Modig

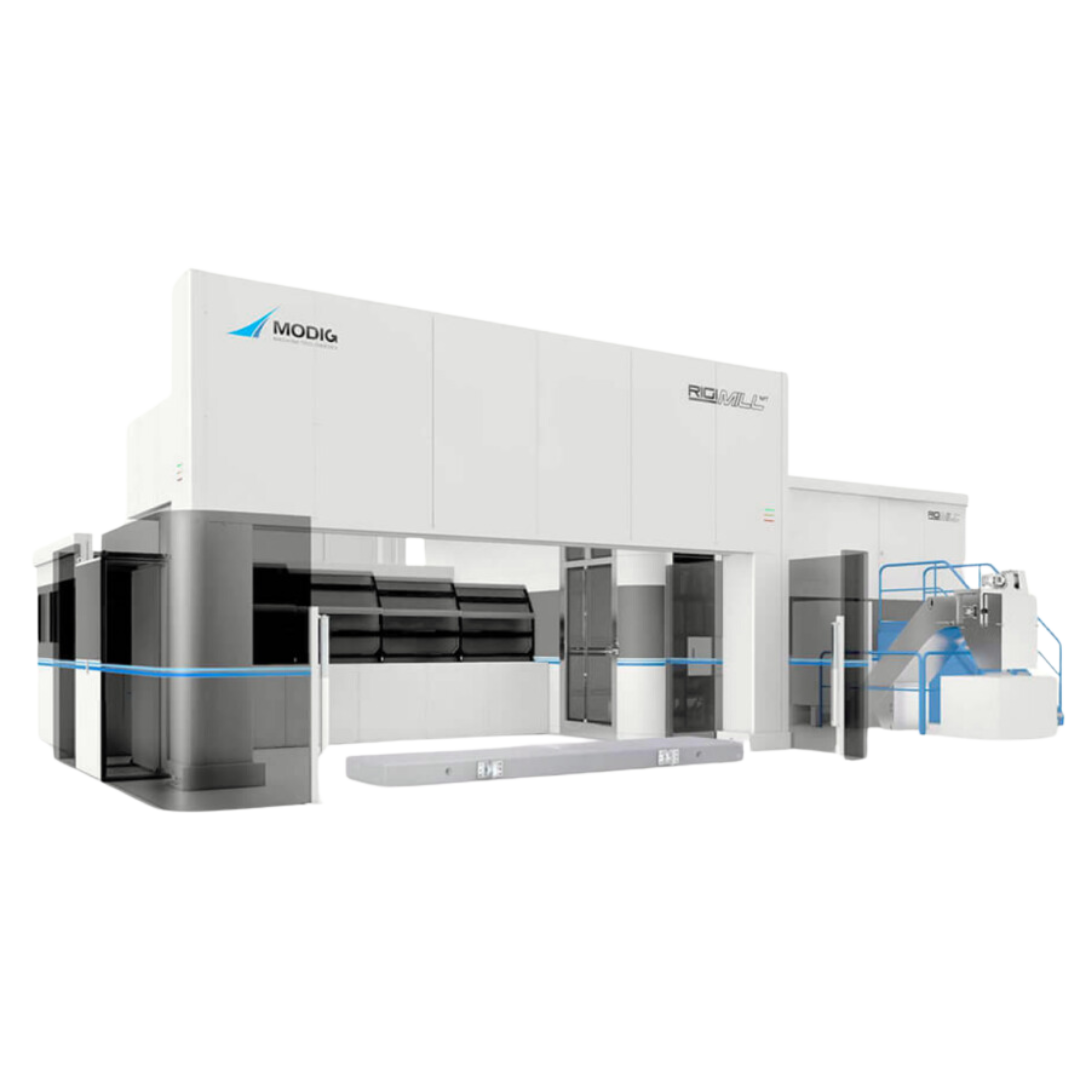

RigiMill MG

Modig

RigiMill MG

Product description

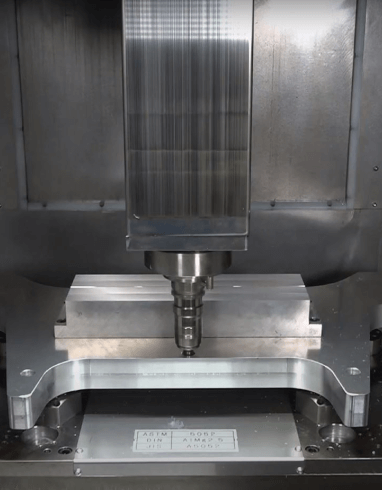

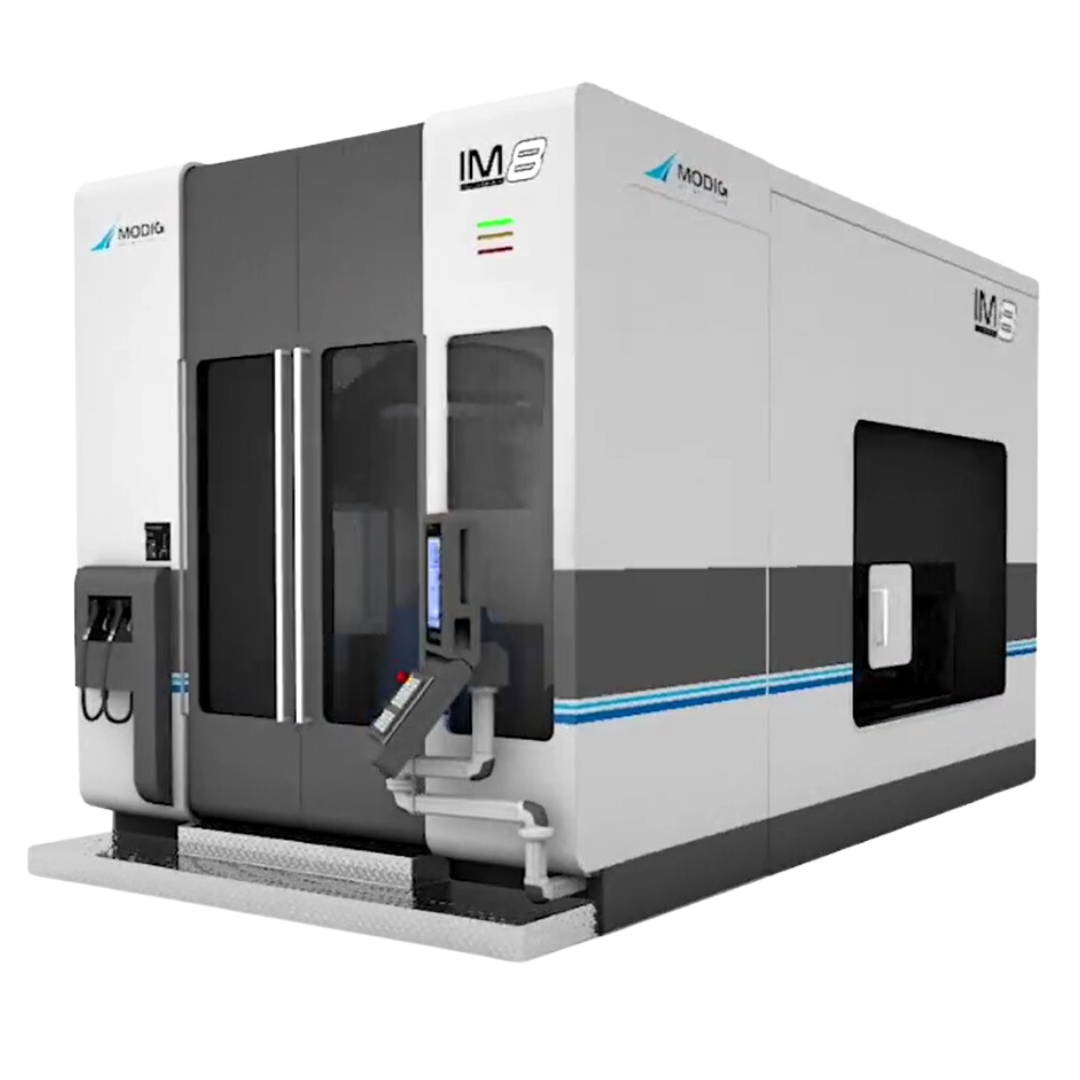

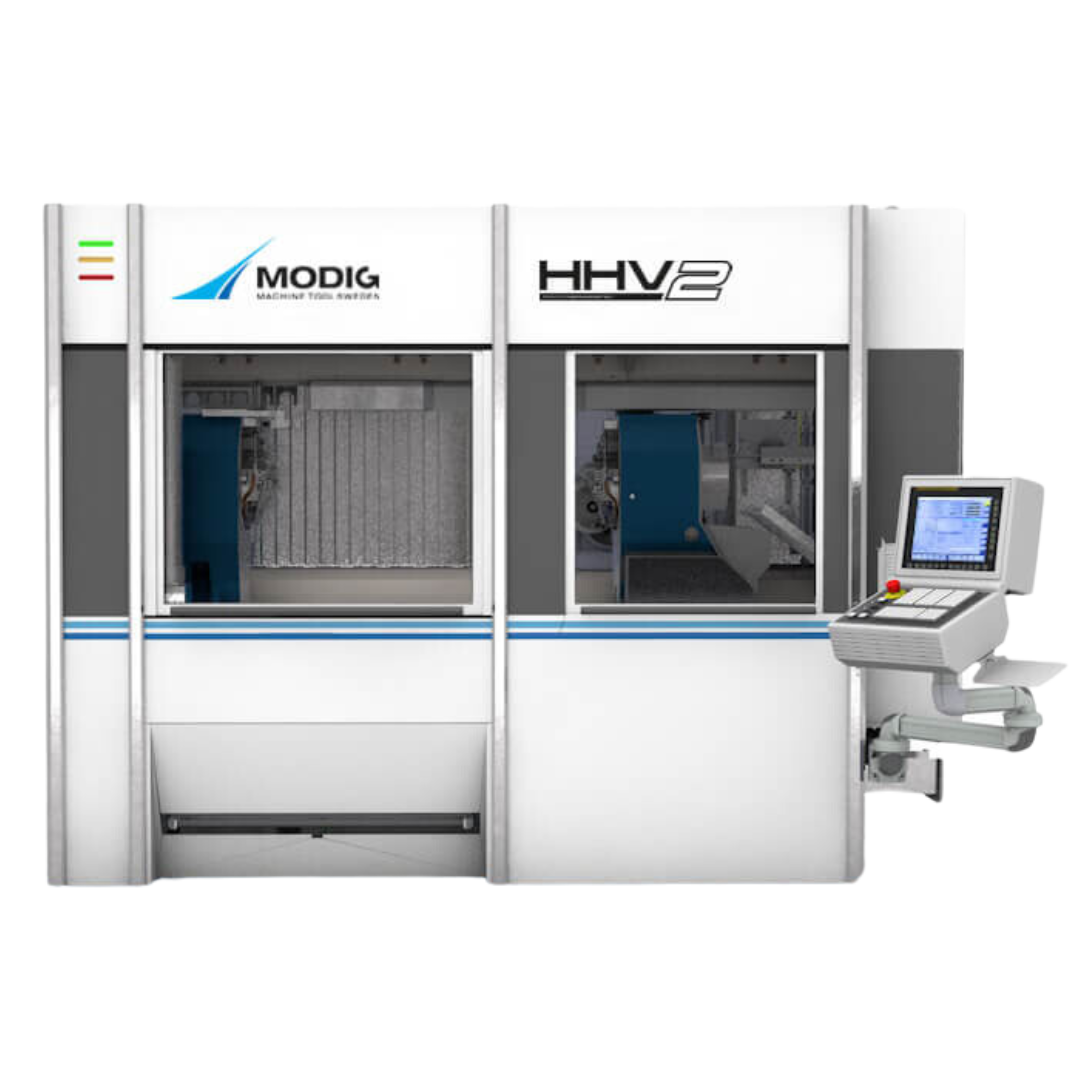

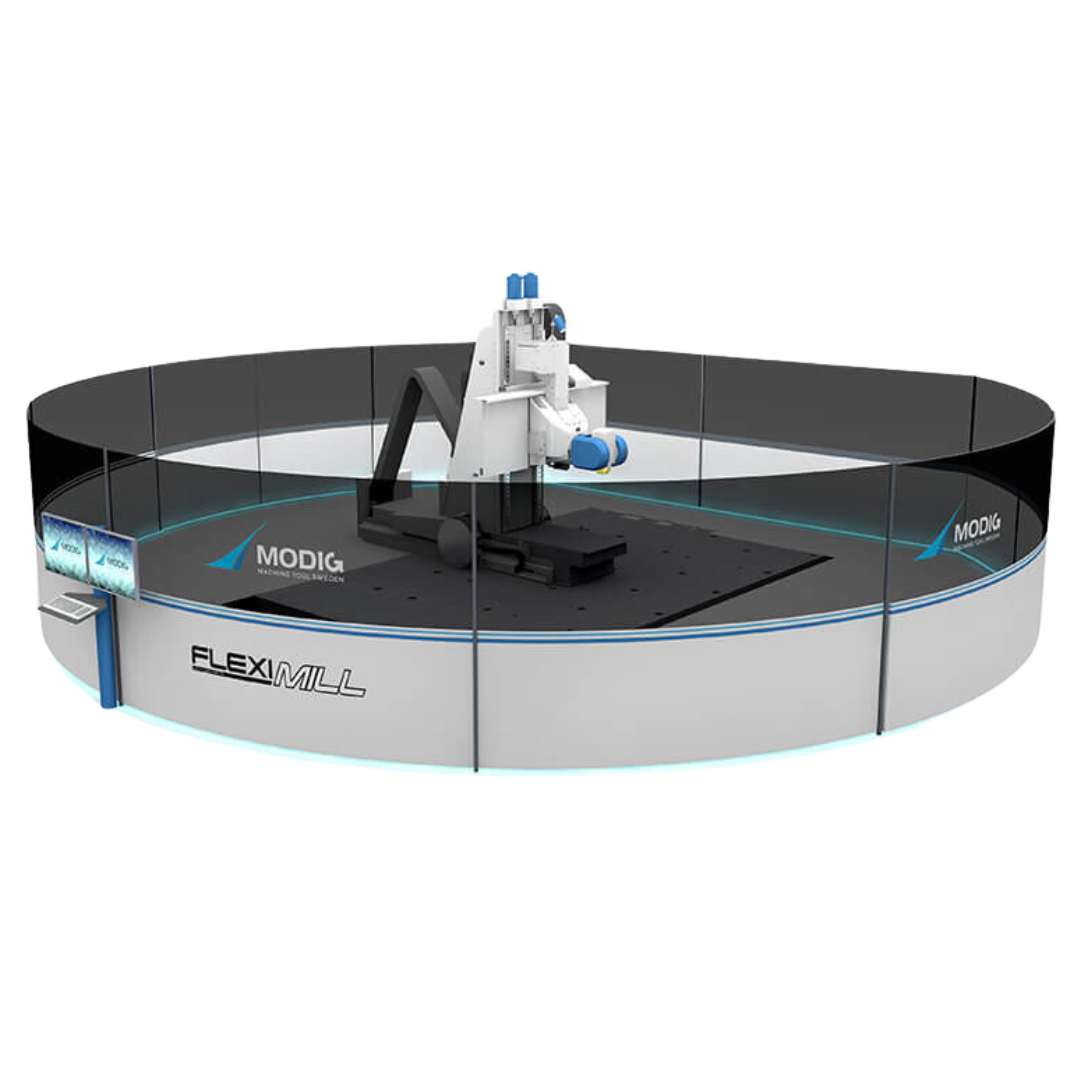

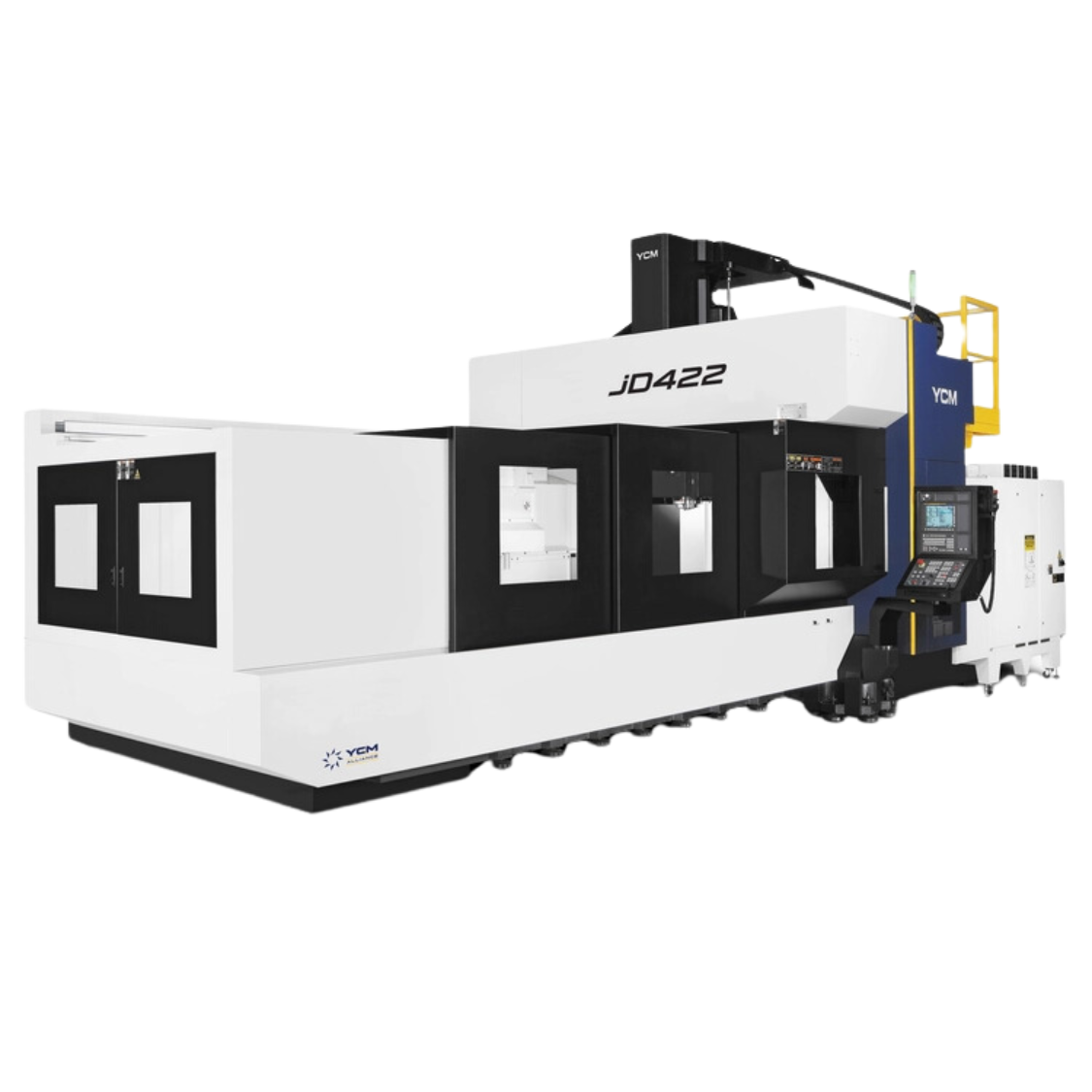

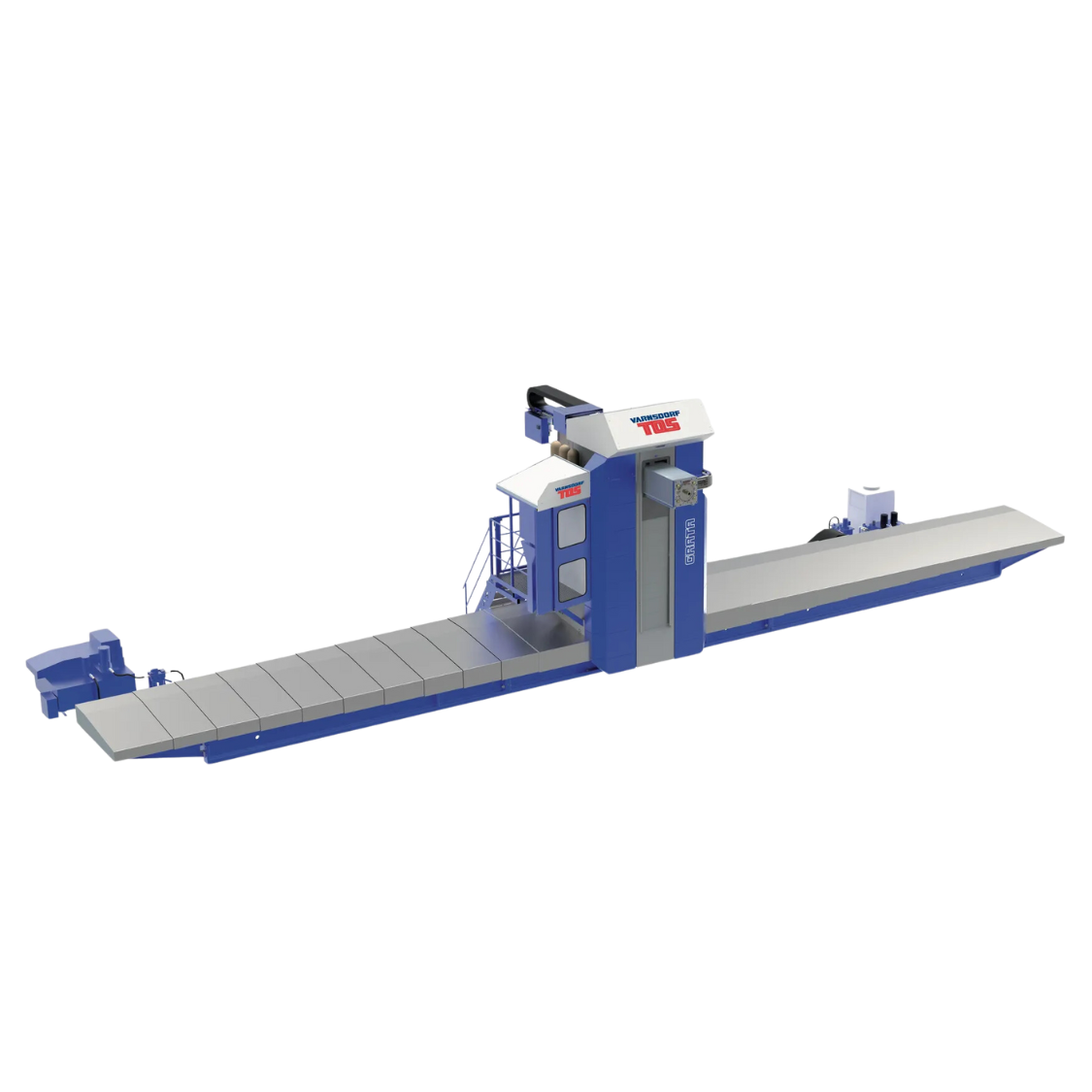

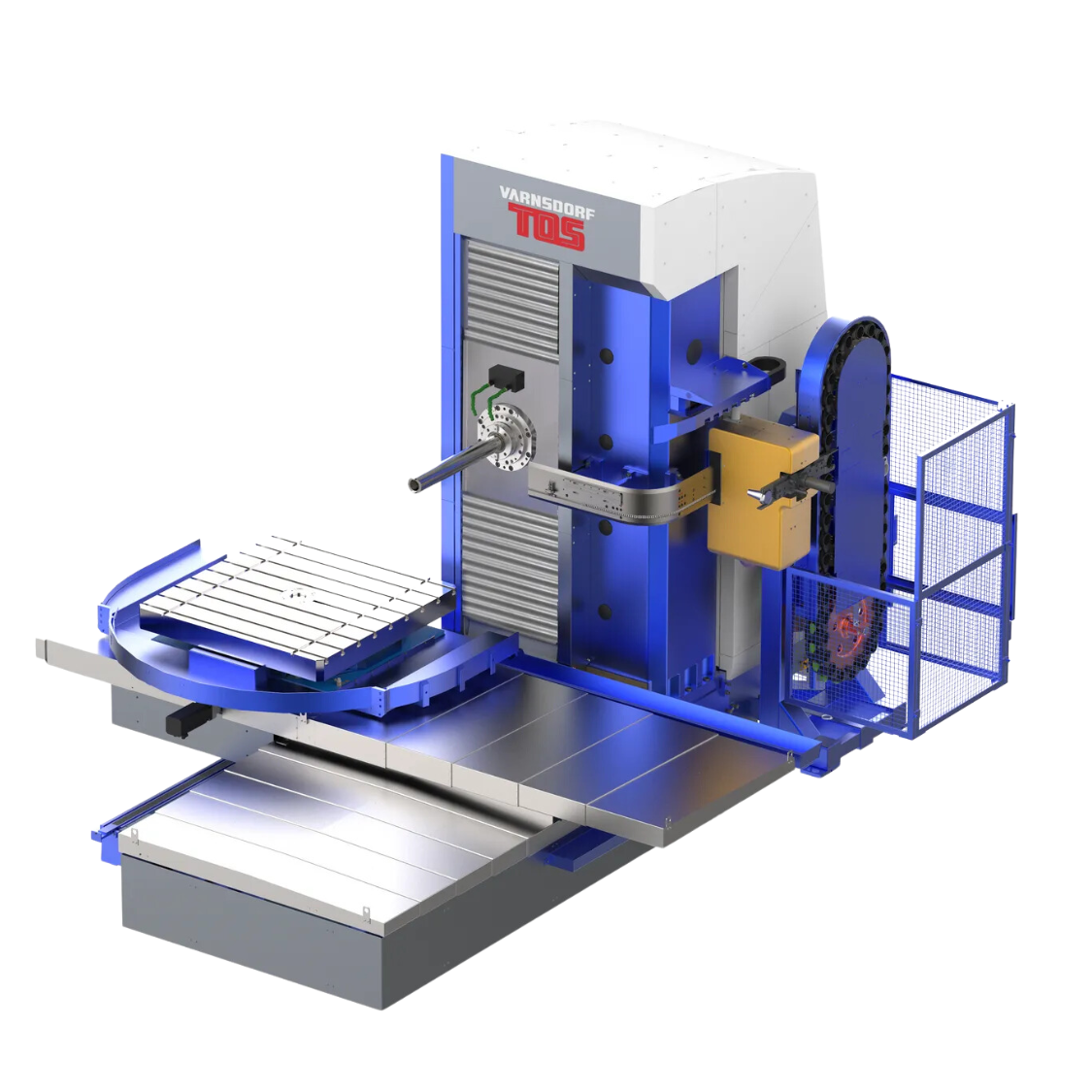

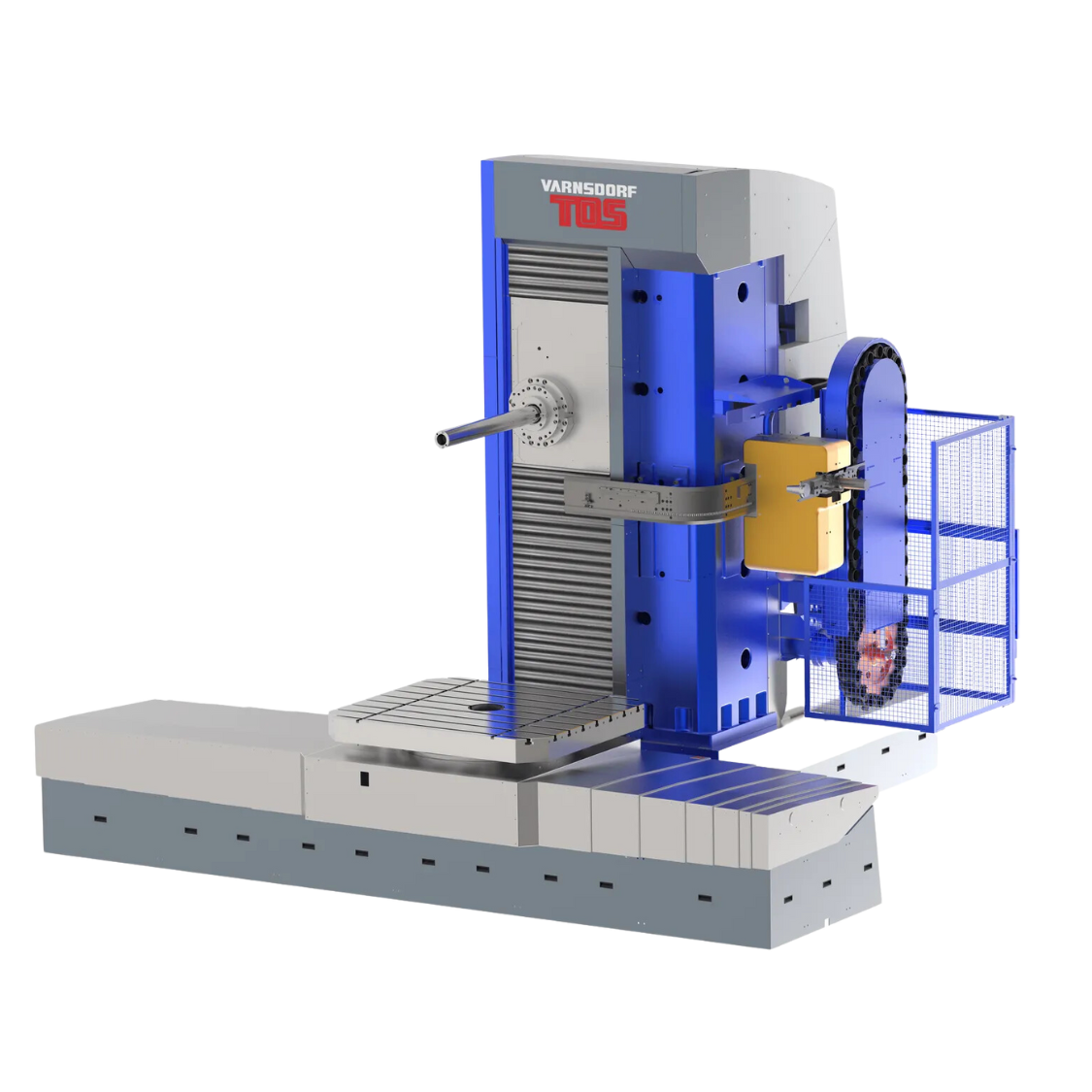

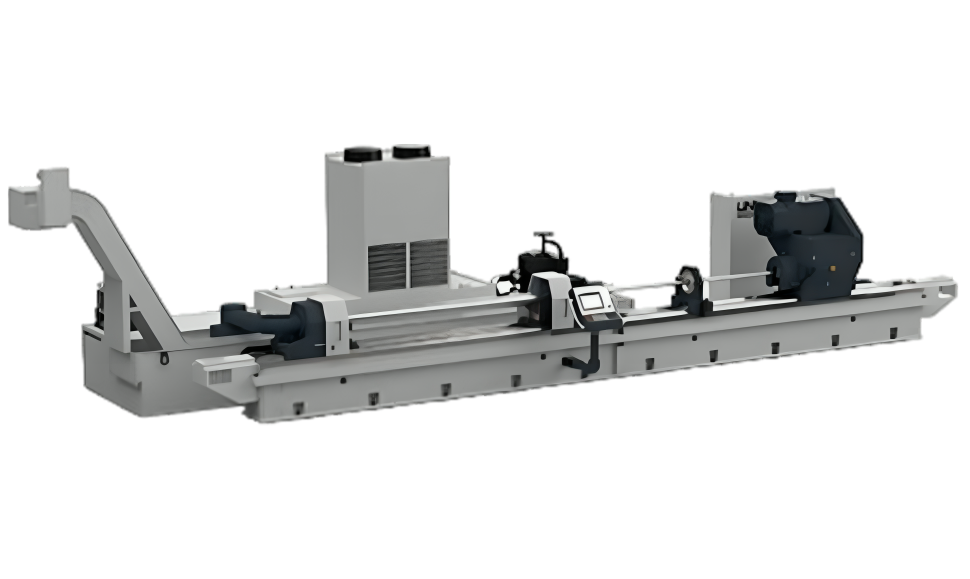

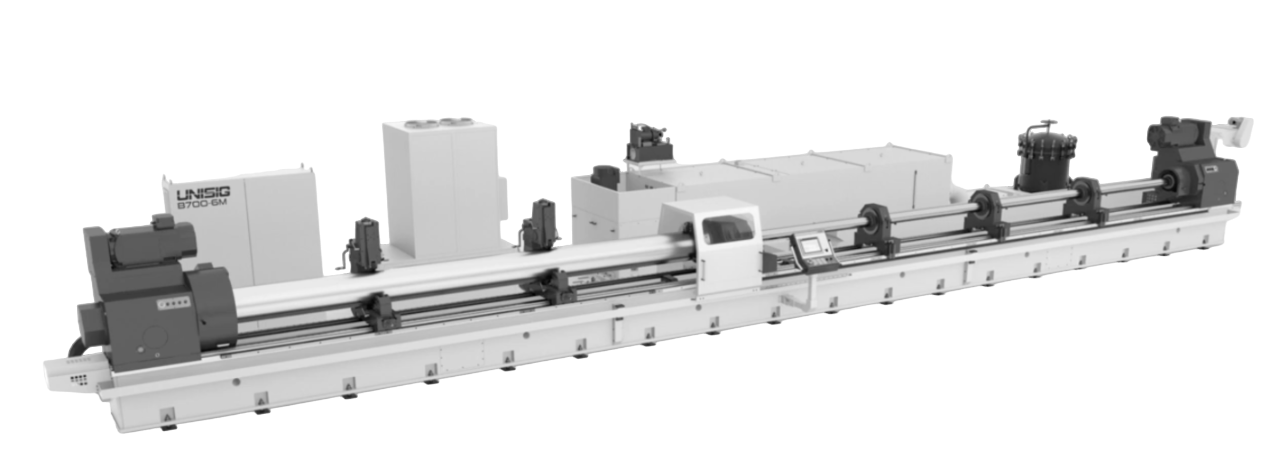

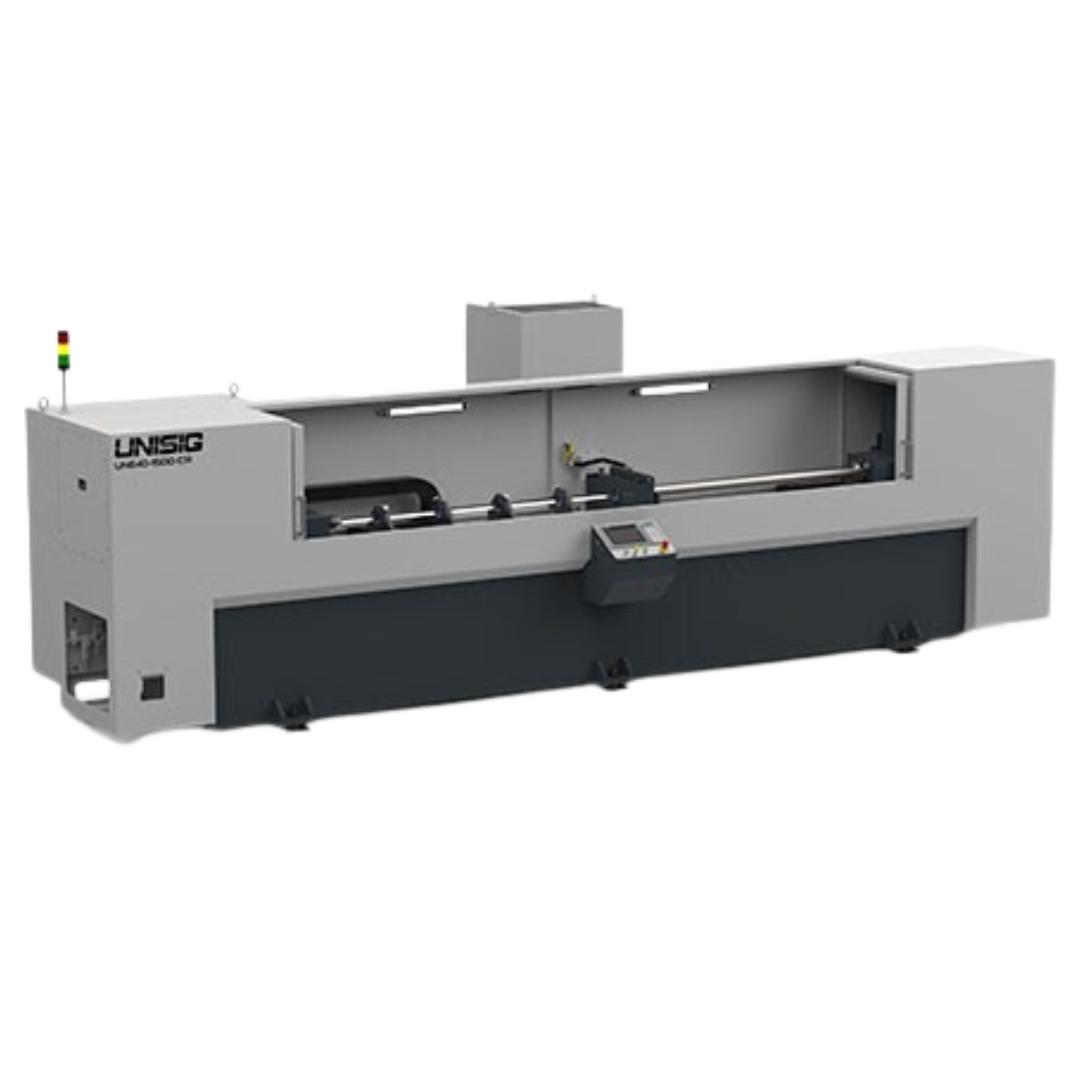

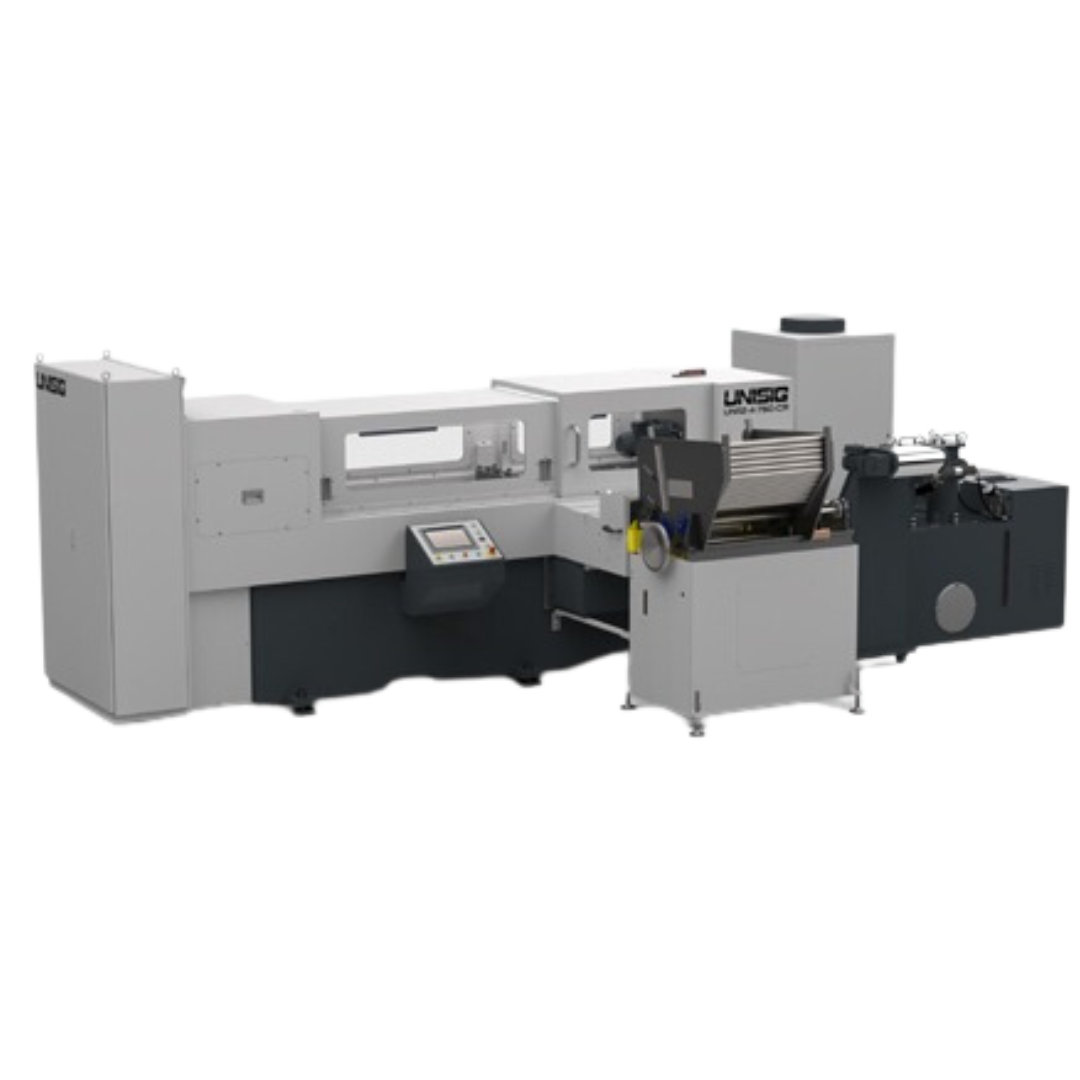

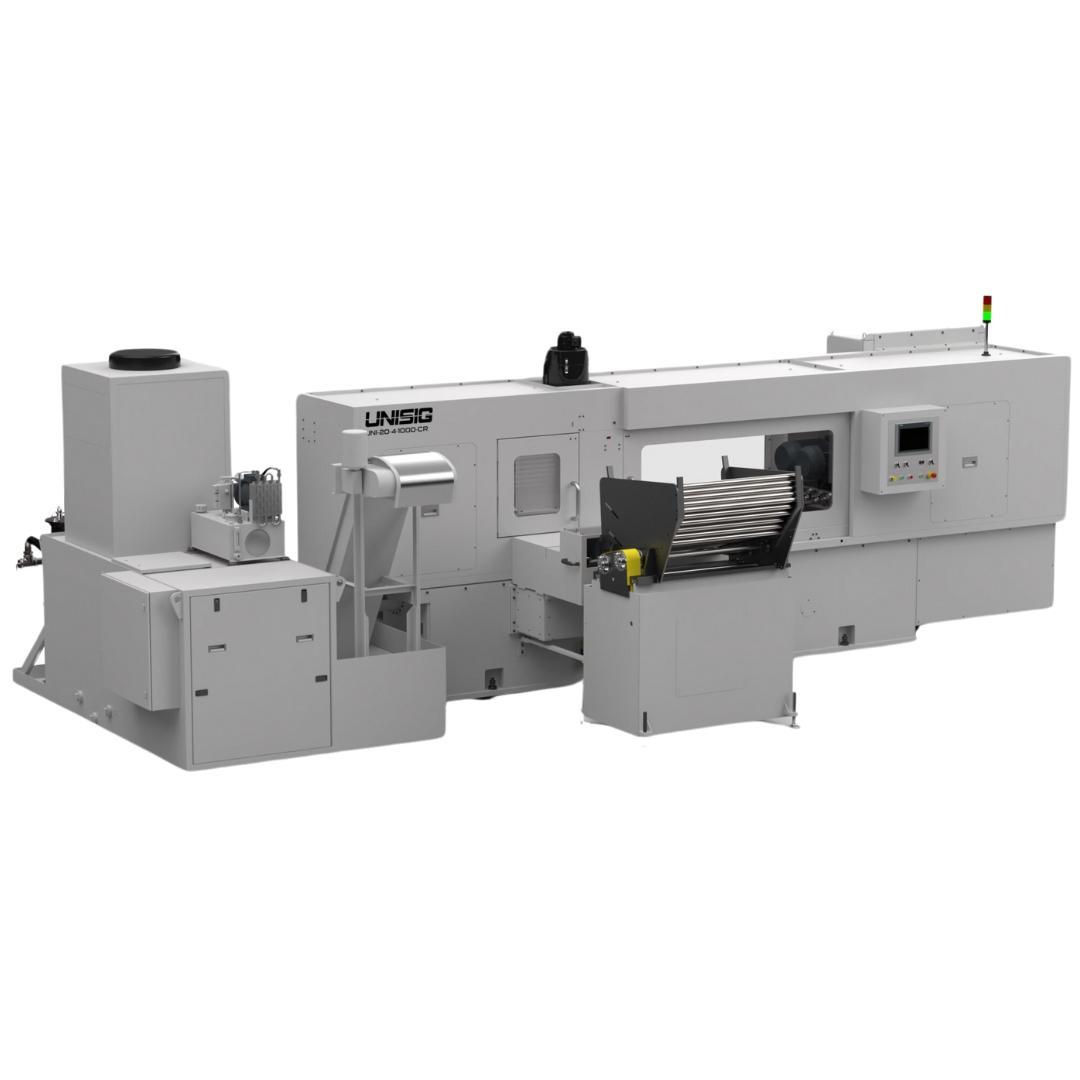

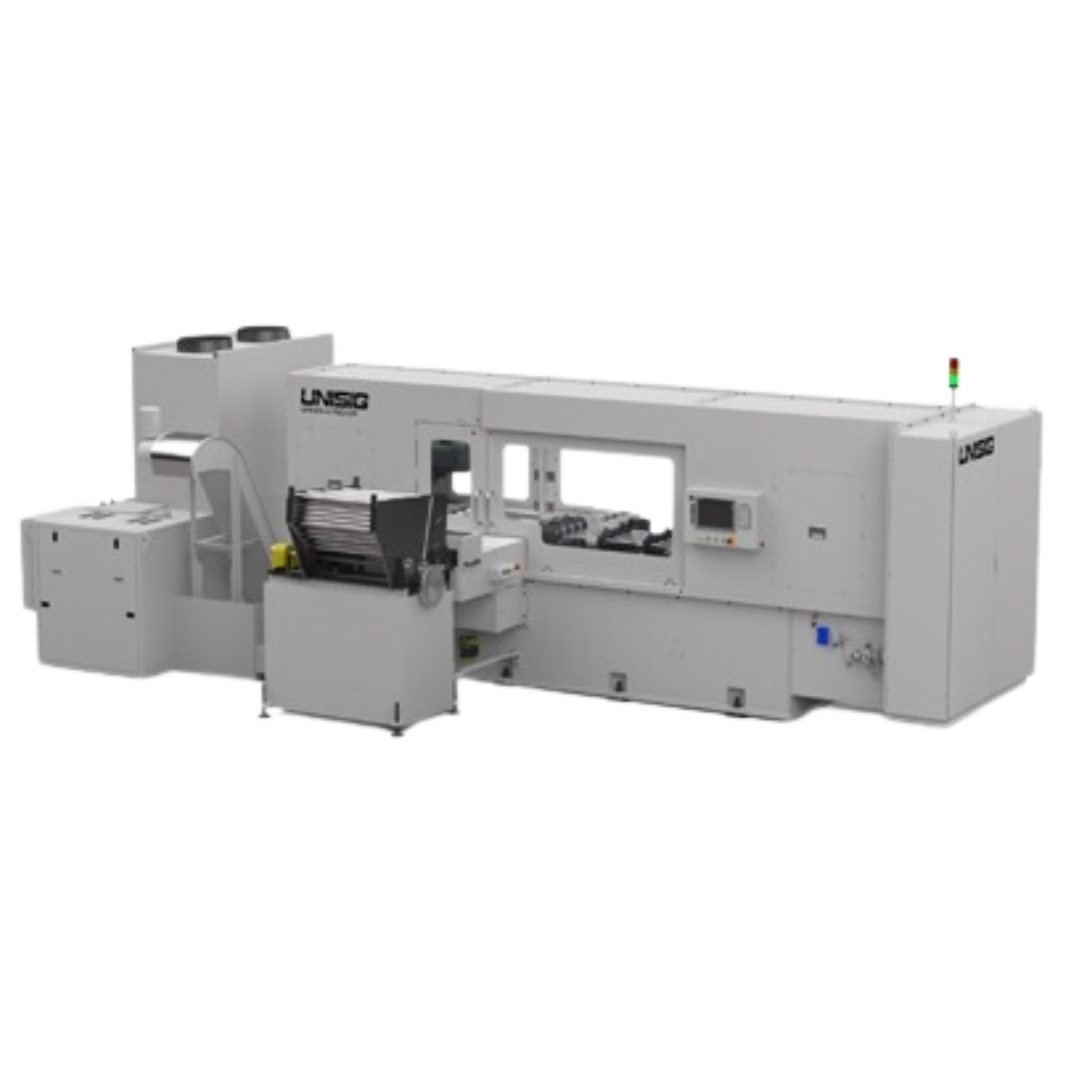

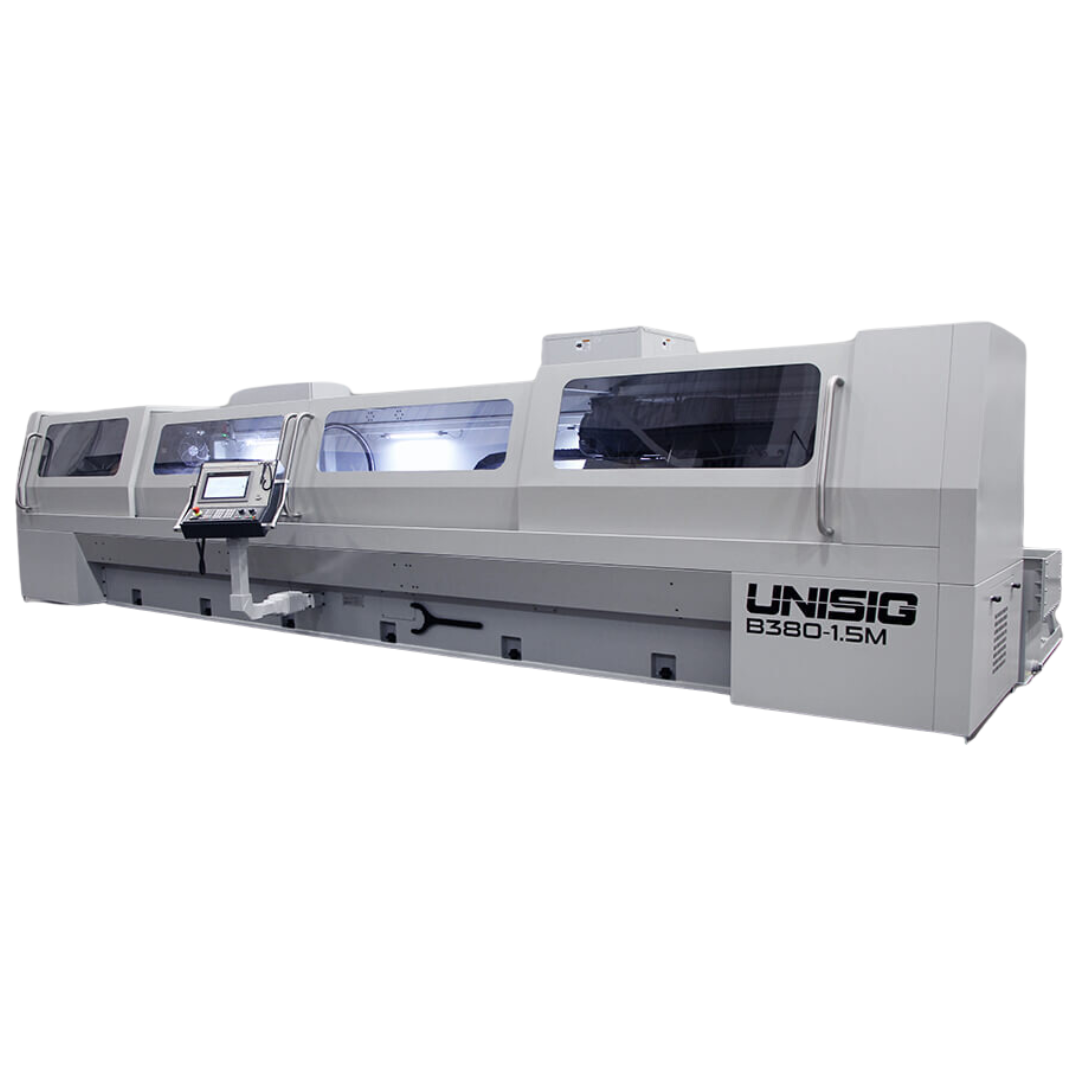

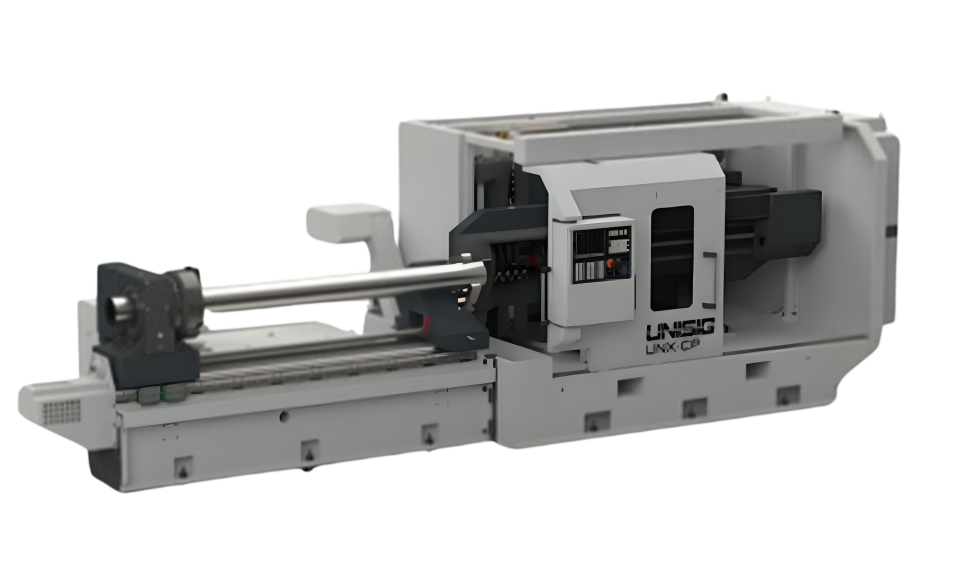

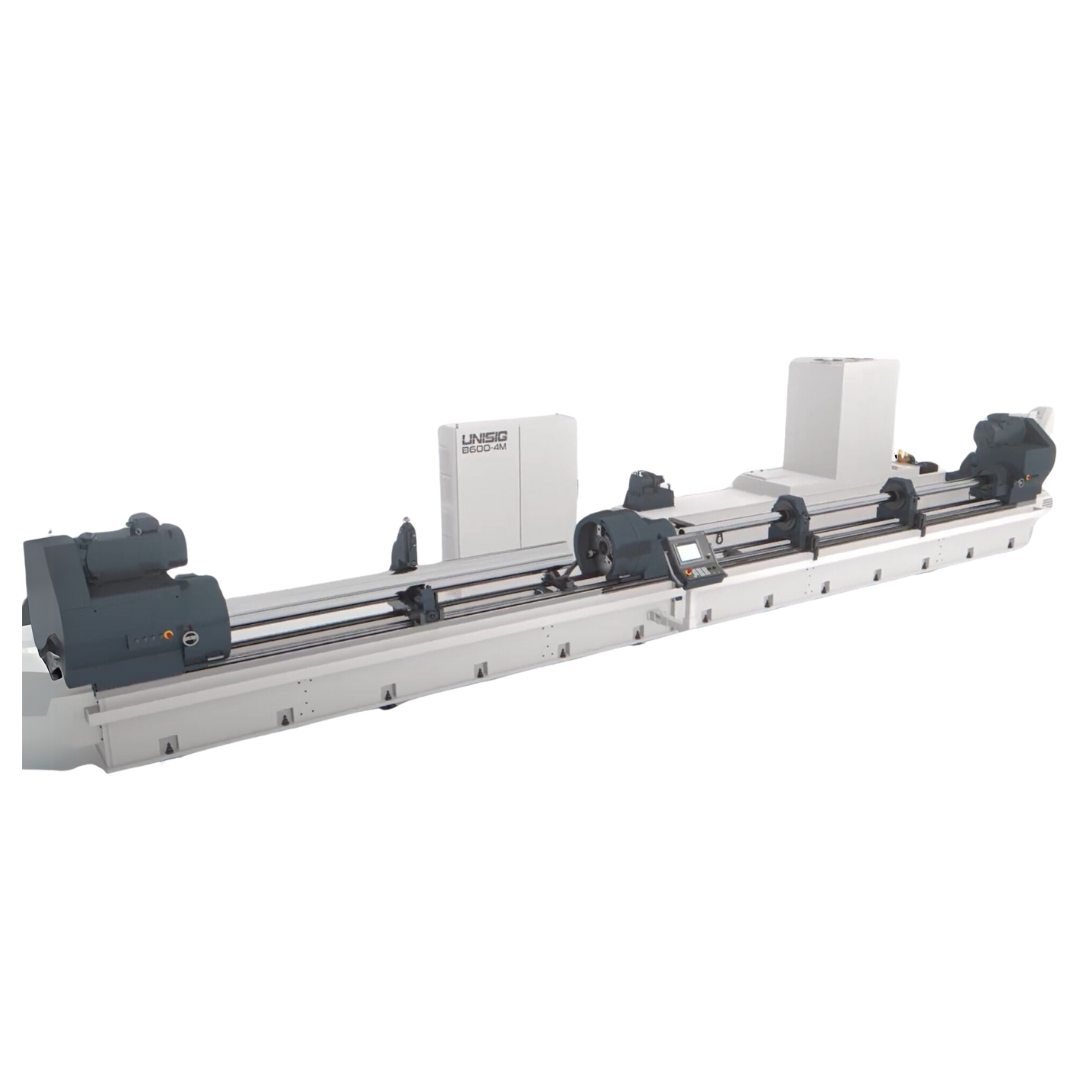

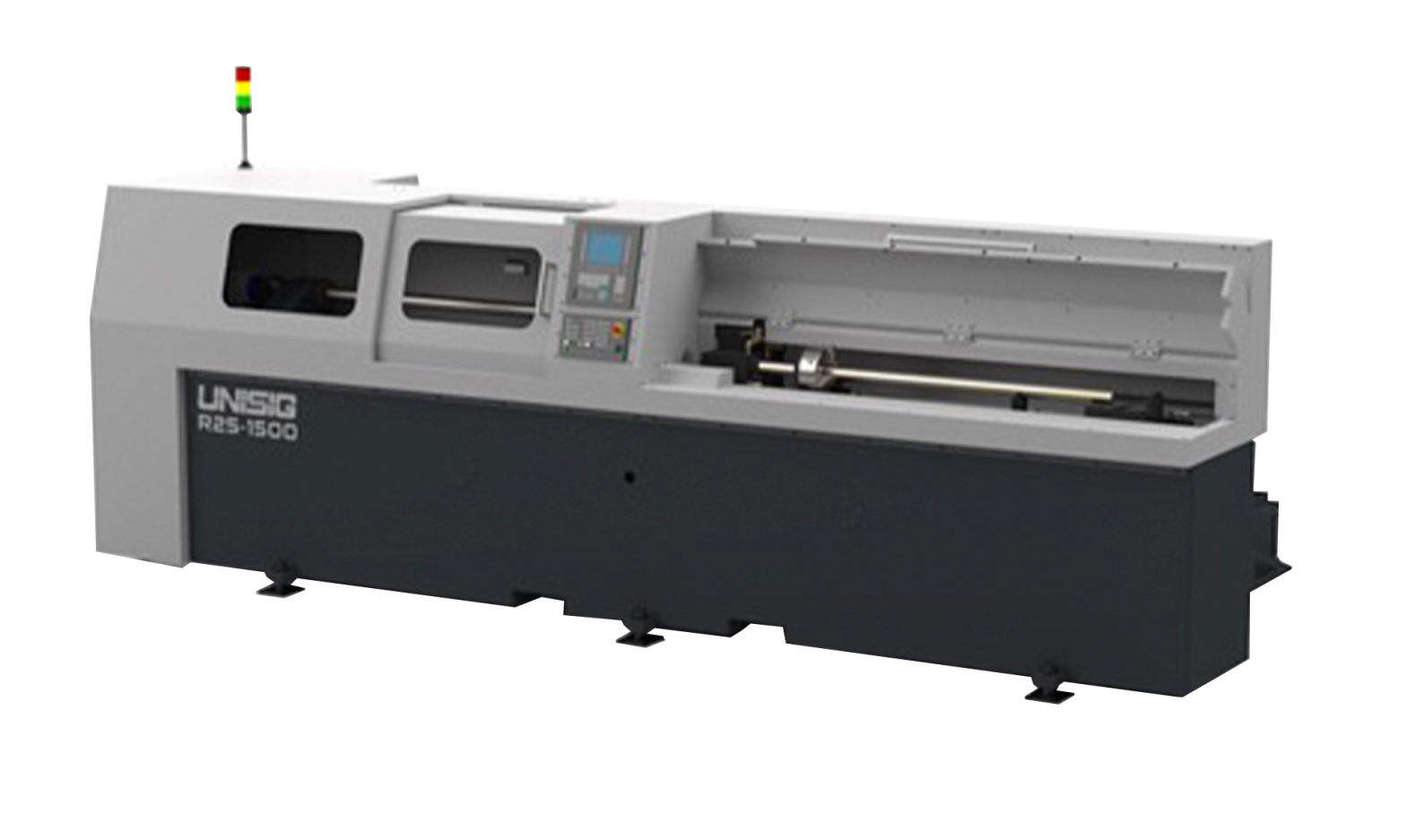

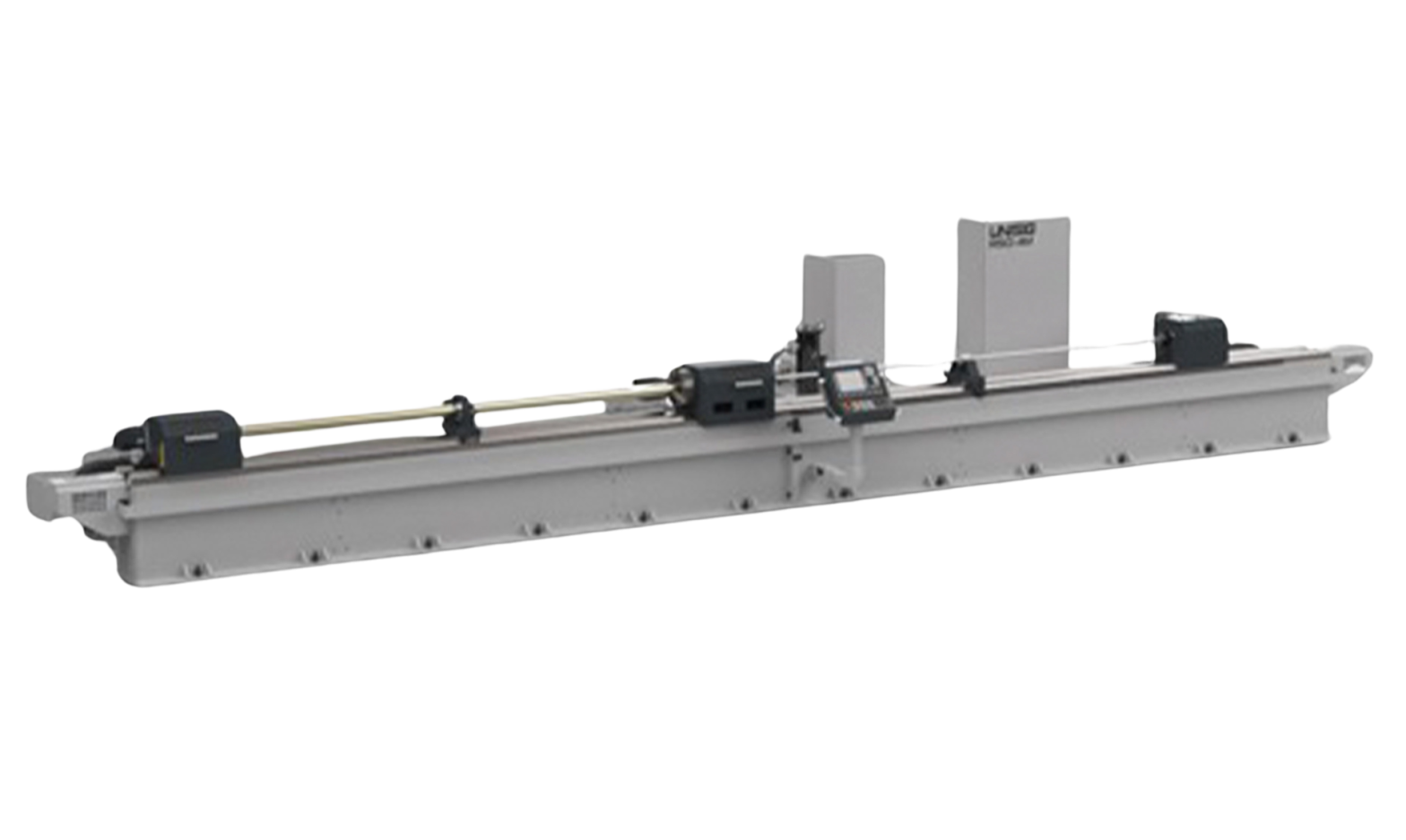

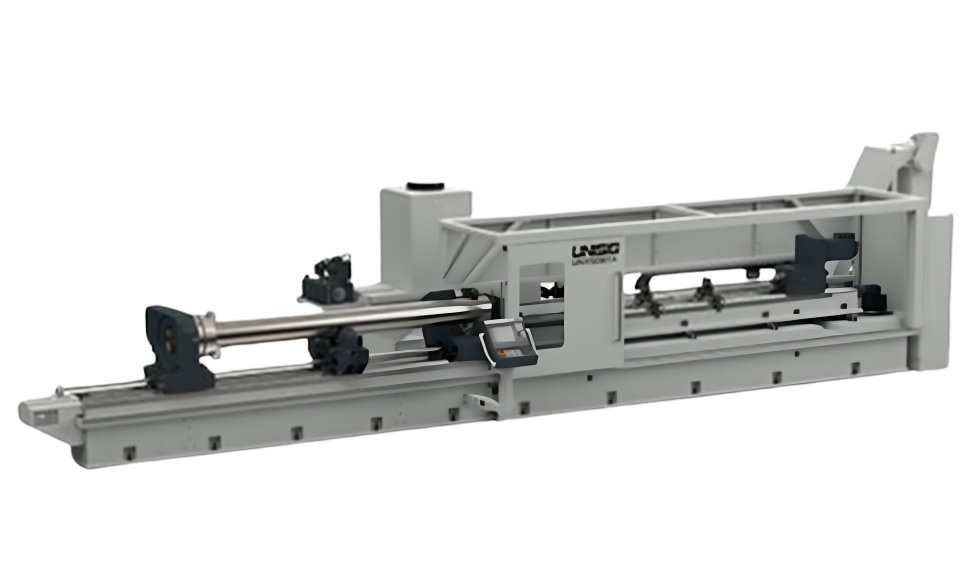

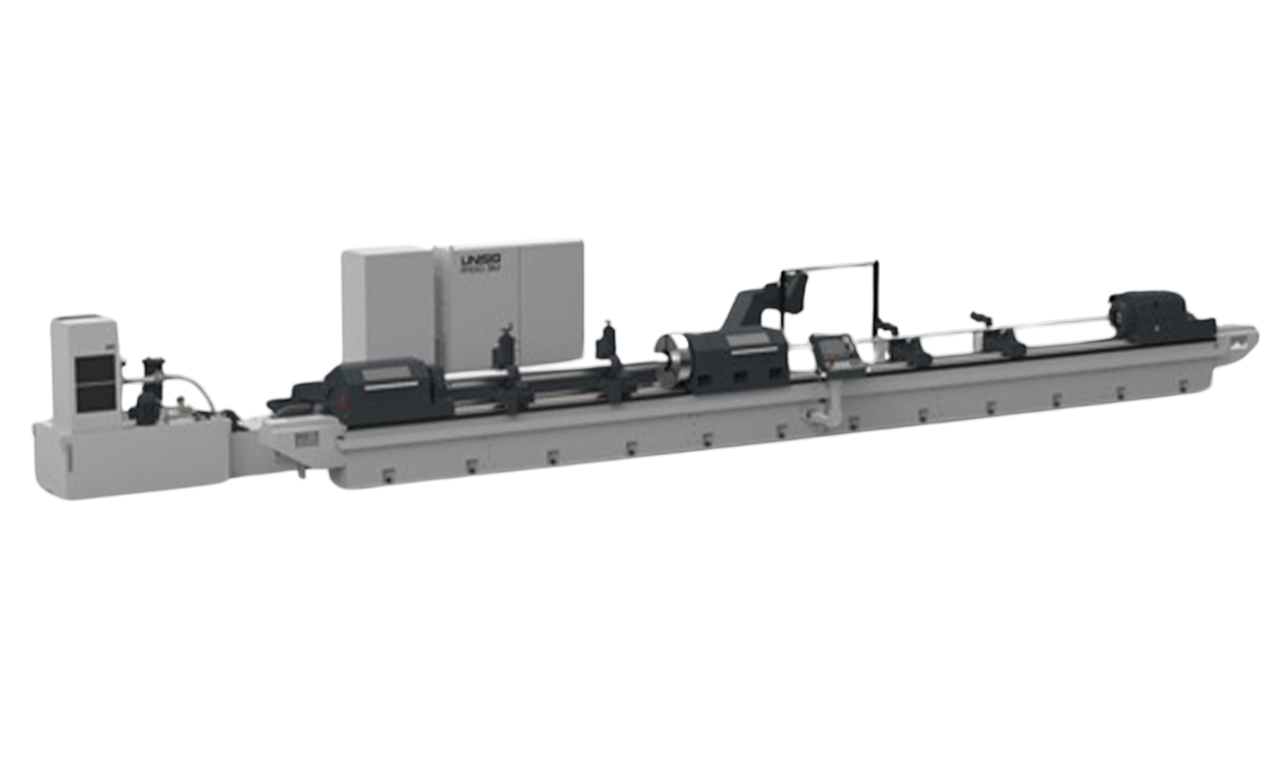

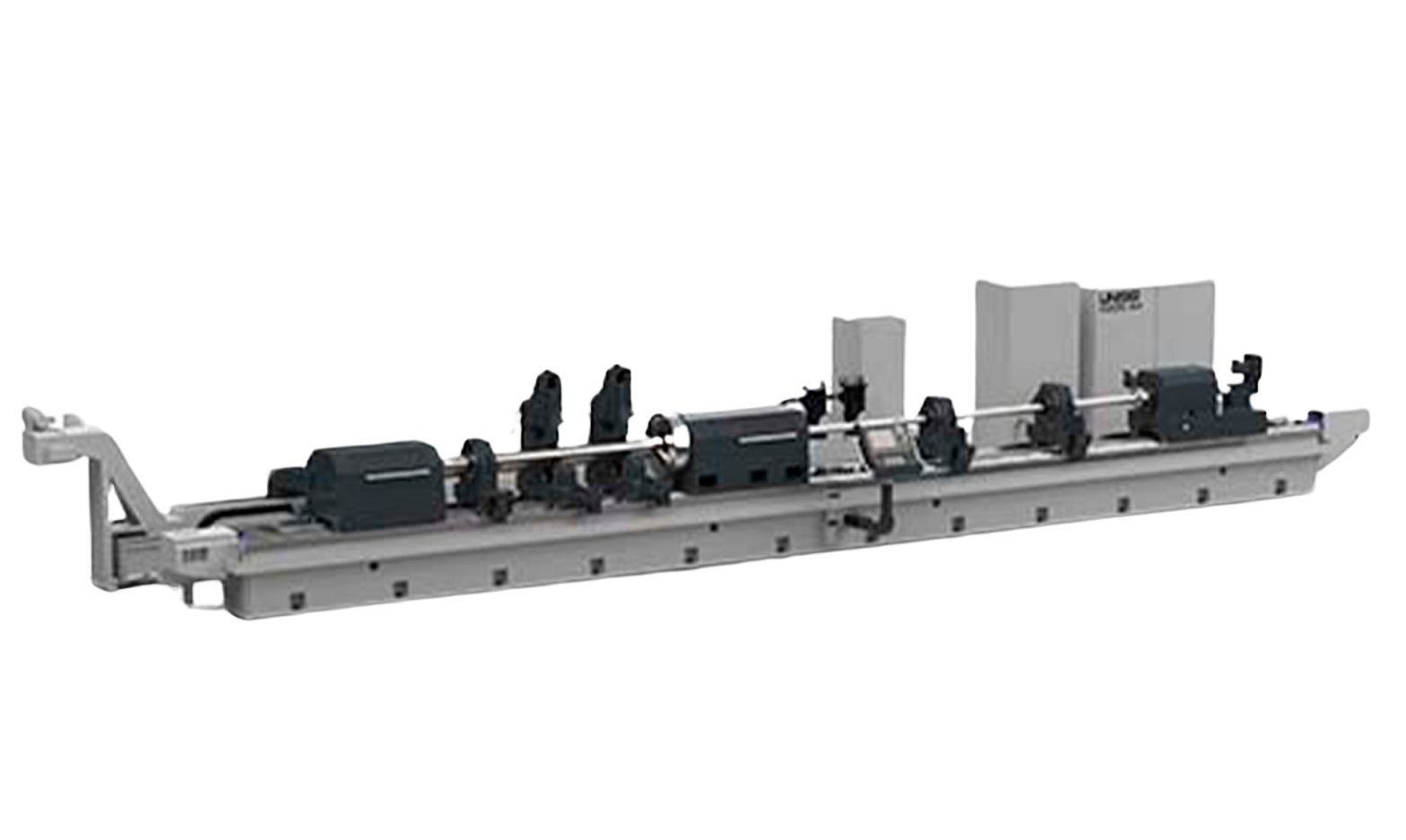

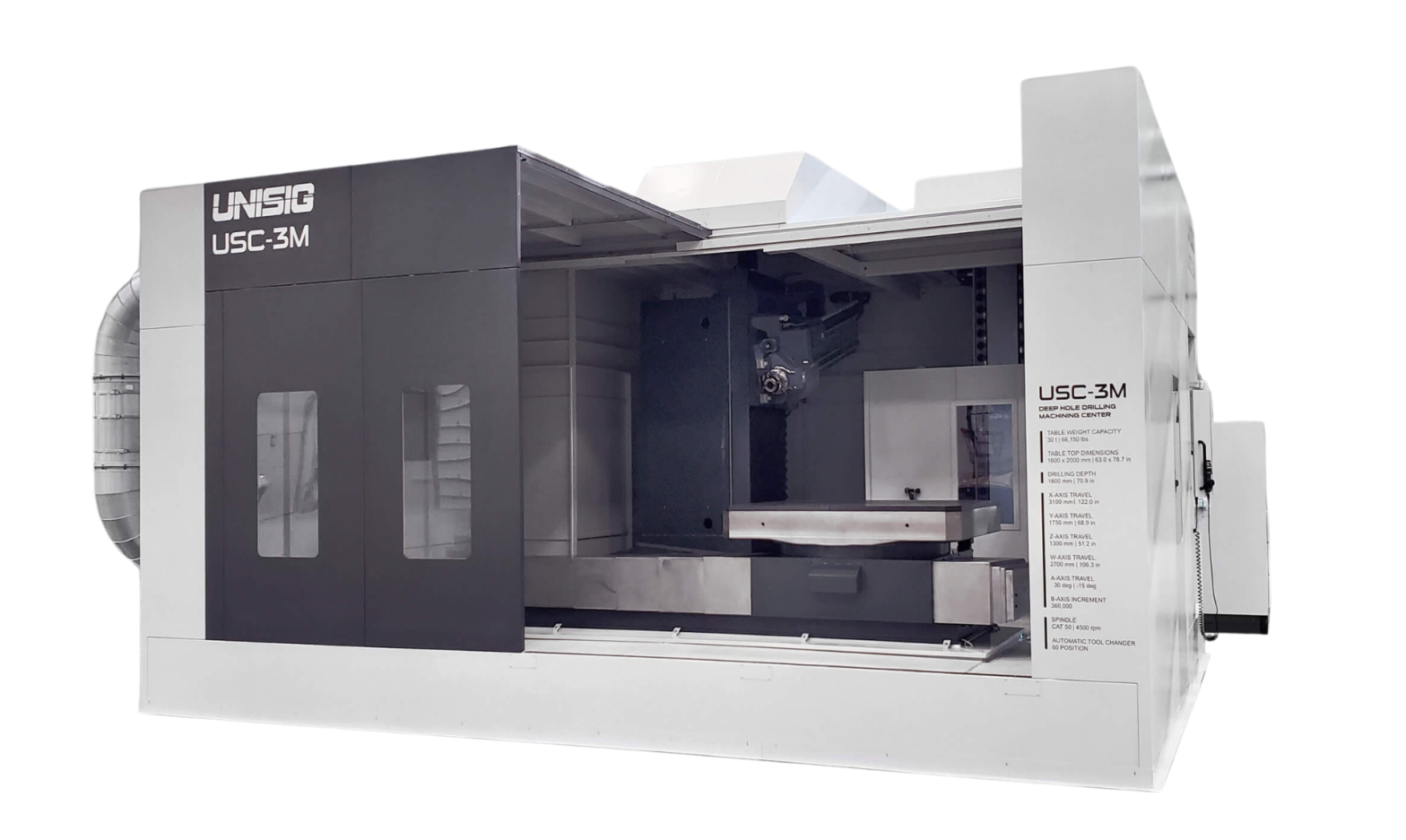

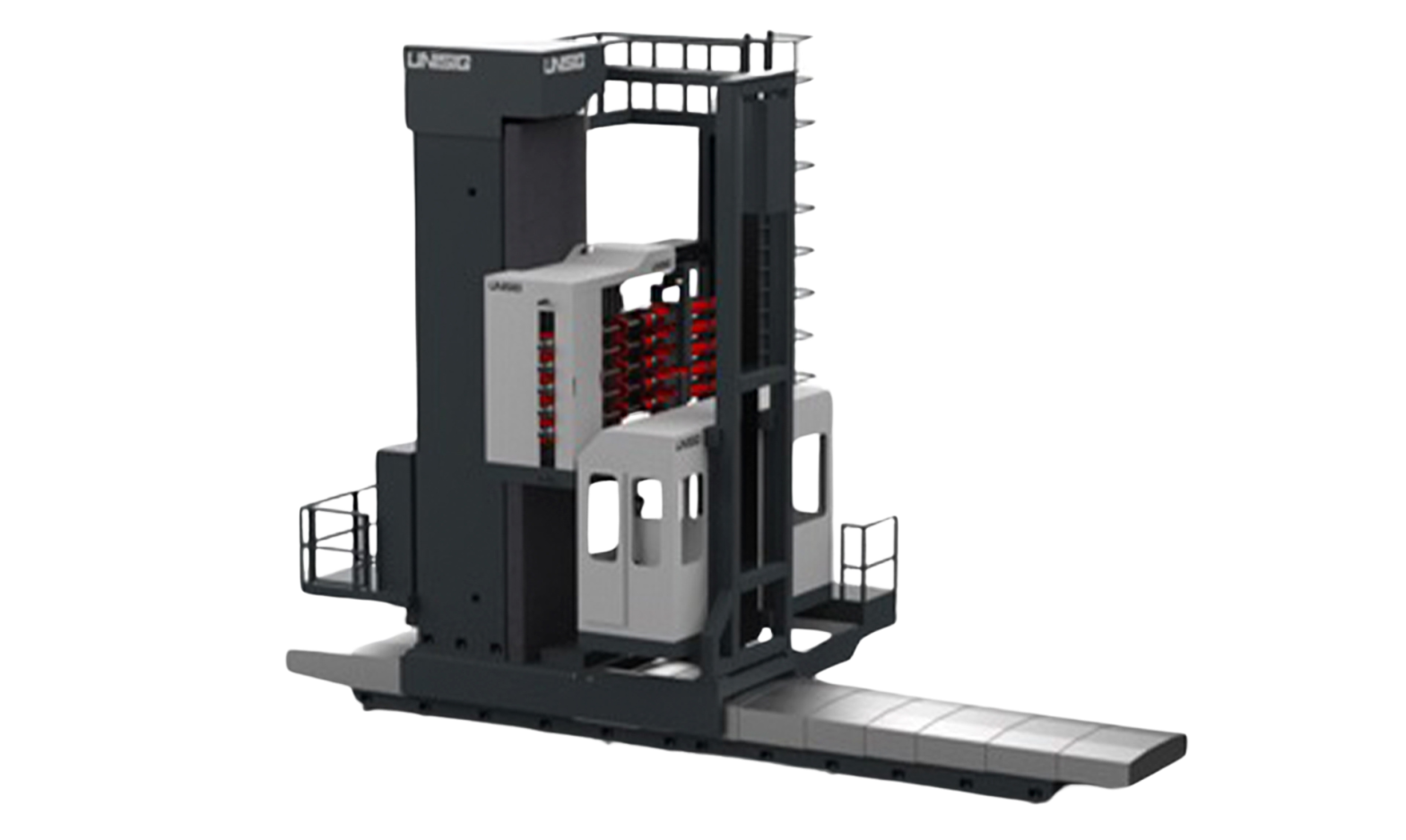

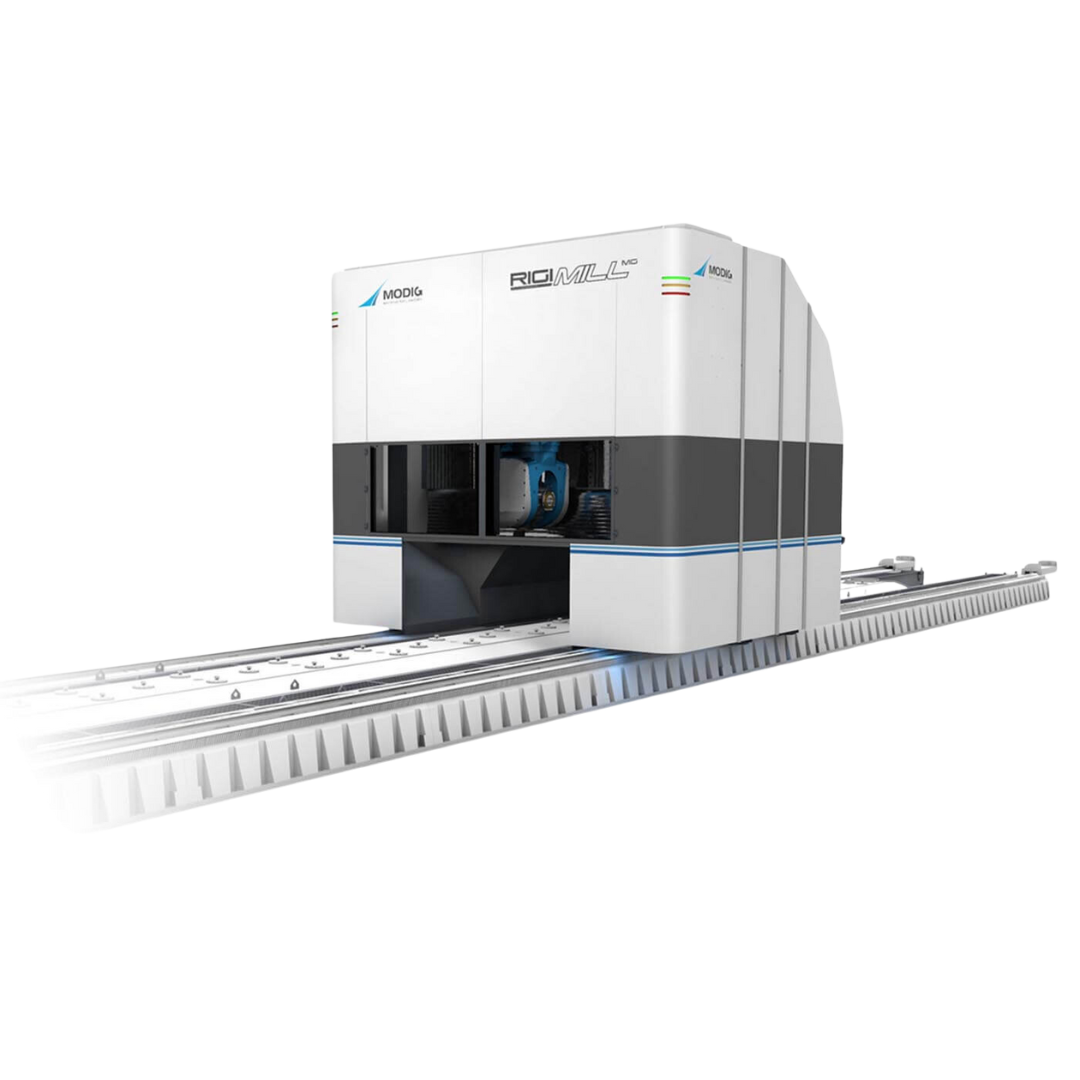

The RigiMill MG features a chip removal rate of 1,200 cubic inches (19.7 liters) per minute in aerospace aluminum and is available with an automatic pallet system up to 950 ″ (24 m).

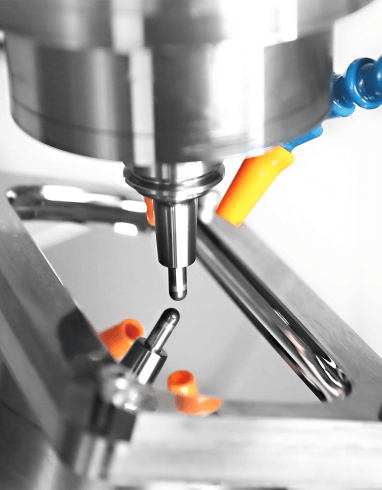

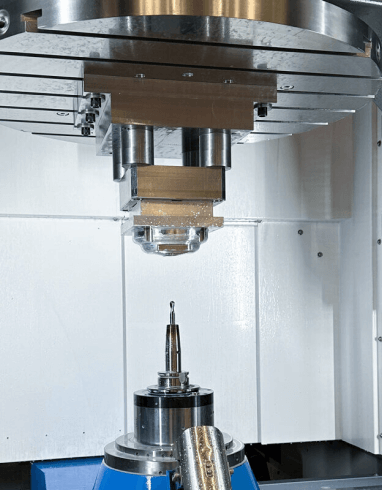

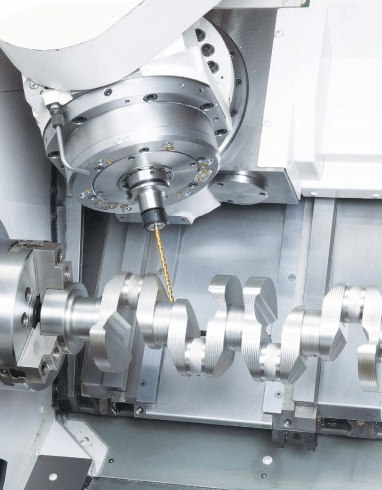

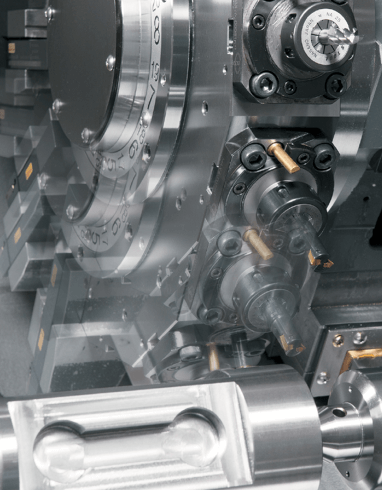

The RigiMill Moving Gantry (MG) was developed to produce the world's fastest chip removal rates. Various spindle configurations achieve chip removal rates of up to 55 cubic inches/min (0.9 liters/min) on titanium and 1,200 cubic inches/min (19.7 liters/min) on aluminum. This machine allows the same machine to be used for roughing and finishing. Equipped with a high-speed gantry and a single spindle, the RigiMill MG provides the highest quality and precision machining of aluminum or hard metals.

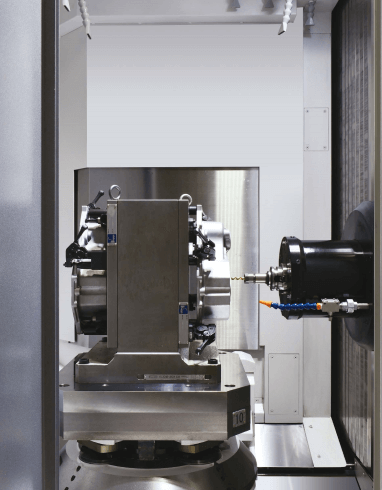

Its unique architecture and compact gantry structure make it a highly efficient machine. In addition, it is highly rigid thanks to its heavy cast iron monobloc bridge structure and vertically movable cross rail.

The deliberately small scale of the RigiMill MG is an innovative design solution that offers new achievable performance compared to existing machines on the market. It can be configured to the specific needs of each customer and can be extended in the X-axis direction after installation. RigiMill MG is the world's best manufacturing platform for machining long parts.

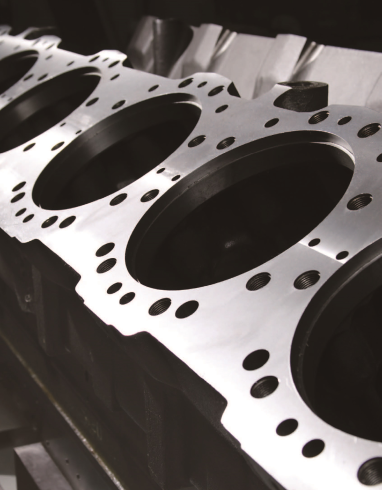

Industries

Aerospace

Automotive

Energy

Heavy Duty

Medical

Molds & Dies

Others

Key product information

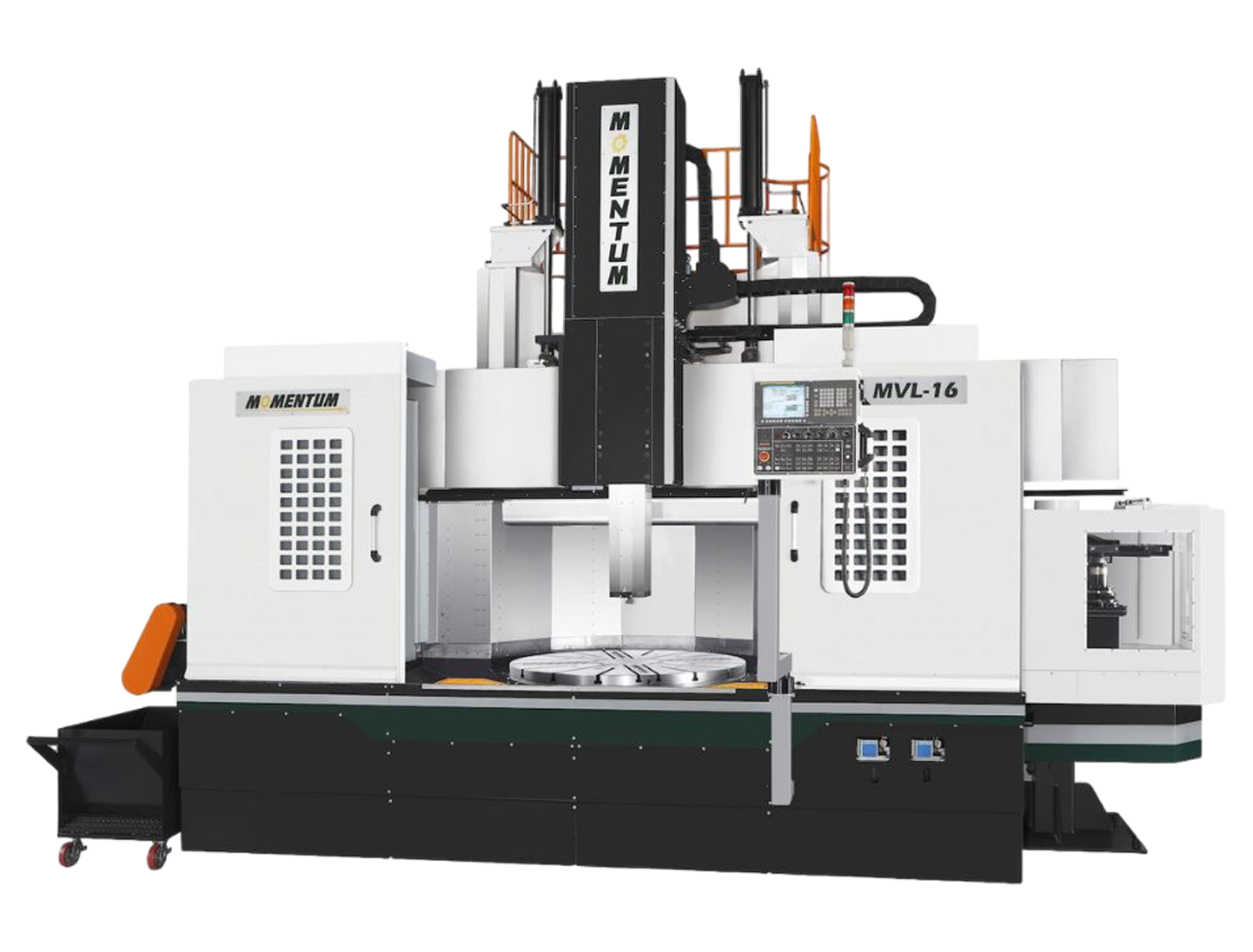

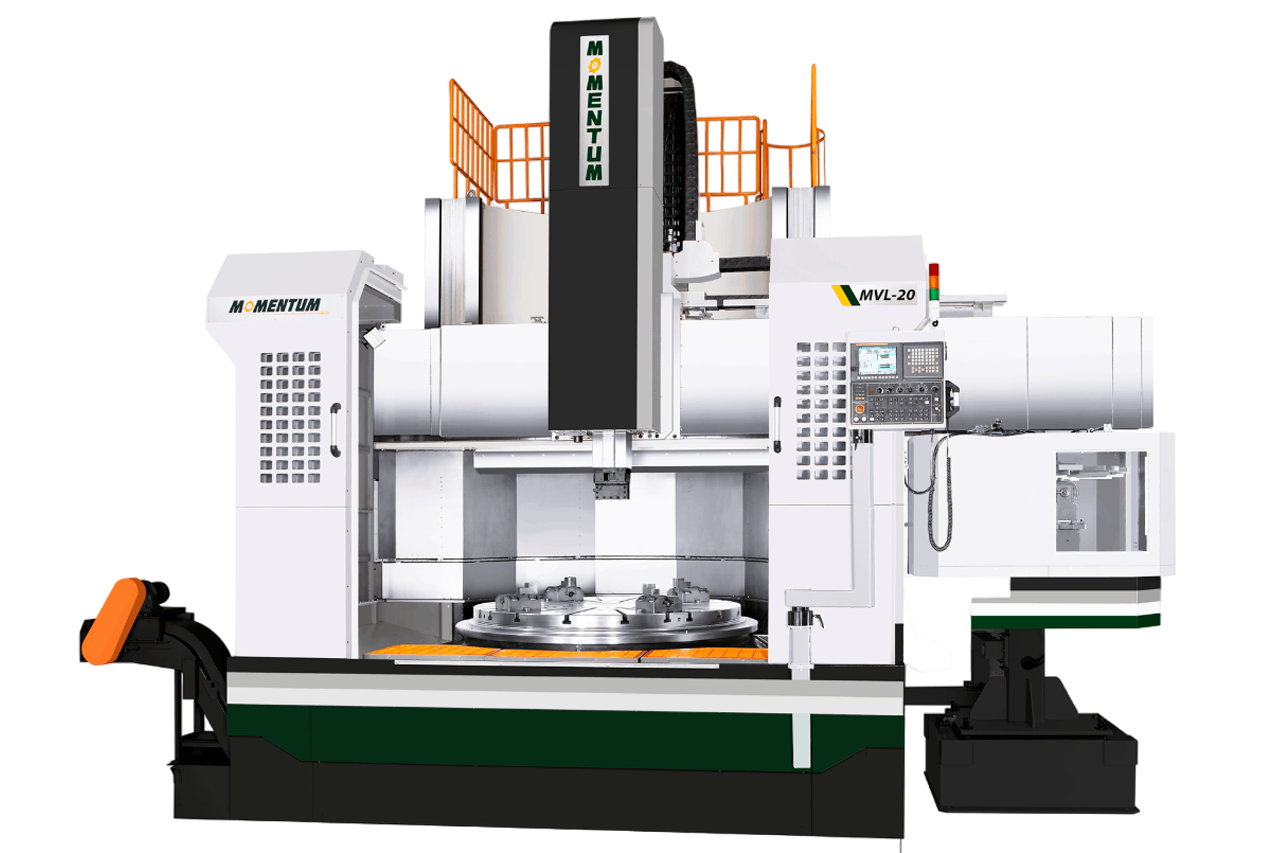

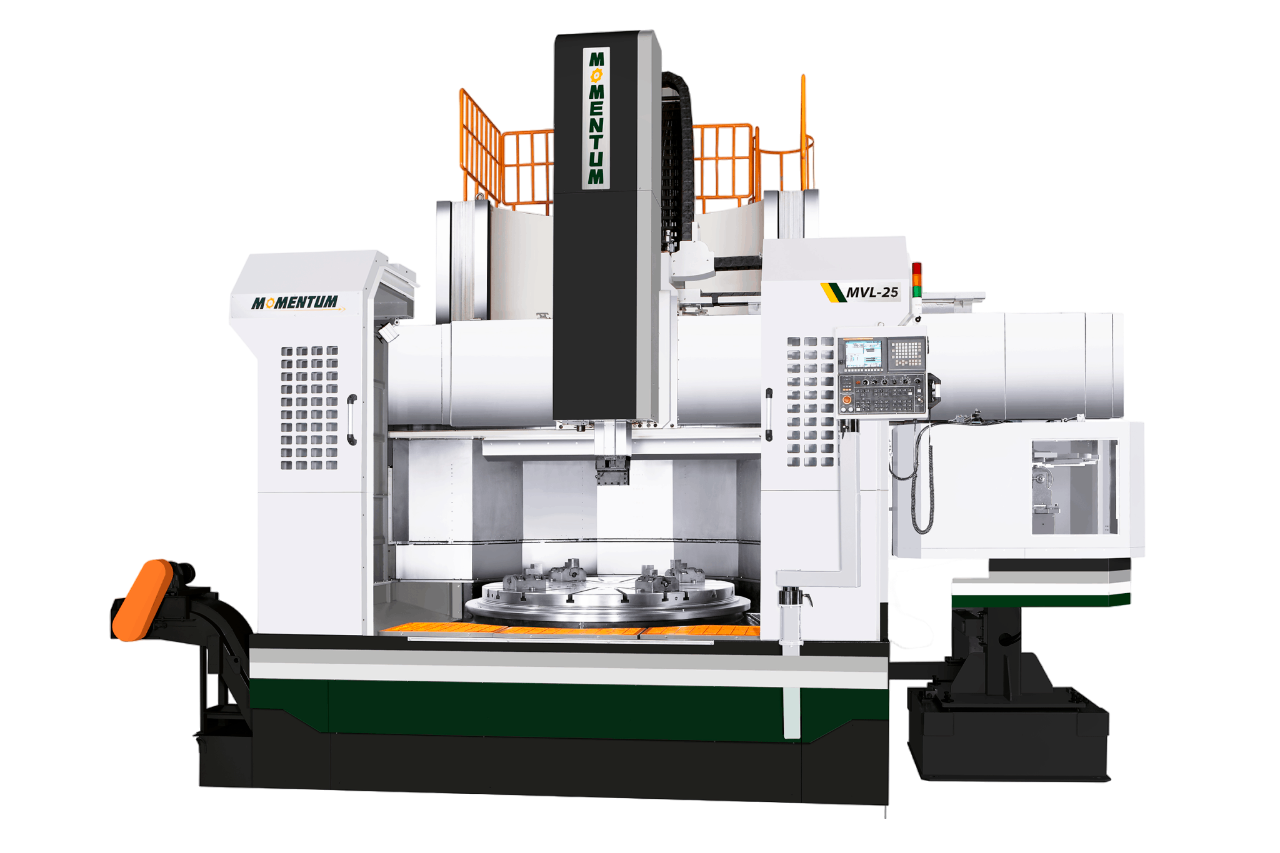

Maximum part size (in)Maximum part size (mm)

Unlimited x 61 x 35 Unlimited x 1560 x 900

Travel (X / Y / Z / C / A) [in]Travel (X / Y / Z / C / A) [mm]

Unlimited / 61.4 / 35.4 / +/- 360 / +/- 110Unlimited / 1560 / 900 / +/- 360 / +/- 110

Maximum part height (in)Maximum part height (mm)

35.4 900

Maximum part cross-section (length / width / height) [in]Maximum part cross-section (length / width / height) [mm]

Unlimited x 61.4 x 35.4Unlimited x 1560 x 900

Standard Spindle (Speed) [rpm] [rpm]

8,000

Aluminum spindle (rpm)

30,000

Maximum weight (lbs)Maximum weight (kgs)

4420

Tool changer (# Tools)

In steps of 50 up to 500

Tool Changer (Tool Taper)

HSK 100 or HSK 125

Recommended solutions to improve your processes

Equip and maximize the productivity of your CNC machines with comprehensive solutions.

Accessories and peripherals

Mist collector

Cooling system

Coolant filtration and magnetic separator equipment

Learn more about PERIFERIQ

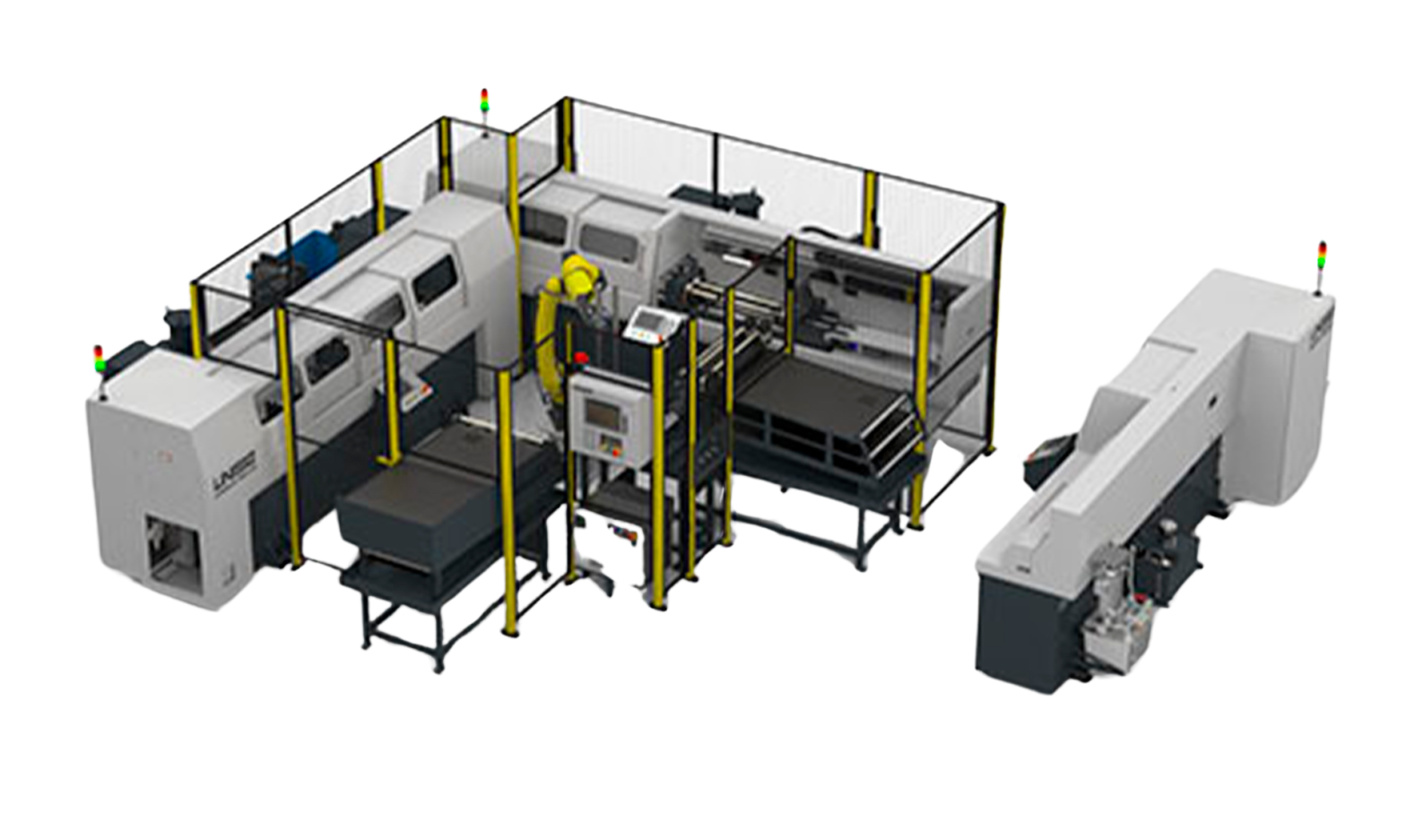

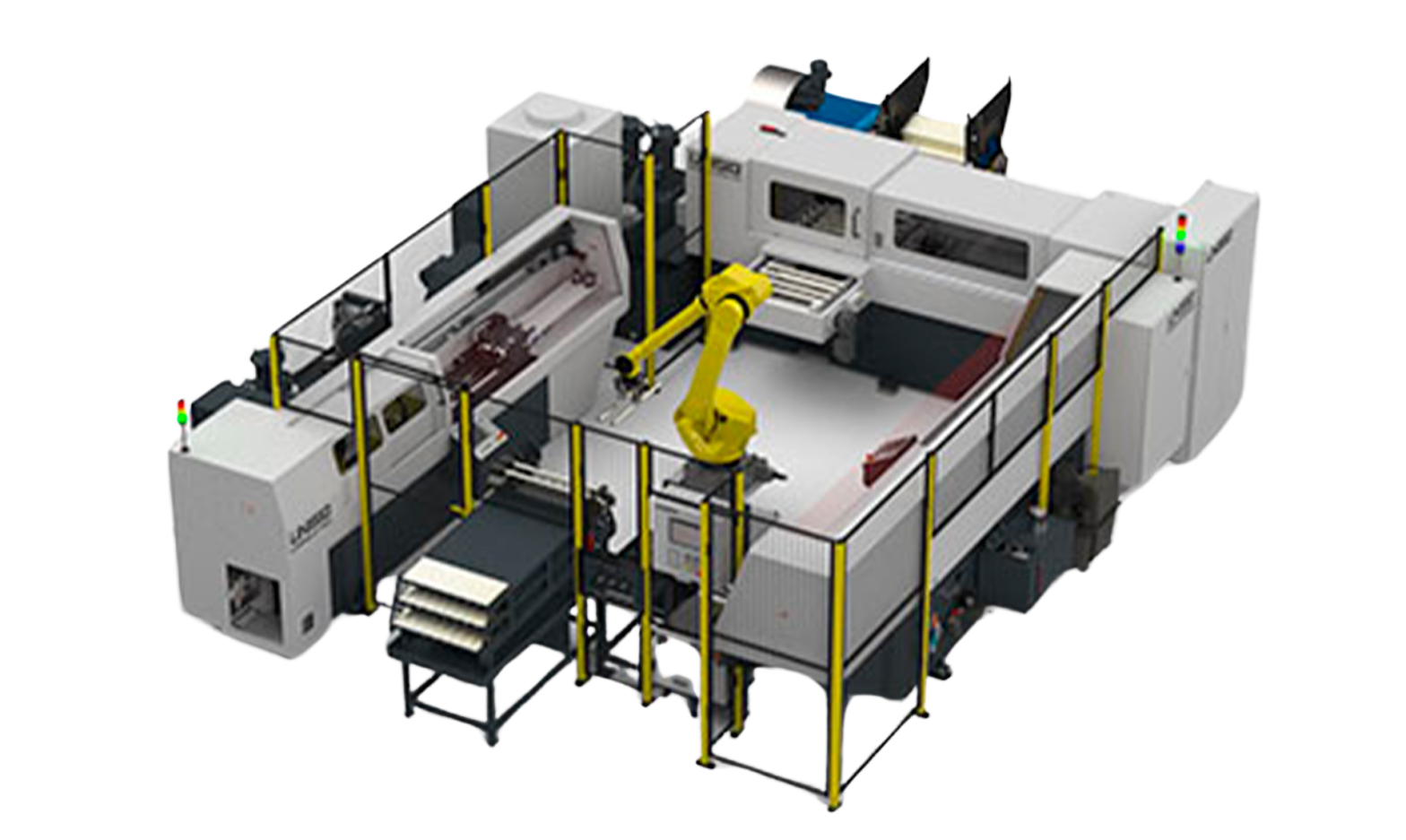

Creation and development of industrial automation customized to meet your needs.

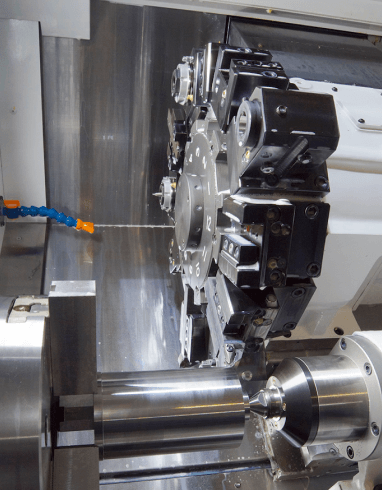

Automatic doors

Automated loading and unloading system

Safety and cleaning systems

Interfaces to external clamping systems

Learn more about OTOMATIQA