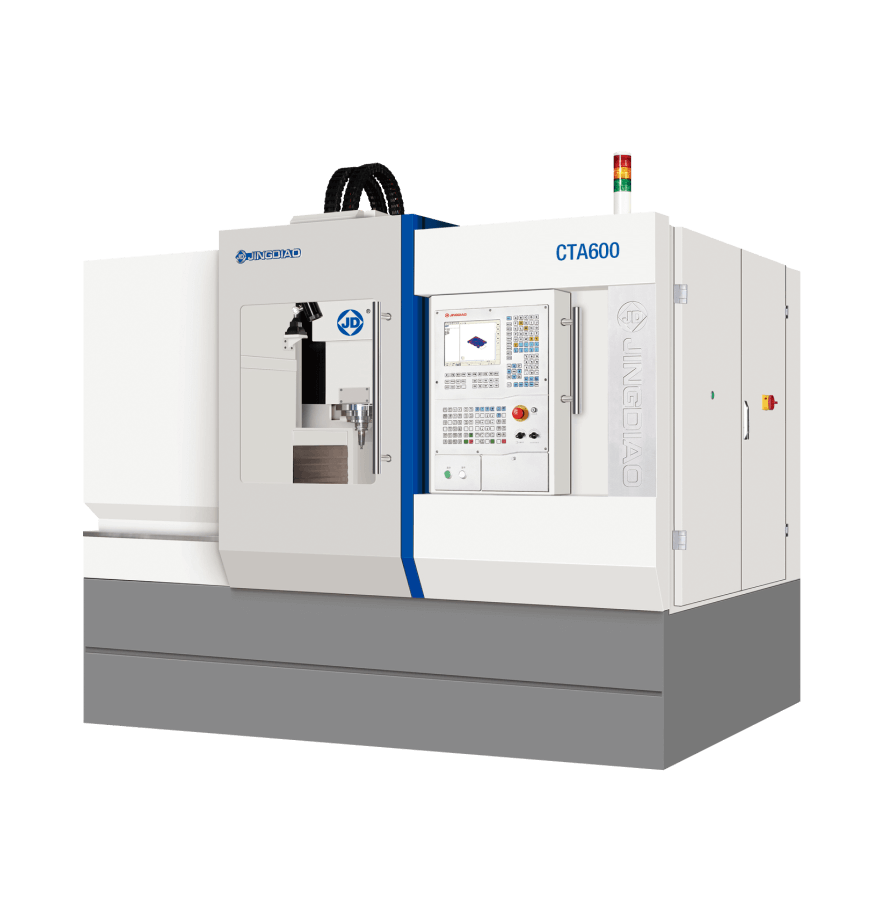

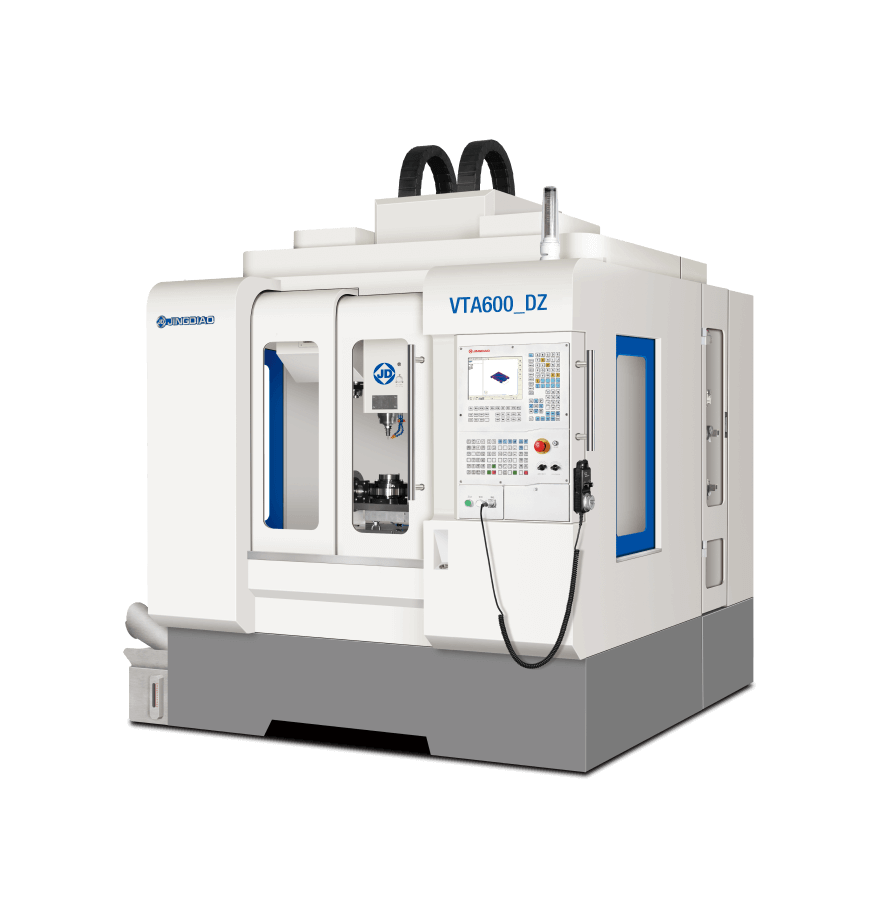

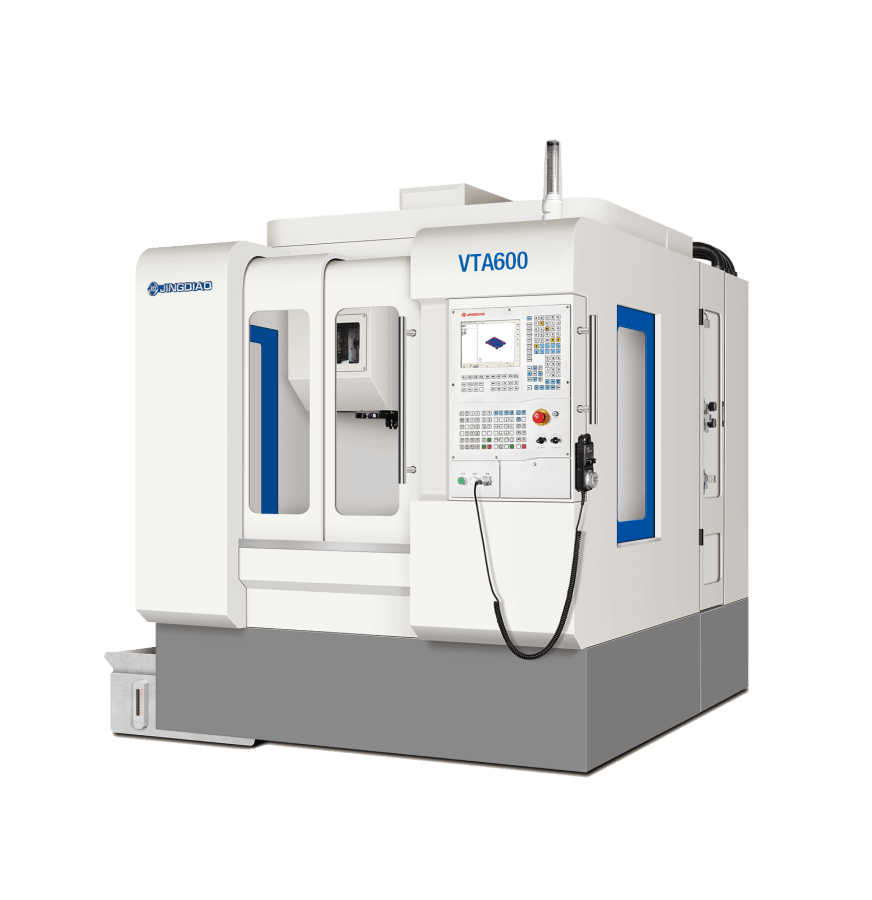

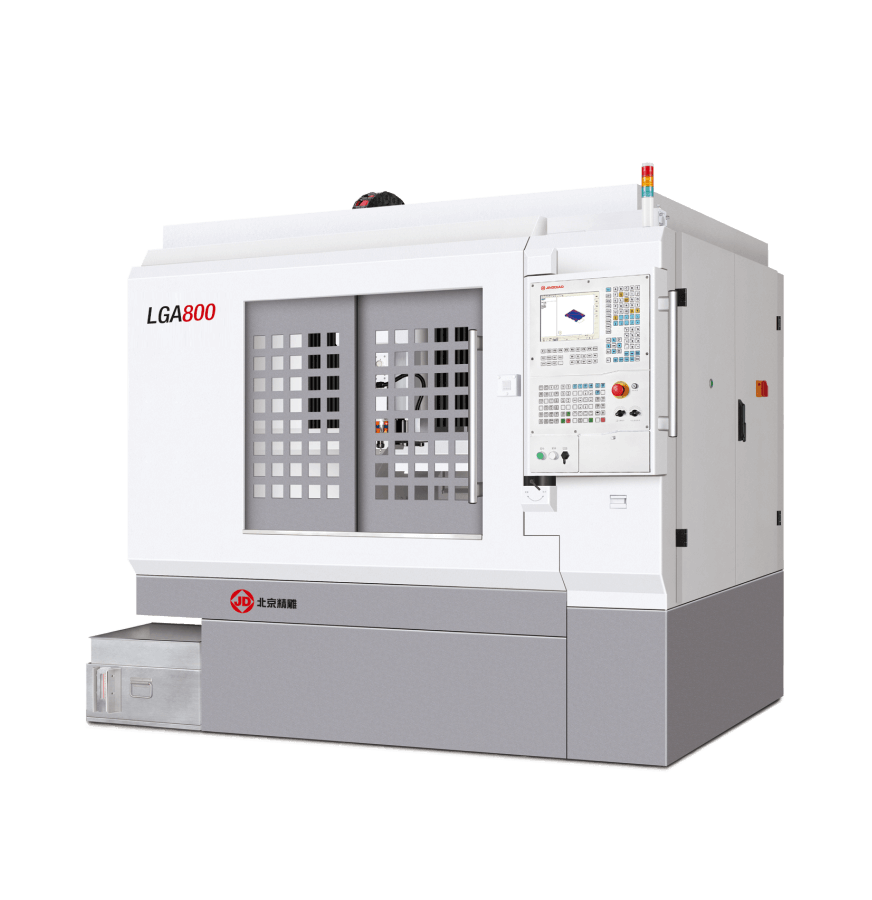

Jingdiao

CTA1200

Jingdiao

CTA1200

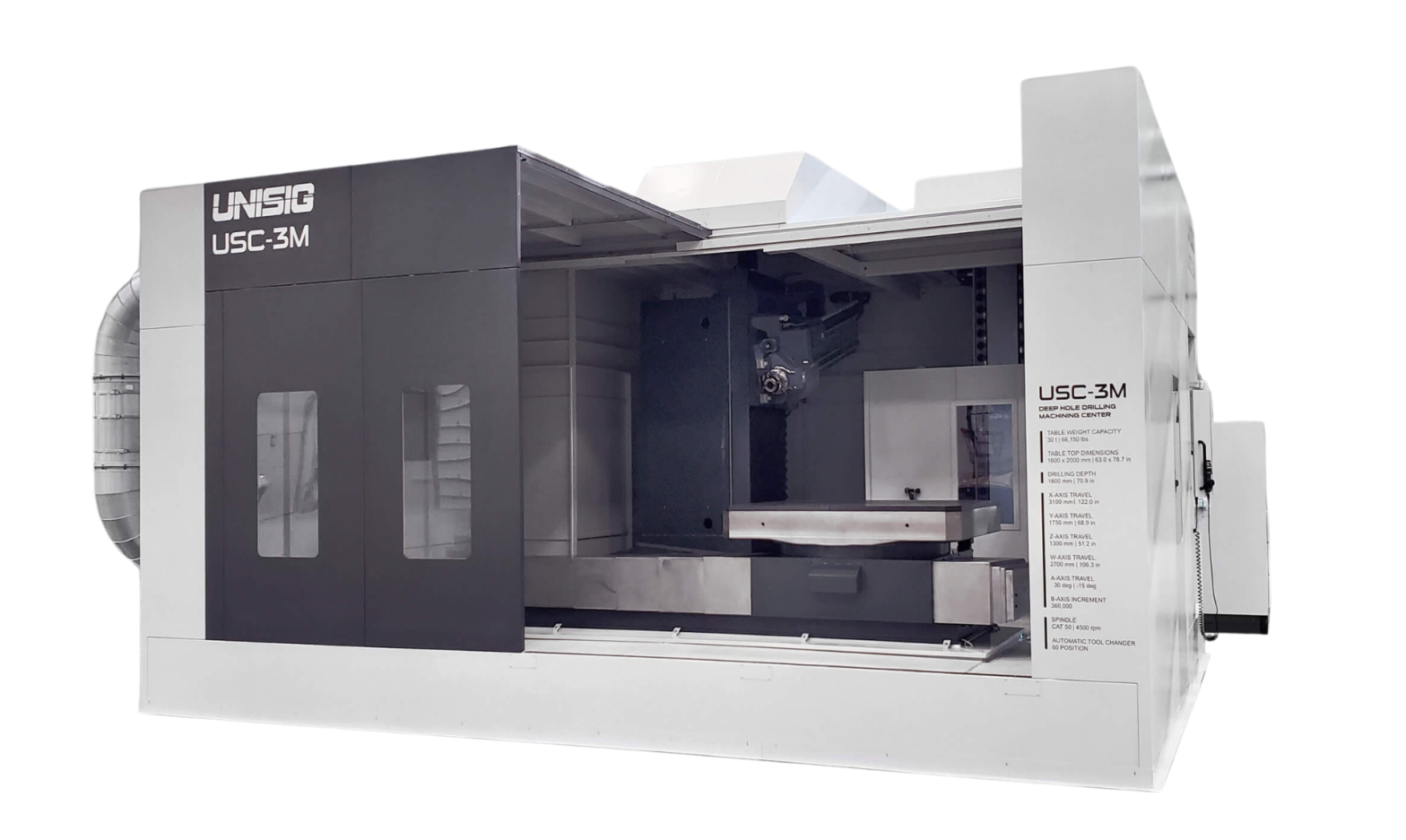

Product description

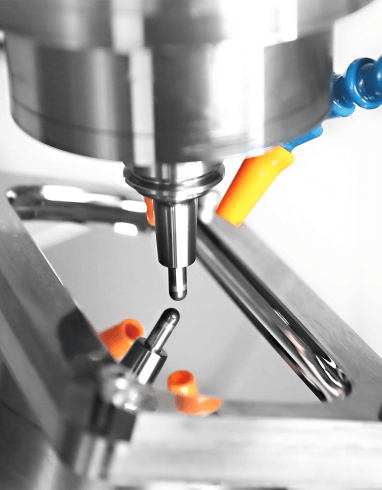

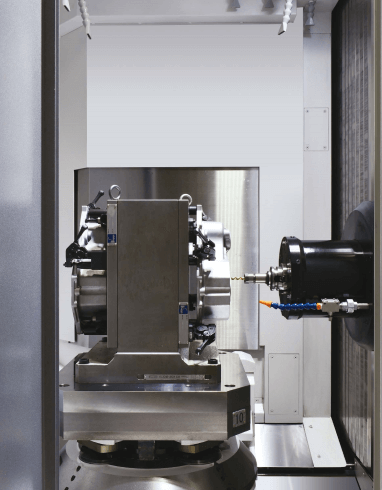

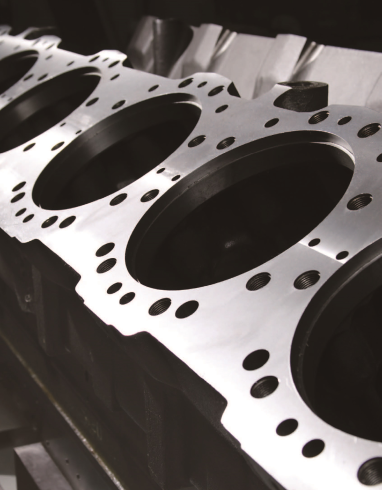

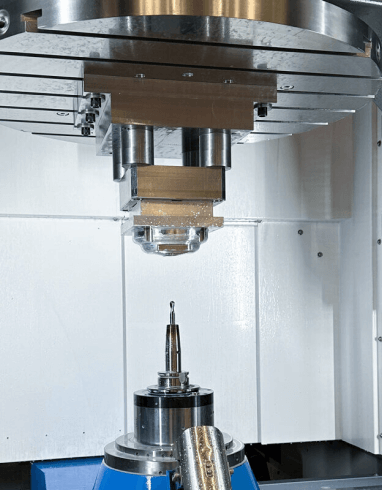

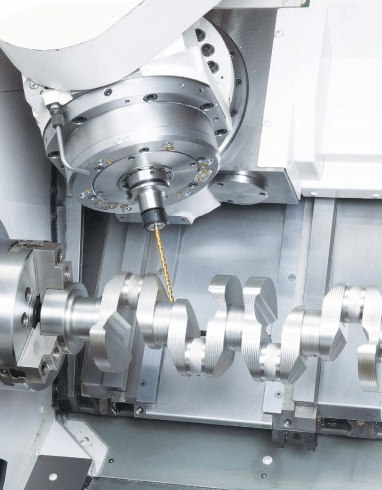

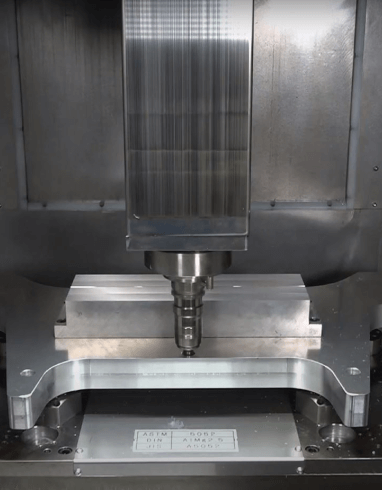

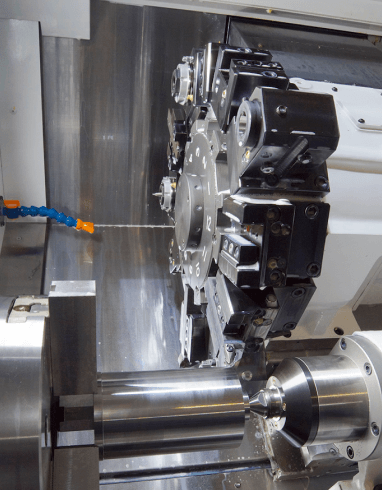

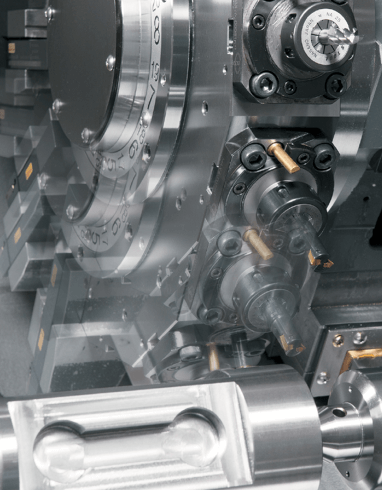

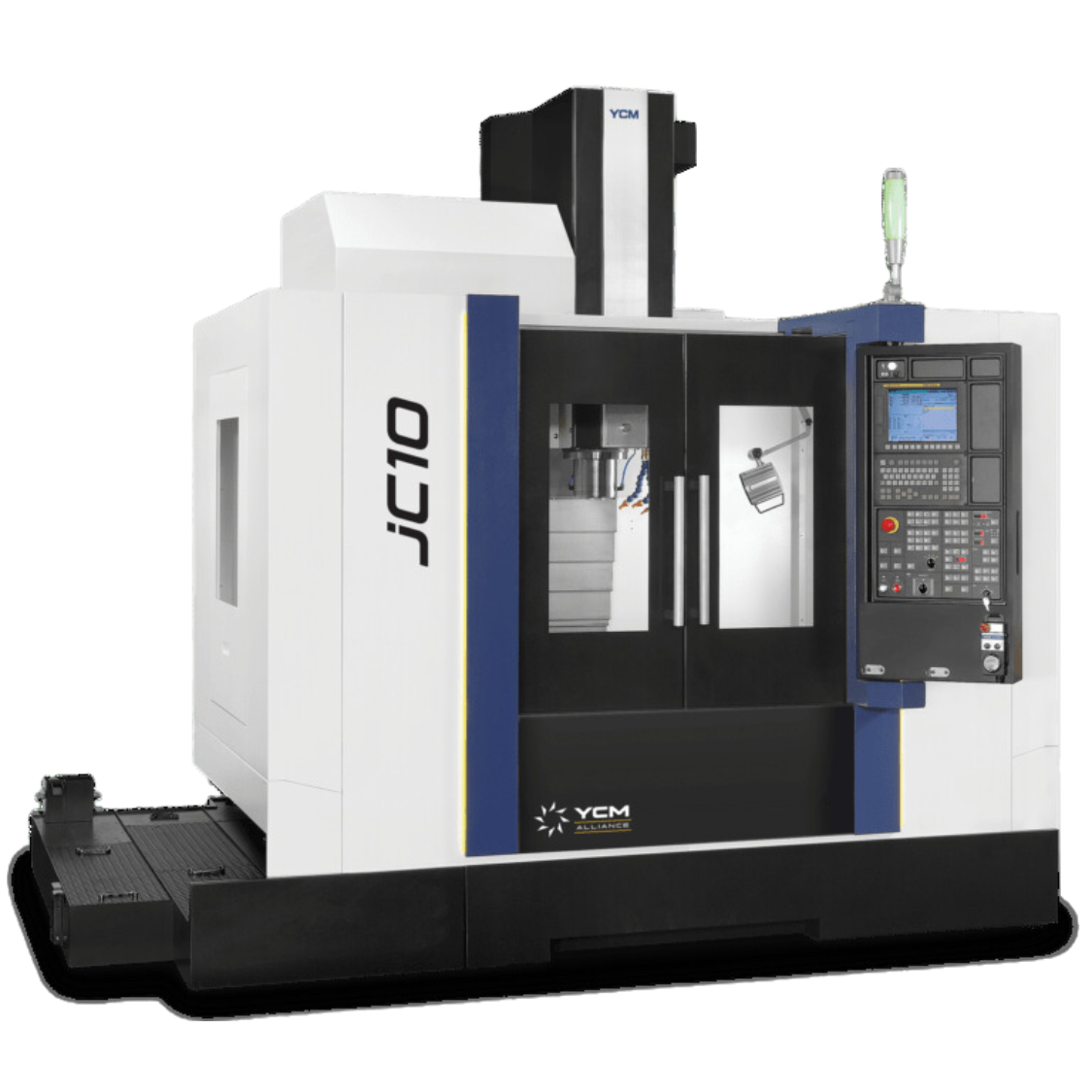

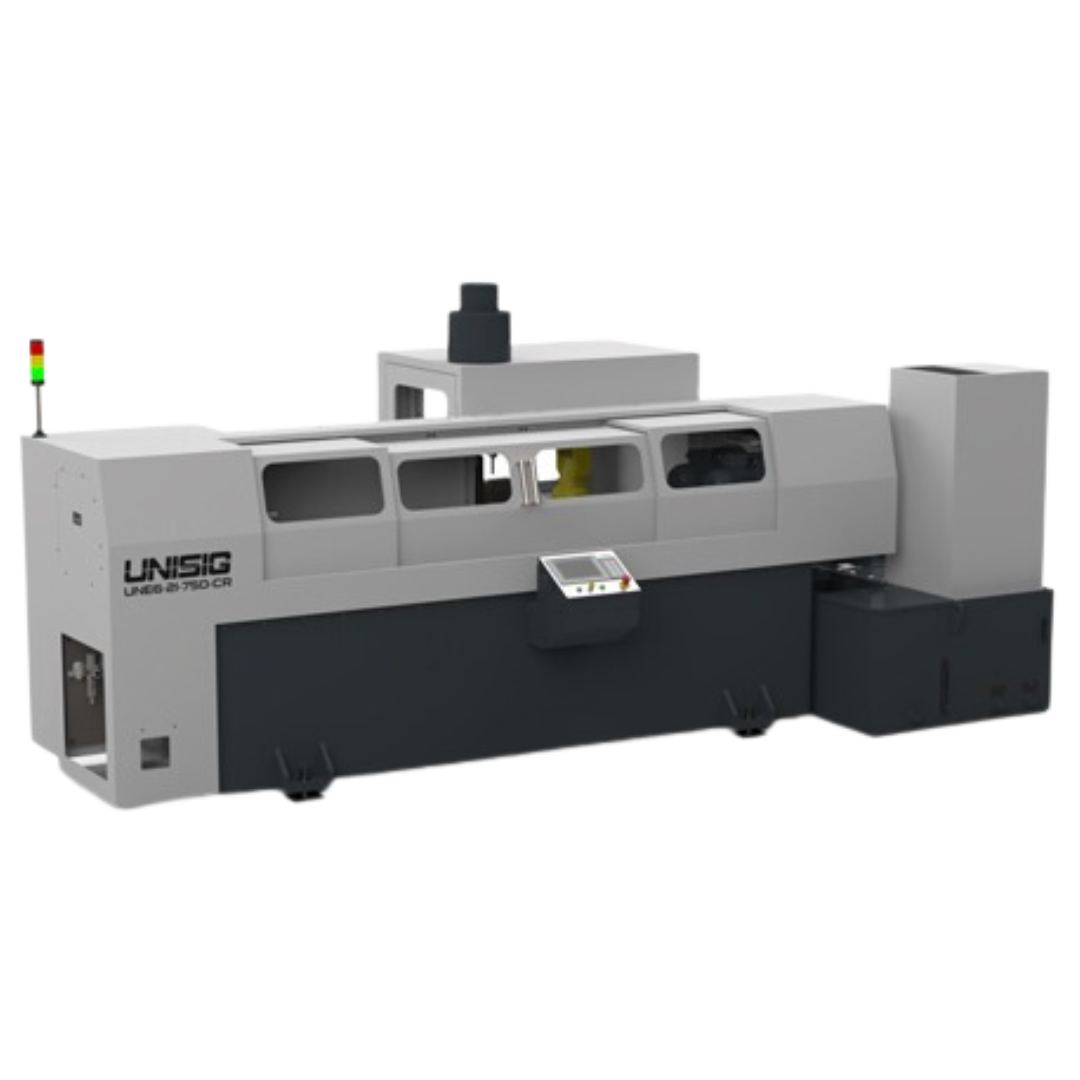

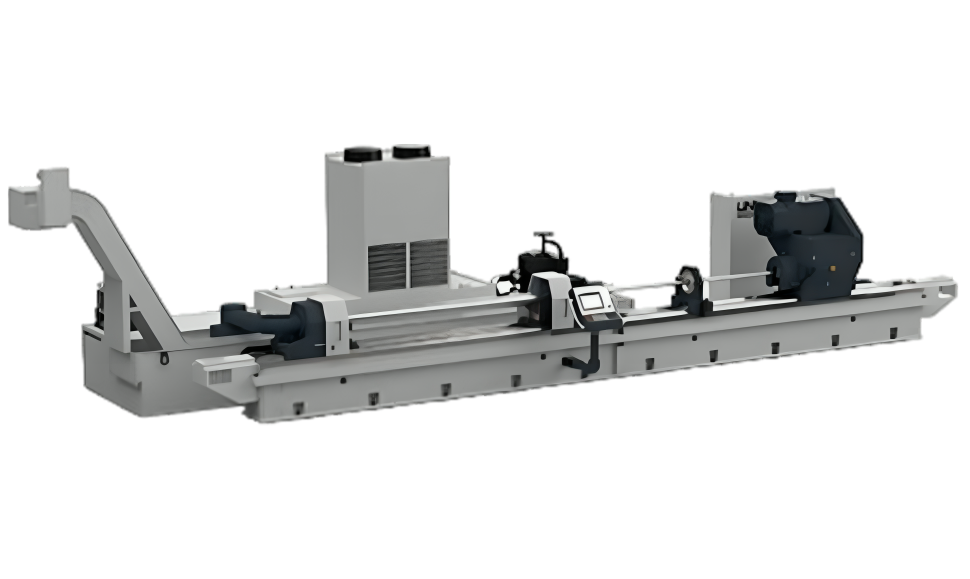

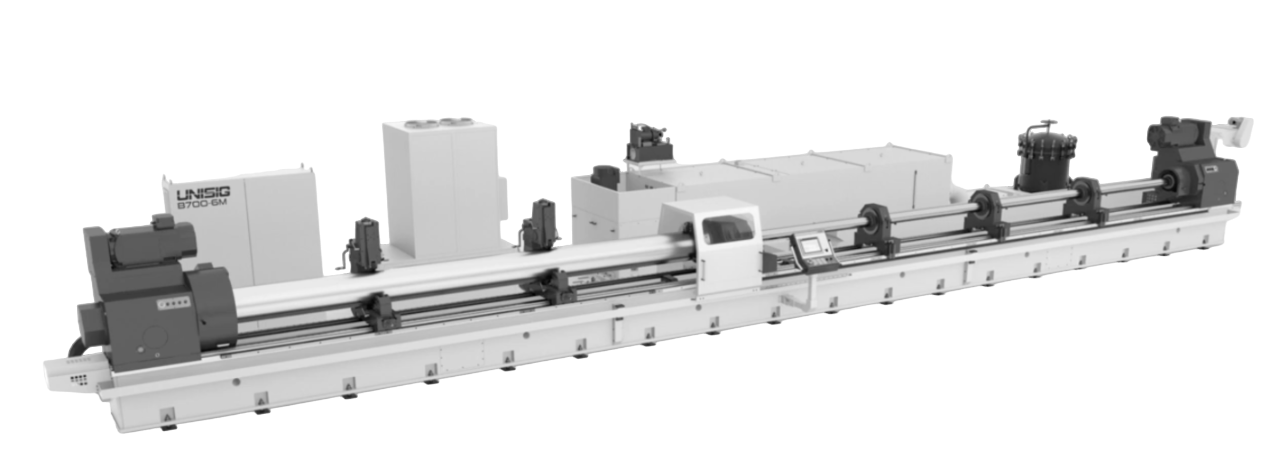

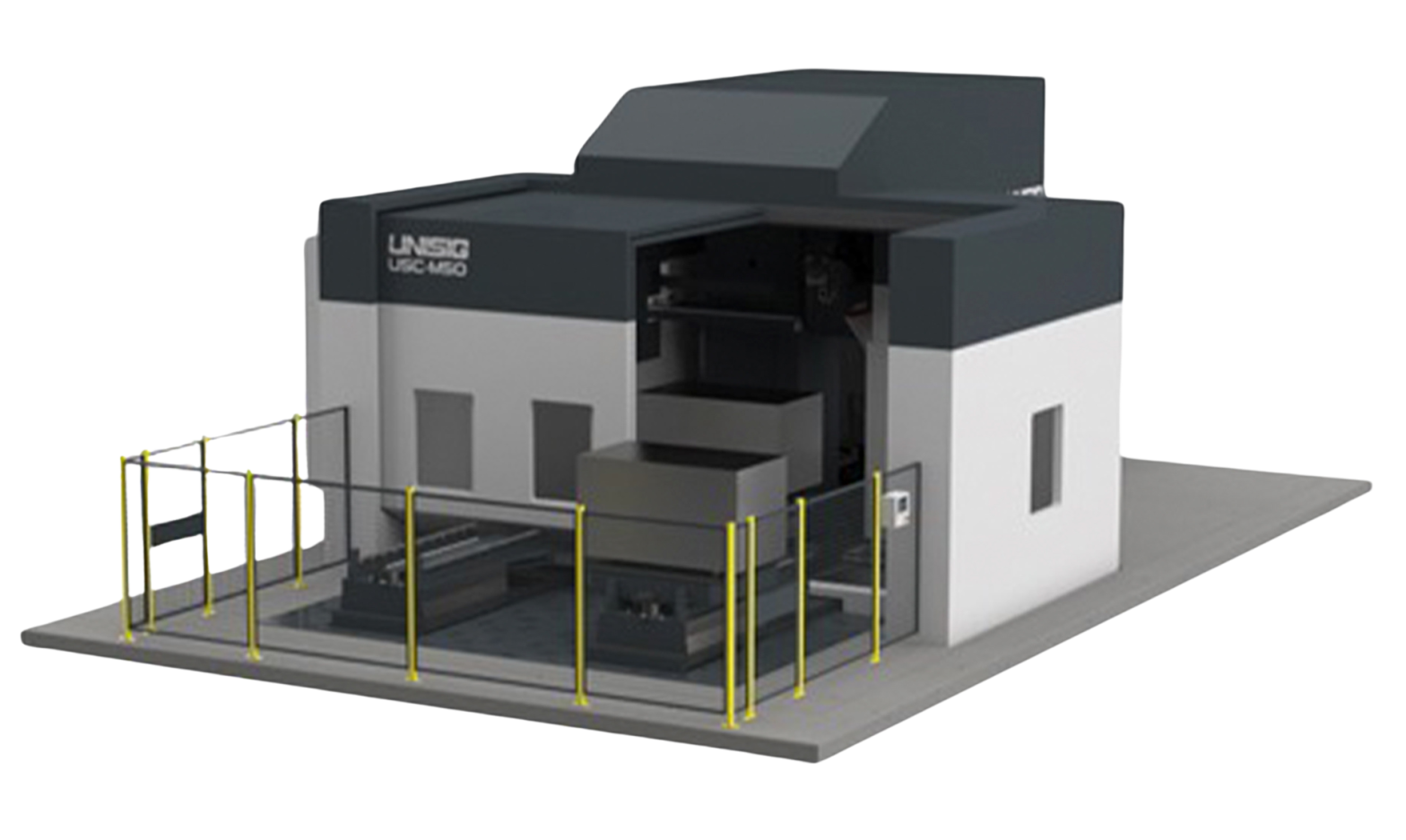

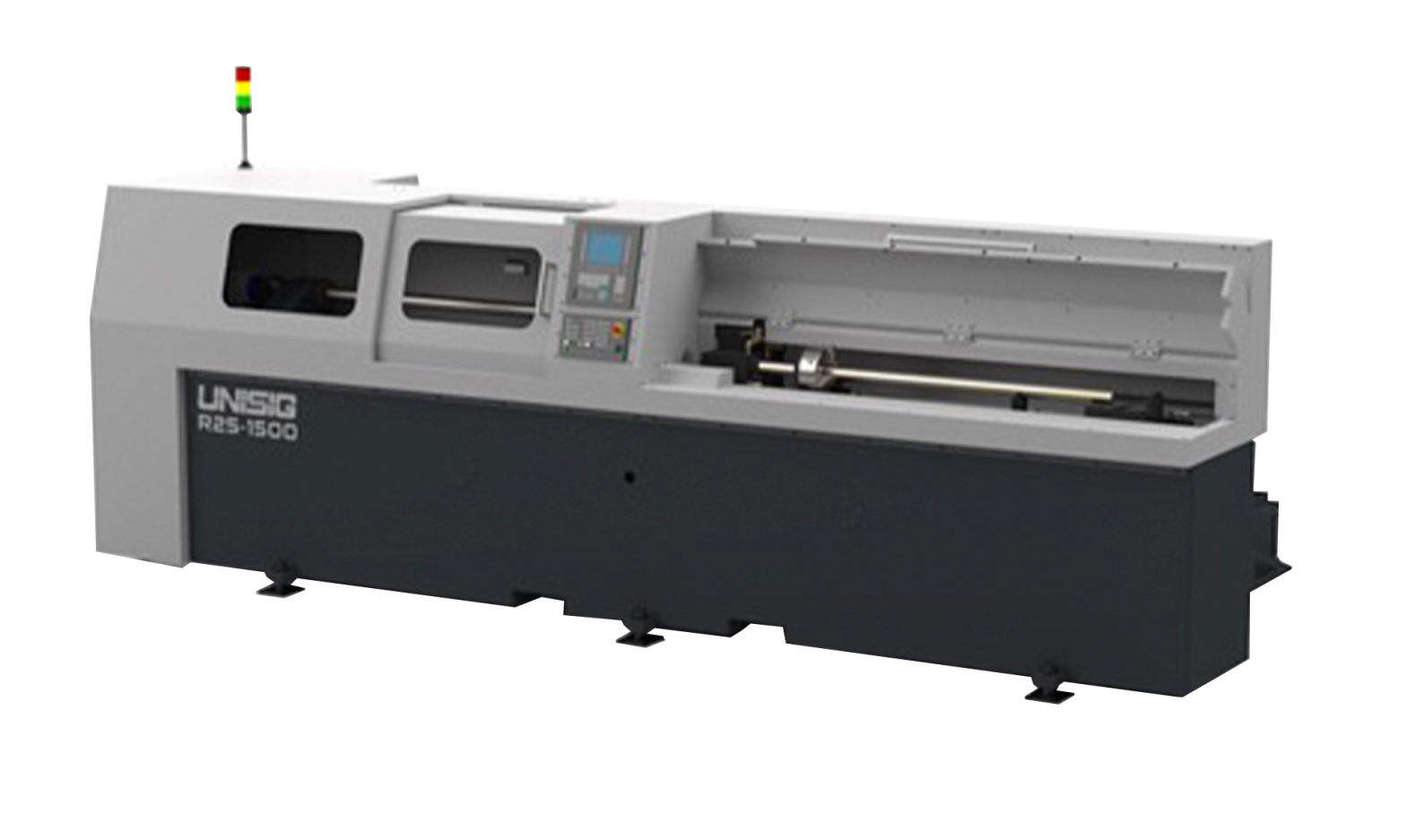

Jingdiao CTA1200 3-Axis CNC Machining Center suitable for the large precision die mold part processing. 10~20μm processing accuracy stably achieved relied on Jingdiao hardware configuration and technical support. Features include an 18-position umbrella tool magazine, a JD150S-20-HA50/C high-speed spindle (standard configuration, with through-spindle coolant option) at 20,000 rpm (HSK-A50). The spacious loading and unloading space of the front door is convenient for the hoisting, loading and unloading of large workpieces. Side operation mode, closer to the part processing area, is convenient for operation and observation. Spiral chip conveyors equipped on the left, right and front sides of the machine, and a chip washing device inside the machine bed, benefit rapid chip disposal.

Industries

Aerospace

Automotive

Energy

Fluid Control

Heavy Duty

Medical

Molds & Dies

Others

Product highlights

Product highlights

Position Accuracy X / Y / Z (in)Position Accuracy X / Y / Z (mm)

0.00047 / 0.00032 / 0.000320.012 / 0.008 / 0.008

Repeatability X / Y / Z (in)Repeatability X / Y / Z (mm)

0.00035 / 0.00020 / 0.000200.009 / 0.005 / 0.005

Travel X / Y / Z (in)Travel X / Y / Z (mm)

47.2 / 31.5 / 13.81,200 / 800 / 350

Worktable Size (in)Worktable Size (mm)

49.2 × 33.51,250 × 850

Max. Load (Ib)Max. Load (kg)

2,204.61,000

Spindle Speed (rpm)

20,000 (HSK-A50)

Tool Magazine / Capacity

Servo Tool Magazine 1/20

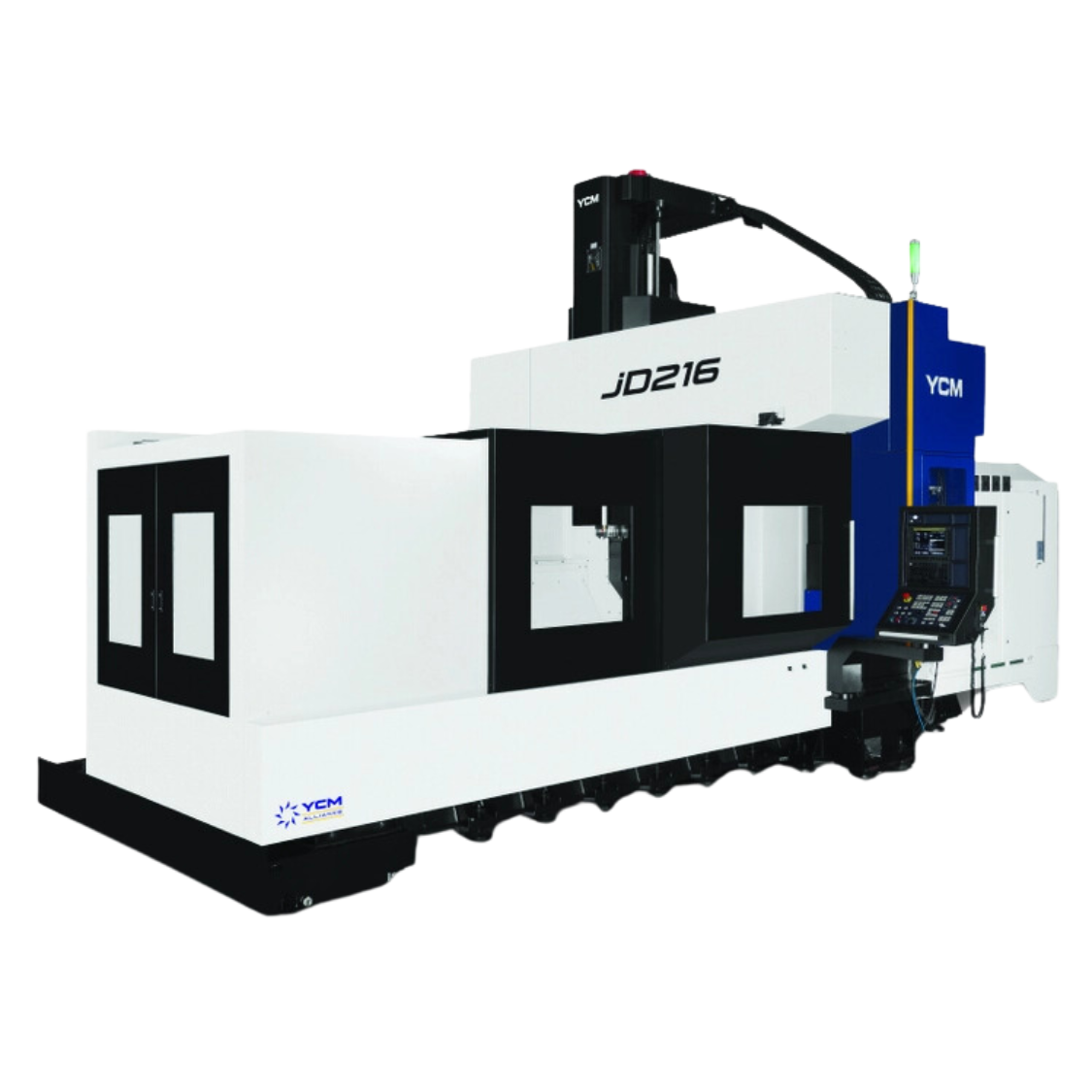

Recommended solutions to improve your processes

Equip and maximize the productivity of your CNC machines with comprehensive solutions.

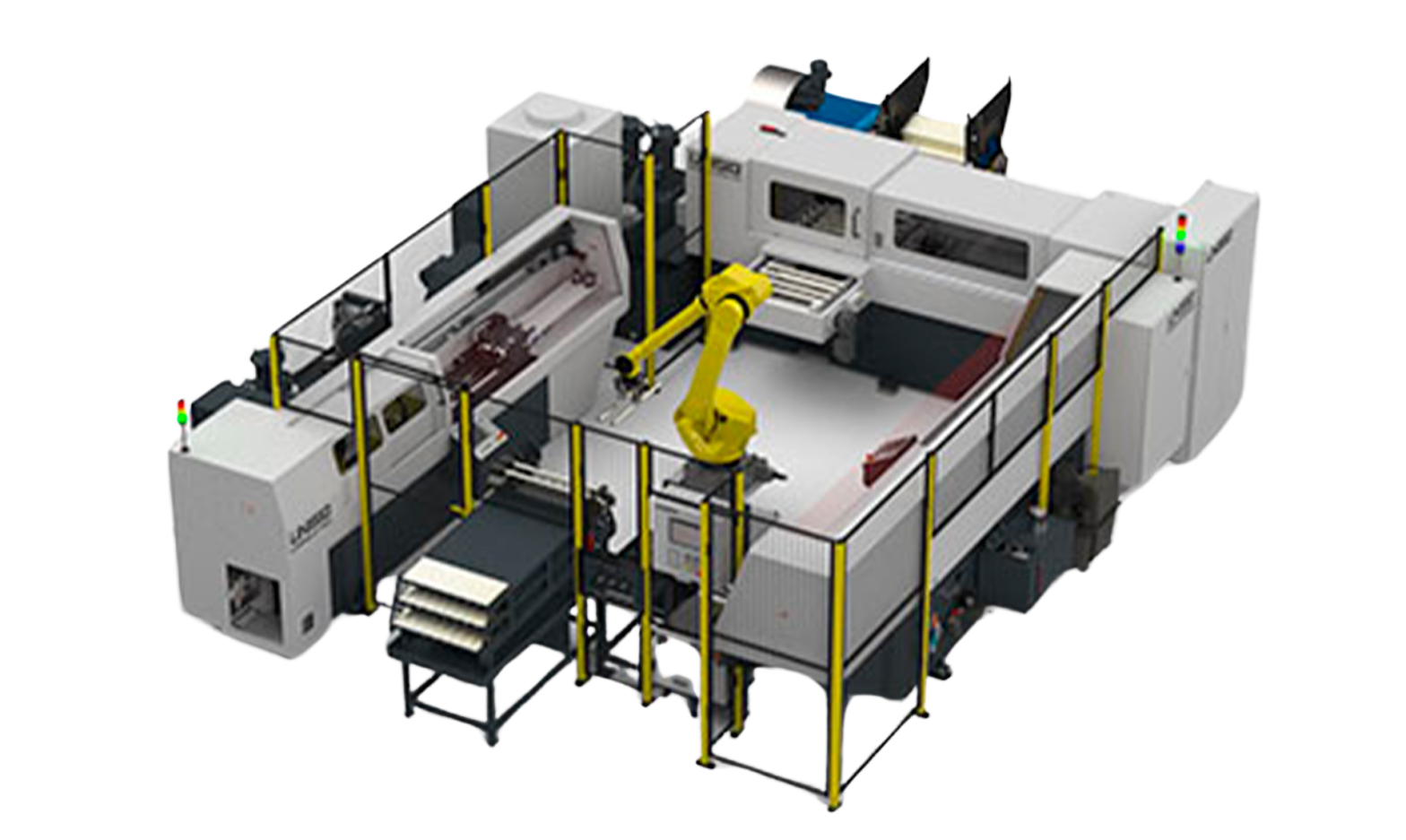

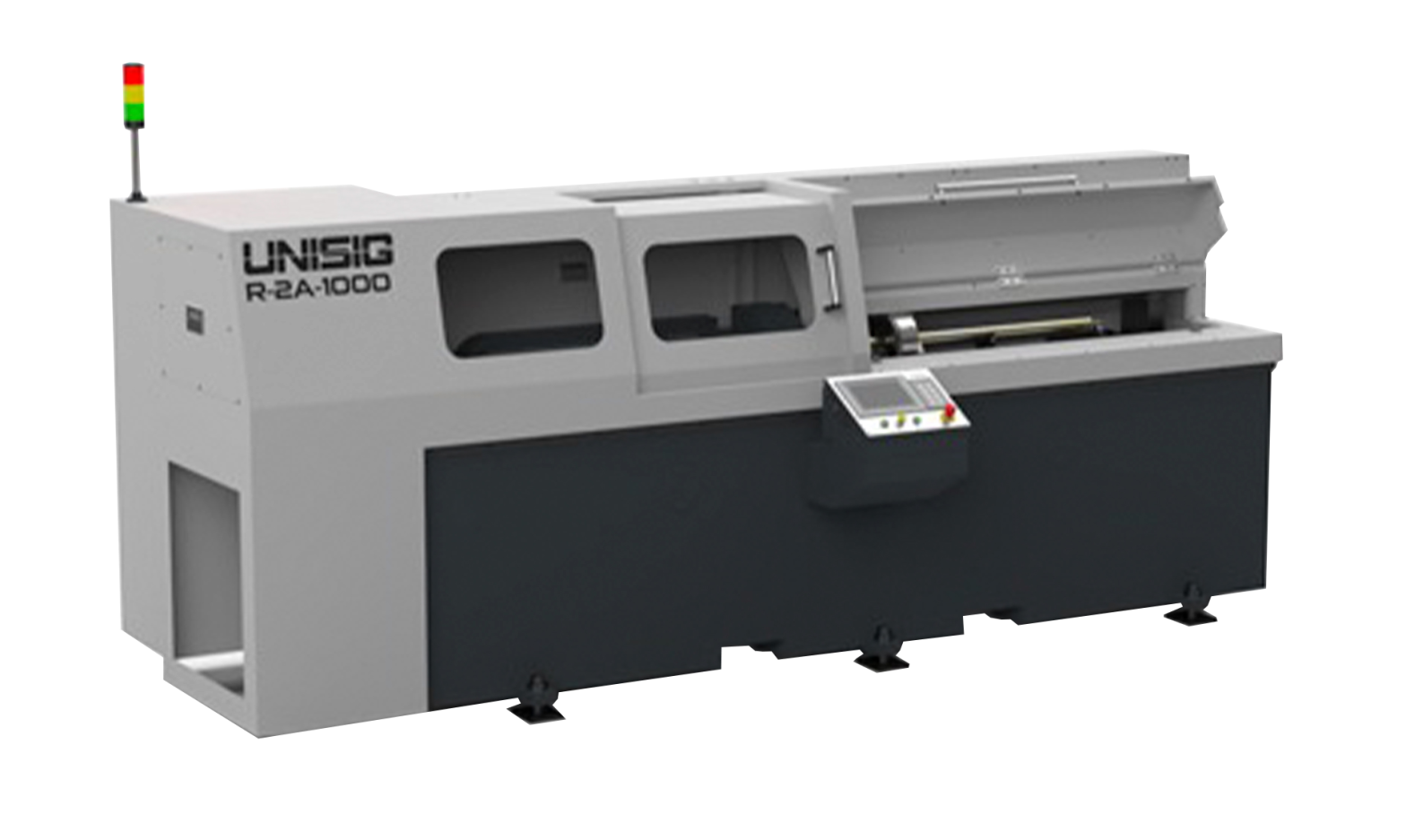

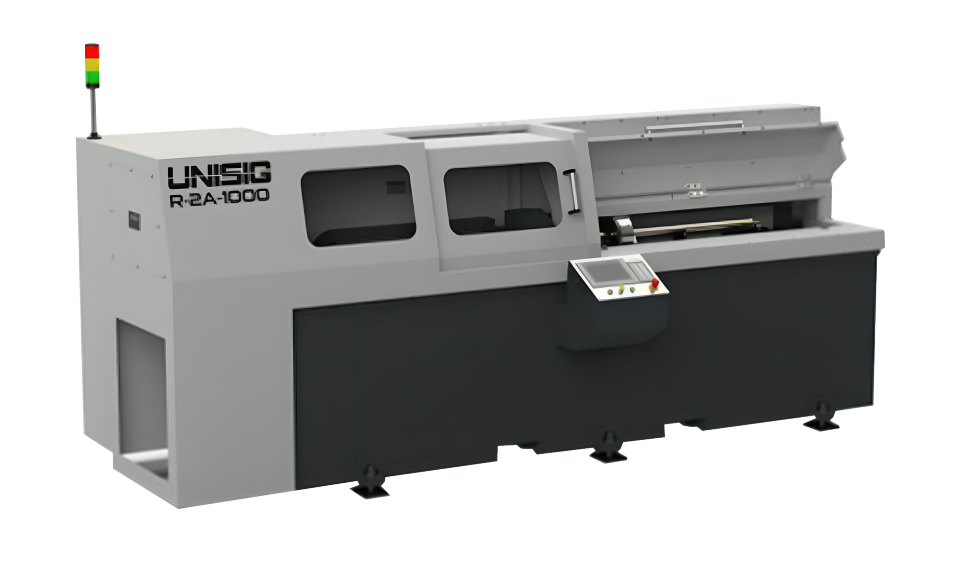

Accessories and peripherals

Mist collector

Cooling system

Coolant filtration and magnetic separator equipment

Learn more about PERIFERIQ

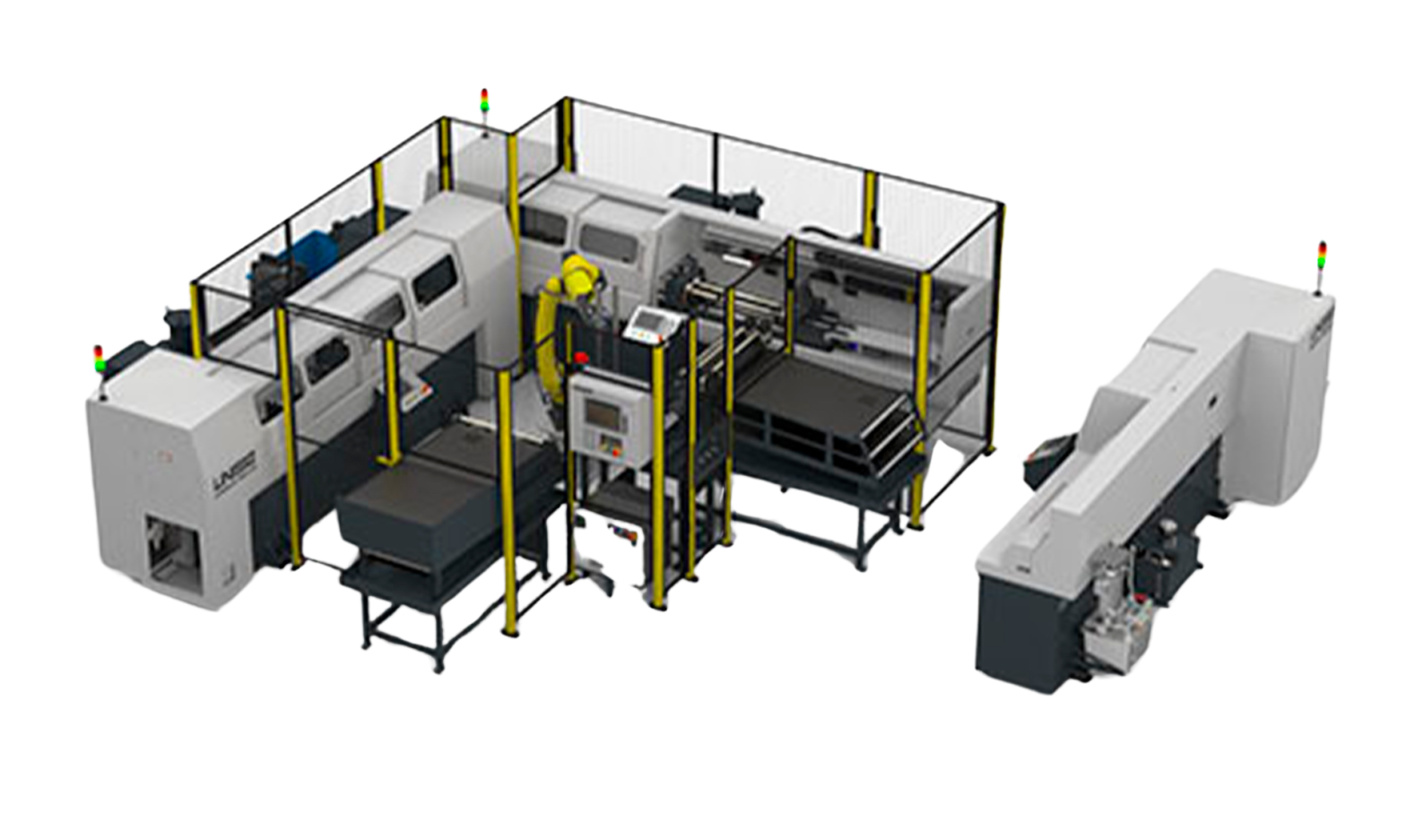

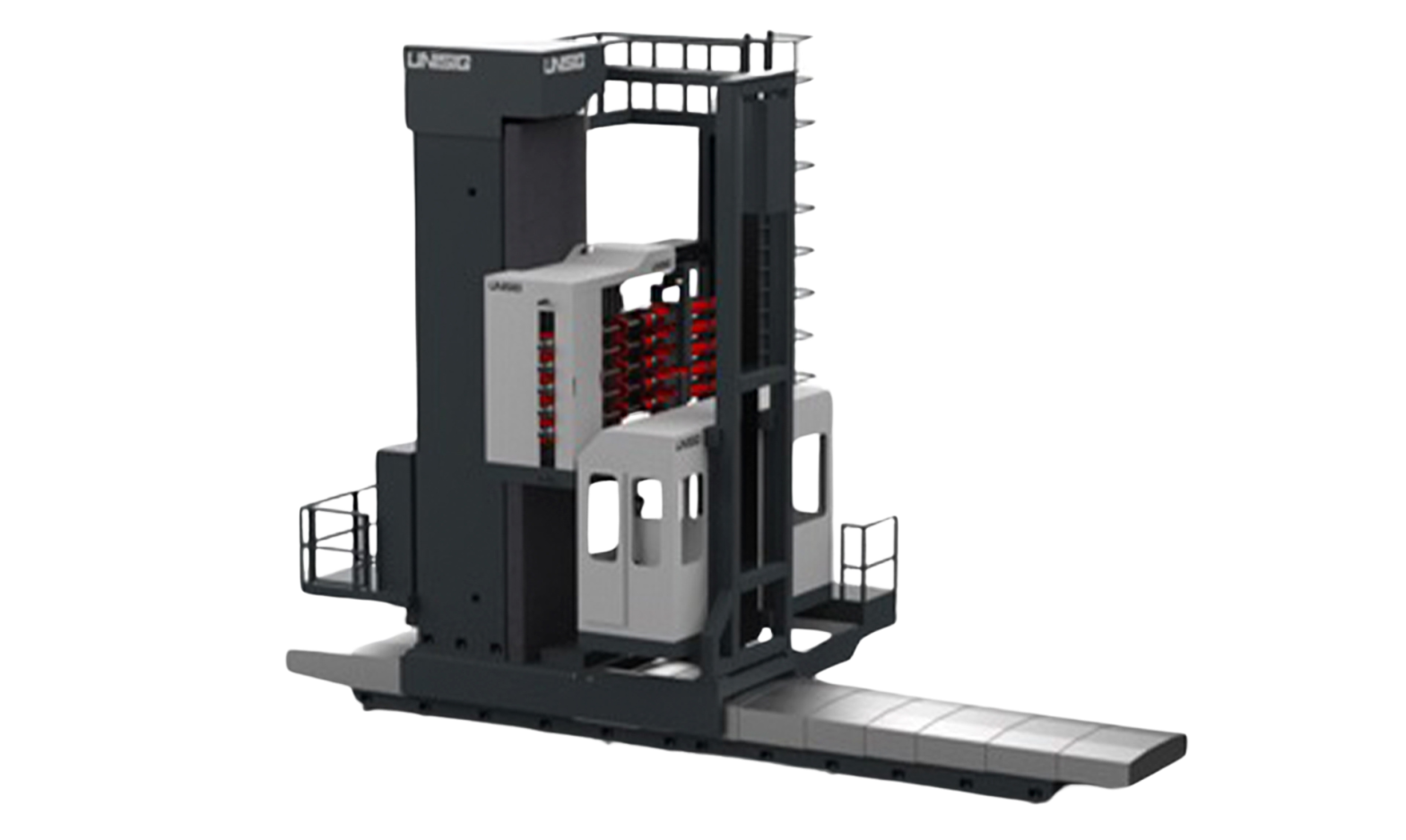

Creation and development of industrial automation customized to meet your needs.

Automatic doors

Automated loading and unloading system

Safety and cleaning systems

Interfaces to external clamping systems

Learn more about OTOMATIQA