Unisig

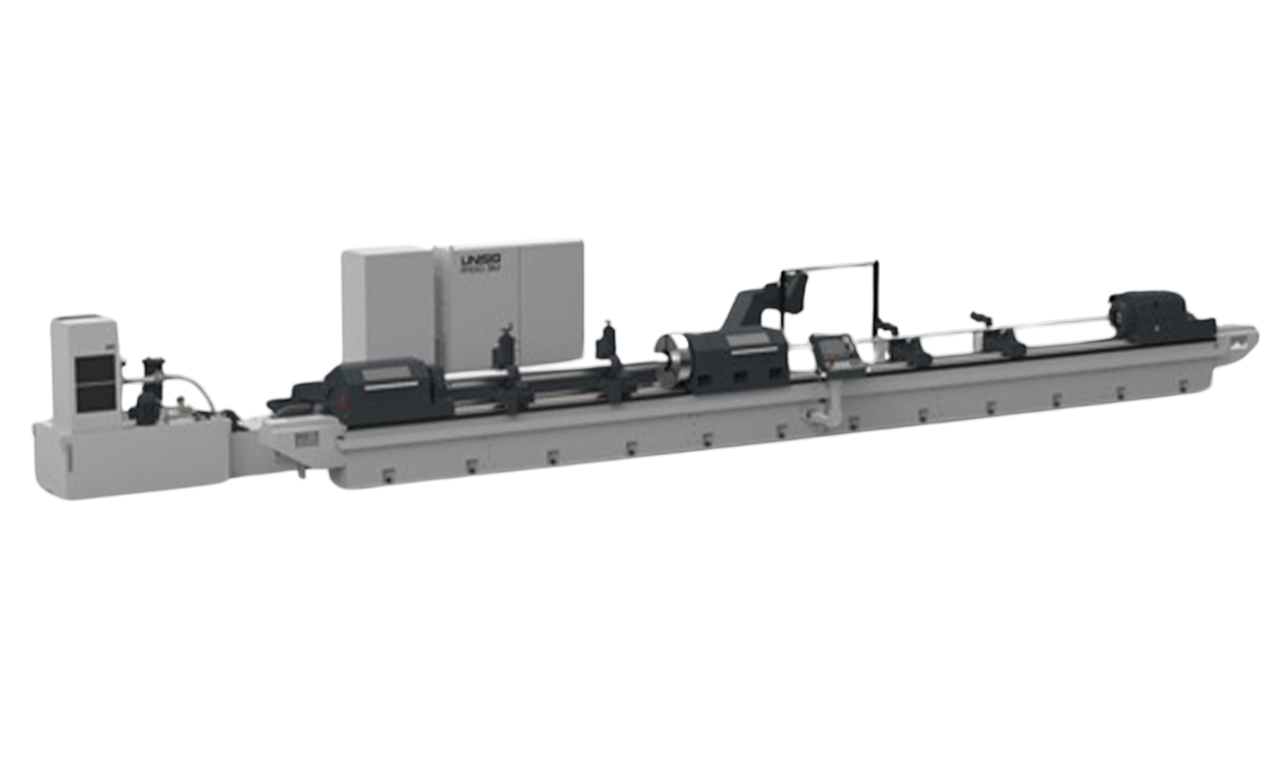

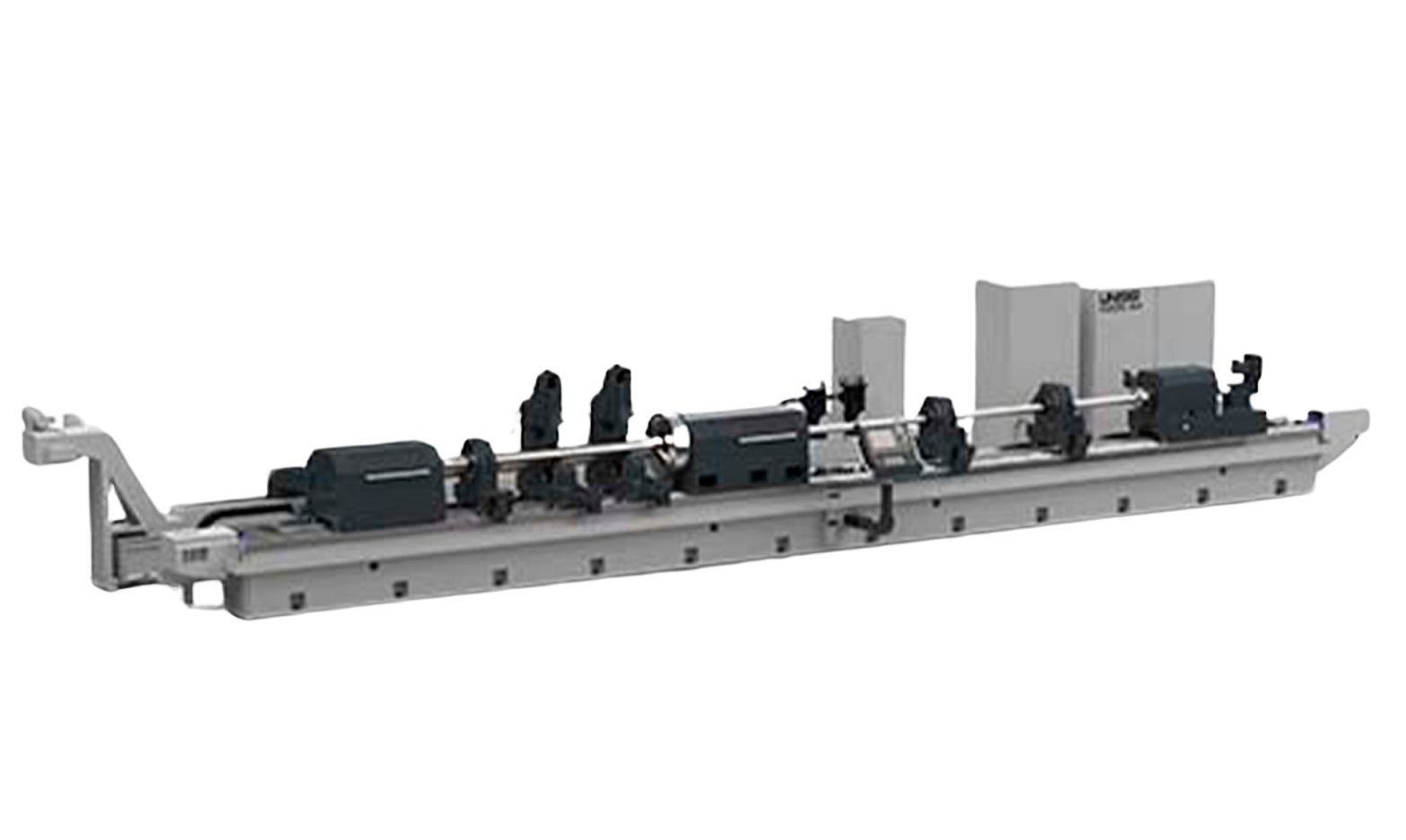

USC-TS50

Unisig

USC-TS50

Product description

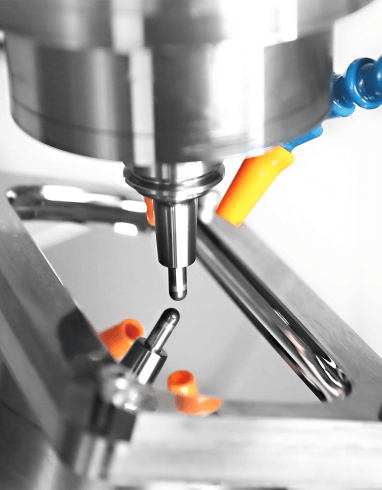

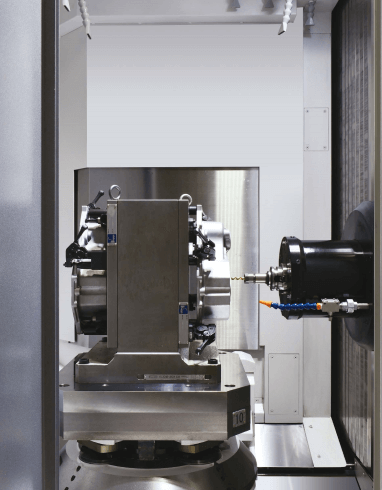

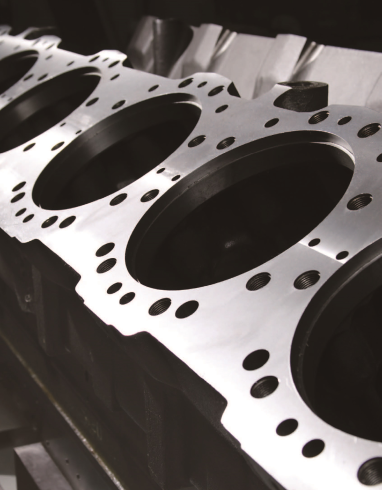

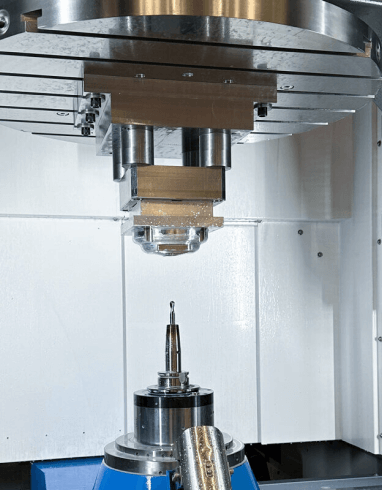

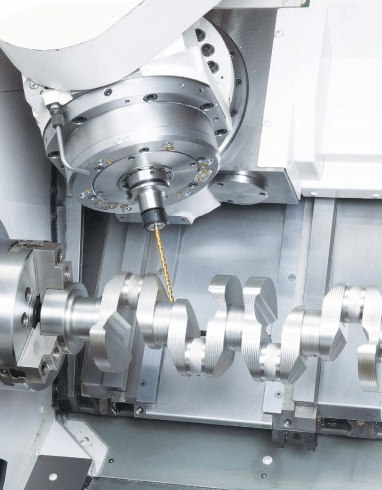

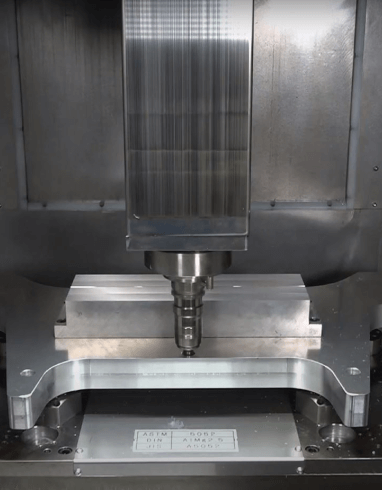

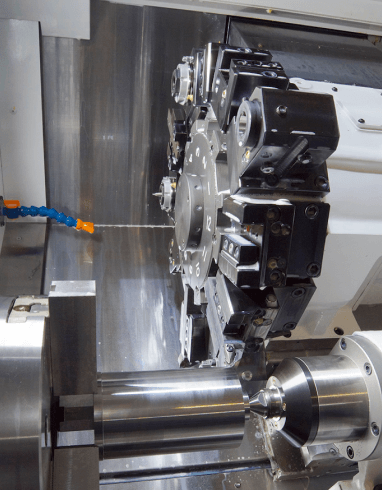

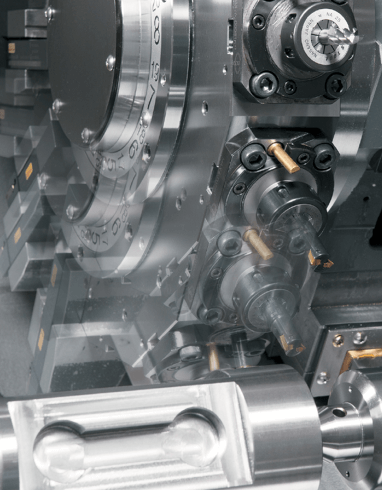

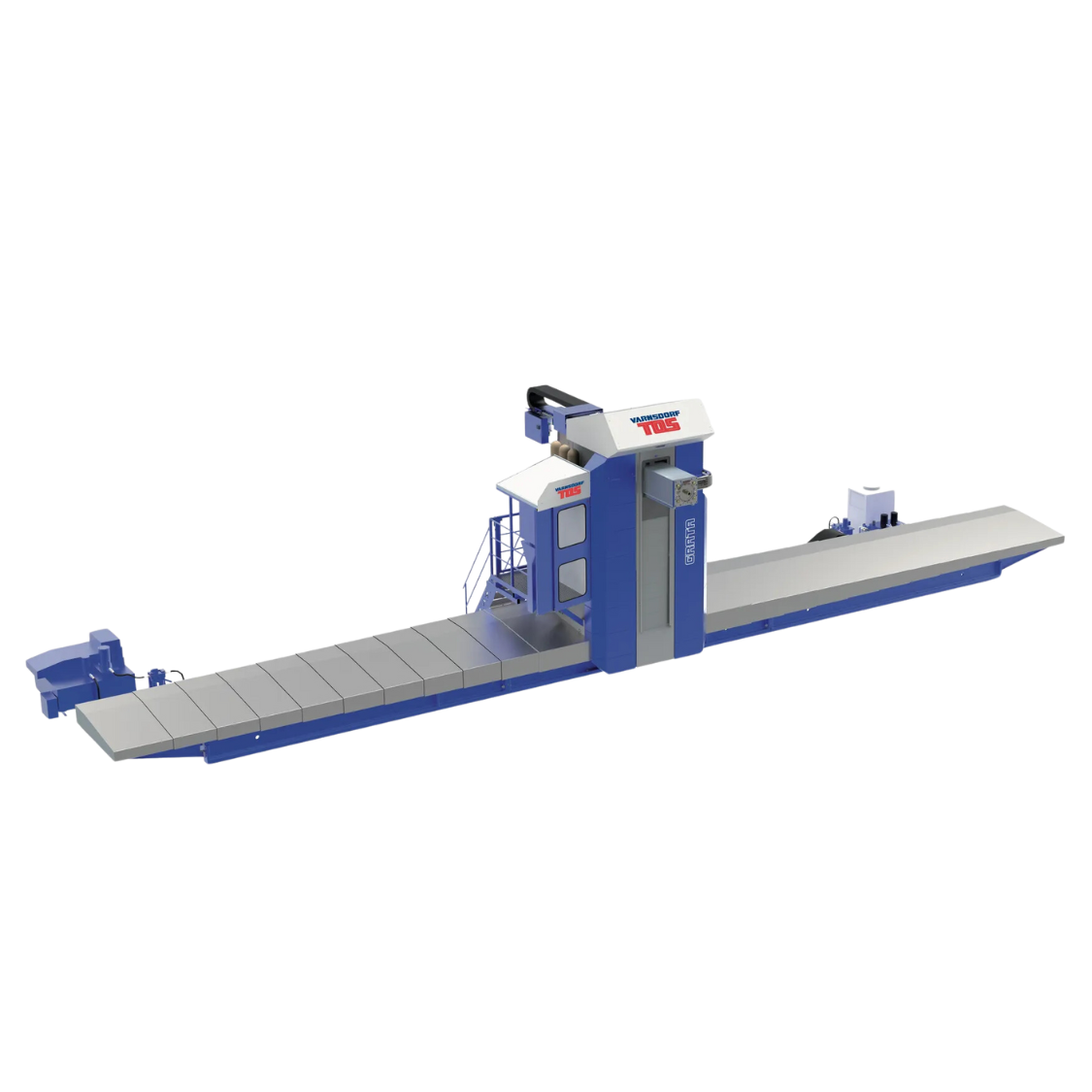

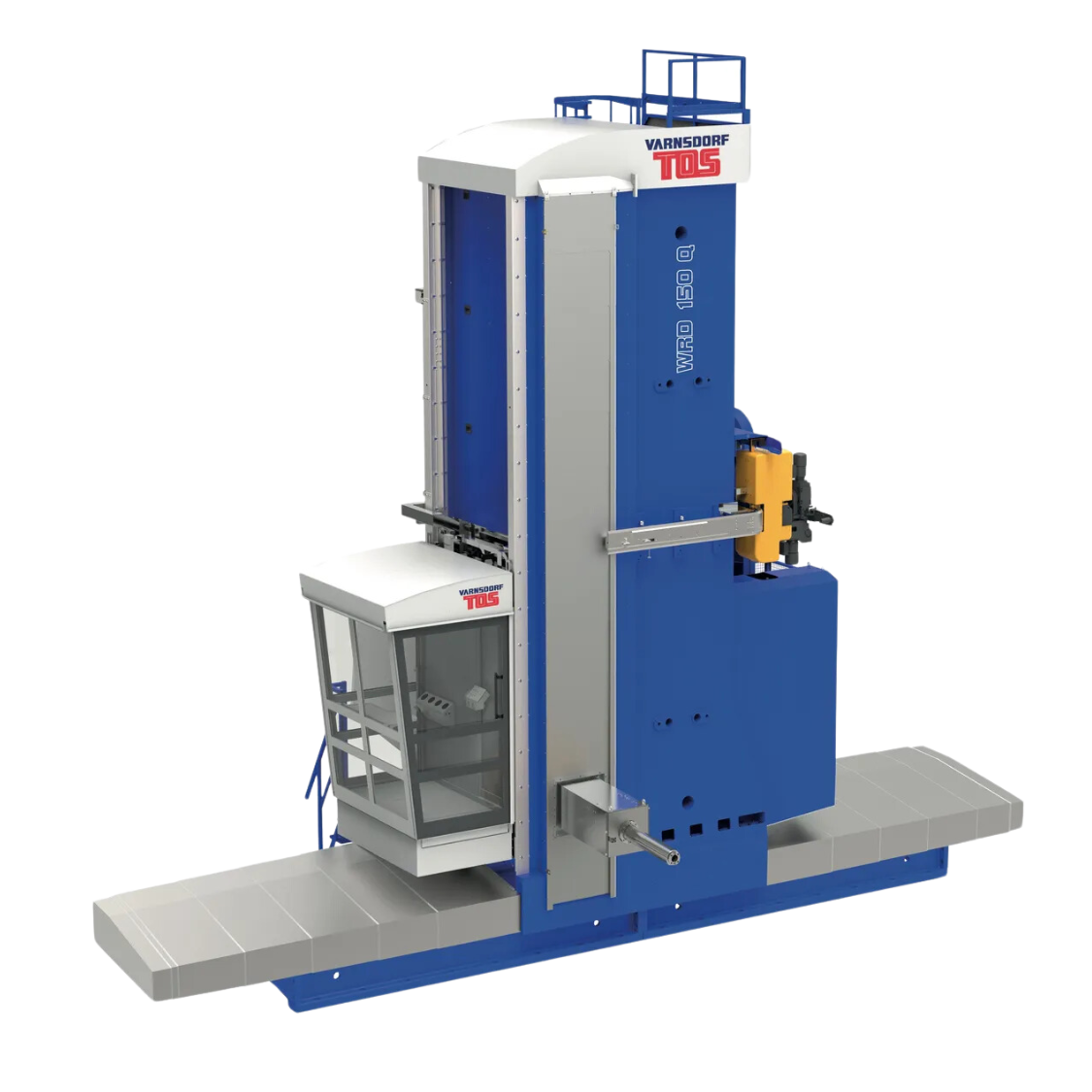

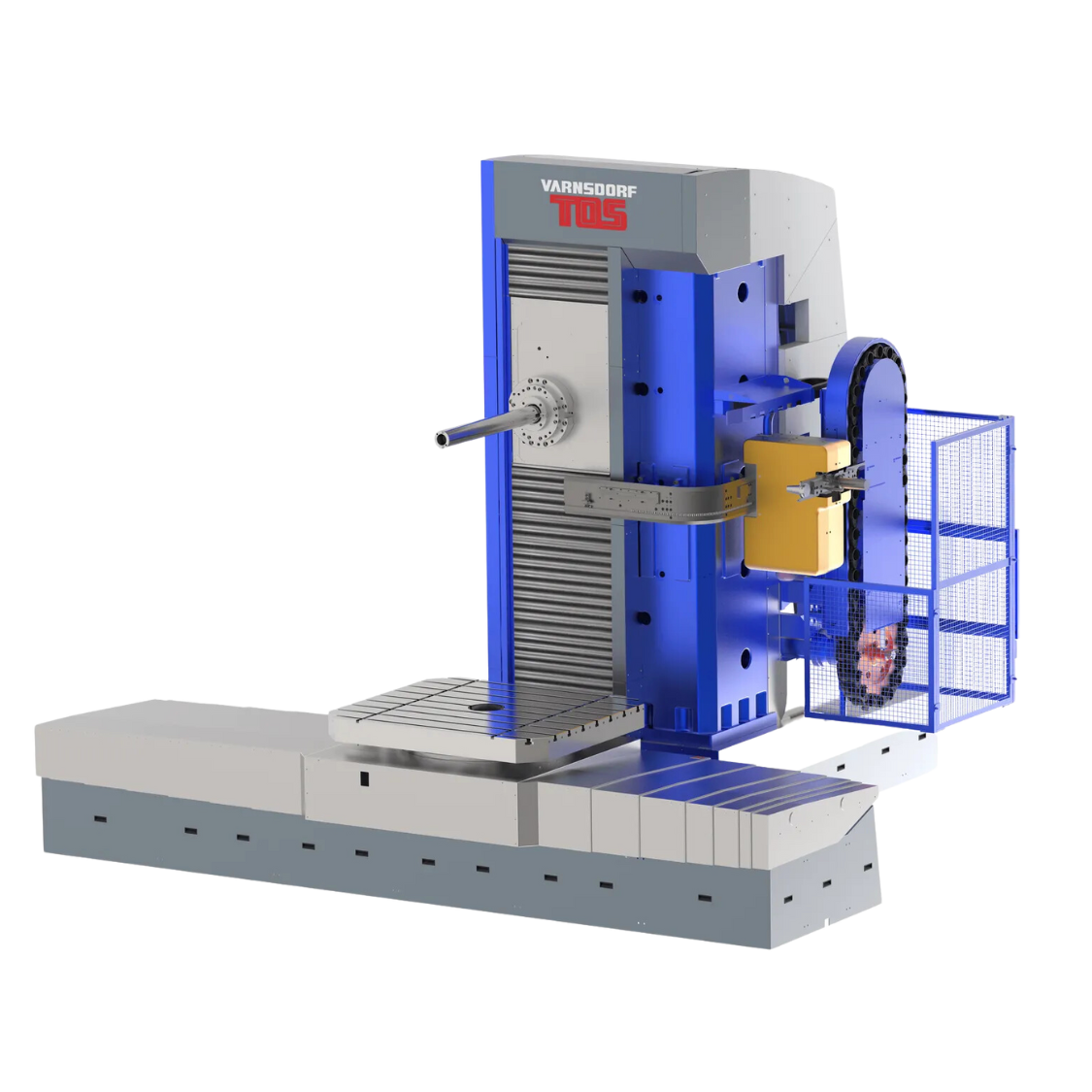

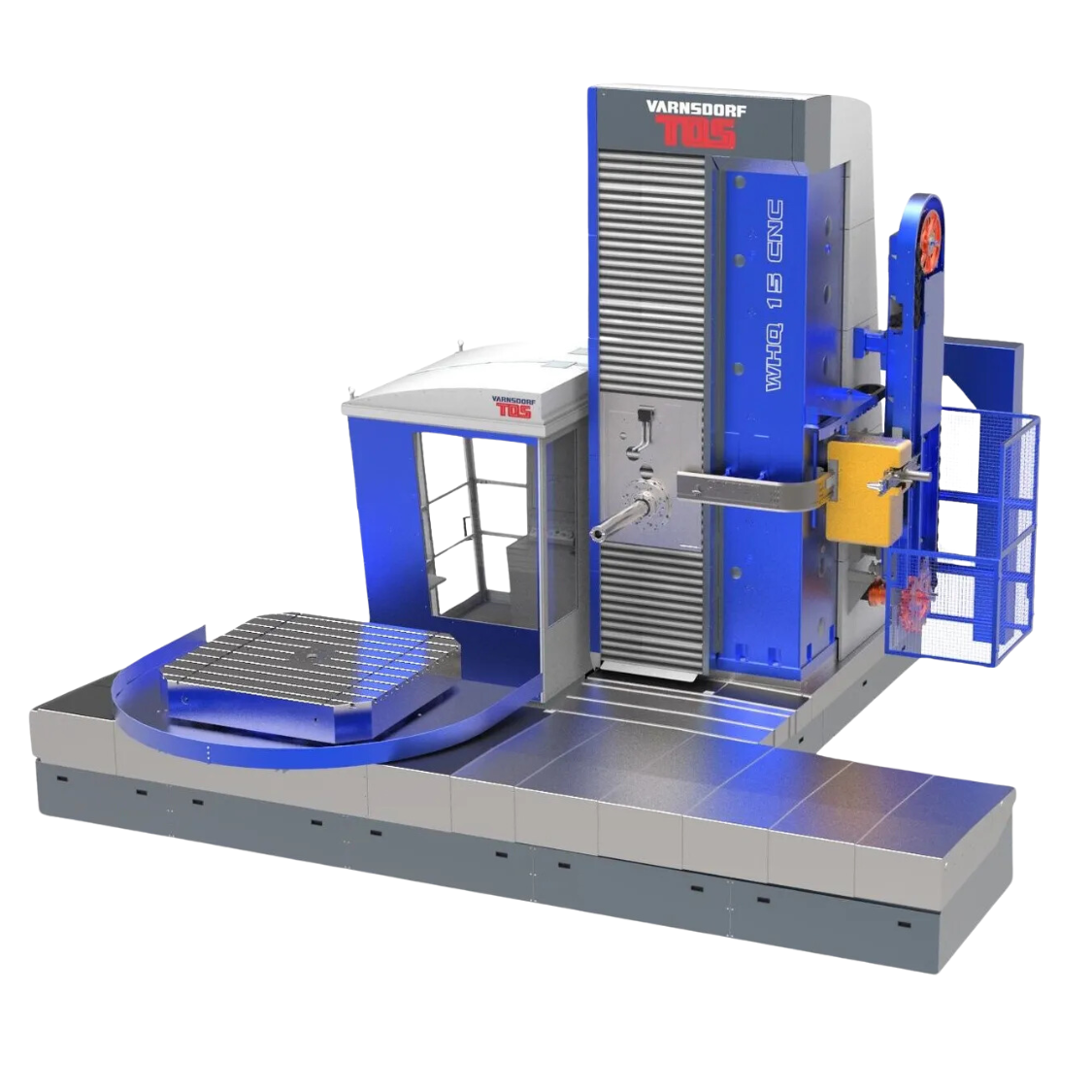

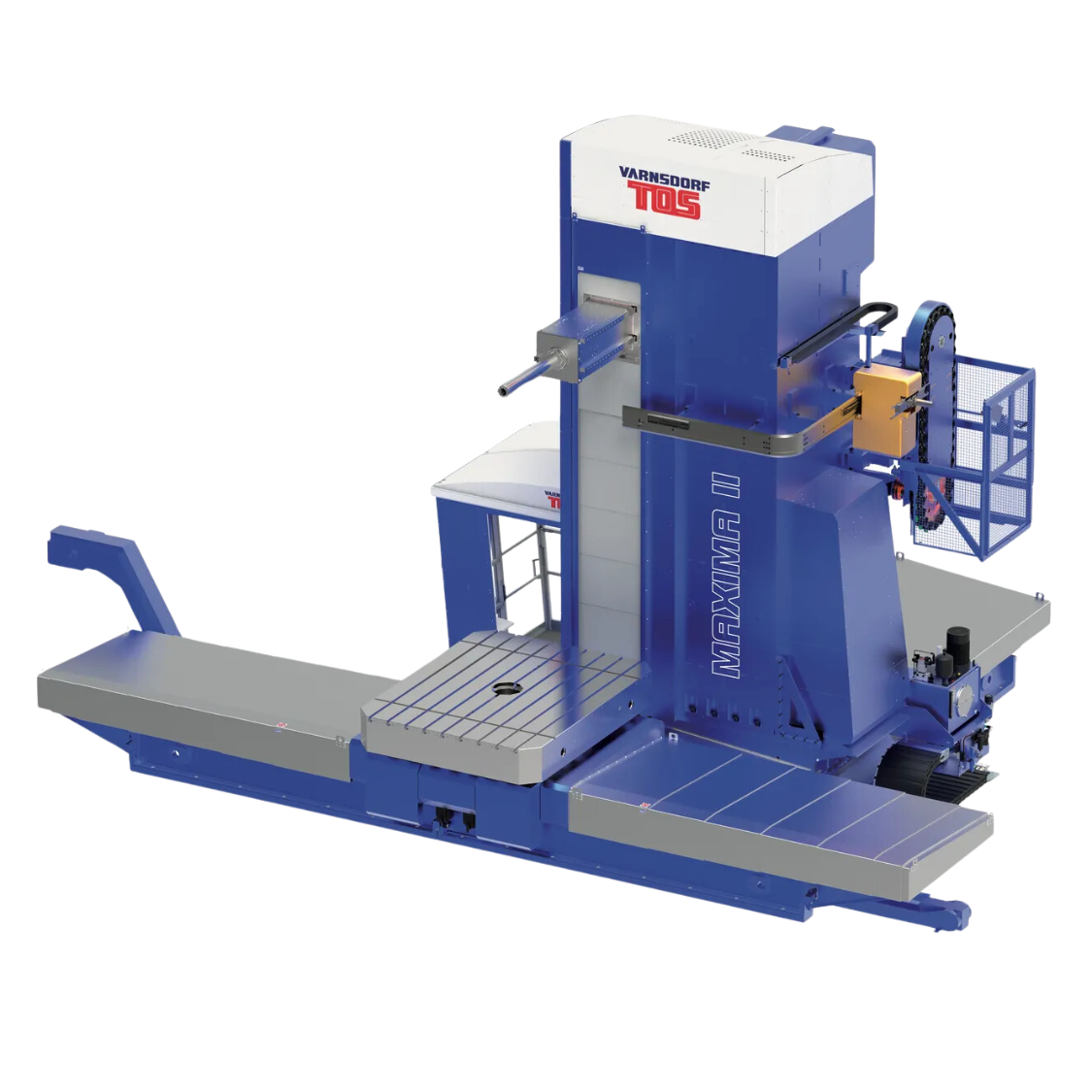

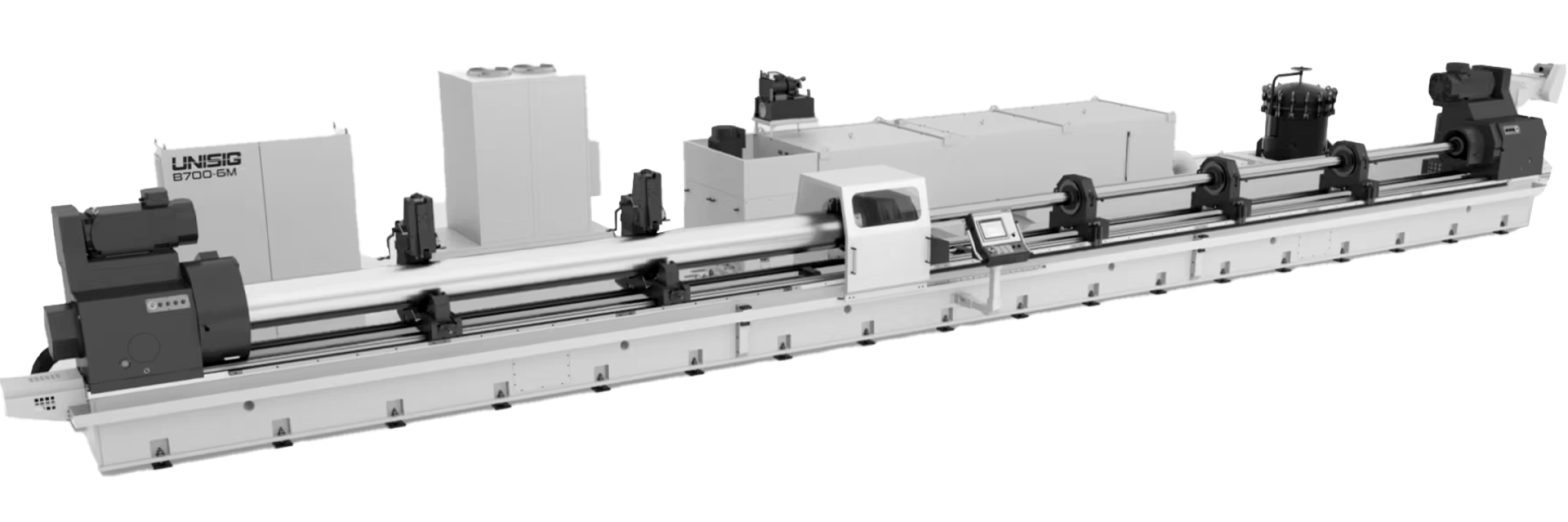

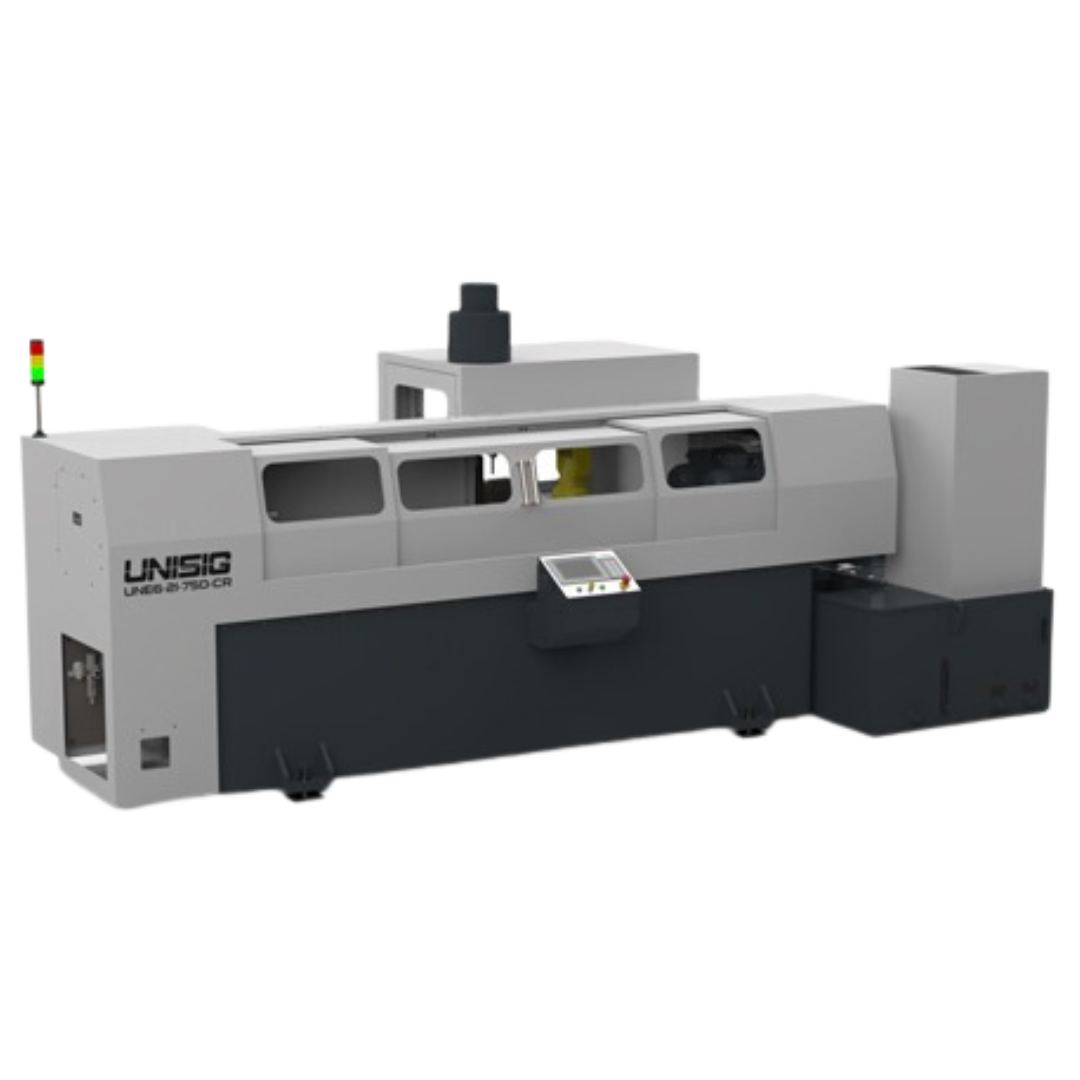

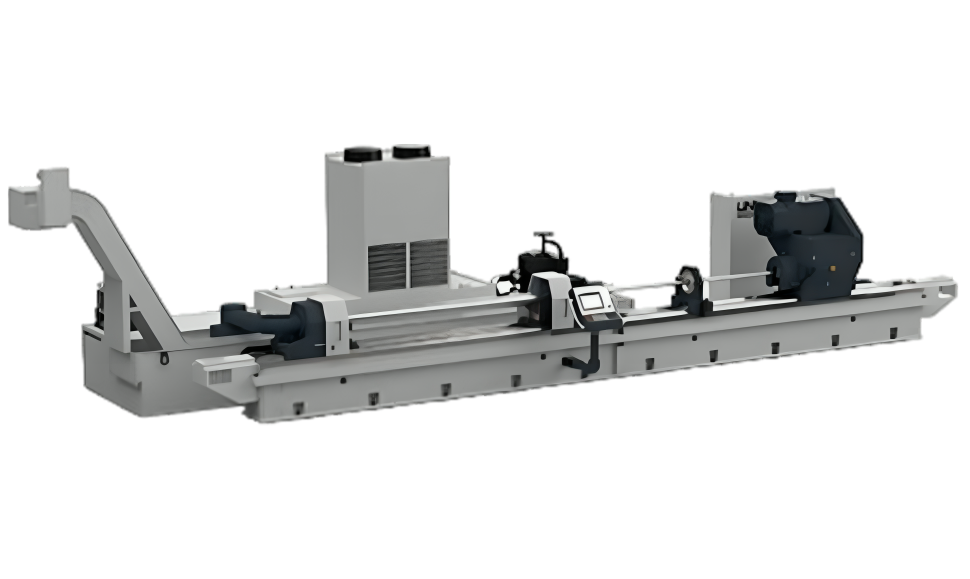

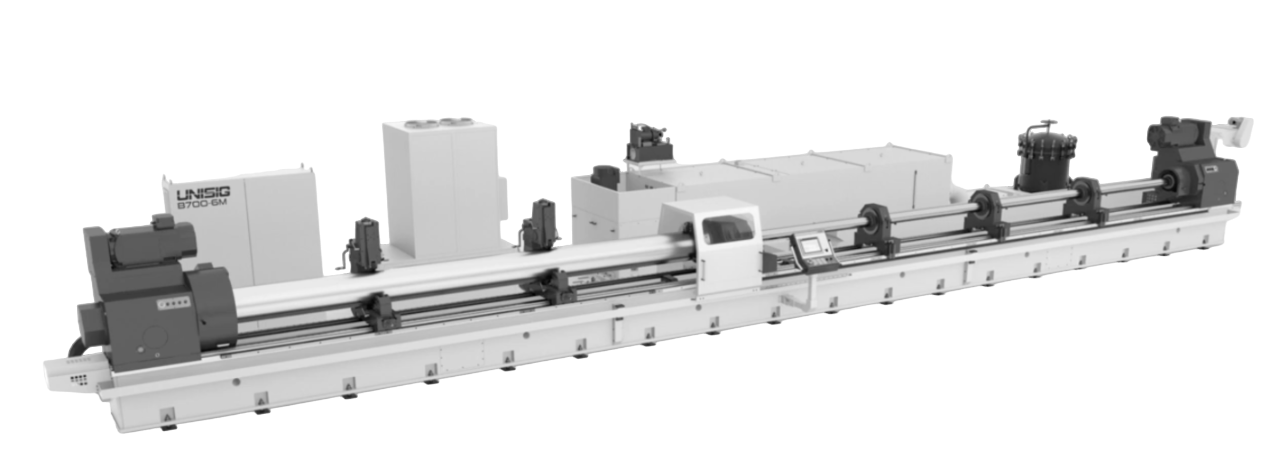

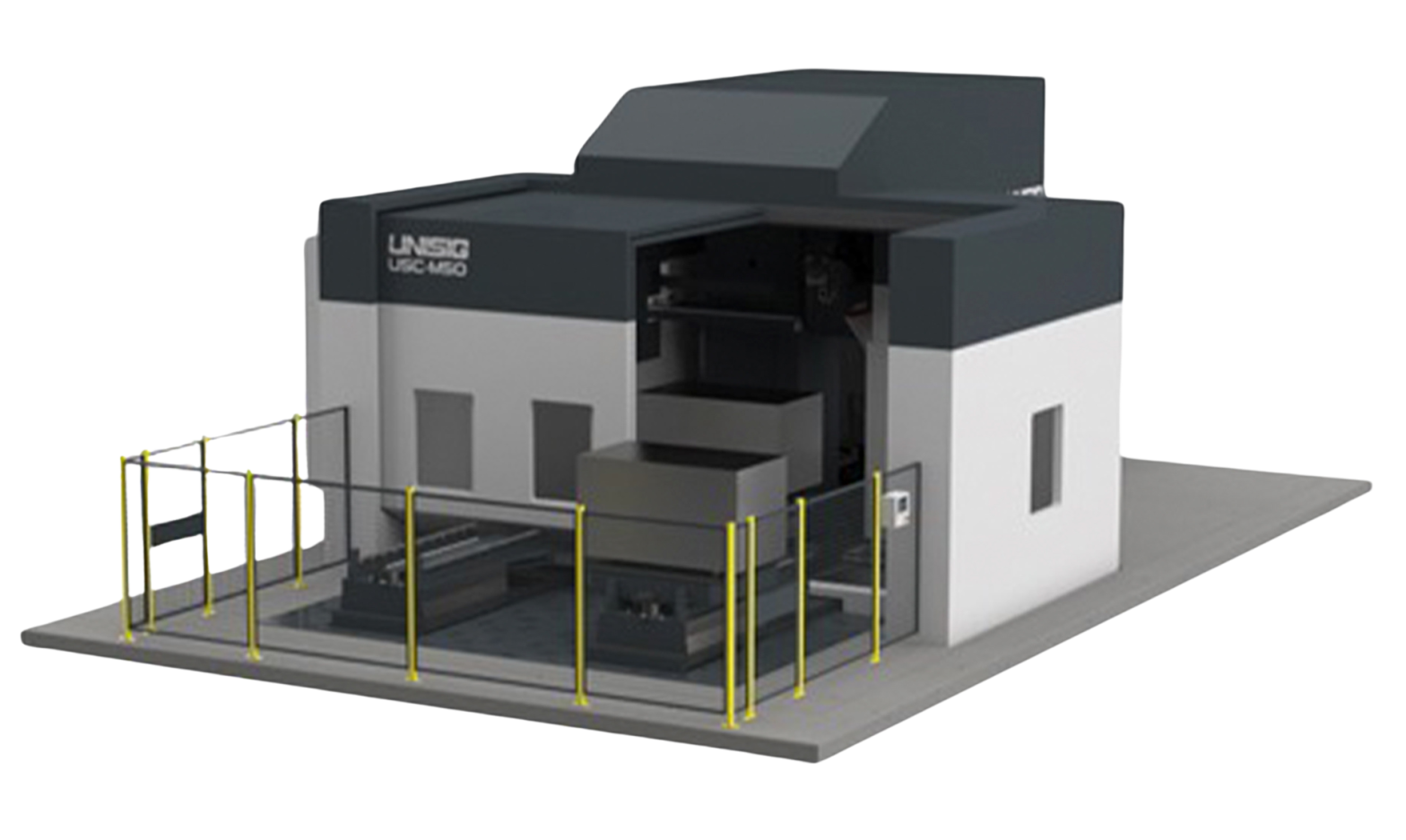

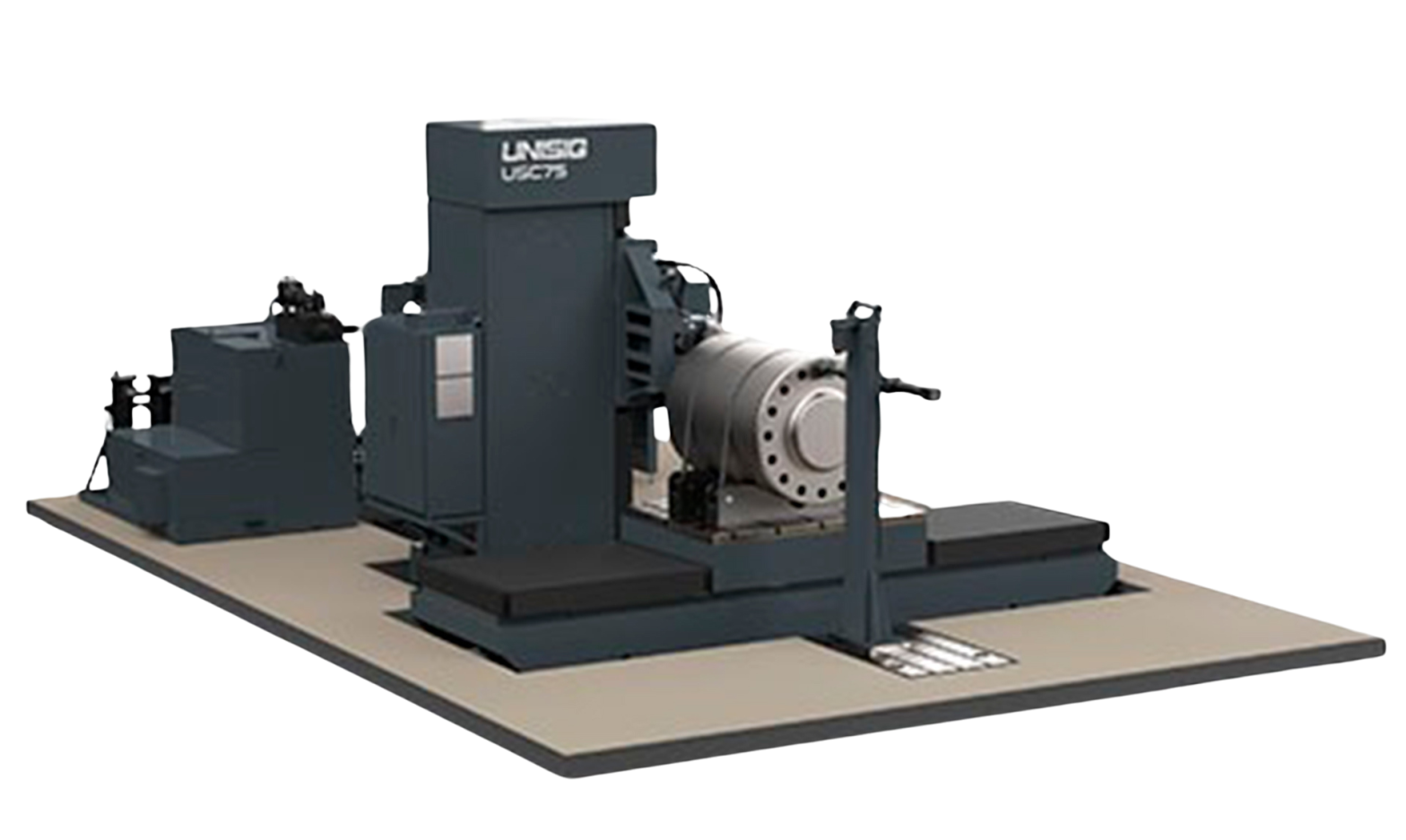

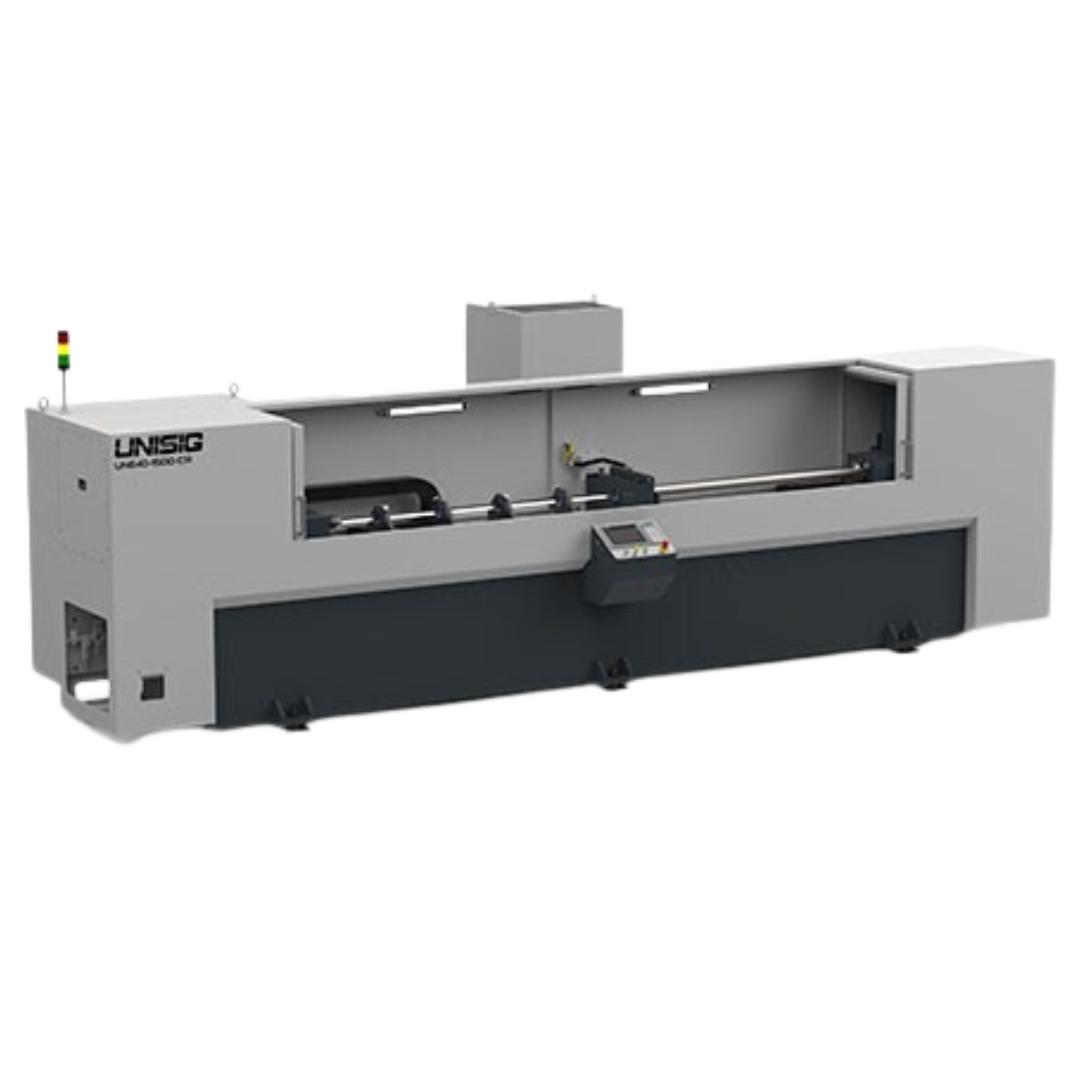

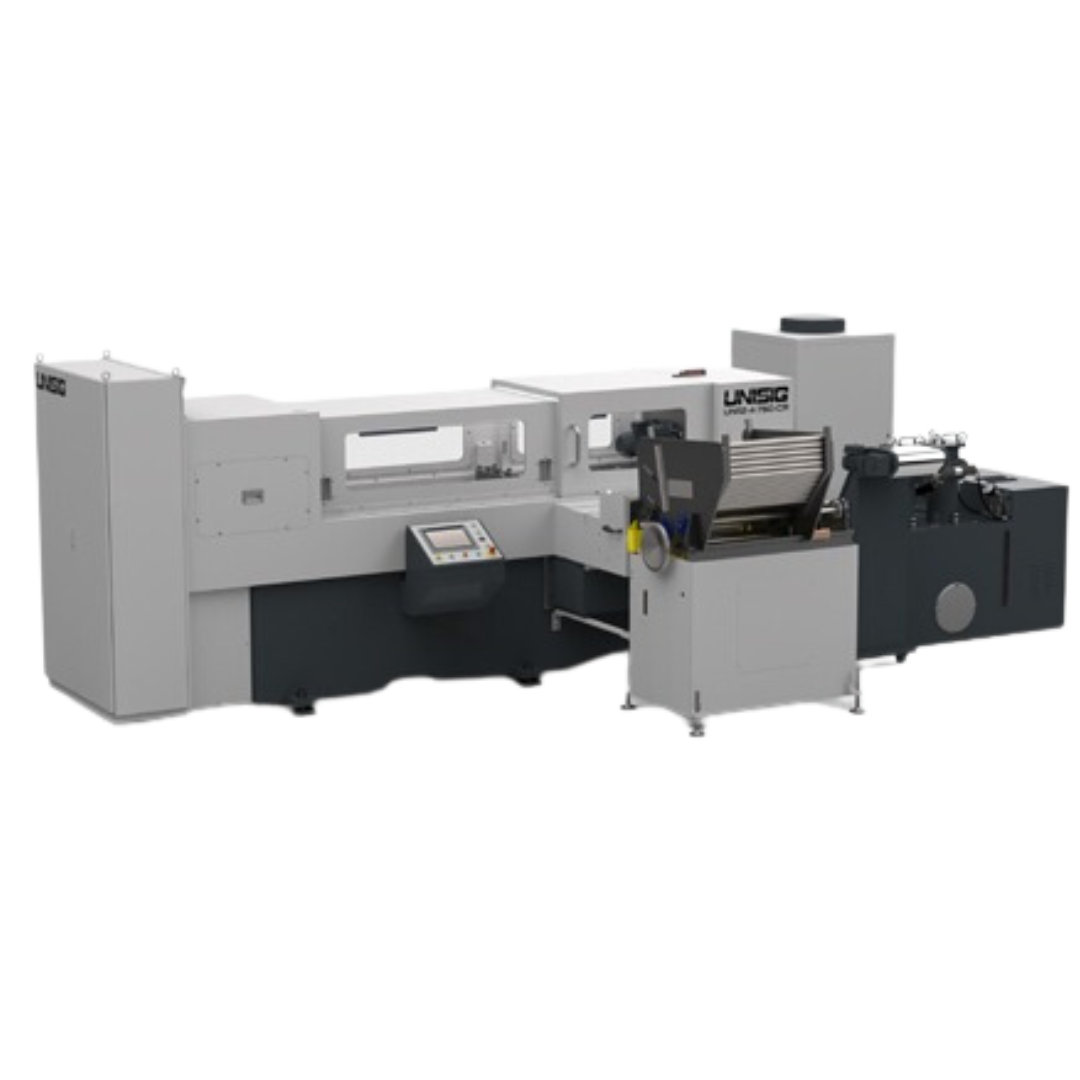

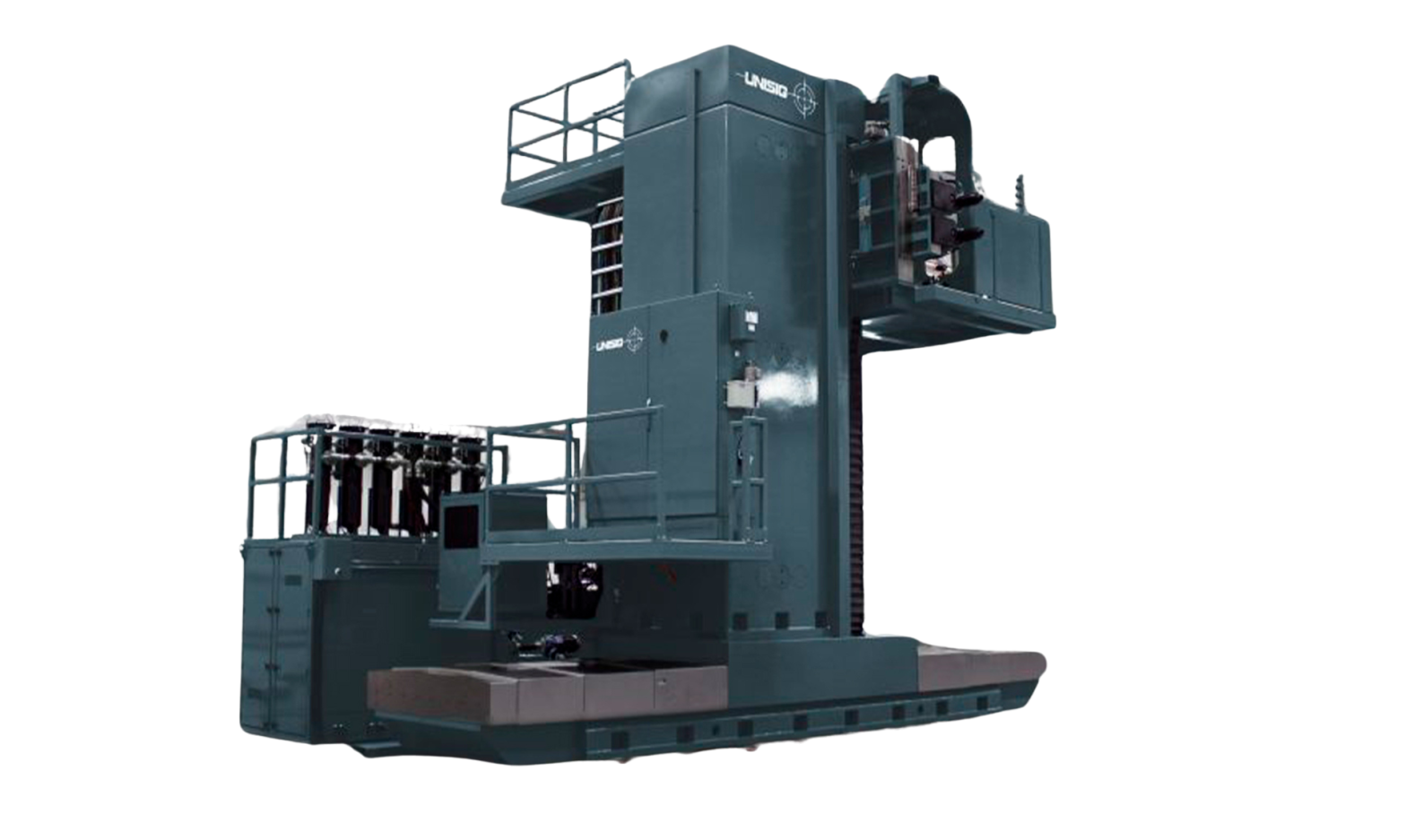

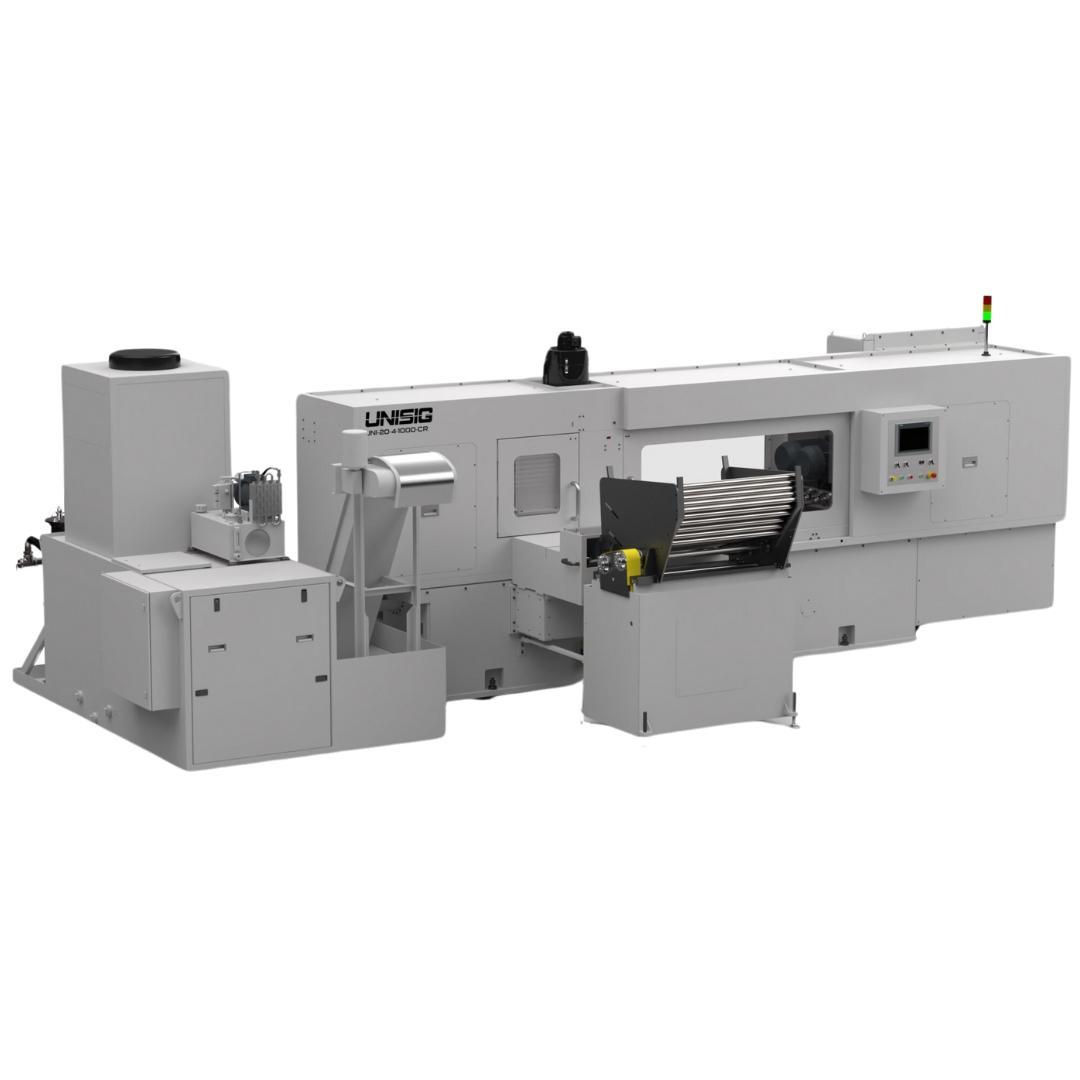

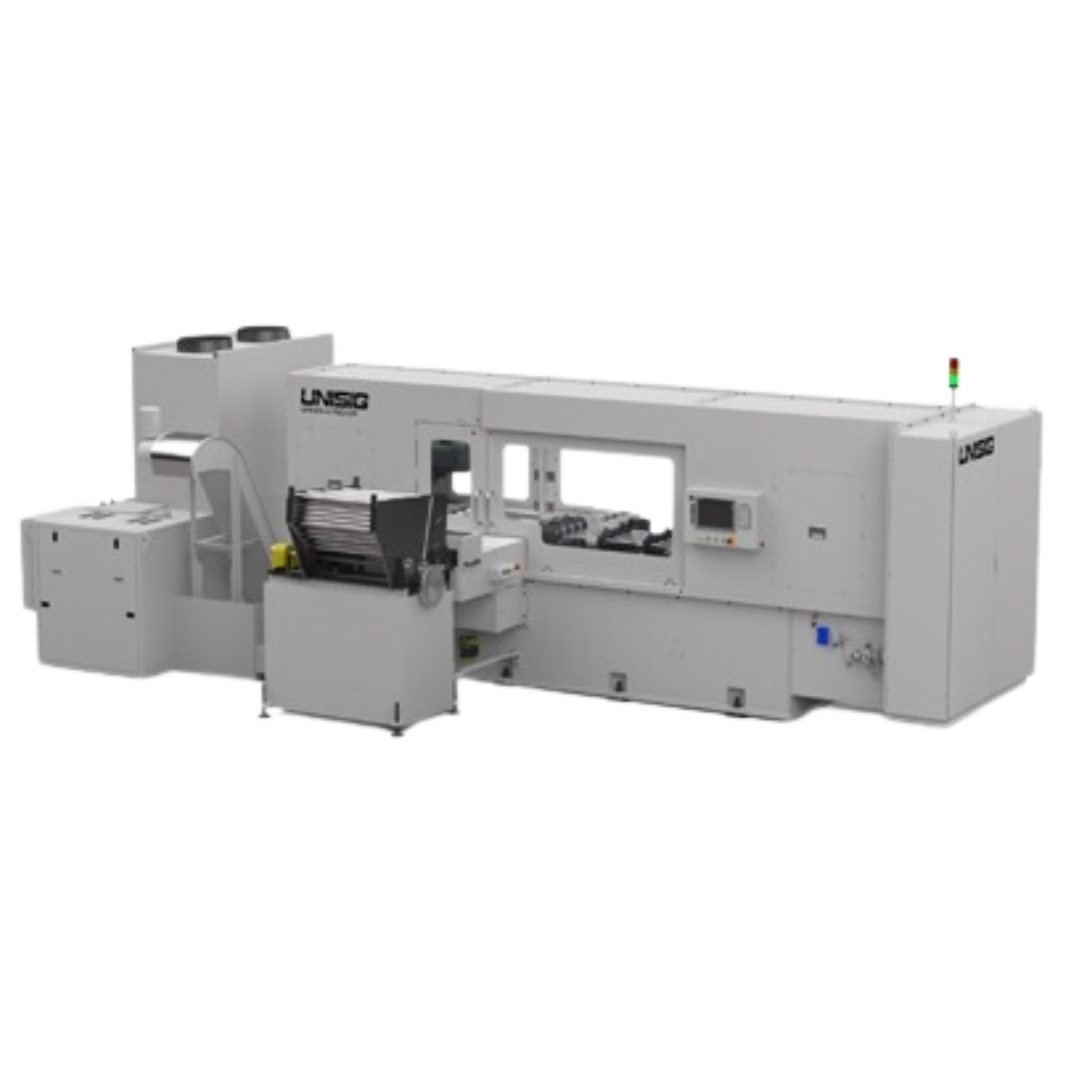

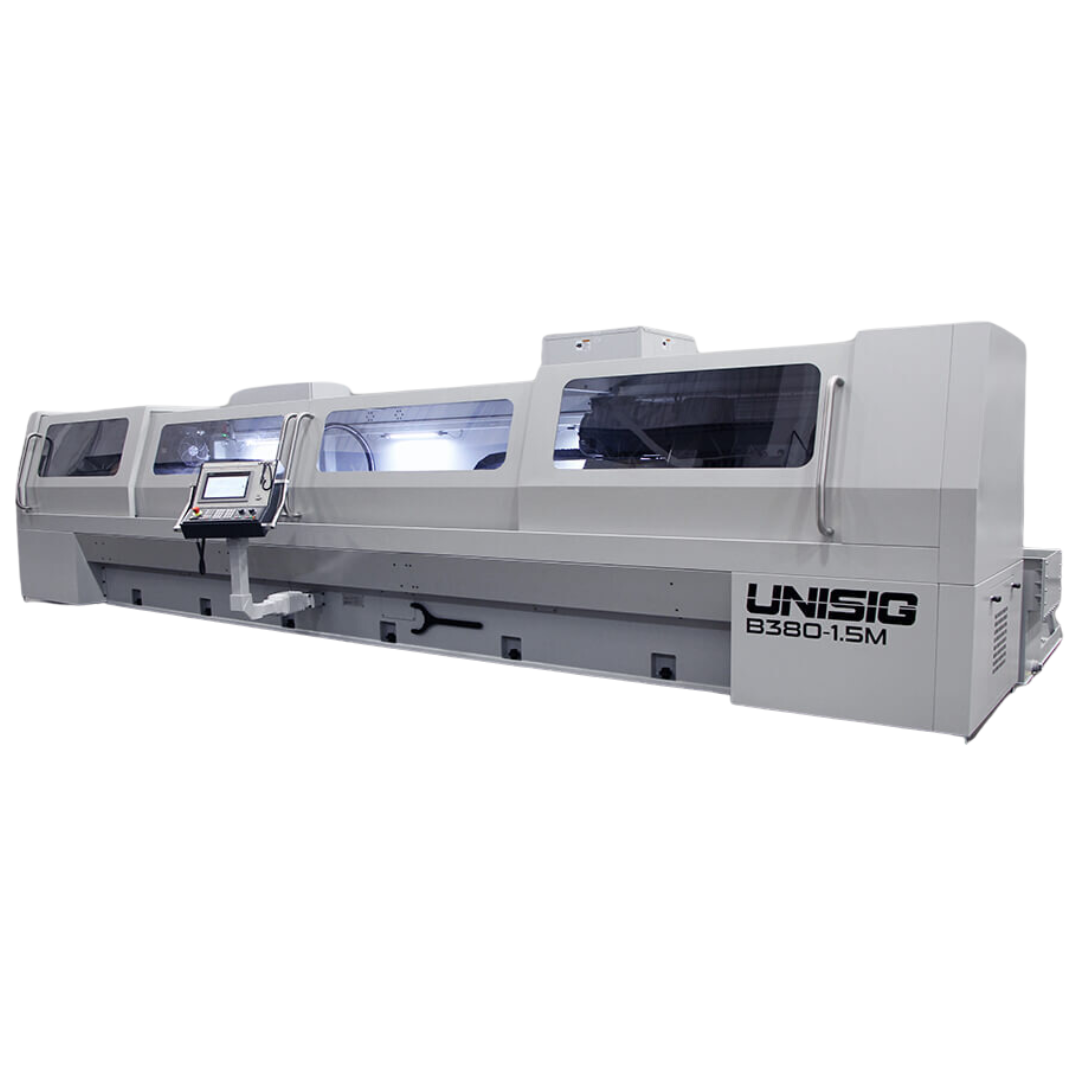

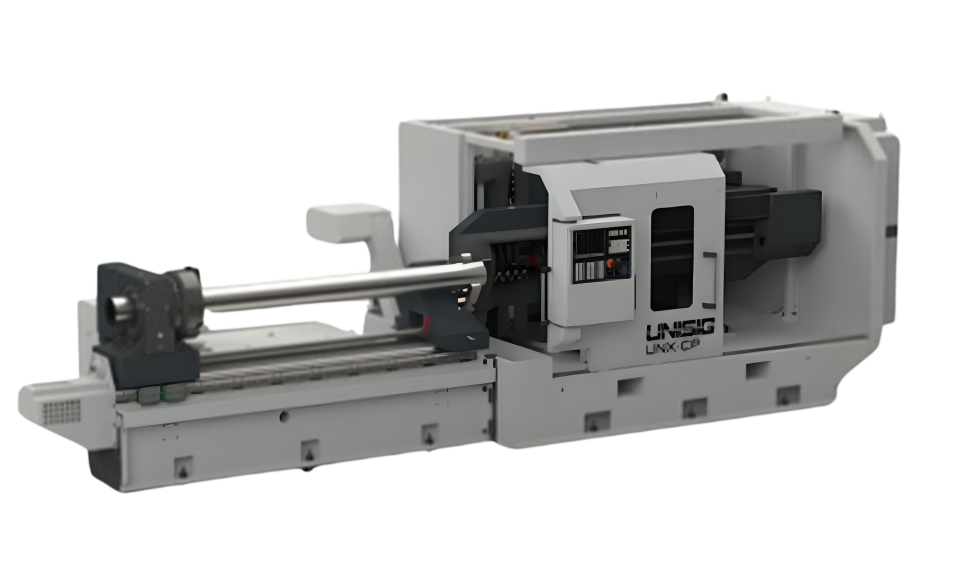

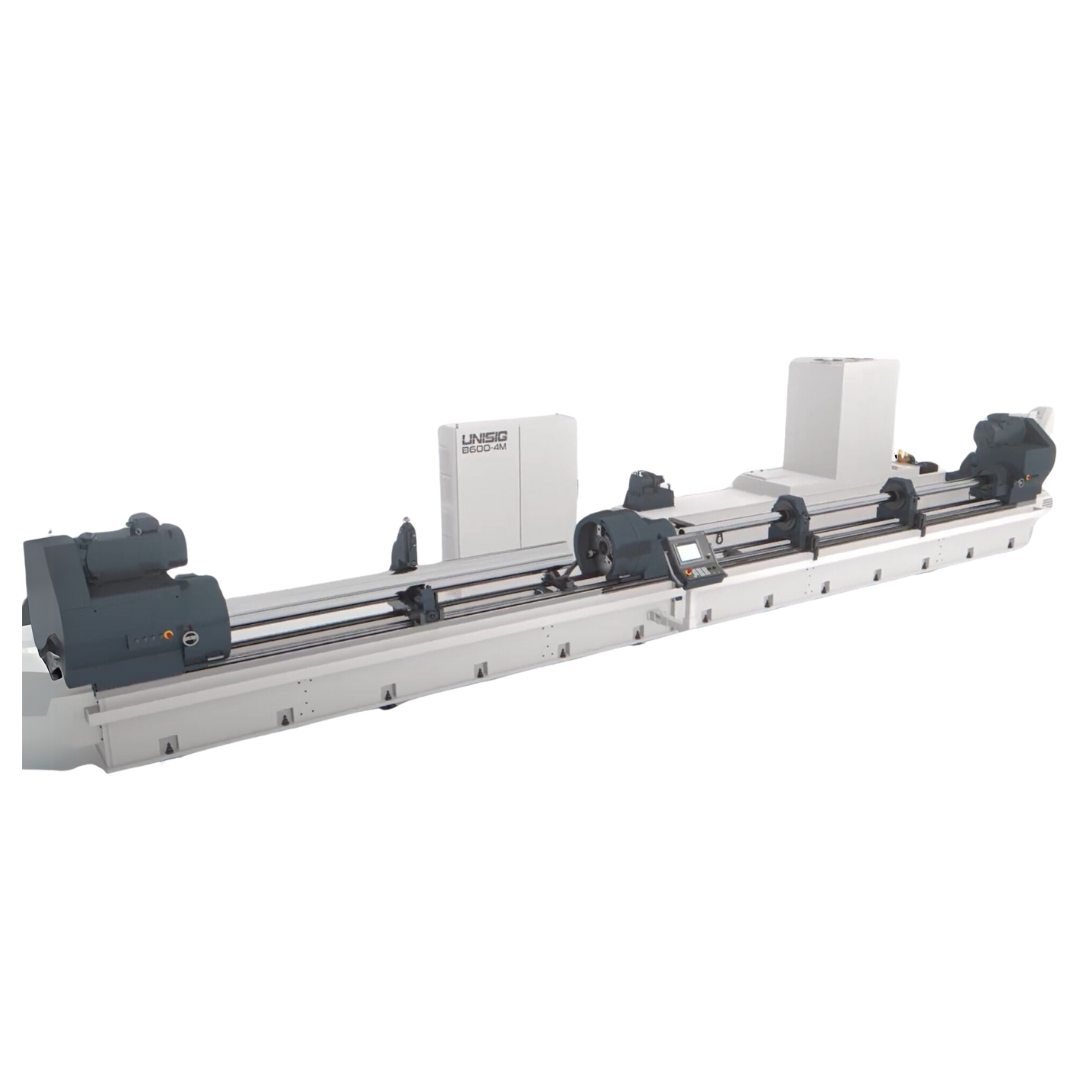

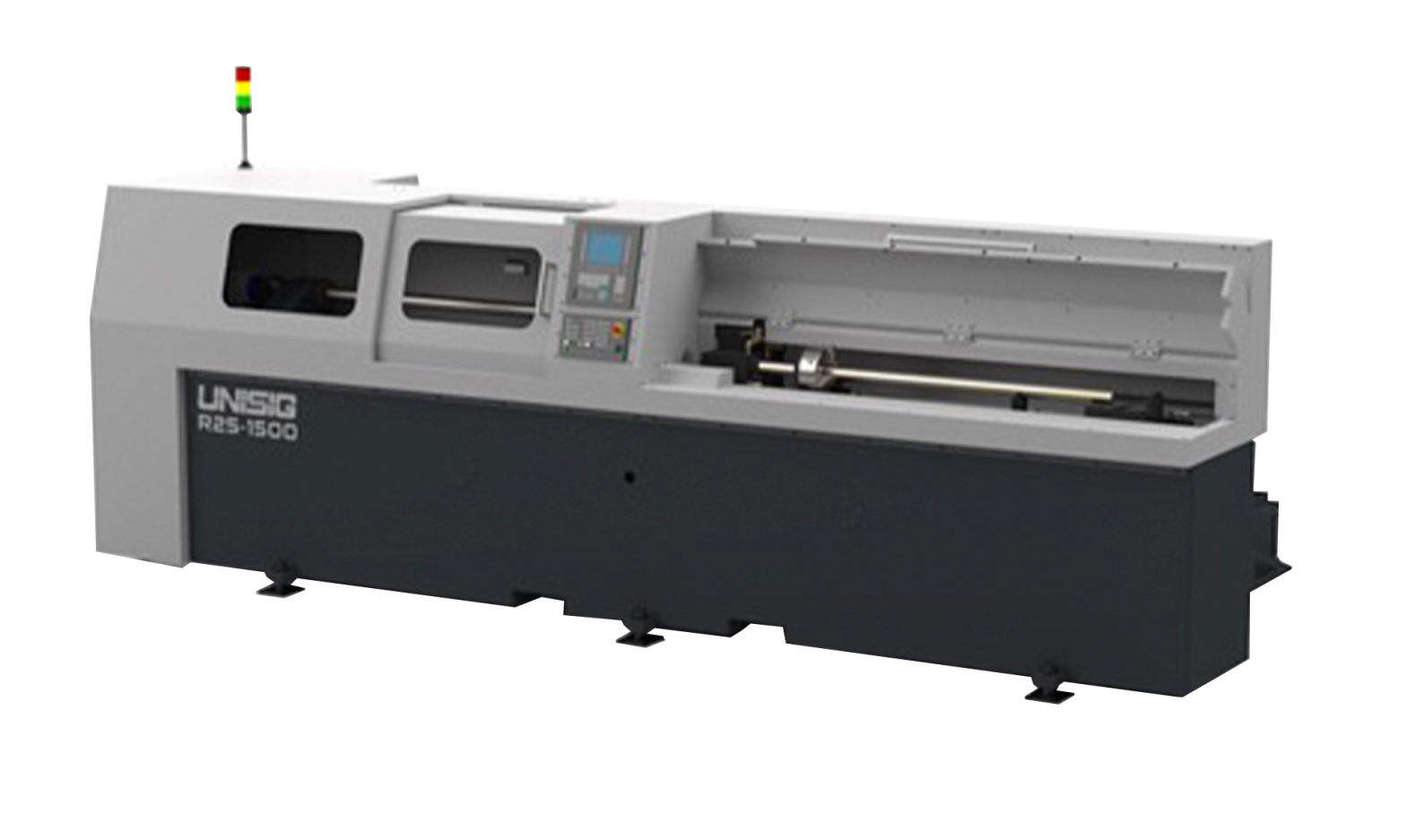

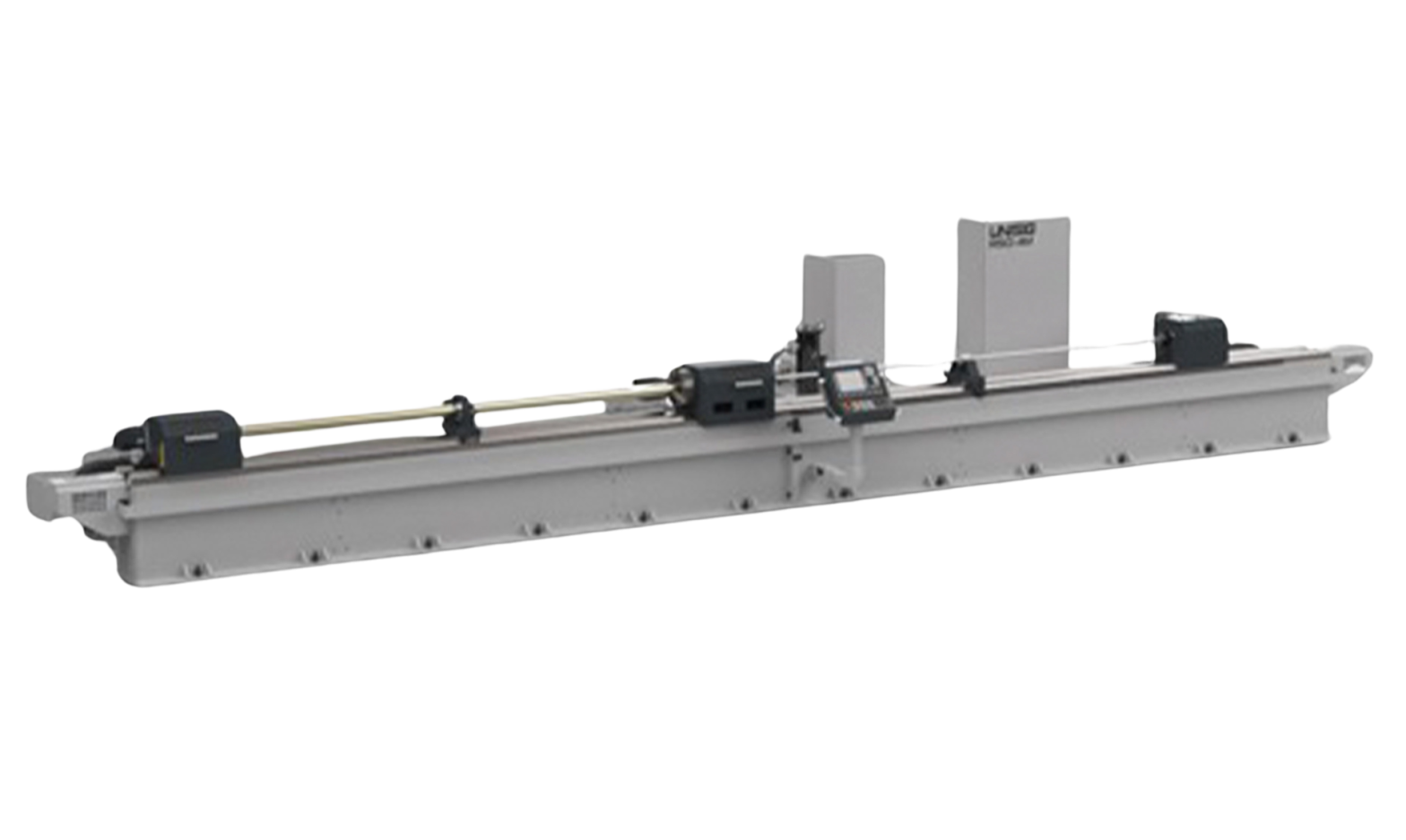

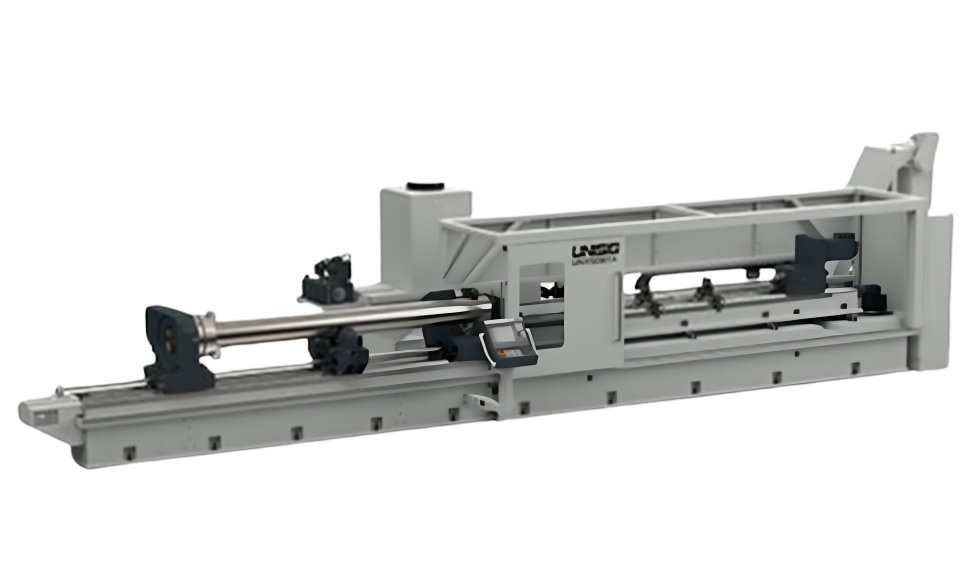

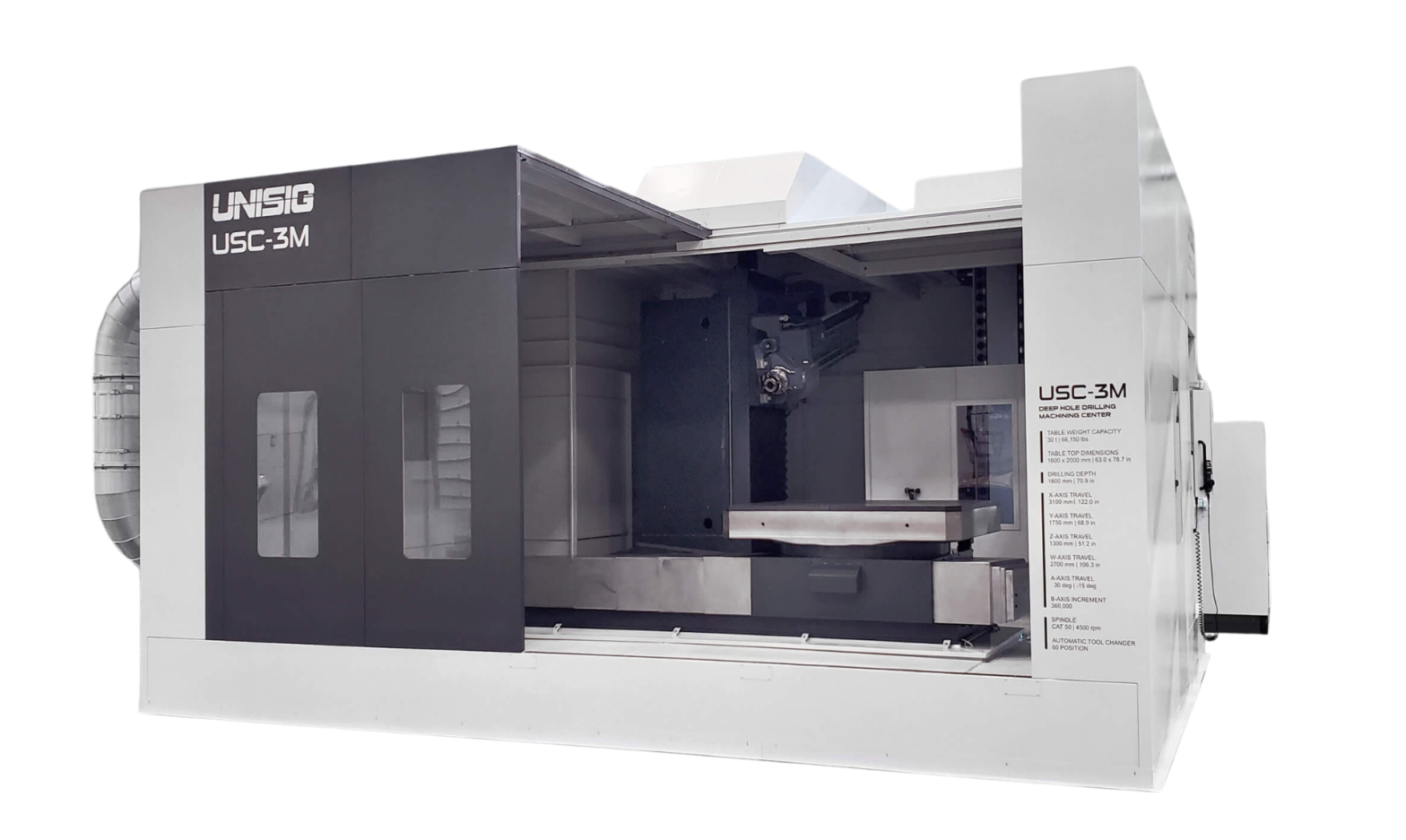

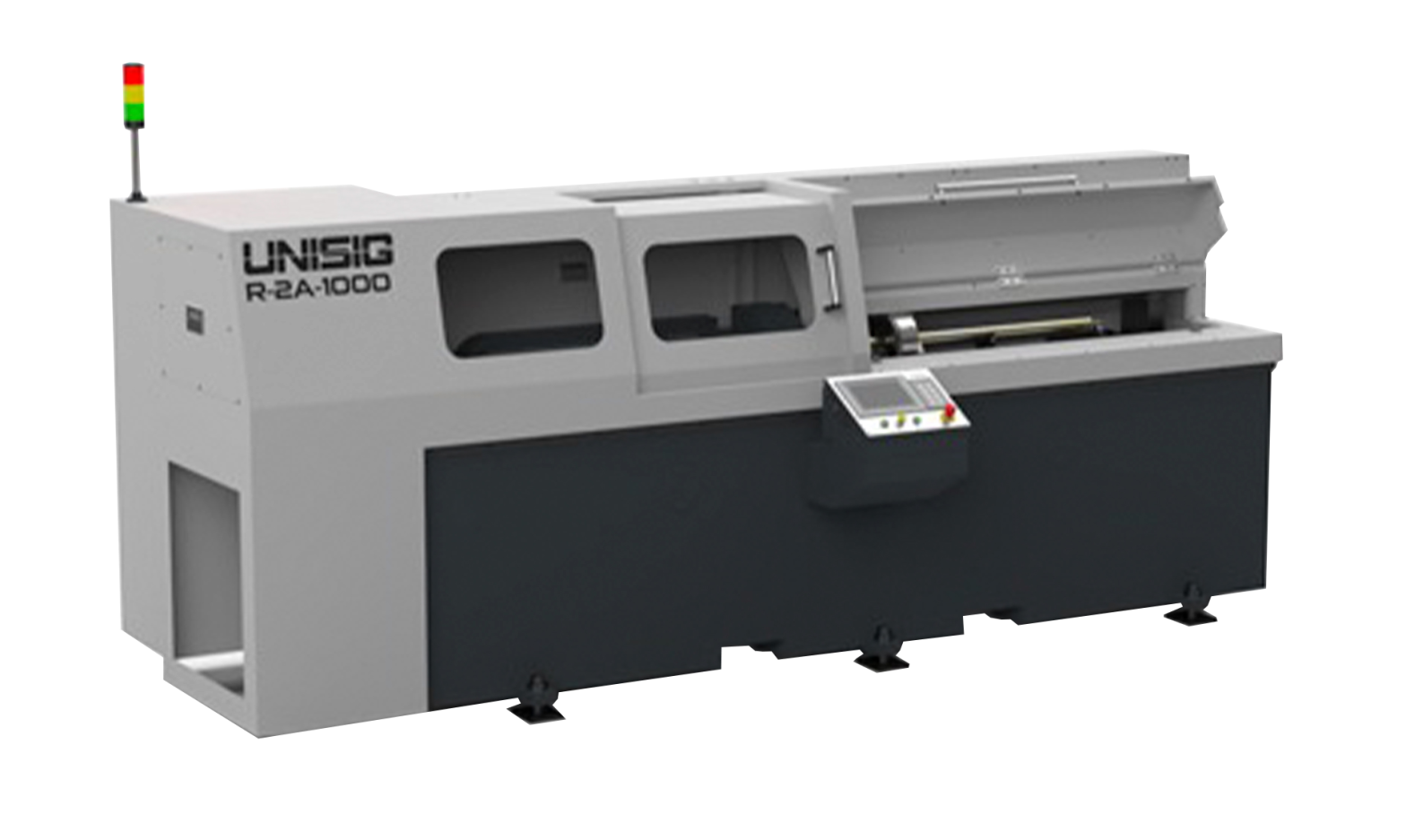

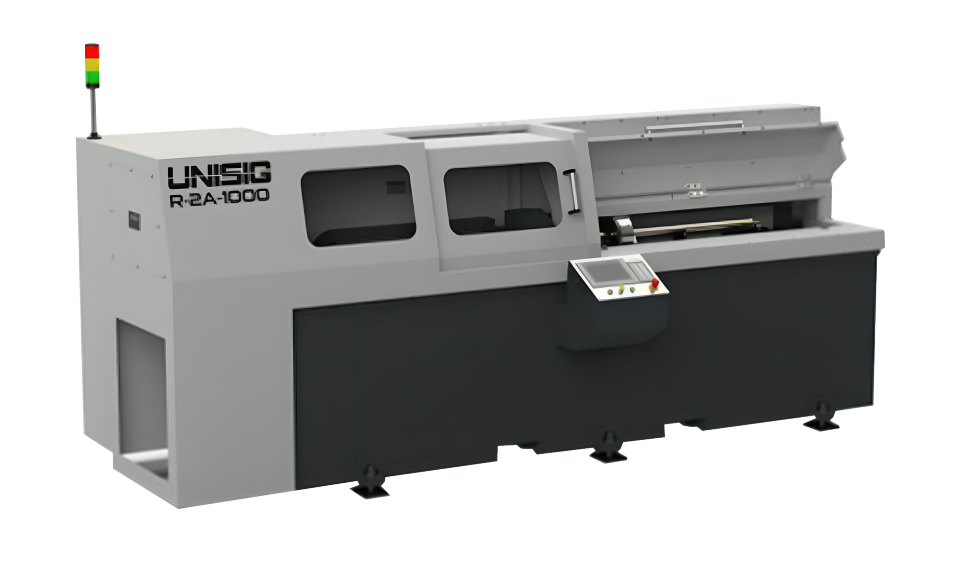

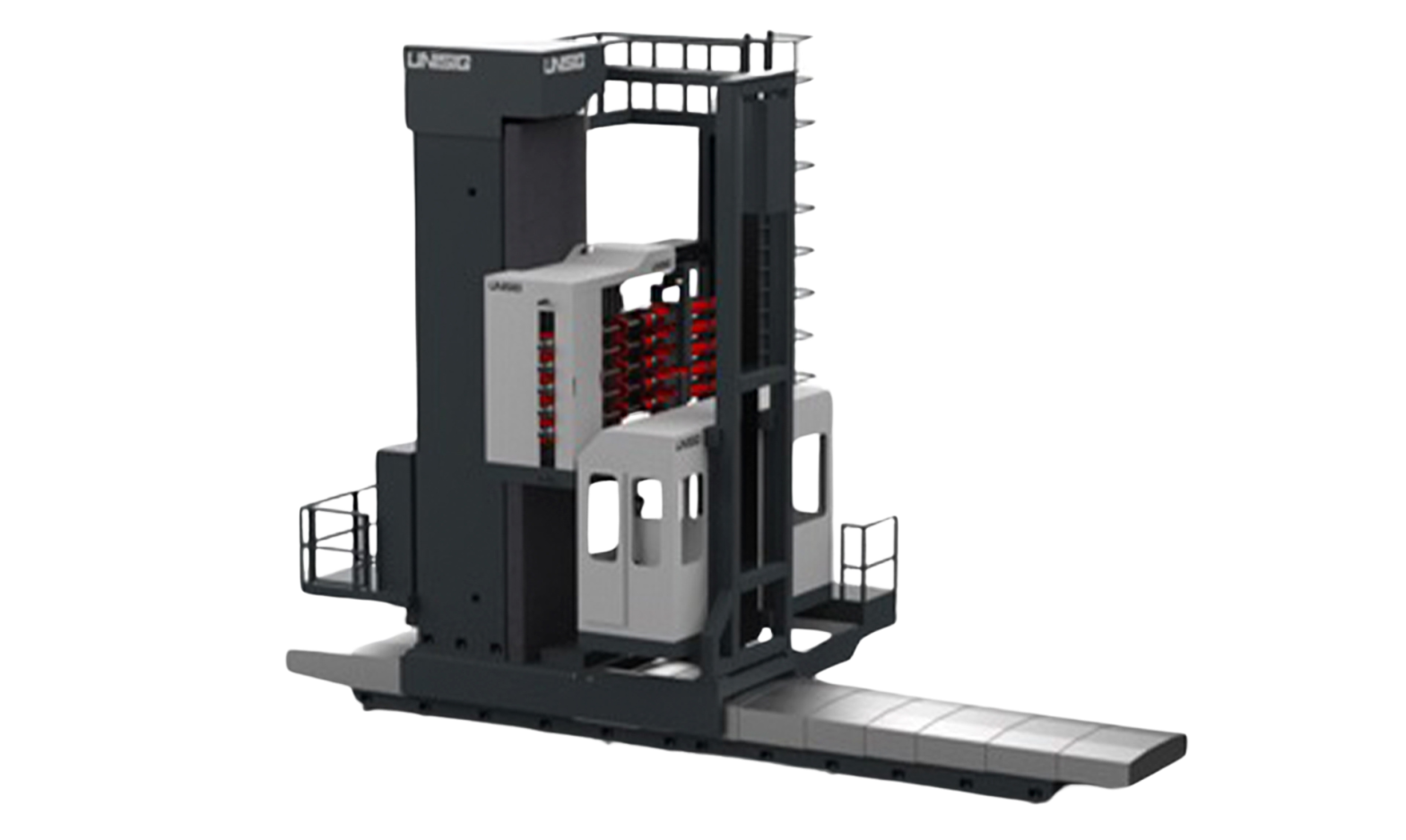

When tube sheet manufacturers require thousands of precision holes in extremely large, high-value workpieces, there is no room for error. The USC-TS tube sheet deep hole drilling machines use multiple-spindle configurations, and programmable positioning to bring confident drilling to heat exchanger tube sheets. Accurate drilling in fast cycles allows manufacturers to drill more holes with improved accuracy, without risk.

USC-TS machines are based on proven USC column-type machines, designed for the specific demands of the tube sheet industry. Machines have virtually limitless weight capacity, extremely large travels, and high efficiency BTA and gundrilling, all on a rigid machine base and column. Spindles are independent and available in 2, 3, or 5 spindle configurations to meet specific application demands.

Industries

Aerospace

Automotive

Fluid Control

Medical

Molds & Dies

Others

Product Highlights

Product Highlights

Number of Spindles

2, 3, 5

Hole Diameter Min (in) Hole Diameter Min (mm)

0.318

Drill Diameter Max (in) Drill Diameter Max (mm)

250

Hole Diameter Max (in) Hole Diameter Max (mm)

250

Hole Depth Max (in) Hole Depth Max (mm)

39.371000

Workpiece dimensions (in)Workpiece dimensions (mm)

401000

Workpiece weight max (kg)

100000

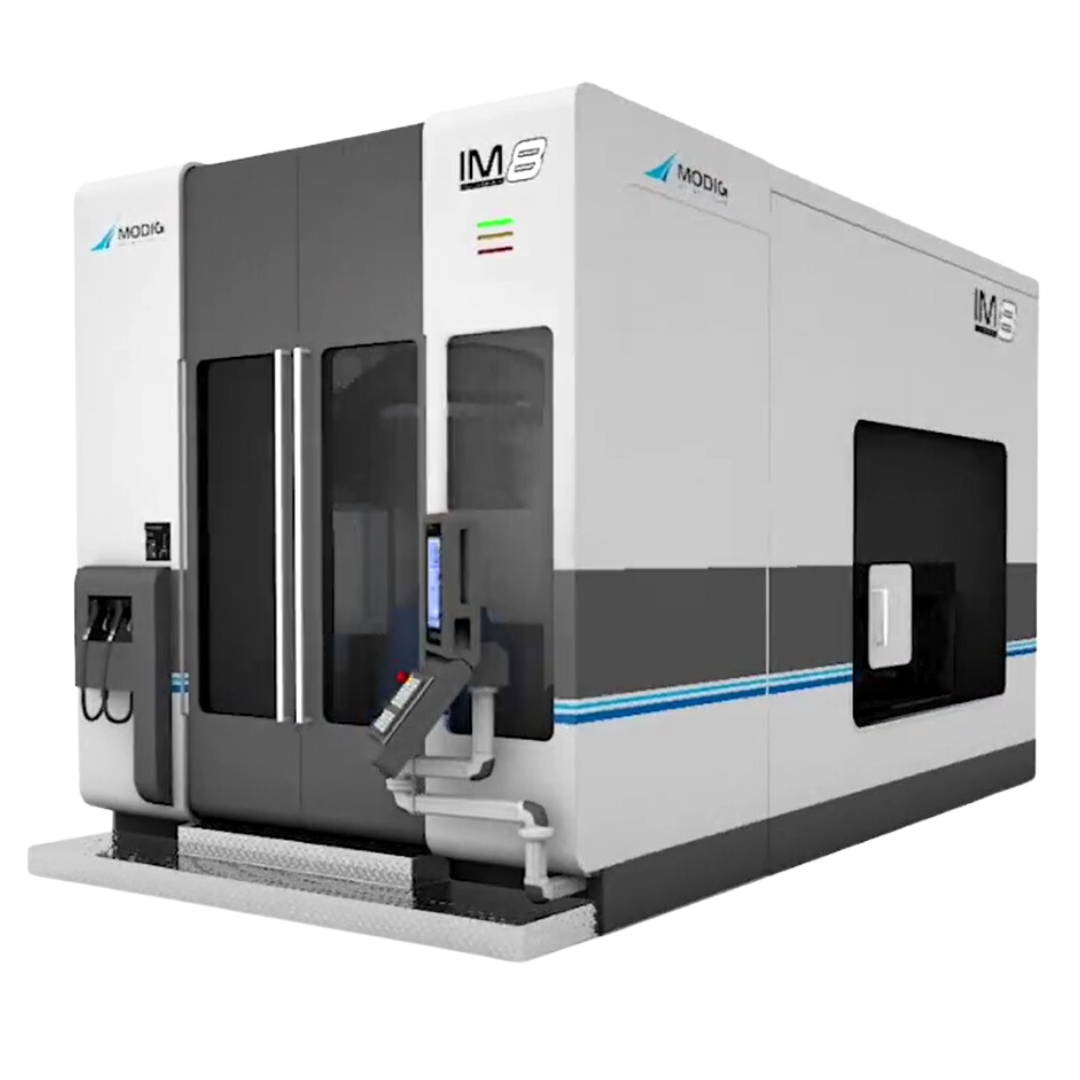

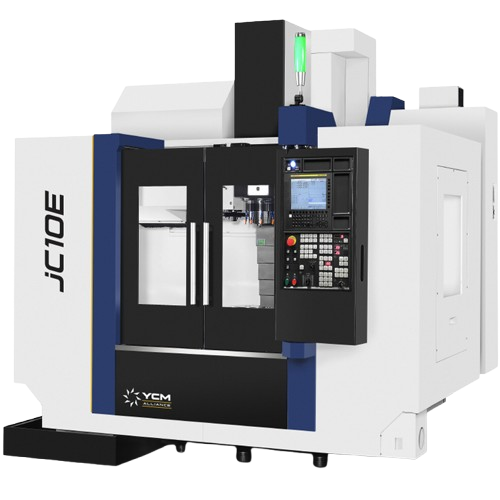

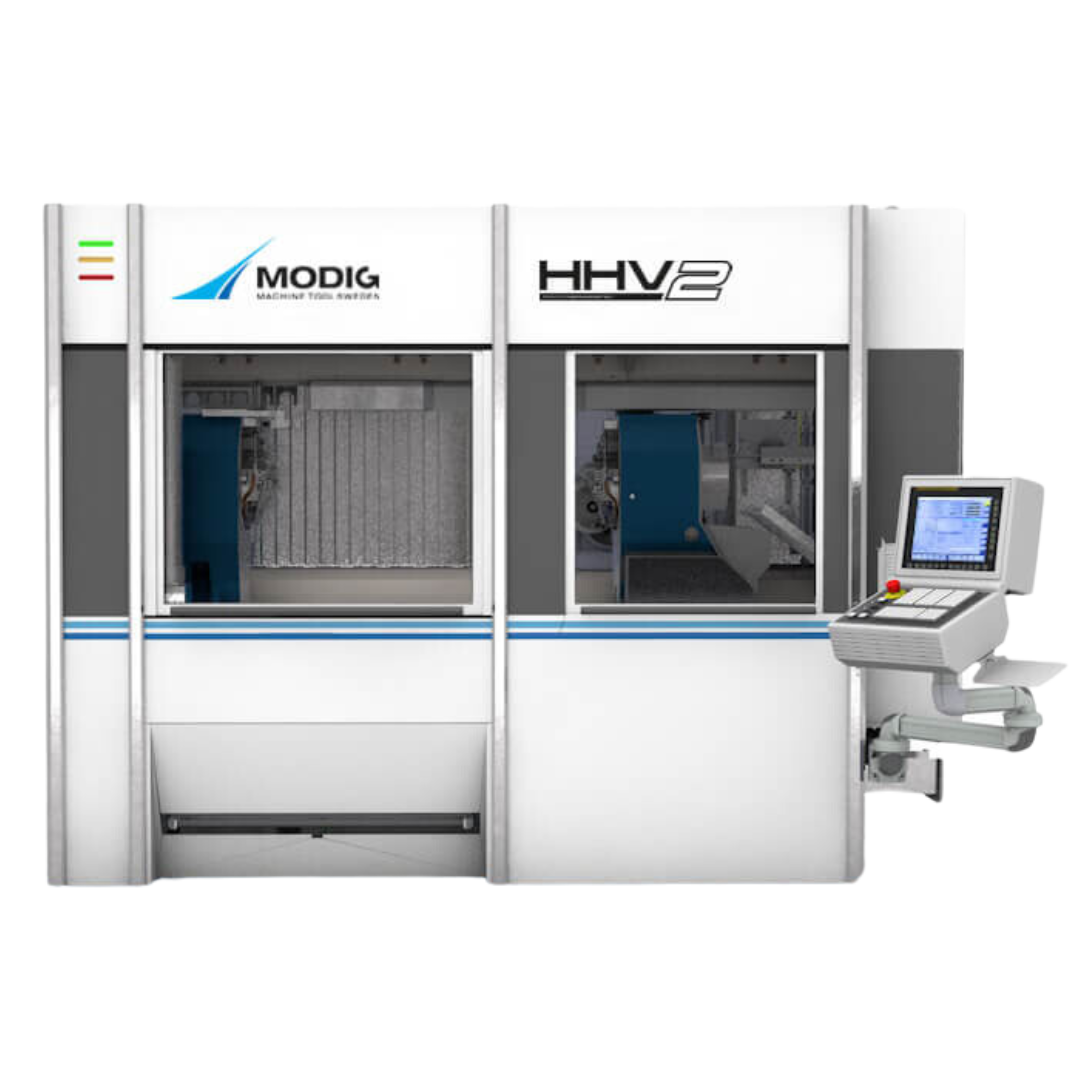

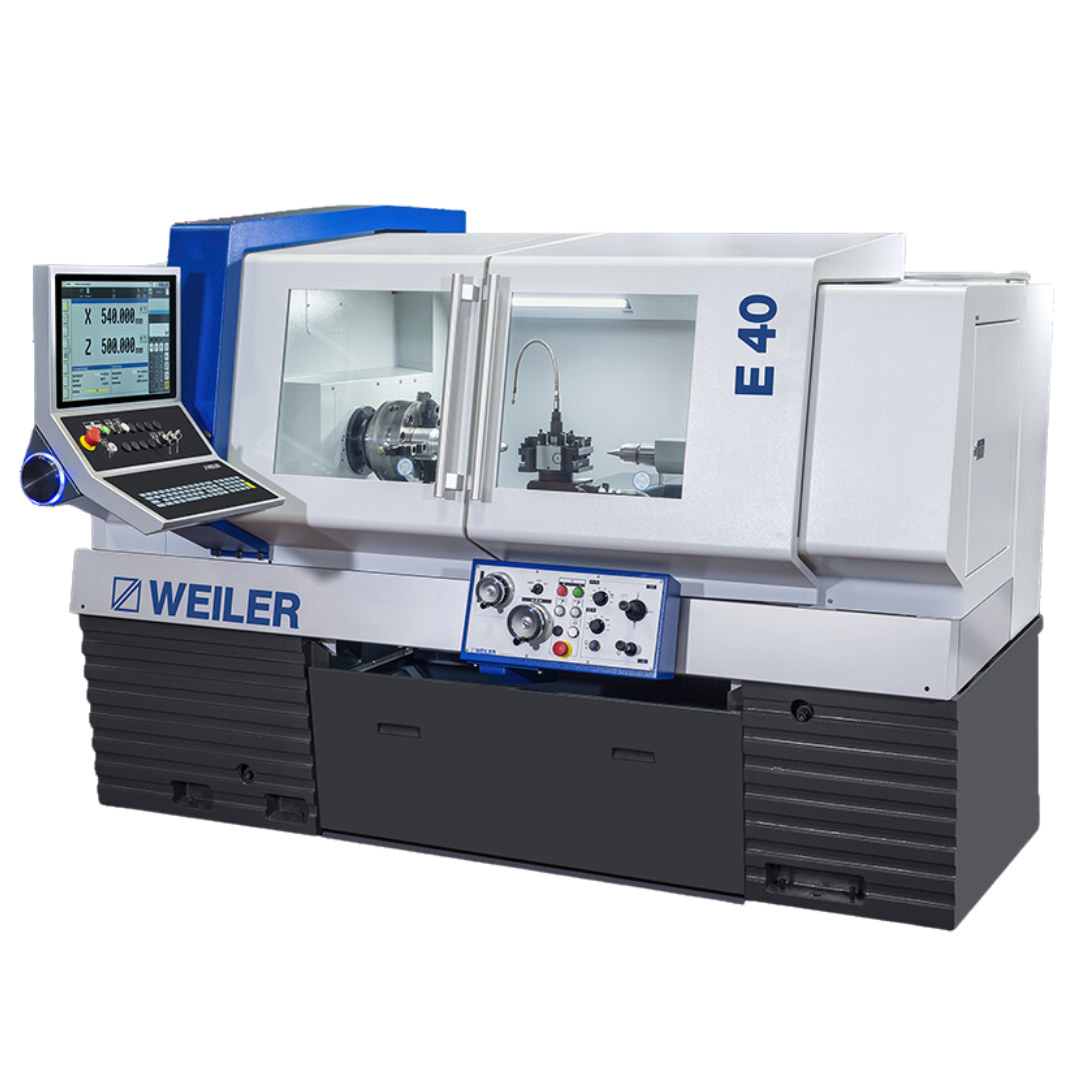

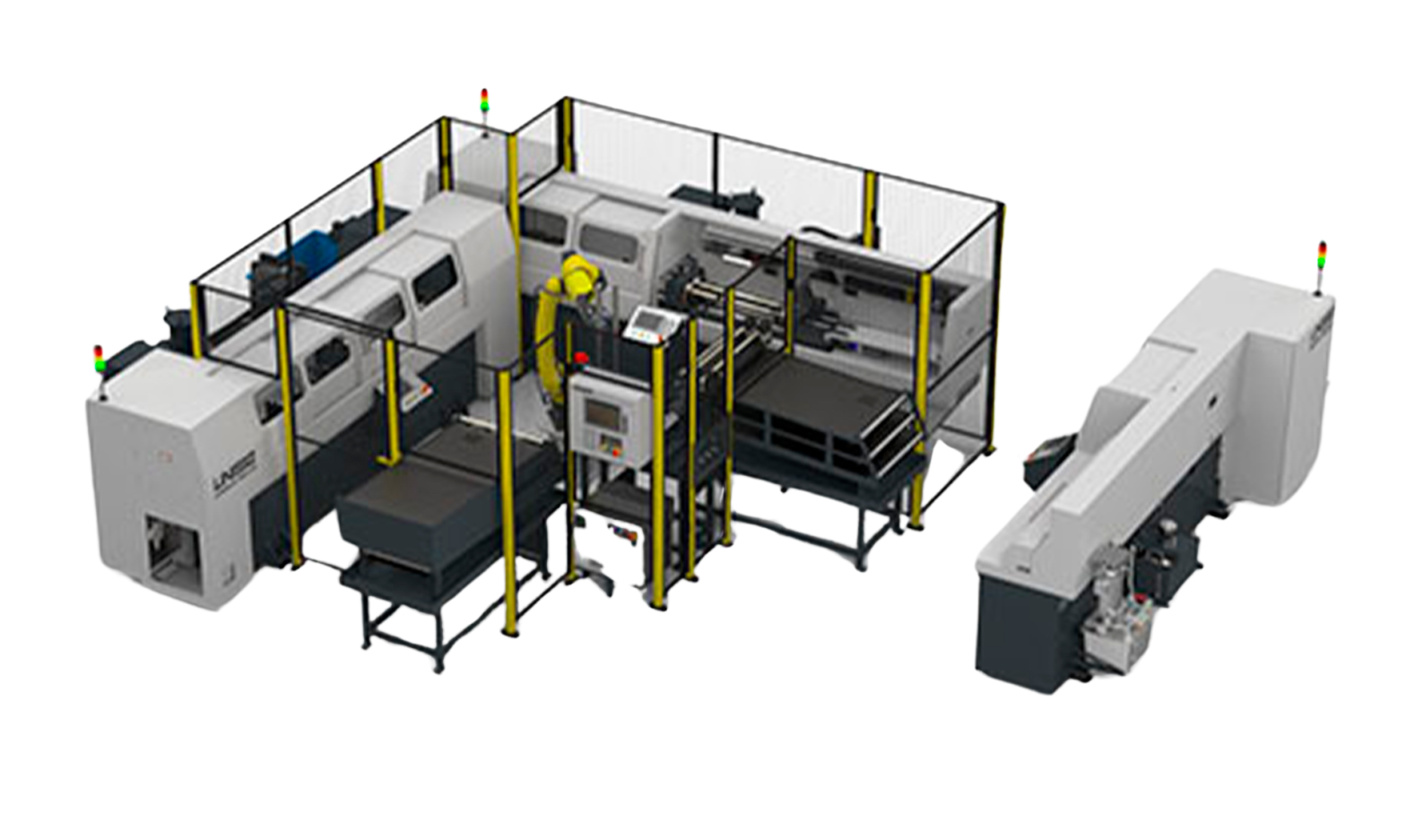

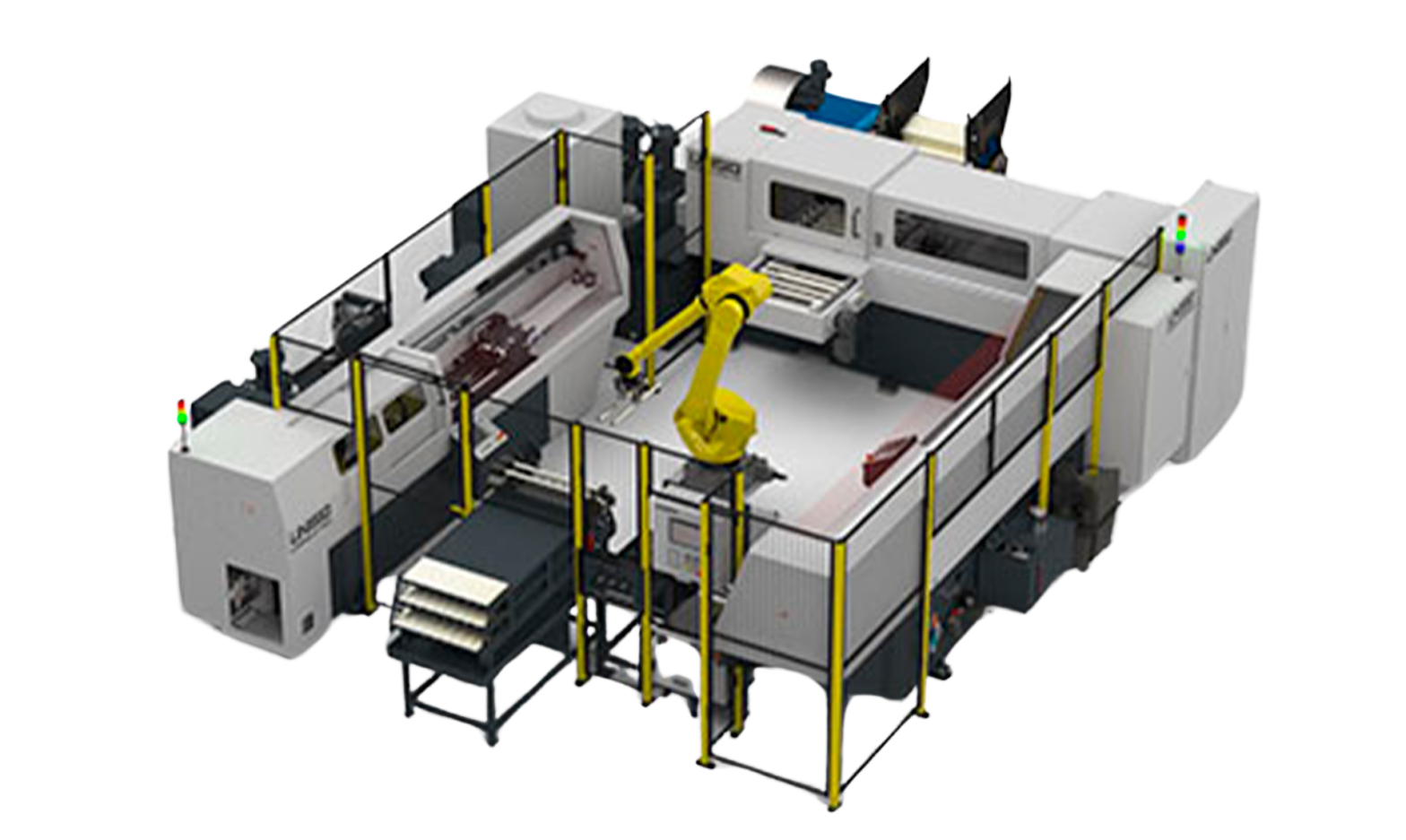

Recommended solutions to improve your processes

Equip and maximize the productivity of your CNC machines with comprehensive solutions.

Accessories and peripherals

Mist collector

Cooling system

Coolant filtration and magnetic separator equipment

Learn more about PERIFERIQ

Creation and development of industrial automation customized to meet your needs.

Automatic doors

Automated loading and unloading system

Safety and cleaning systems

Interfaces to external clamping systems

Learn more about OTOMATIQA