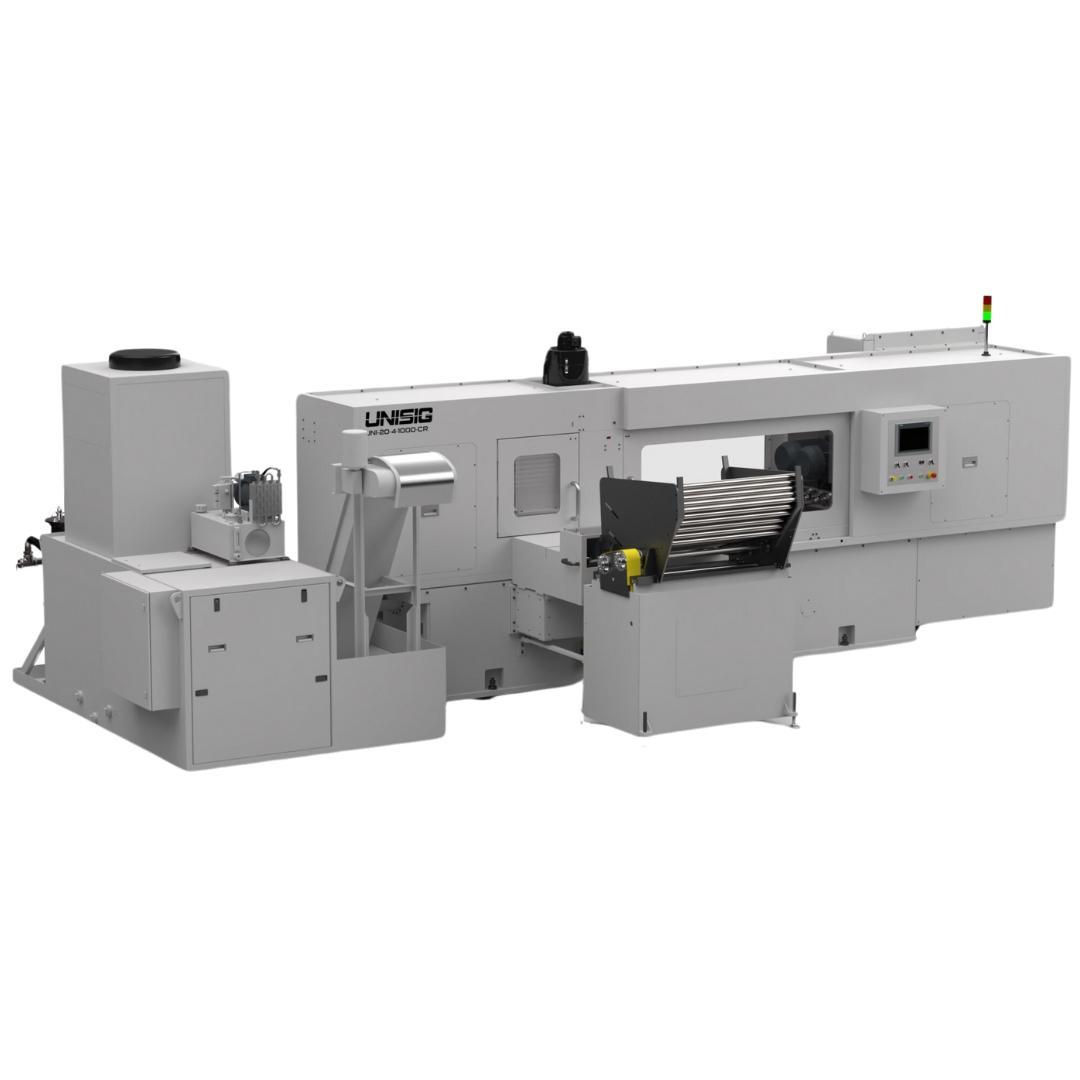

Swing Over Bed (in)Swing Over Bed (mm)

19.7500

Drilling depths – Ballscrew drive (ft)Drilling depths – Ballscrew drive (m)

6, 10, 13, o 202, 3, 4, o 6

Drilling depths – Rack and prinion drive (ft) Drilling depths – Rack and prinion drive (m)

26, 32 and longer8, 10 and longer

Rated skiving and burnishing diameter (in)Rated skiving and burnishing diameter (mm)

5.51140

Spindle nose

ISO 702/1 A2-15

Power, continuous S1 (400/480 VAC) (hp)Power, continuous S1 (400/480 VAC) (kW)

67/9050/67

Spindle speed maximum (rpm)

1,500

Headstock transmission

Single reduction

Maximum programmable flow (gpm)Maximum programmable flow (L/min)

140529

Recommended solutions to improve your processes

Equip and maximize the productivity of your CNC machines with comprehensive solutions.

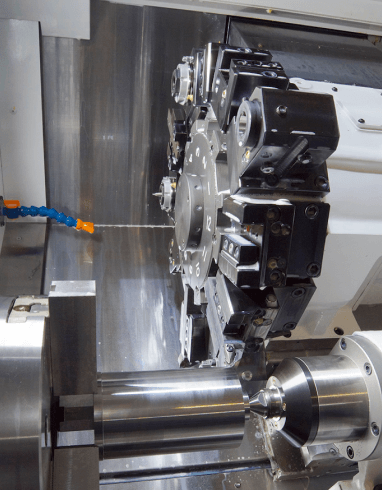

Accessories and peripherals

Mist collector

Cooling system

Coolant filtration and magnetic separator equipment

Learn more about PERIFERIQ

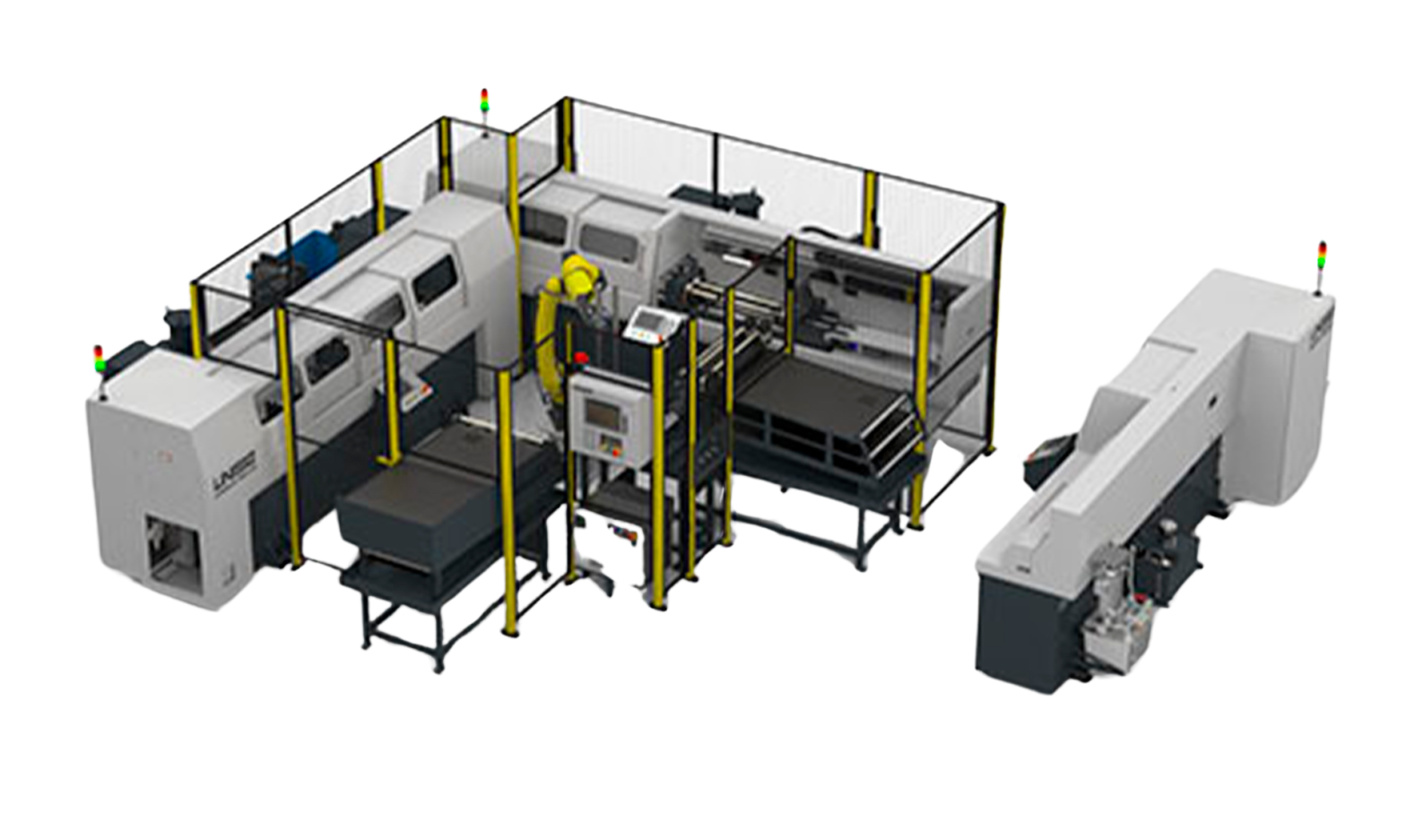

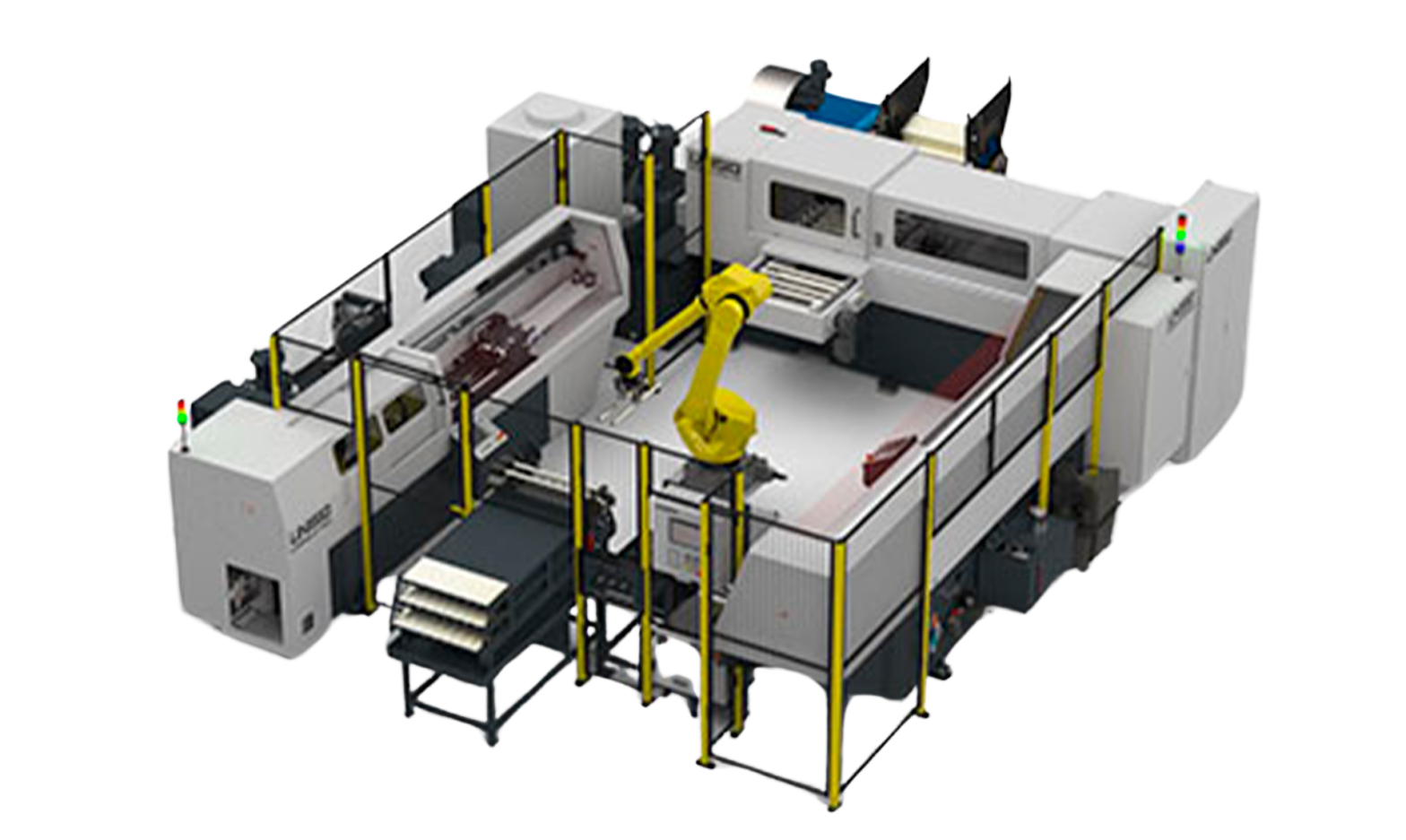

Creation and development of industrial automation customized to meet your needs.

Automatic doors

Automated loading and unloading system

Safety and cleaning systems

Interfaces to external clamping systems

Learn more about OTOMATIQA