Unisig

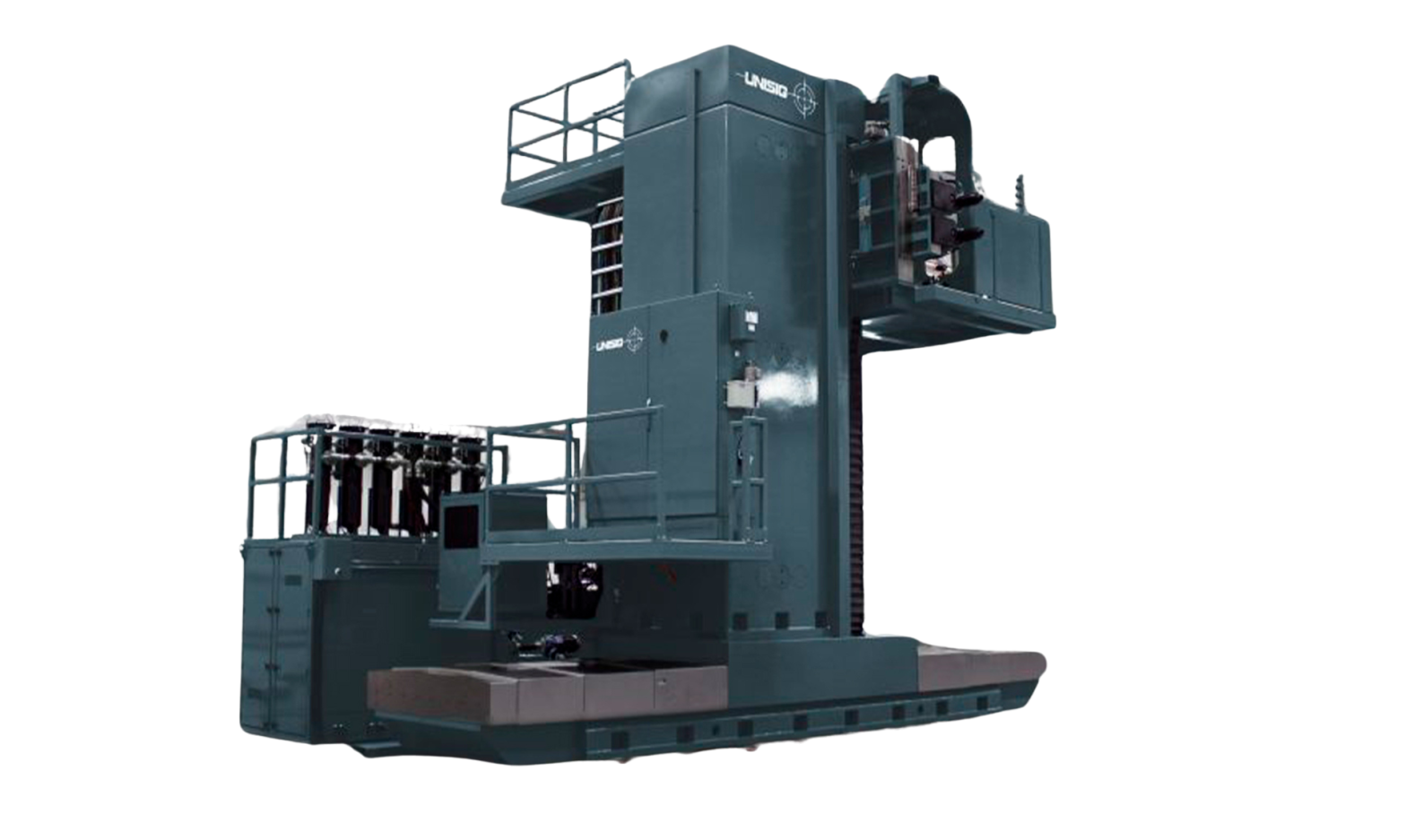

R200

Unisig

R200

Product description

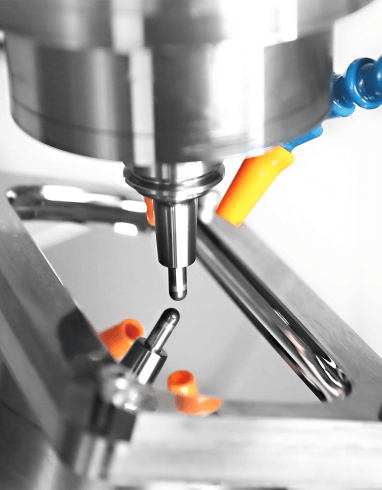

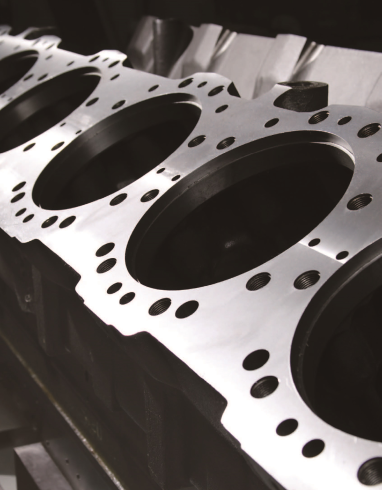

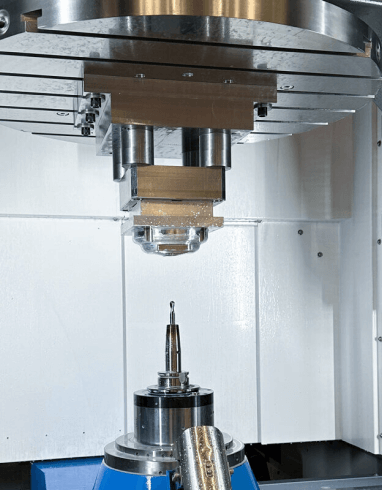

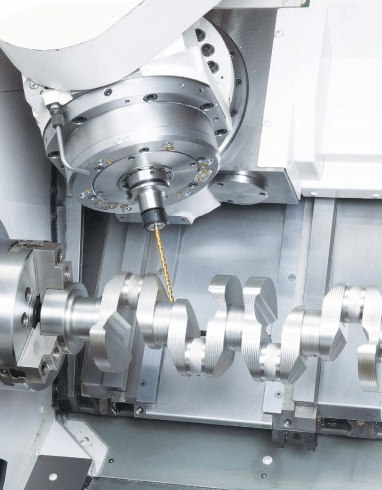

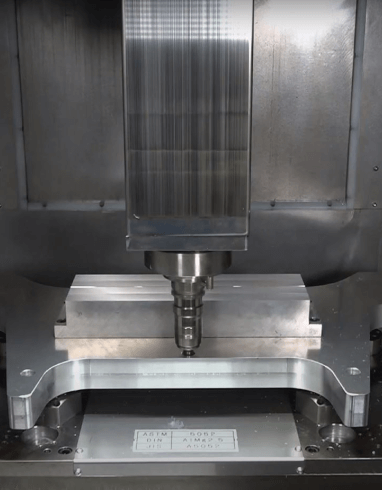

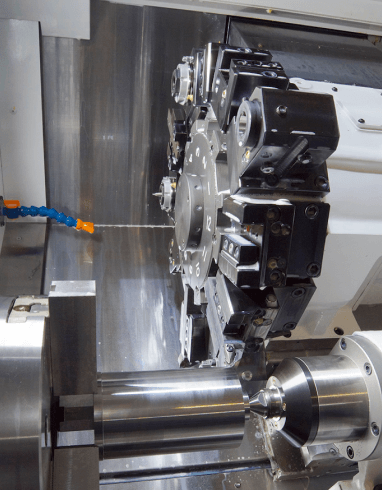

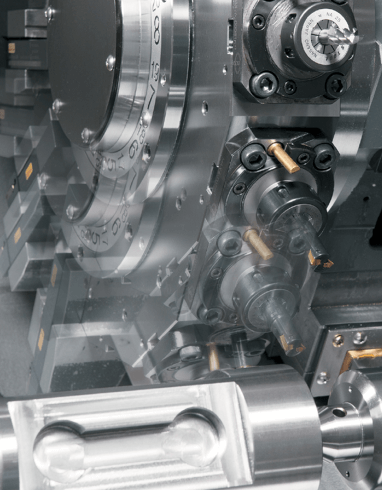

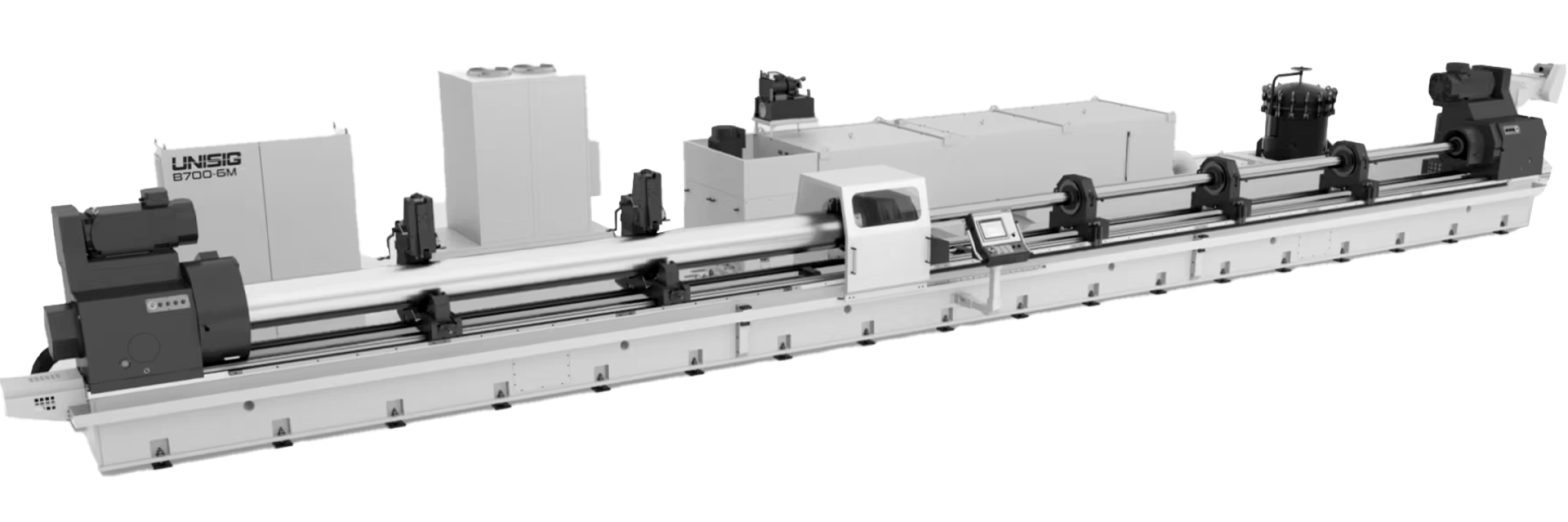

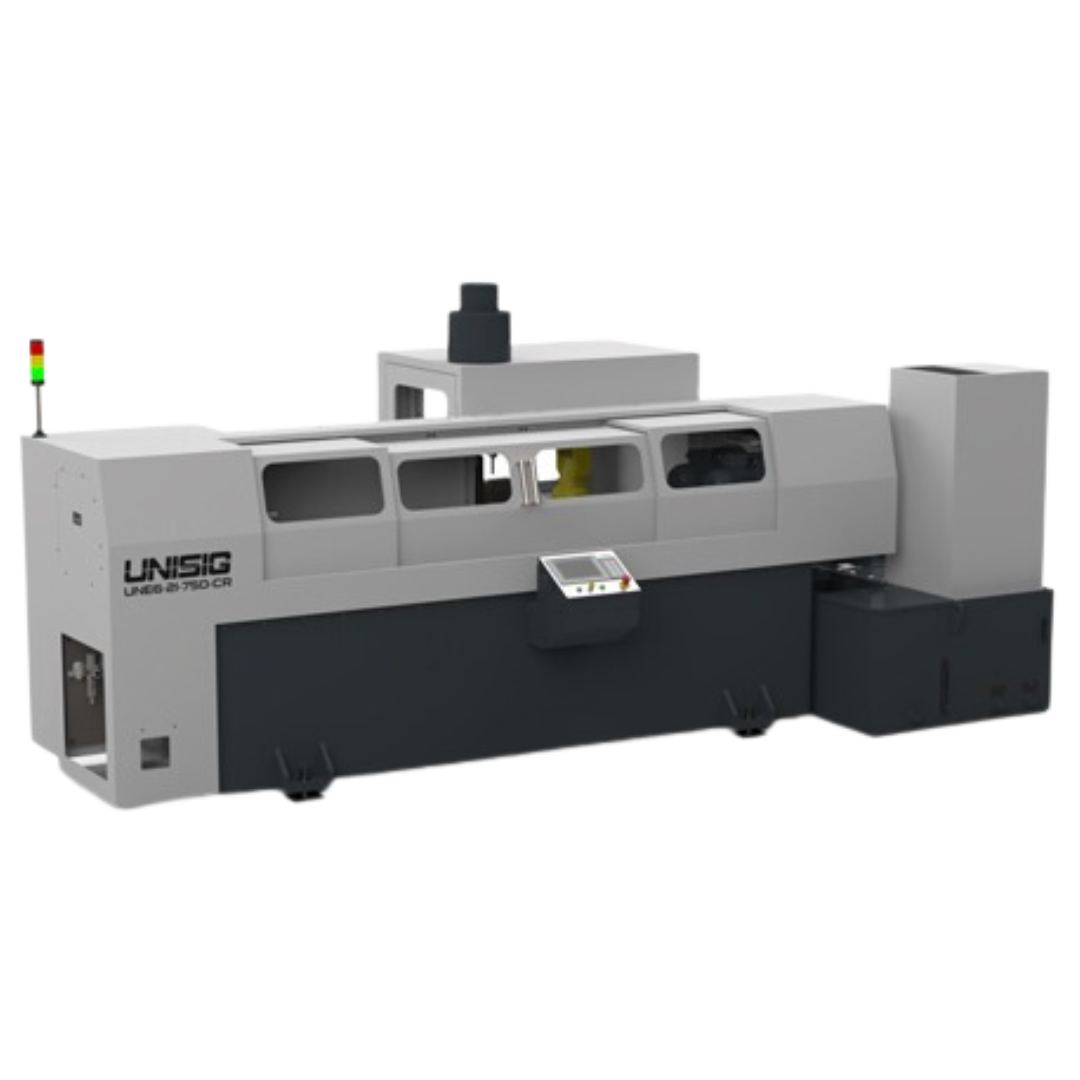

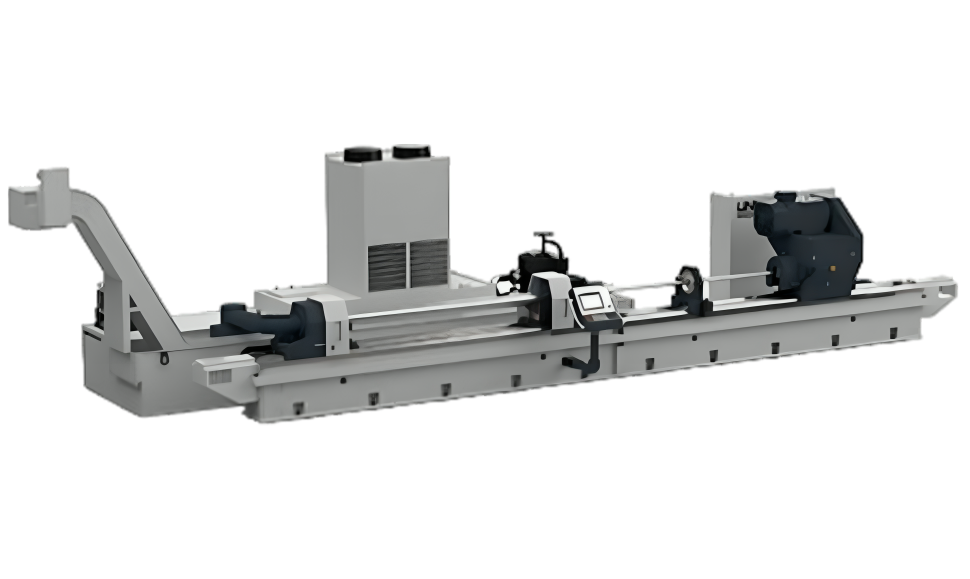

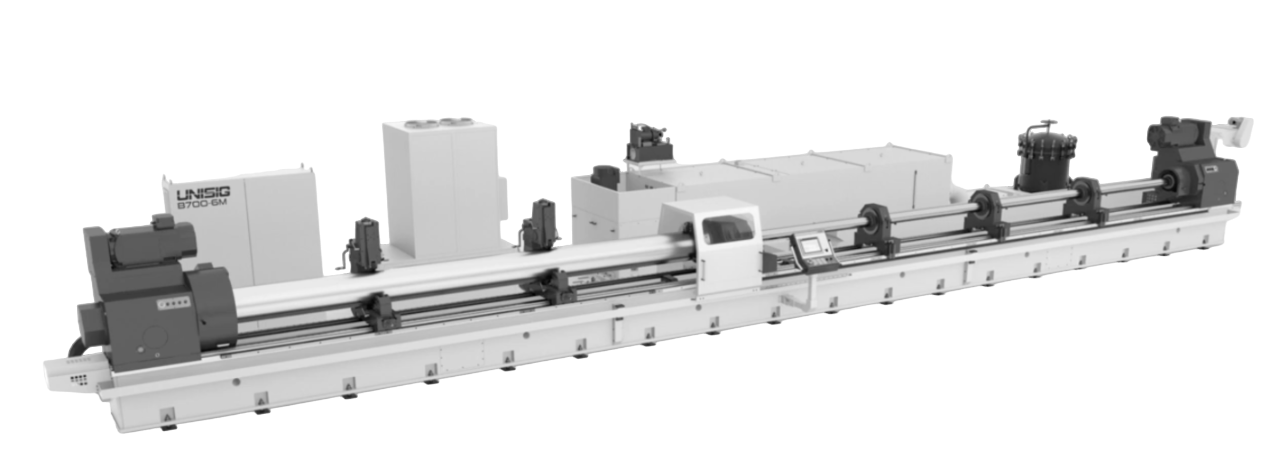

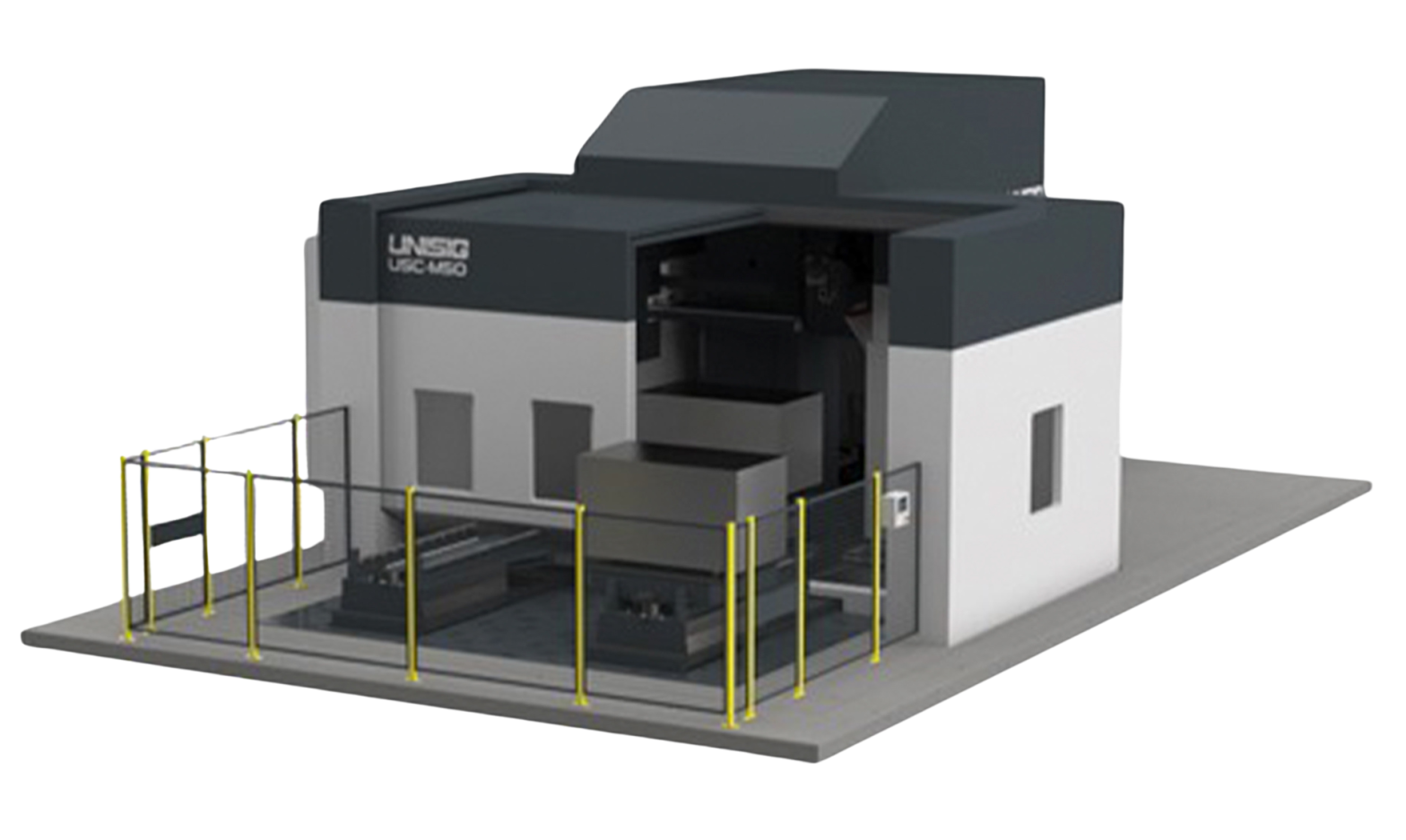

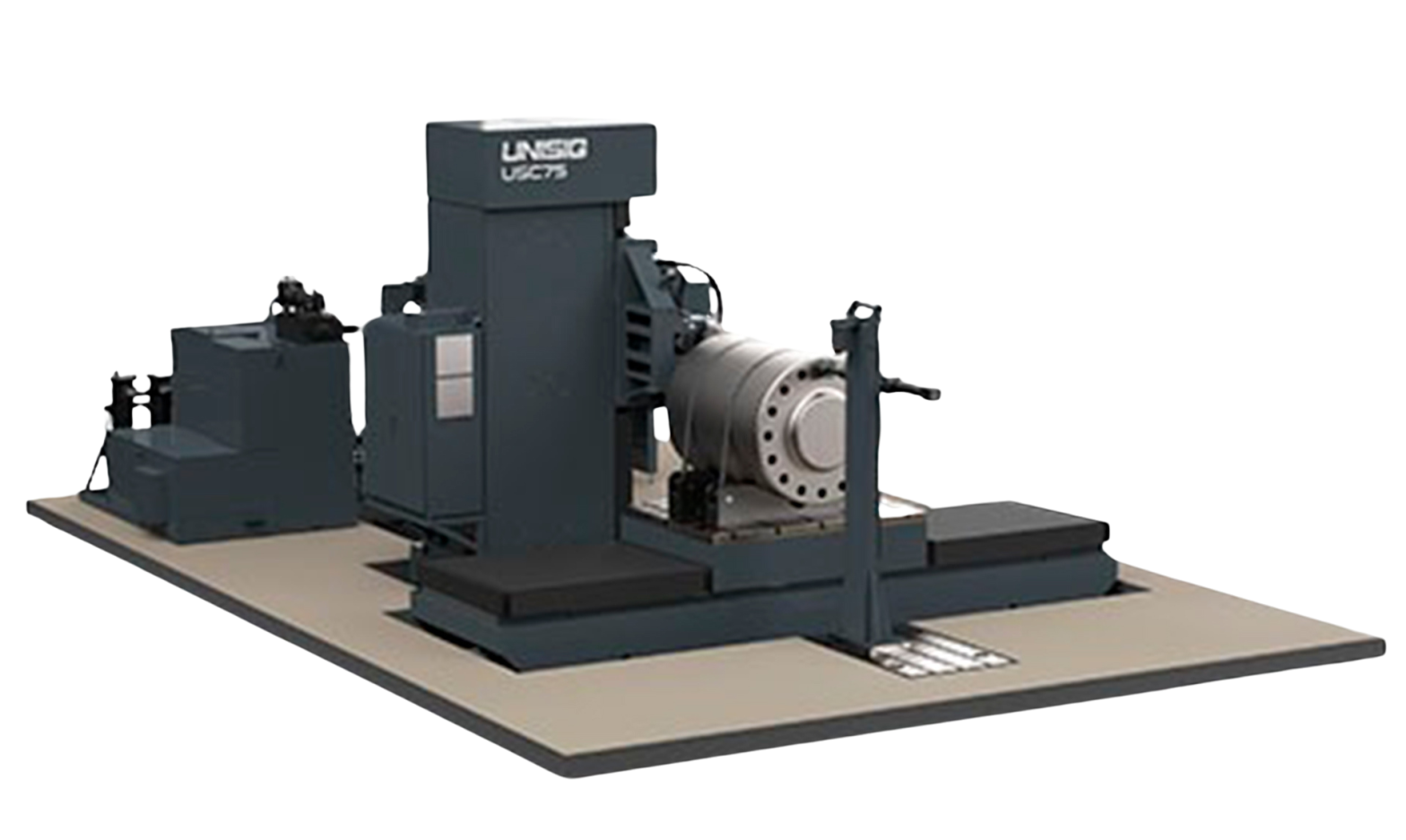

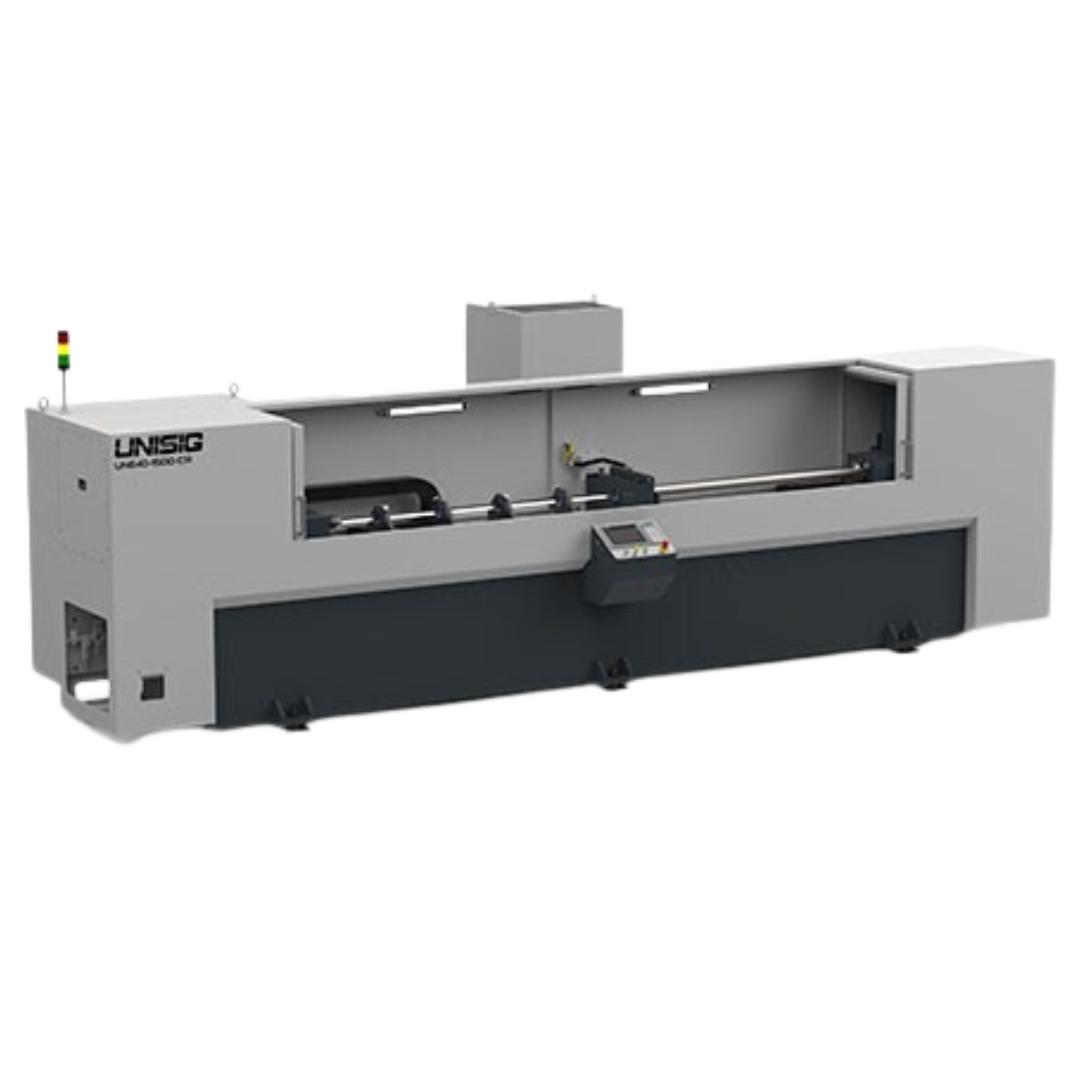

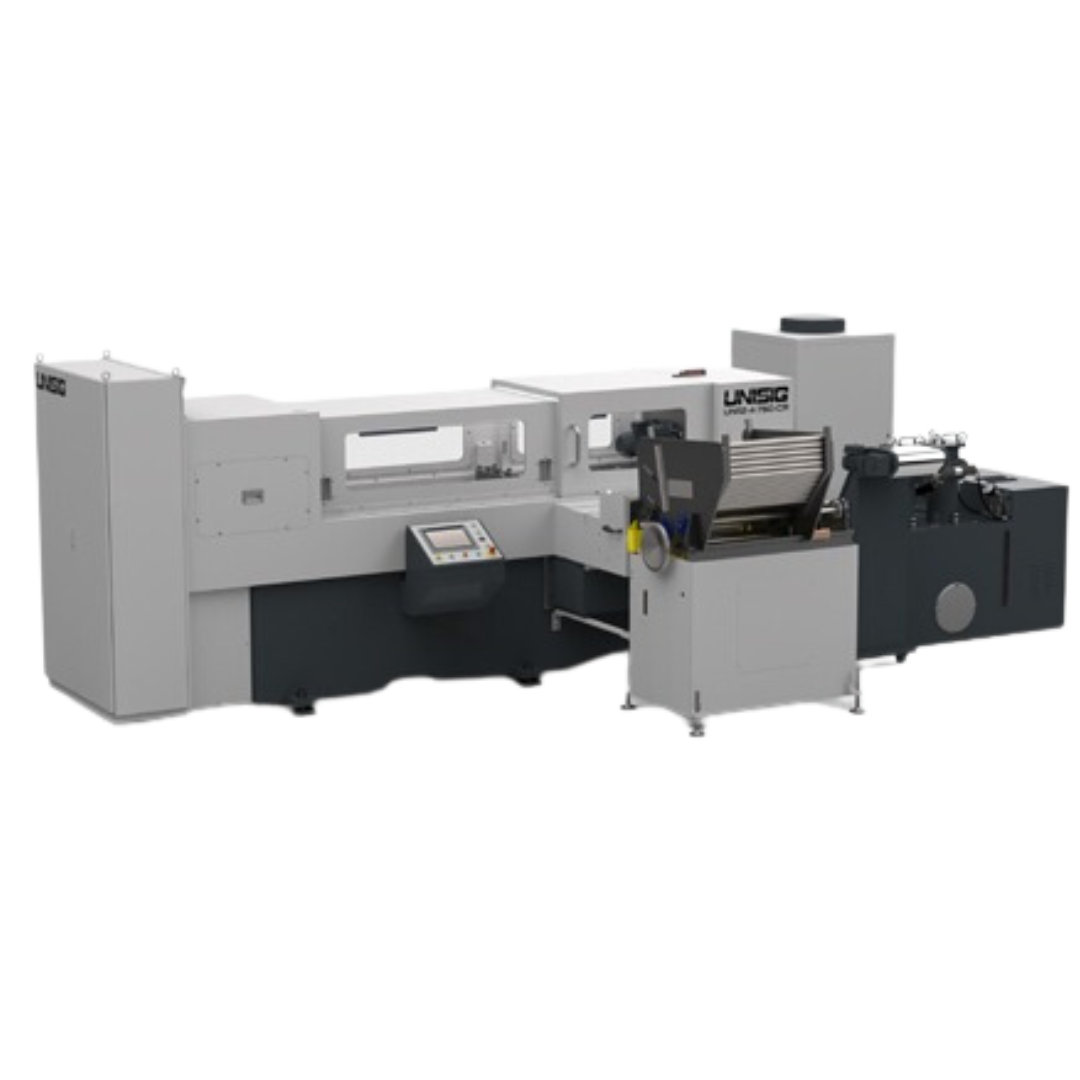

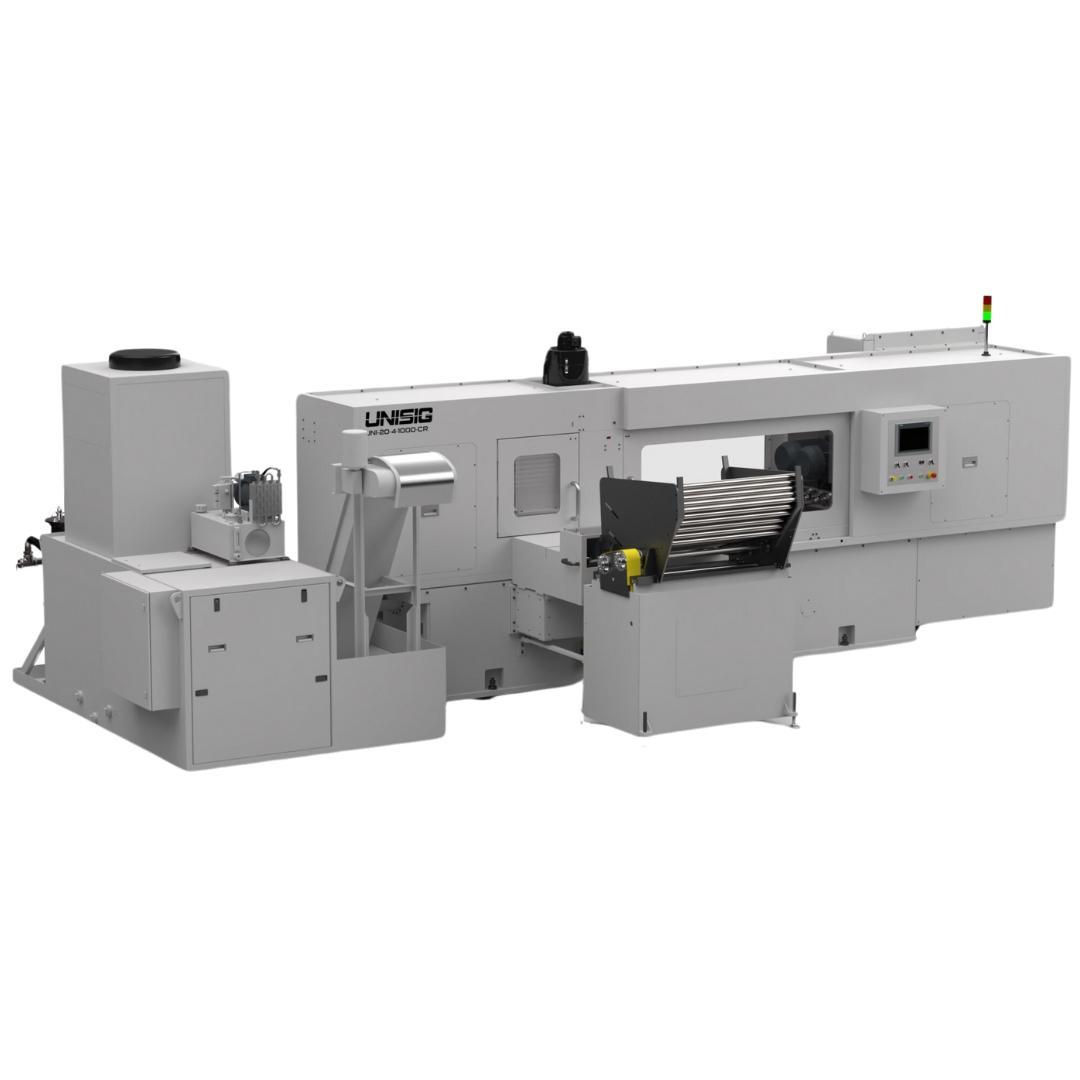

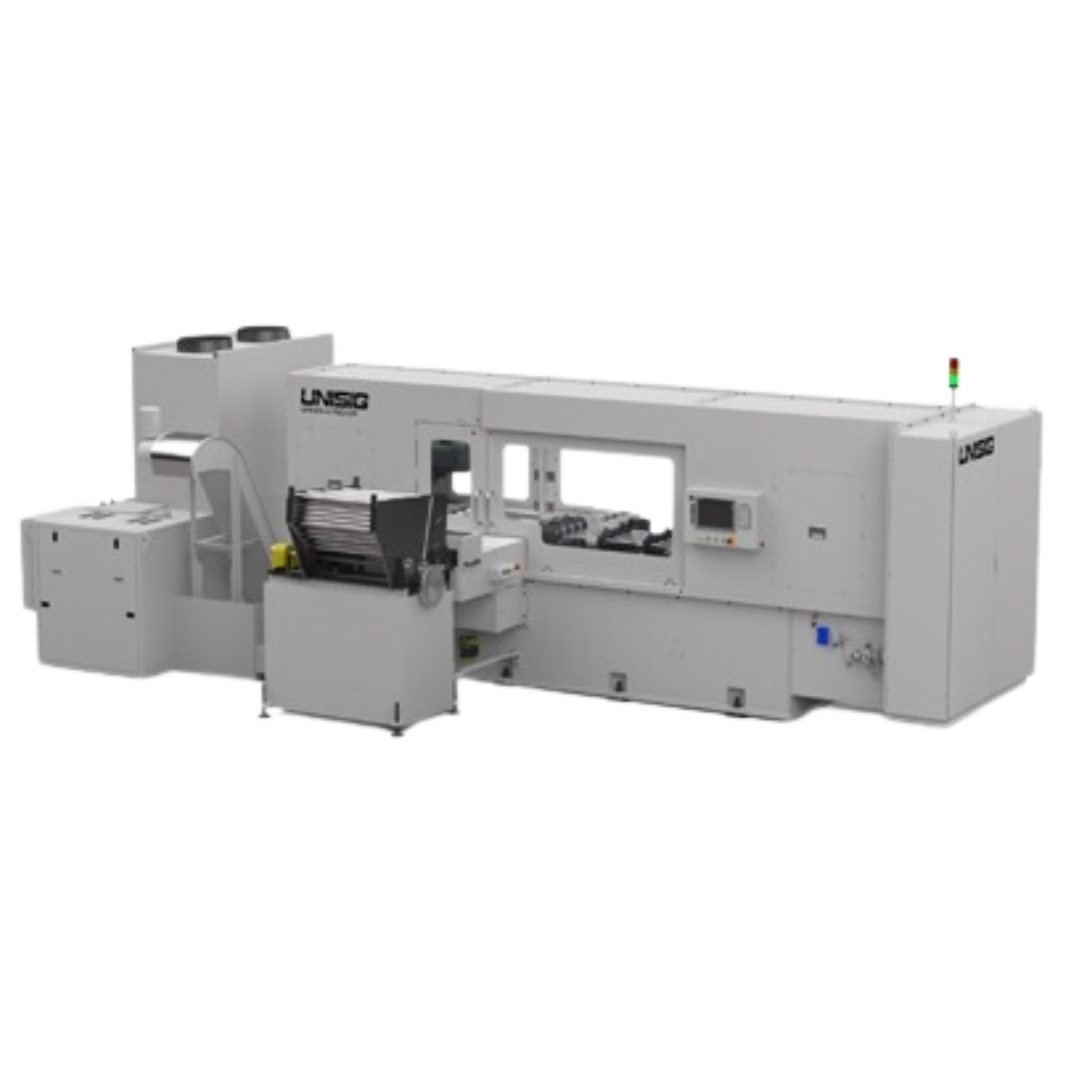

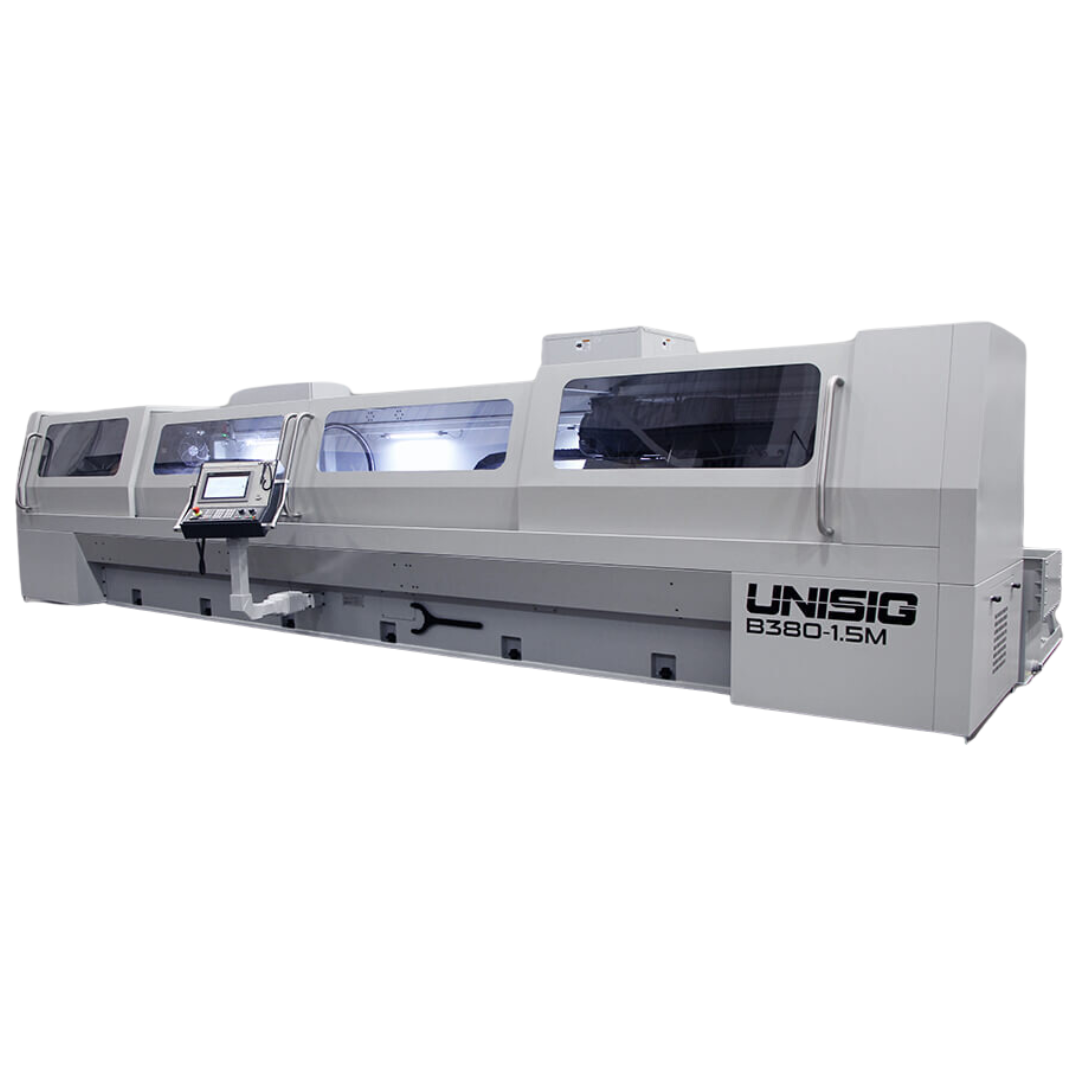

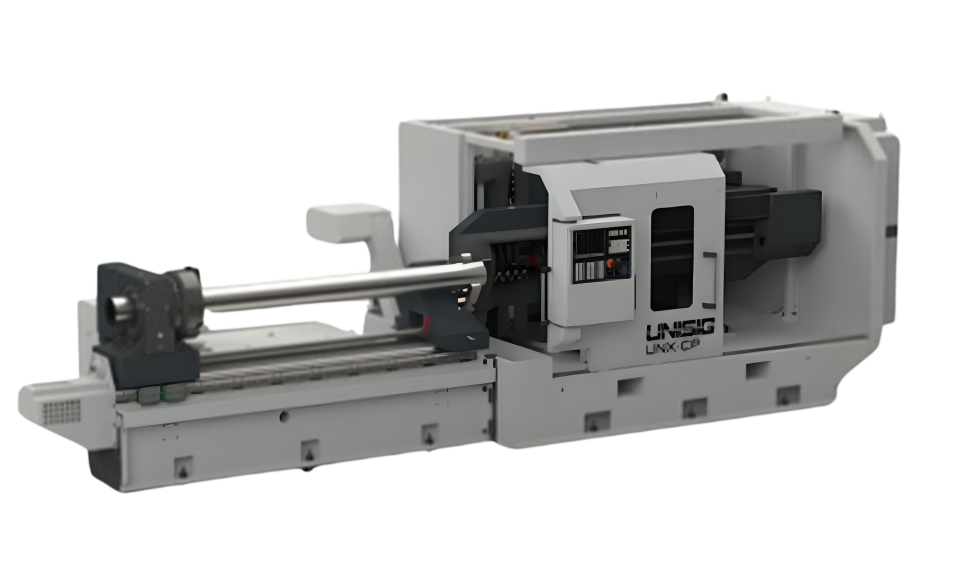

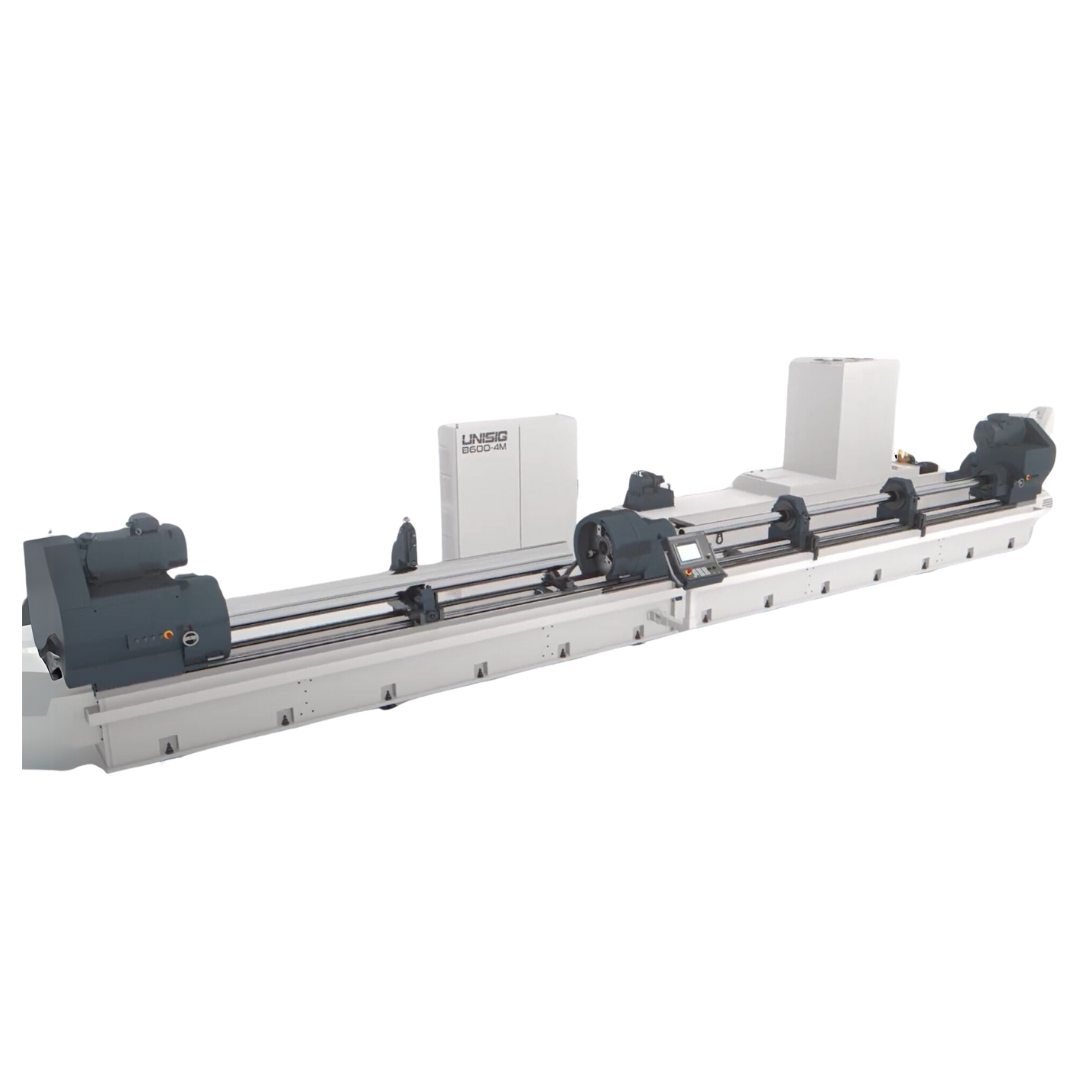

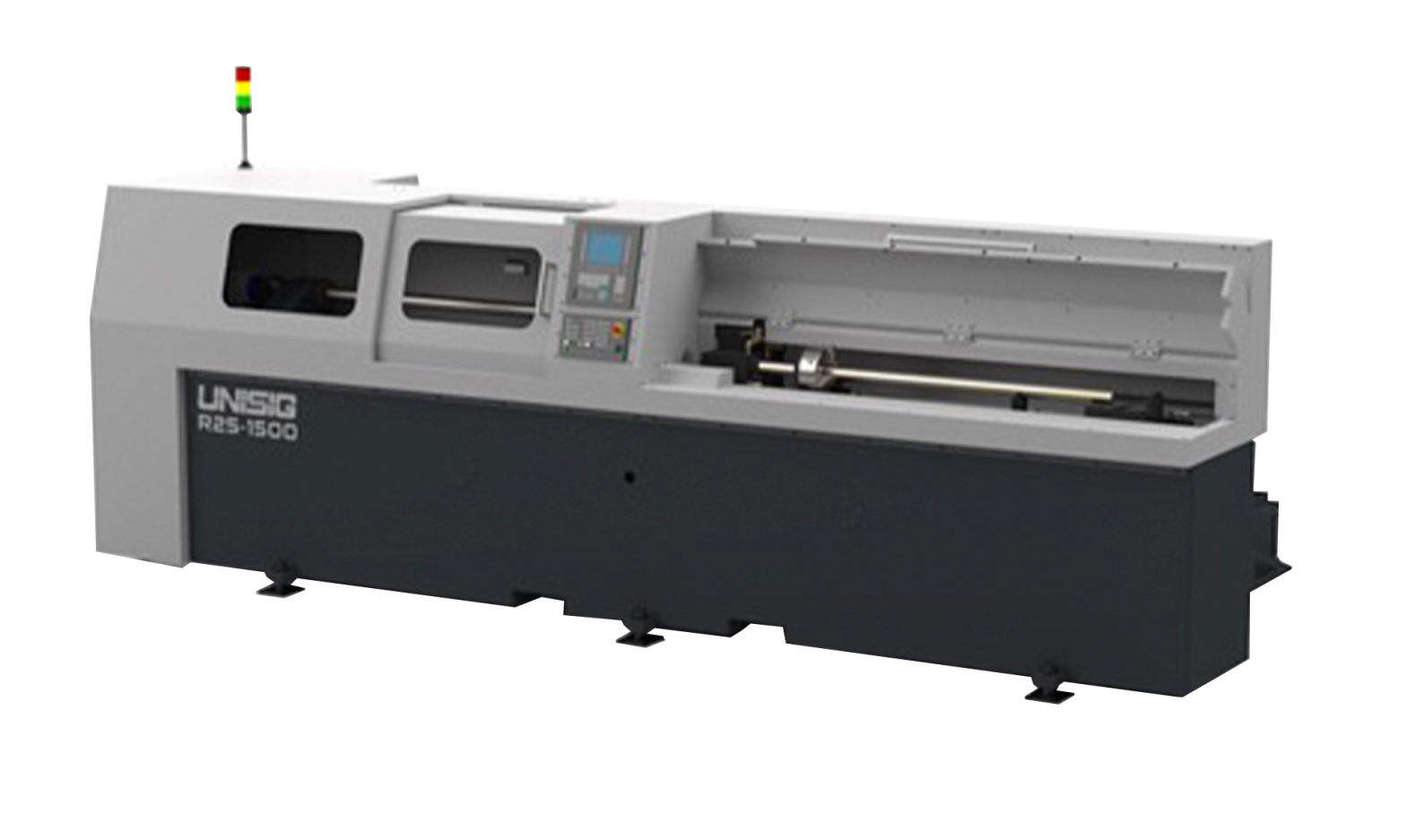

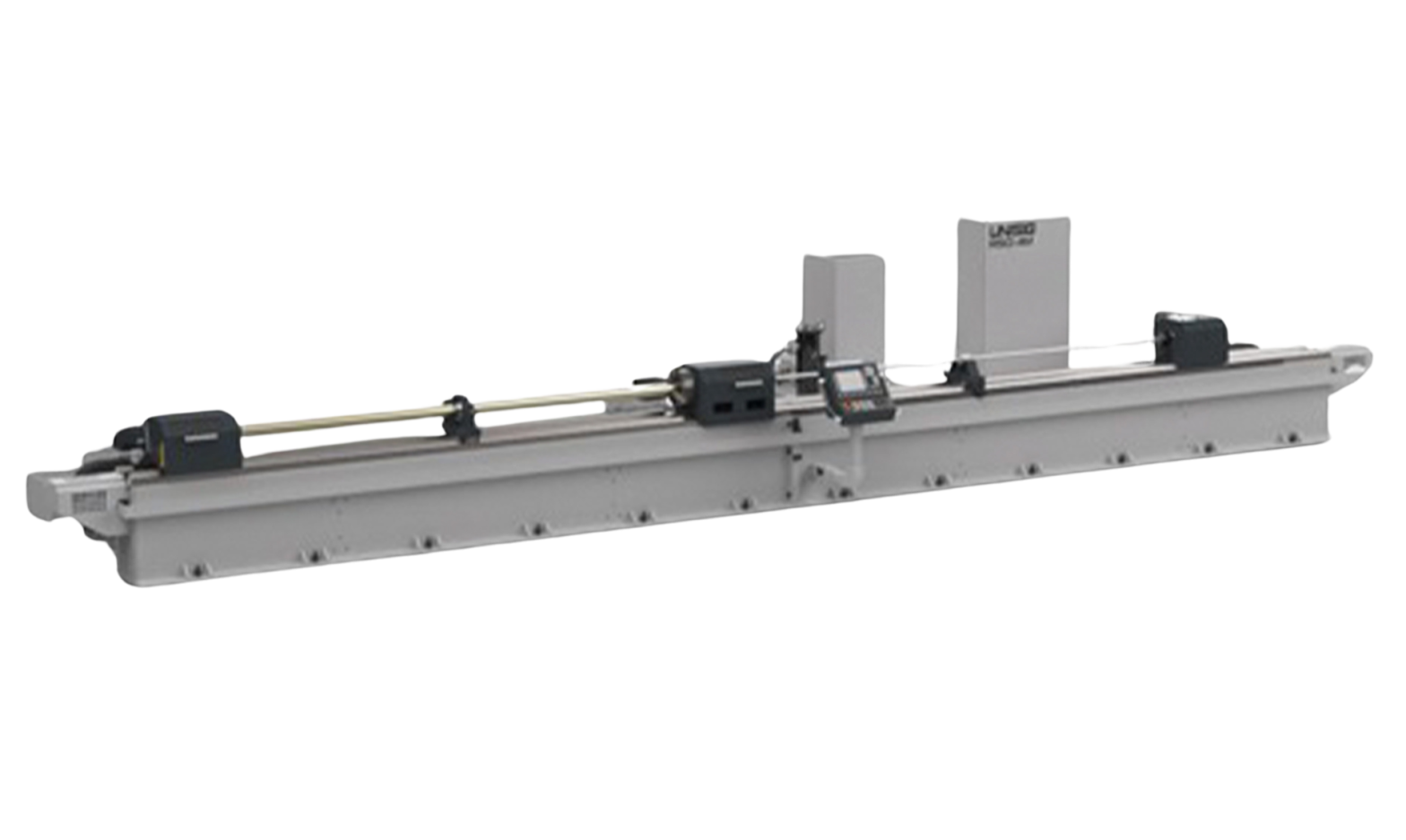

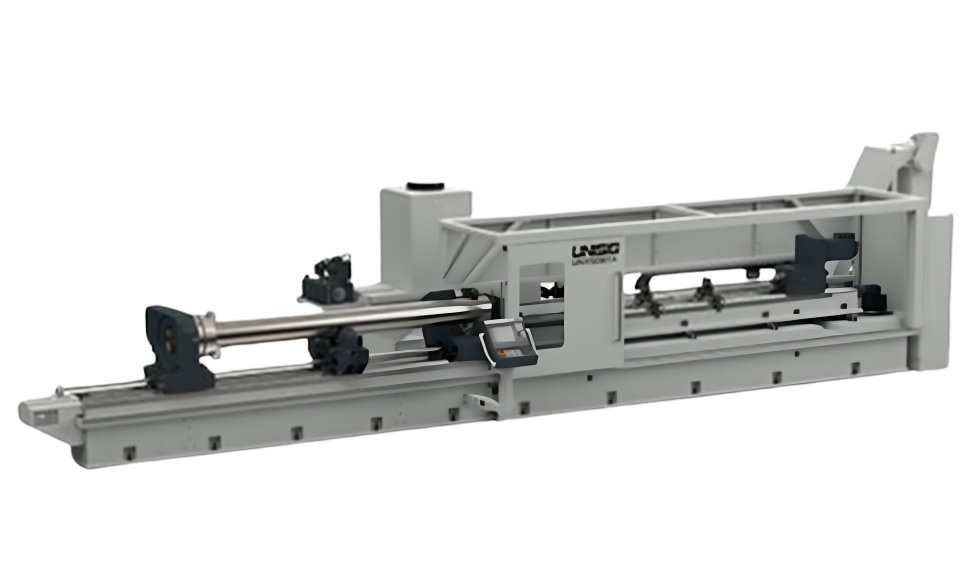

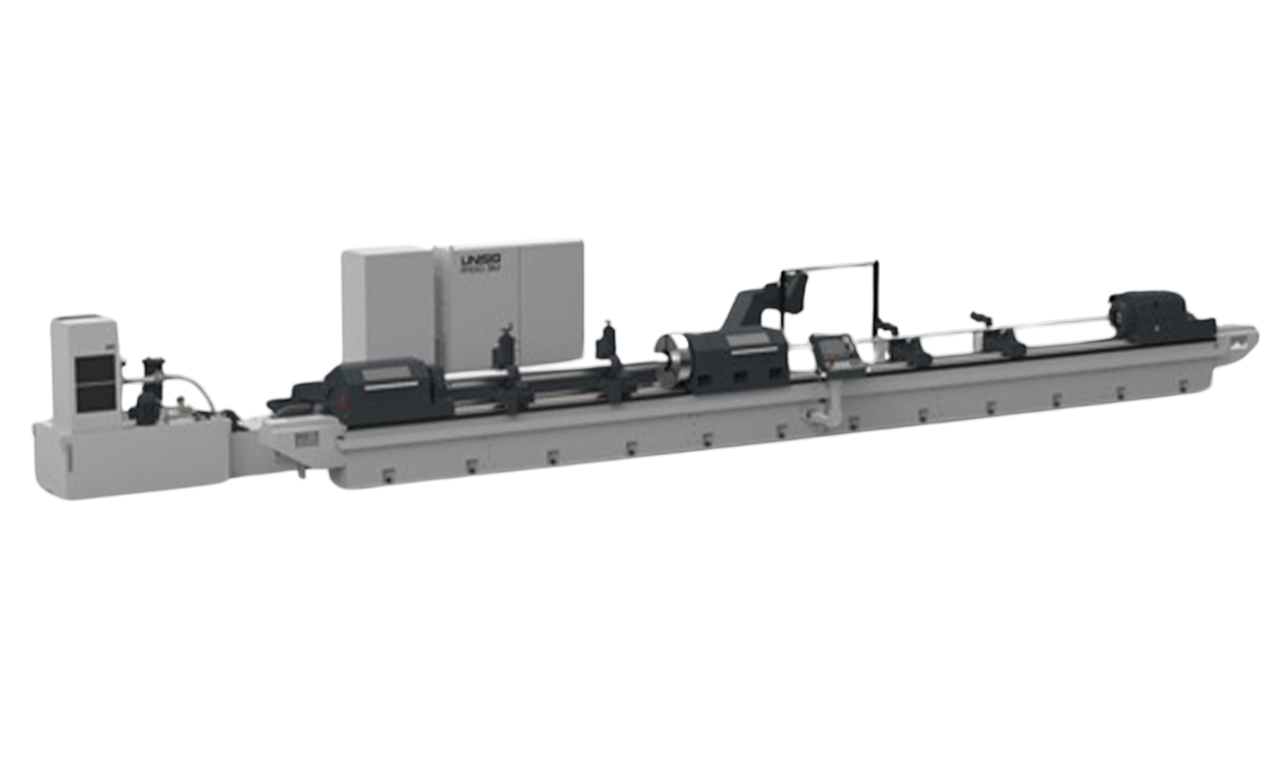

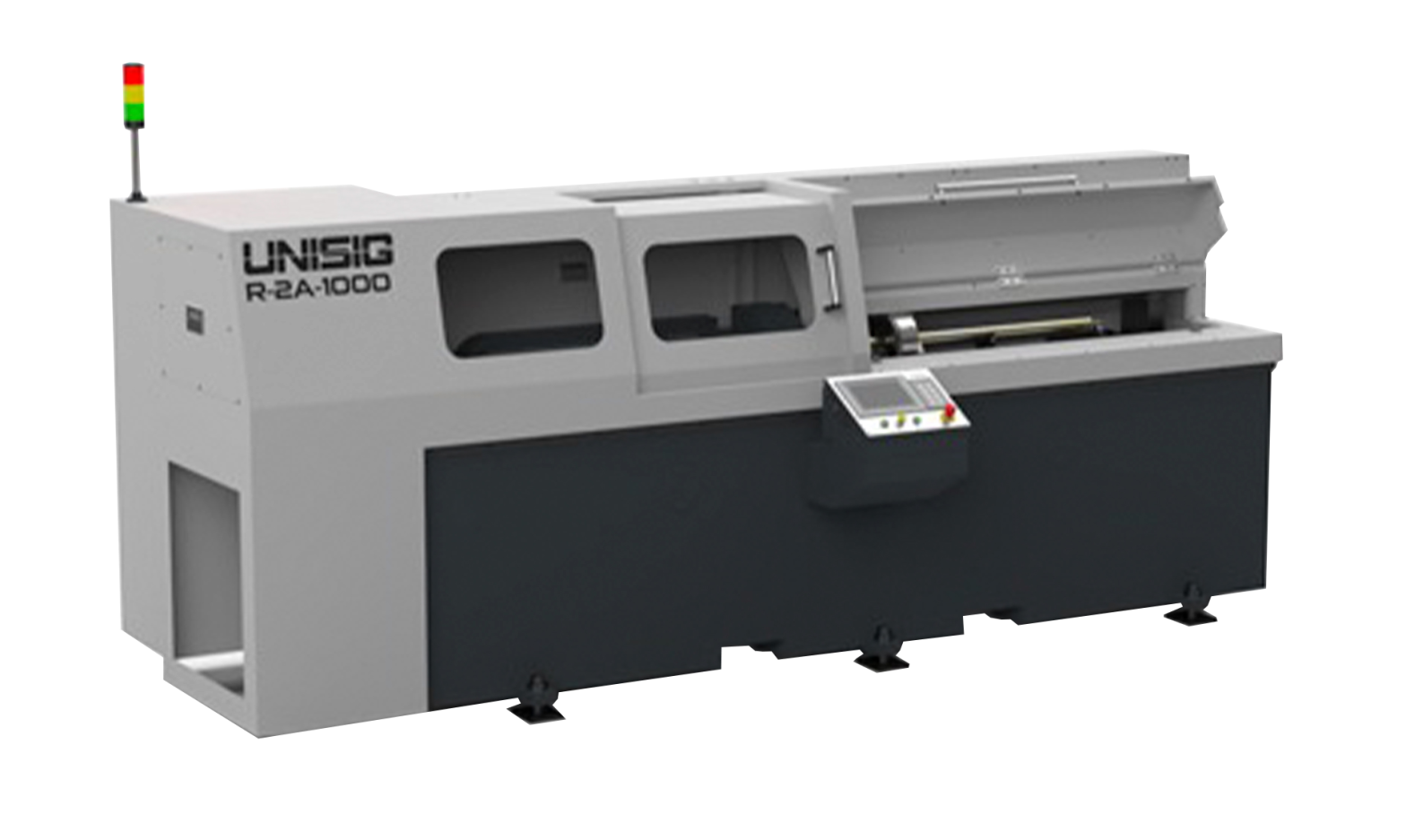

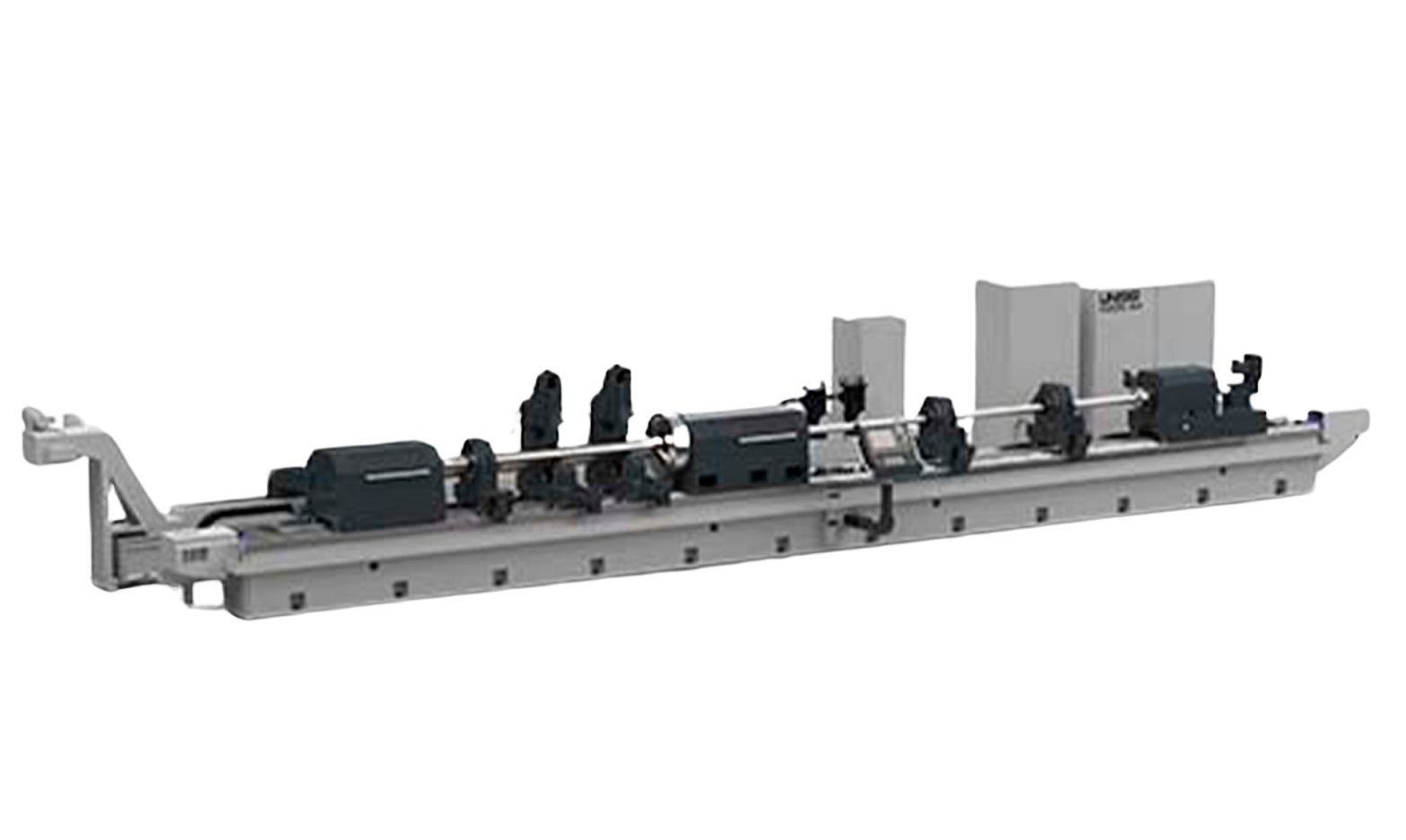

Accuracy and control in the rifling process create accuracy and control in finished rifle barrels. R-Series rifling machines use fully programmable twist rate for rifling, powered by servo-driven motors, and closed loop feedback to put unmatched manufacturing control in the hands of operators. Manufacturers are able to produce exceptional barrels in higher quantities, with intuitive technology and choice components.

R-Series rifling machines have a compact footprint with minimal installation, automatic tool lubrication, and available robot-ready or full automation. Machines utilize button rifling across all calibers of barrels, for precision rifle grooves. Intuitive operation allows rifle manufacturers to push the limits of rifle barrel technology with unmatched confidence.

Industries

Heavy Duty

Others

Product Highlights

Number of Spindles

1

Hole Diameter Min (in) Hole Diameter Min (mm)

0.512

Hole Diameter Max (in)Hole Diameter Max (mm)

8200

Hole Depth Max (in) Hole Depth Max (mm)

472.4412000

Workpiece dimensions (in) Workpiece dimensions (mm)

236, 394, 472, 8151000, 6000, 8000, 12000

Workpiece weight max (kg)

12000

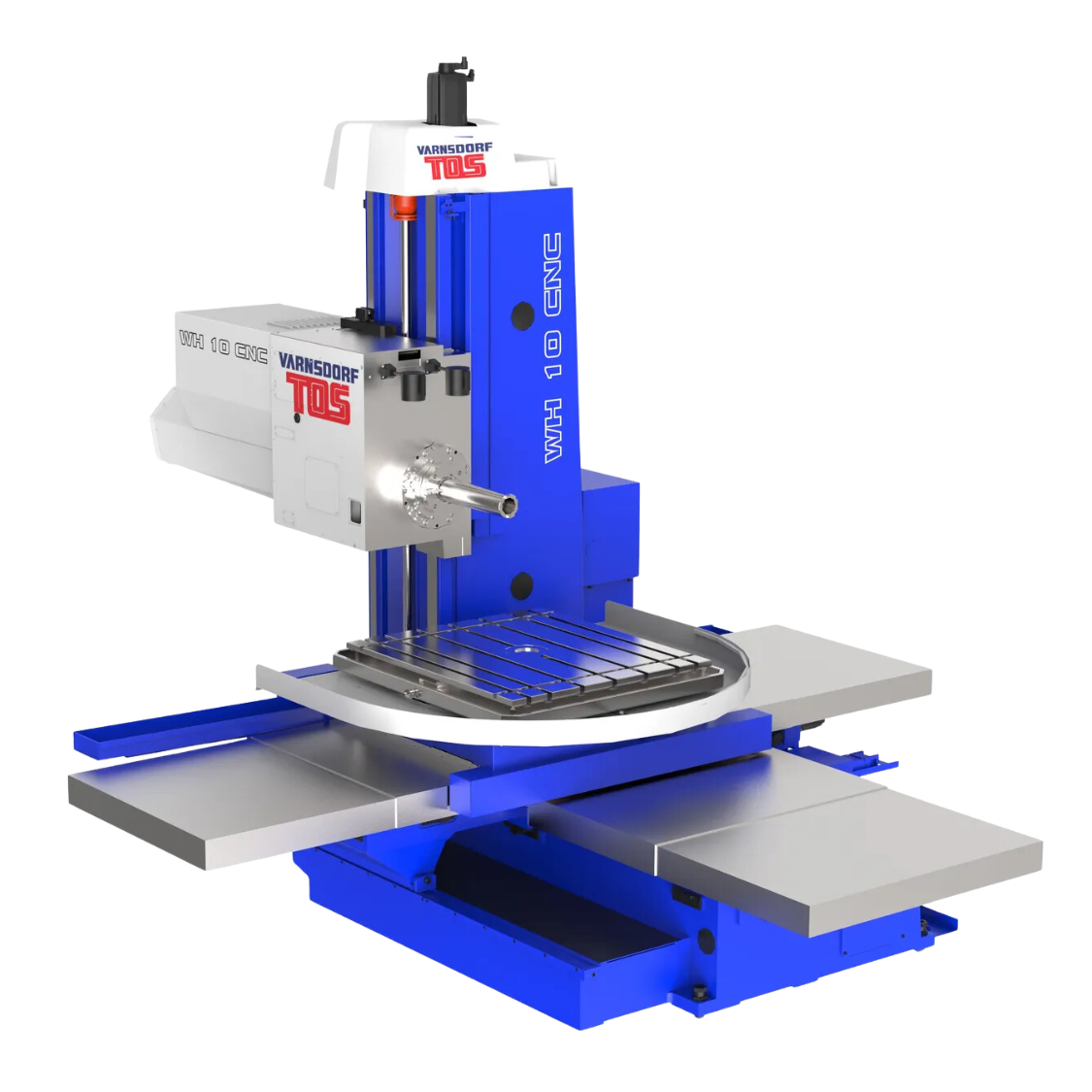

Recommended solutions to improve your processes

Equip and maximize the productivity of your CNC machines with comprehensive solutions.

Accessories and peripherals

Mist collector

Cooling system

Coolant filtration and magnetic separator equipment

Learn more about PERIFERIQ

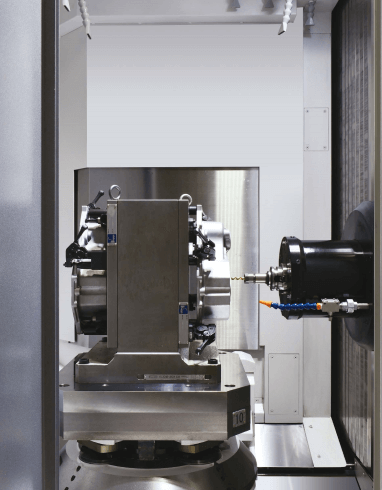

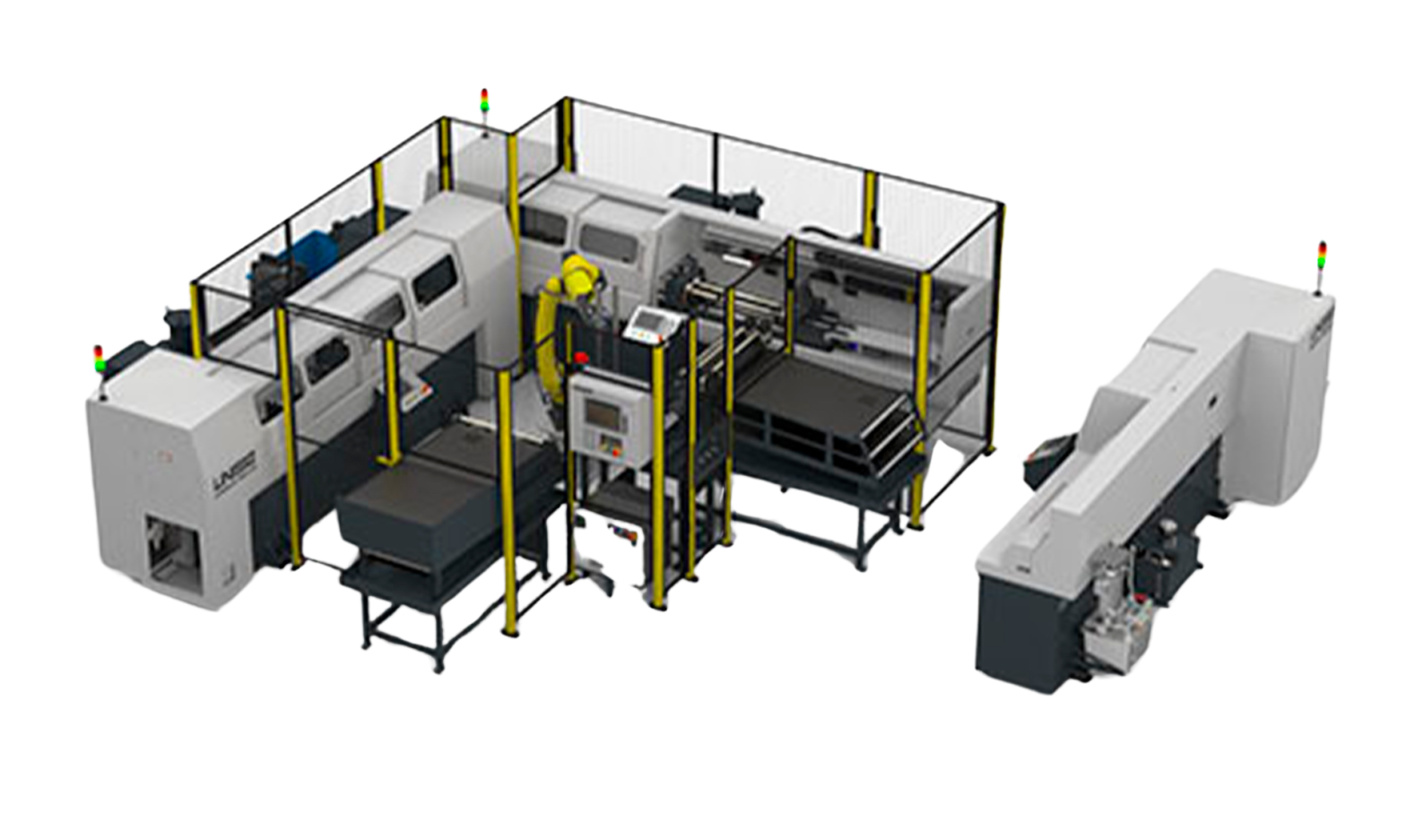

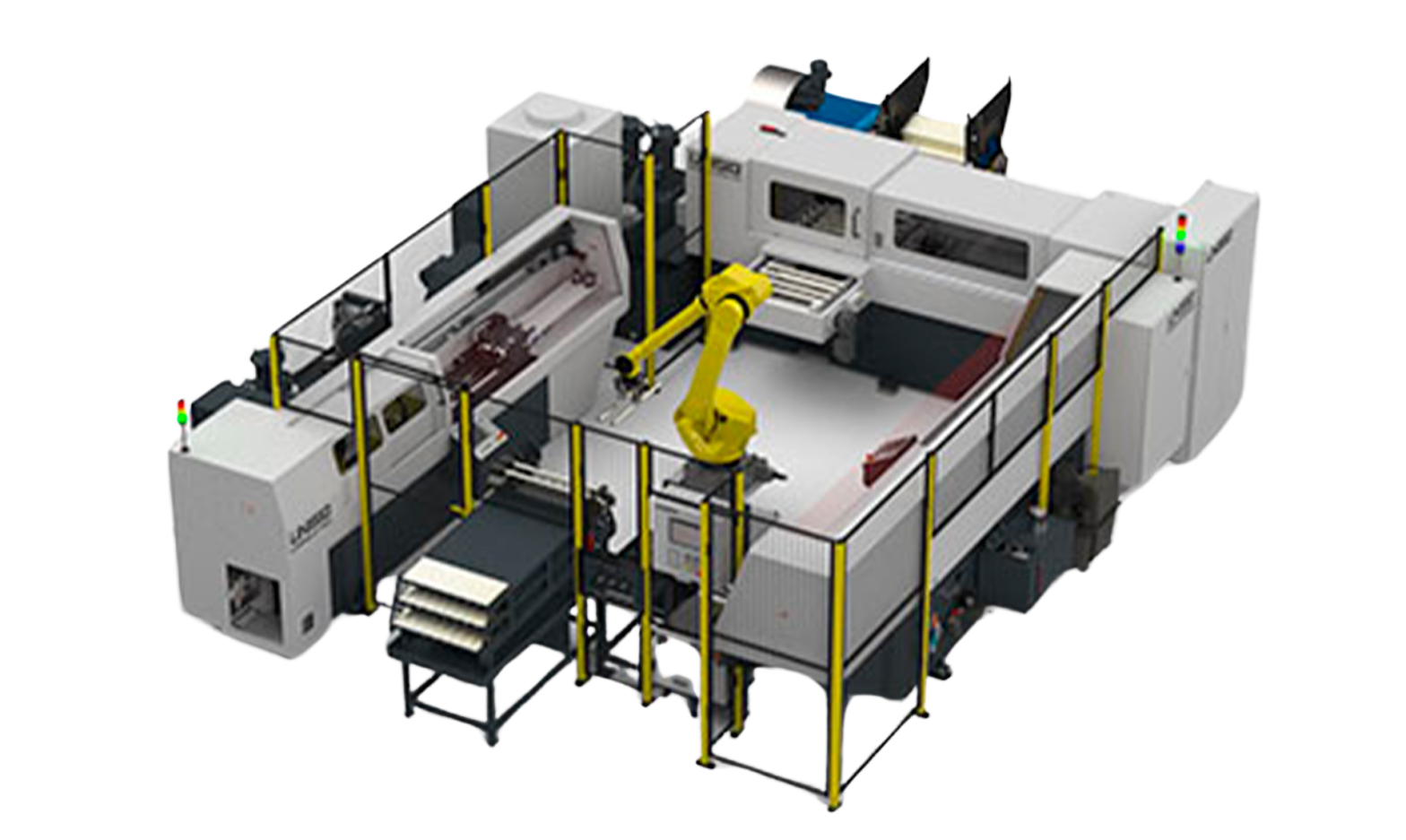

Creation and development of industrial automation customized to meet your needs.

Automatic doors

Automated loading and unloading system

Safety and cleaning systems

Interfaces to external clamping systems

Learn more about OTOMATIQA